Detachable coaxial nozzle, electrospinning device and preparation method of core sheath nanofiber

A coaxial nozzle and core liquid technology, applied in fiber processing, sustainable manufacturing/processing, textile/flexible product manufacturing, etc., can solve the problems of high quality core-sheath nanofibers, energy consumption in the preparation process, and difficulty in cleaning nozzles. Achieve the effect of clear core-sheath structure, smooth process and easy cleaning

Active Publication Date: 2022-05-31

UNIV OF SHANGHAI FOR SCI & TECH

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to provide a detachable, high-efficiency and energy-saving coaxial nozzle, related electrospinning device and core-sheath nanofiber preparation method, which can overcome the shortcomings of the prior art that the nozzle is easily blocked, the preparation process consumes energy, and the nozzle is not easy to clean. , and the produced core-sheath nanofibers are of high quality

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0026] On the basis of the above-mentioned single-needle spray head, the detachable outer sheath liquid guide part is assembled. Specifically: in the middle of the single needle

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

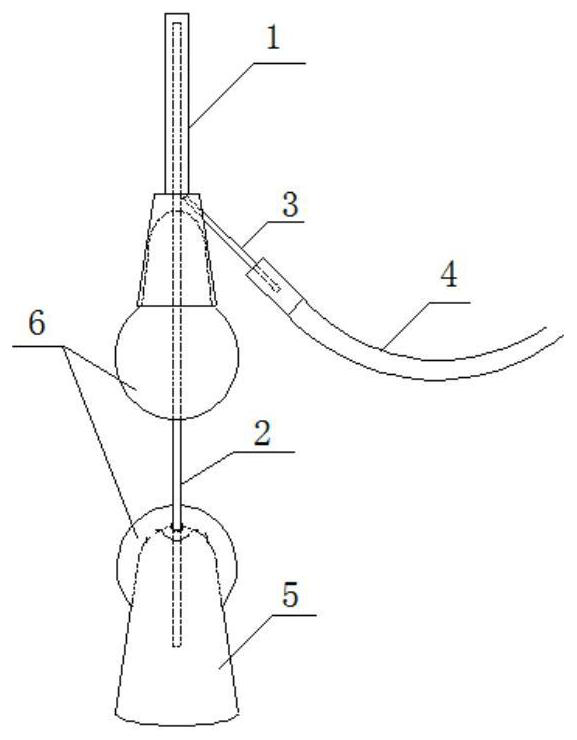

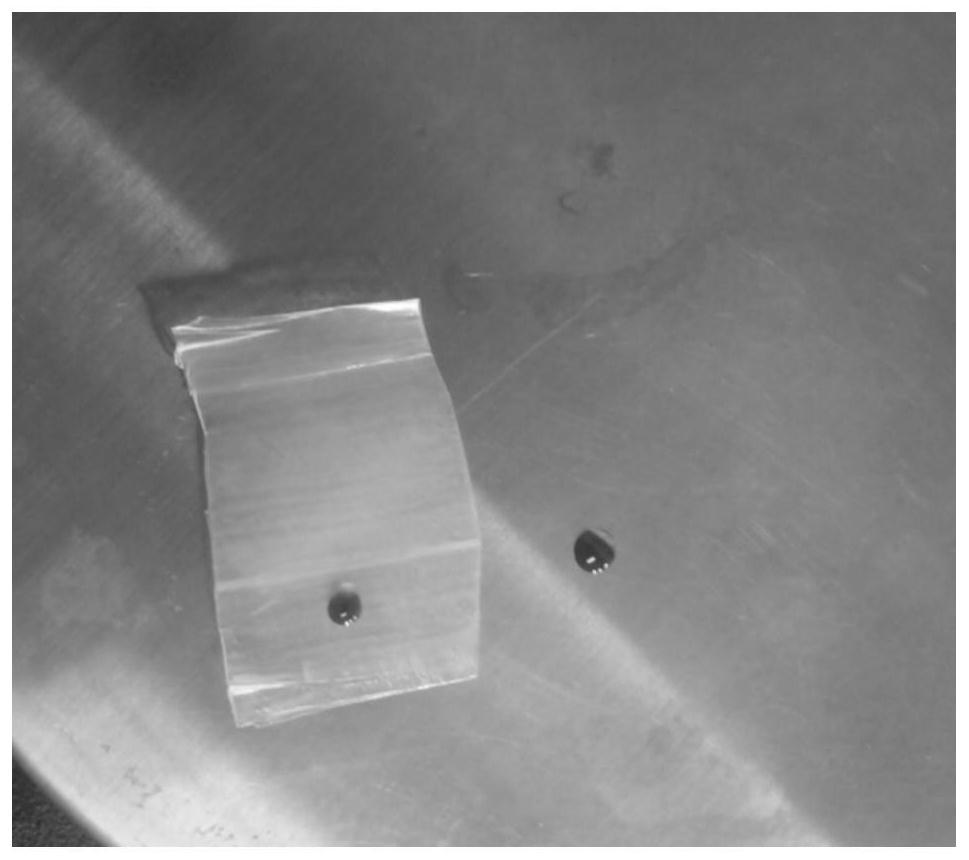

The invention provides a detachable coaxial nozzle, an electrospinning device and a preparation method of core-sheath nanofibers. The detachable coaxial nozzle includes an insulating polymer tube, a core liquid guiding metal capillary and a sheath liquid injection needle. The back end of the material tube is detachably connected with the core fluid guiding metal capillary, and one end of the sheath fluid injection needle communicates with the insulating polymer tube. The invention has a series of advantages, such as: 1) the operation of coaxial electrospinning is convenient and the process is smooth; 2) the nozzle is easy to clean after electrospinning; 3) the design of the nozzle conforms to the basic principle of electro-fluid interaction, which is highly efficient and energy-saving Effect; 4) The axis of the nozzle is precise, and high-quality core-sheath nanofibers can be prepared. The invention has the advantages of simple process, single-step feasible, energy-saving and high-efficiency in the preparation of high-quality core-sheath nanofibers with complete structure.

Description

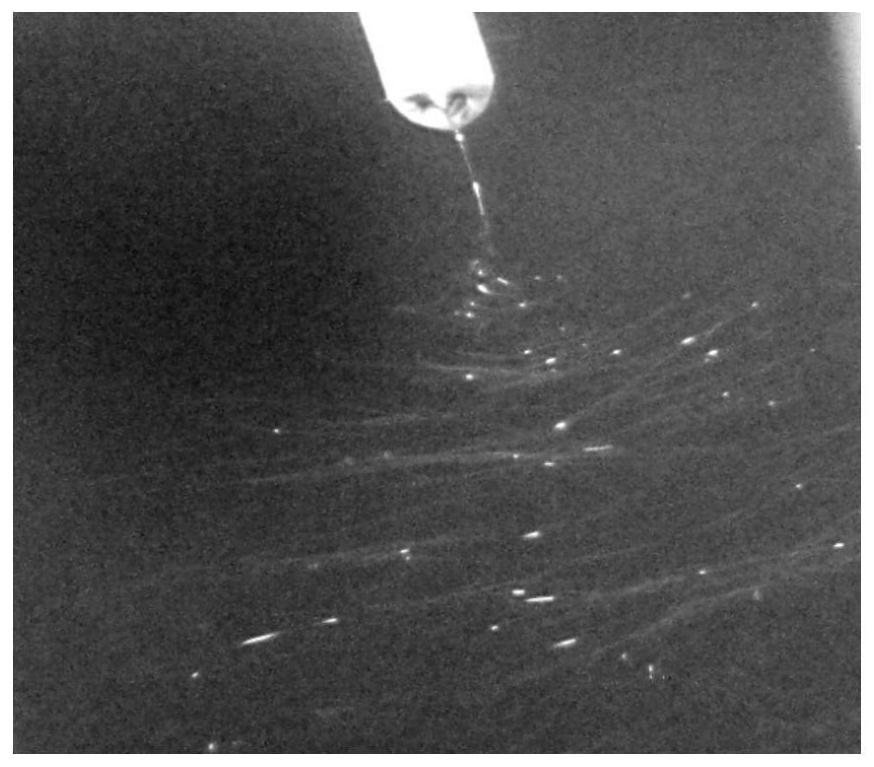

Detachable coaxial nozzle, electrospinning device and preparation method of core-sheath nanofiber technical field The present invention relates to a kind of detachable and high-efficiency energy-saving coaxial nozzle and related electrospinning device and core-sheath nanofiber system. A preparation method belongs to the technical field of nanostructure material preparation. Background technique High-voltage electrospinning technology (abbreviated as electrospinning) is a top-down (top-down) nano-fabrication technology. The applied electric field force overcomes the liquid surface tension and viscoelastic force of the droplet at the tip of the nozzle to form a jet. Under the combined action of surface tension, the atomized liquid jet is bent, stretched, and split at high frequency, and is pulled within tens of milliseconds. Tens of thousands of times, the nanofibers are obtained at the receiving end through solvent evaporation or melt cooling. The technology is simpl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D01D5/00D01D5/34

CPCD01D5/0069D01D5/34Y02P70/62

Inventor 余灯广海涛万熙侯媛杨垚瑶

Owner UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com