Electrospinning preparation method of nanofibers with material gradient distribution characteristics

A gradient distribution, nanofiber technology, applied in the direction of single-component cellulose rayon, electrospinning, fiber processing, etc., can solve the problem of lack of preparation methods for micro-nanofibers, and achieve small nanometer diameter, uniform diameter distribution, Clearly structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

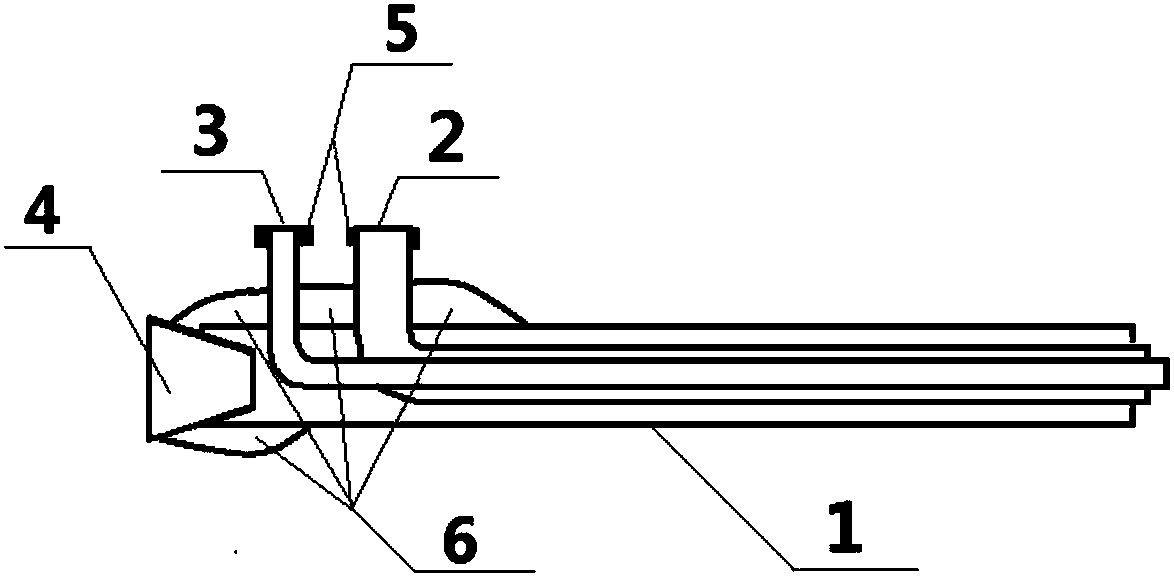

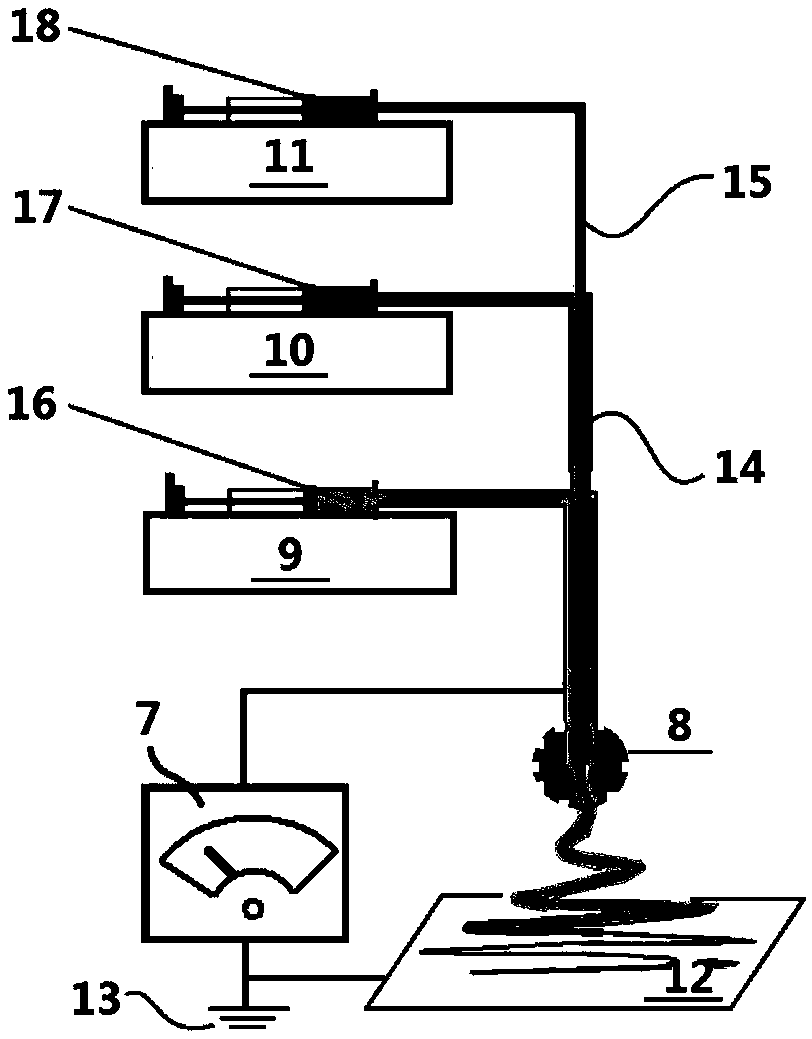

[0020] Nanofibers with material gradient outward decreasing distribution characteristics, the three-stage coaxial spinning head used in the present invention is such as figure 1 As shown, it is composed of inner, middle and outer coaxial capillaries of different sizes, including: outer capillary 1, middle capillary 2, inner capillary 3, outer capillary 1 end rubber inlet joint 4, middle capillary 2 And the convex ring joint 5 at the end of the inner layer capillary 3 and the adhesive epoxy resin 6 for fixing. Three-stage coaxial electrospinning technology implementation device diagram as shown figure 2 As shown, it includes a high-pressure generator 7, a three-stage coaxial spinning head 8, an outer layer fluid injection pump 9, an intermediate layer fluid injection pump 10, an inner layer fluid injection pump 11, a fiber receiving plate 12, a ground 13, an intermediate layer A highly elastic silicone hose 14 for fluid delivery, and a highly elastic silicone hose 15 for flui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com