Nanofiber with medicine material radial and reverse distribution characteristics and preparation method thereof

A technology of distribution characteristics and nanofibers, which is applied in the field of materials science, can solve the problems of poor slow-release effect of nanofibers, and achieve the effect of small nanometer diameter, simple preparation process and smooth fiber surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

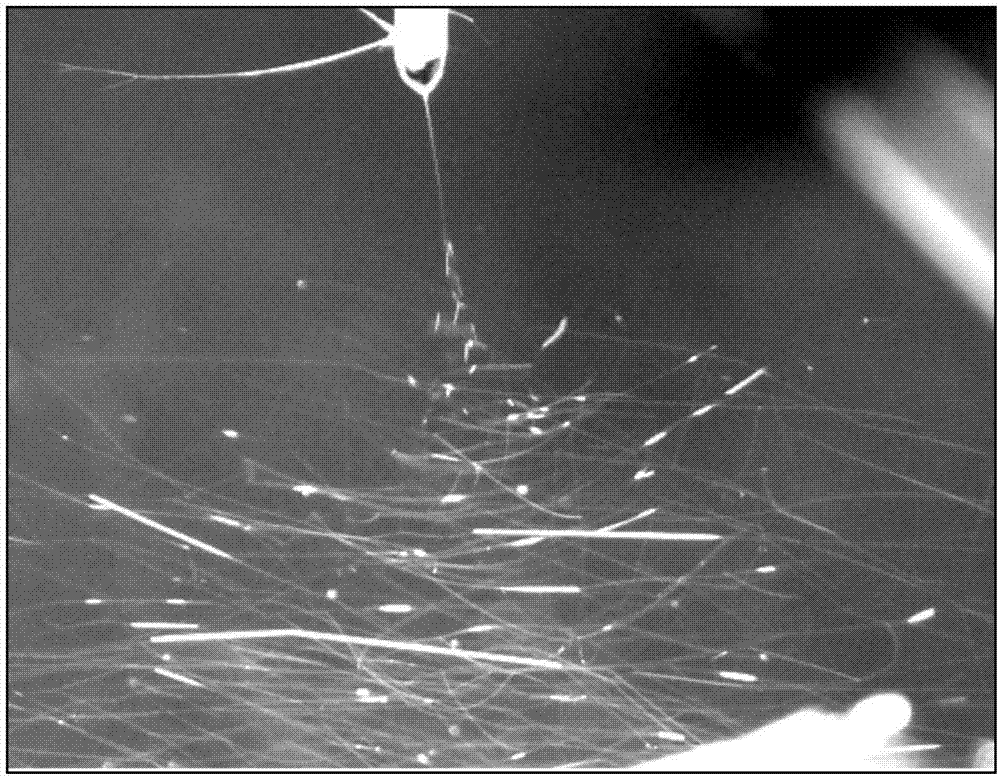

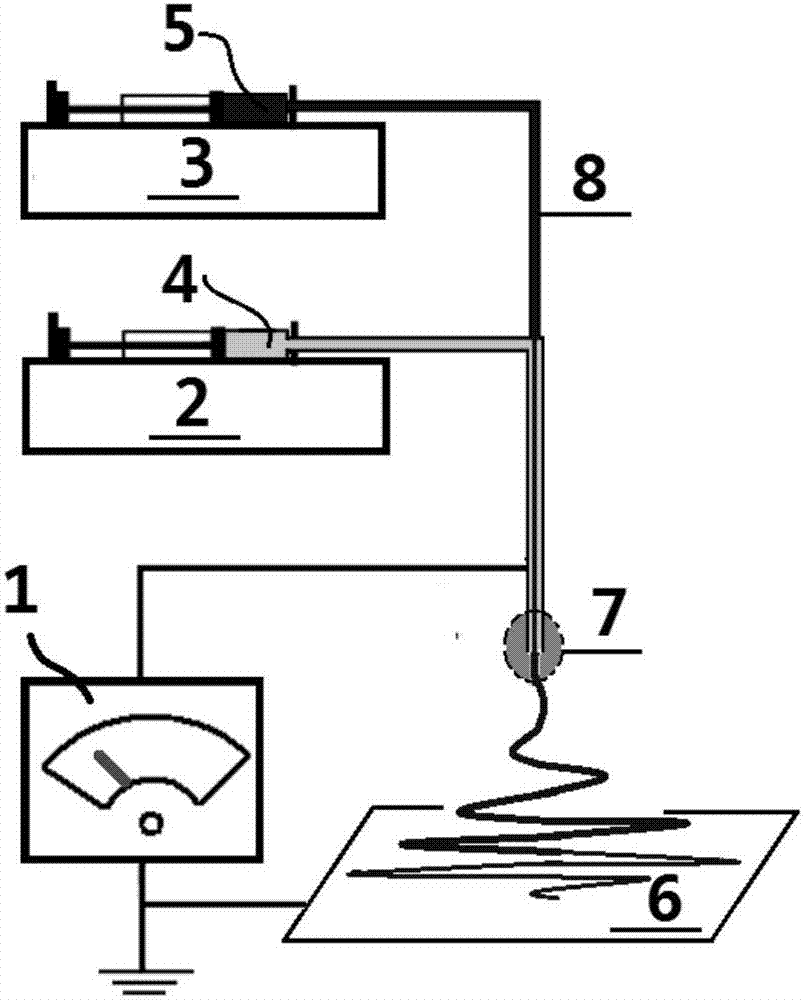

[0023] Embodiment 1: Implementation of coaxial electrospinning process

[0024] Put 12 grams of vinyl acetate cellulose and 1 gram of ibuprofen into 100 grams of a mixed solvent composed of acetone and N,N-dimethylformamide at a mass ratio of 3:1 to prepare the working fluid of the outer sheath. Put 6 grams of vinyl acetate cellulose and 3 grams of ibuprofen into 100 grams of a mixed solvent composed of acetone and N,N-dimethylformamide at a mass ratio of 3:1 to prepare the inner core working fluid. The working fluids of the outer sheath and the inner core are respectively filled into the corresponding syringes of the coaxial electrospinning system, quantitatively transported to the coaxial spinning head by the syringe pump, and connected to the spinning head and the high-voltage electrostatic generator. The coaxial high-voltage electrospinning process was implemented according to the following process conditions and parameters: the sheath / core fluid flow rate was 1.0 / 1.0 mL / h...

Embodiment 2

[0028] Example 2: Characterization analysis of the morphology and structure of nanofibers with the characteristics of radial and reverse distribution of pharmaceutical materials

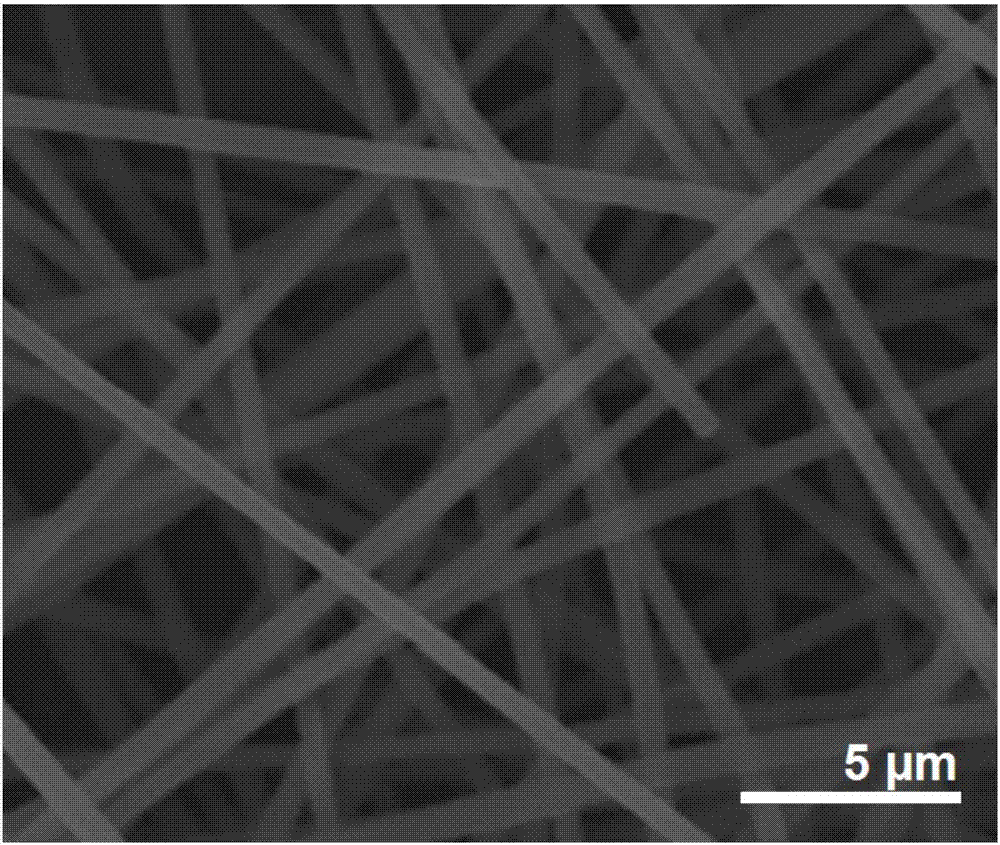

[0029] Field emission scanning electron microscopy (FESEM) was used to observe the surface of the fiber prepared in Example 1 after spraying gold, and the results were as follows image 3 shown. The prepared fiber exhibits a good linear state, no beading structure occurs, the fiber surface is smooth, and the fiber accumulation is uniform. The diameter is 670 ± 110 nm, the distribution is relatively uniform, and the diameter distribution is relatively concentrated.

[0030] The internal structure of the prepared fiber was observed by high-resolution transmission electron microscope (TEM), and the results were as follows: Figure 4 As shown, the core-sheath structure of nanofibers is clear, and the inner core has a larger gray value due to the large drug content and large thickness. The specific str...

Embodiment 3

[0031]Example 3: The sustained and controlled release performance of ibuprofen provided by nanofibers with the characteristics of radial and reverse distribution of drug materials

[0032] According to the 2015 edition of Chinese Pharmacopoeia Appendix ⅩD Release Test Method 2, the drug-loaded nanofibers obtained above were subjected to an in vitro dissolution test using an RCZ-8A intelligent dissolution tester. The control speed is 50rpm, the temperature is 37±0.1℃, and the dissolution medium is 900mL pH7.0 phosphate buffer solution. Under these conditions, the in vitro controlled release performance of nanofiber drugs with the characteristics of radial and reverse distribution of drug materials is investigated. Sampling 5mL at the scheduled time to obtain a sample of the dissolution solution, and immediately replenish the same volume of isothermal fresh medium. After appropriate dilution of the sample, at λ max = 264 nm, the ultraviolet-visible spectrophotometer was used fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com