Preparation methods for composite nanofiber membrane and flexible strain sensor

A composite nanofiber and strain sensor technology, applied in the direction of fiber type, fiber treatment, fiber chemical characteristics, etc., can solve the problems of sensing mechanism failure, weak binding force, and reduced sensitivity, and achieve extended strain sensing range, good pull Good elongation and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

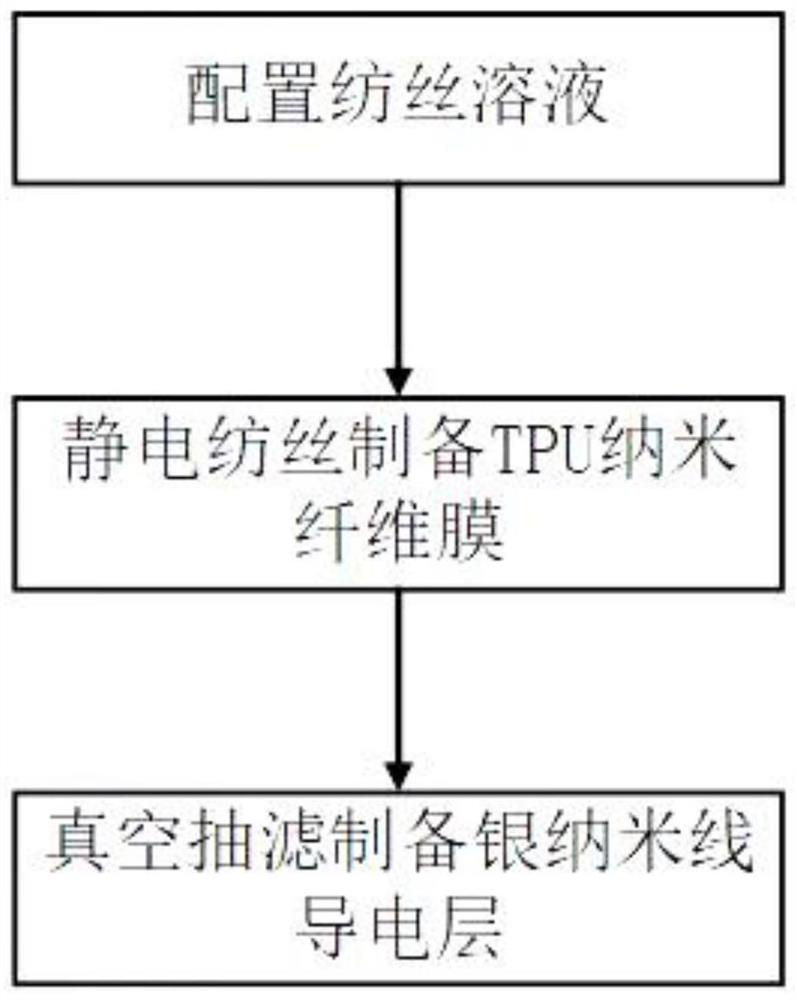

[0039] refer to figure 1 , a method for preparing a composite nanofibrous membrane for a flexible strain sensor, comprising the steps of:

[0040] S1. Use a precision balance to measure polymer materials with good tensile strength such as polyurethane particles, polydimethylsiloxane (PDMS) or polyoxymethylene (POM) with a mass fraction of 25% to 30% and add them to the pre-configured In the solvent, use a magnetic stirrer to stir until the polyurethane particles are completely dissolved to obtain a spinning solution;

[0041] S2. Transfer the spinning solution obtained in S1 to the syringe in the electrospinning equipment, extrude the spinning solution through the syringe, adjust the parameters related to electrospinning, so that the extruded spinning solution drops in the high-voltage electrostatic field Under the action, a stable jet is formed, and the jet is stretched at high speed by electric field force, solvent volatilization and solidification, and finally deposited on...

Embodiment 1

[0052] A preparation method for a composite nanofiber membrane for a flexible strain sensor, comprising the following steps:

[0053] A. Use a precision balance to measure polyurethane particles with a mass fraction of 25% and add them to the pre-configured organic solvent. The organic solvent is composed of N,N-dimethylformamide (DMF) solution and acetone solution, wherein N,N- The mass fraction of dimethylformamide (DMF) solution is 75%. Use a magnetic stirrer to stir until the polyurethane particles are completely dissolved to obtain a spinning solution;

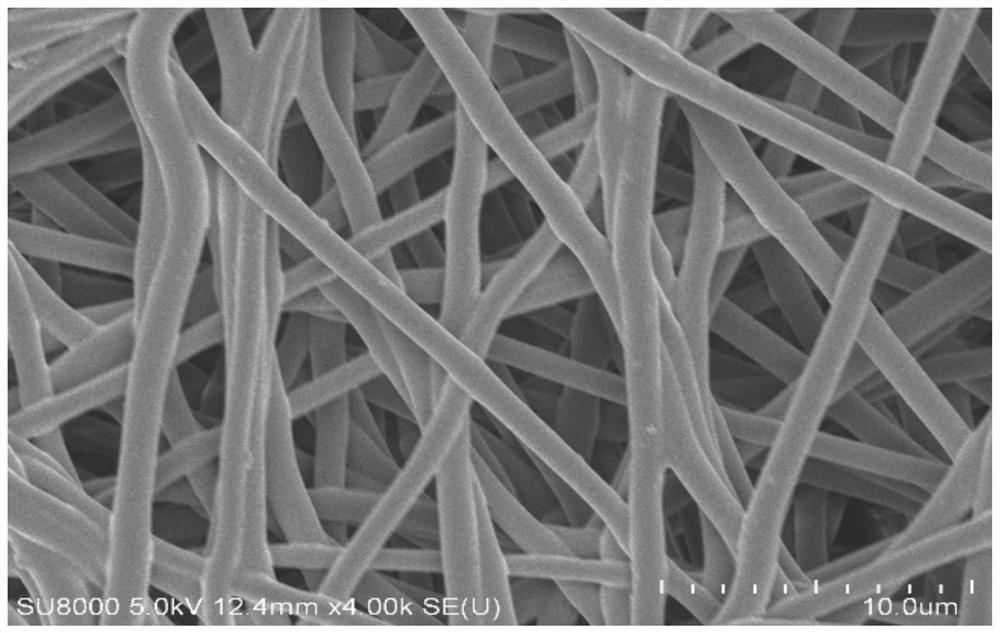

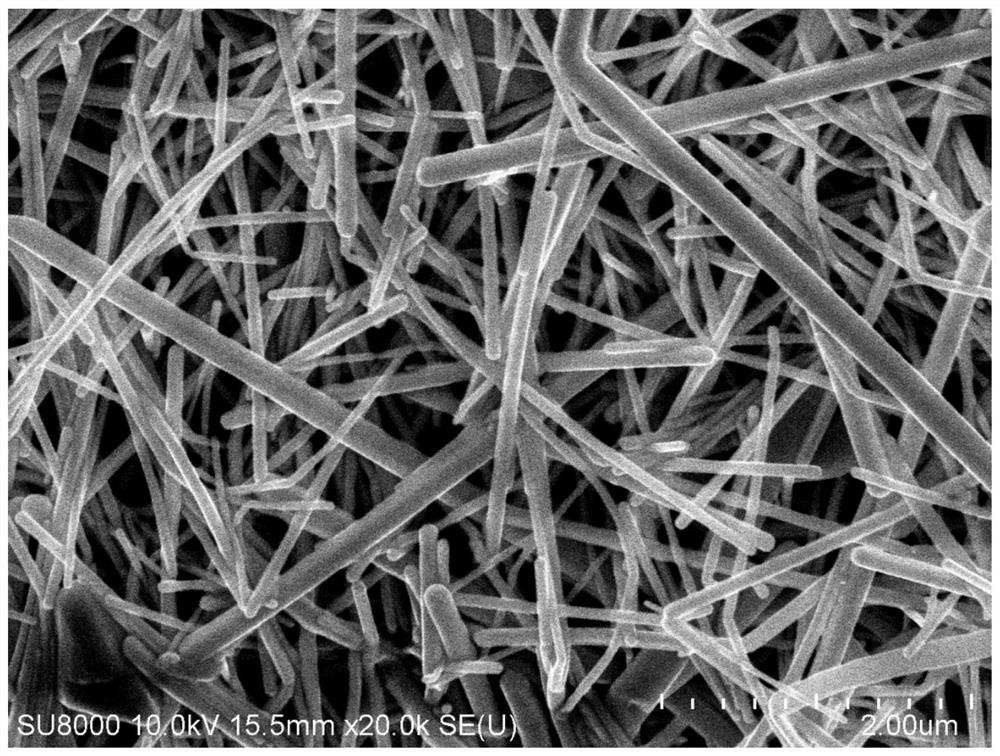

[0054] B. Transfer the spinning solution to the syringe, extrude the spinning solution through the syringe, adjust the parameters related to electrospinning, wherein the advancing speed is 6 μL / min, the spinning voltage is 8.65kV, and the receiving distance is 10cm to make the extruded The droplets form a stable jet under the action of a high-voltage electrostatic field, and the jet is stretched at a high speed by the el...

Embodiment 2

[0058] A preparation method for a composite nanofiber membrane for a flexible strain sensor, comprising the following steps:

[0059] A. Use a precision balance to measure polyurethane particles with a mass fraction of 30% and add them to the pre-configured organic solvent. The organic solvent is composed of N,N-dimethylformamide (DMF) solution and acetone solution, wherein N,N- The mass fraction of dimethylformamide (DMF) solution is 60%. Use a magnetic stirrer to stir until the polyurethane particles are completely dissolved to obtain a spinning solution;

[0060] B. Transfer the spinning solution to the syringe, extrude the spinning solution through the syringe, and adjust the parameters related to electrospinning, wherein the advancing speed is 8 μL / min, the spinning voltage is 10 kV, and the receiving distance is 12 cm to make the extruded liquid The droplets form a stable jet under the action of a high-voltage electrostatic field. The jet is stretched at a high speed by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com