Method for manufacturing CuZnAl or CuZn alloy continuous fiber through cold drawing

A continuous fiber and cold drawing technology, applied in the field of preparation of CuZnAl or CuZn alloy continuous fibers, can solve the problems of difficult preparation of fine fibers, low yield strength of CuZnAl or CuZn alloy, etc., and achieve grain refinement and yield strength improvement. , the effect of uniform diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

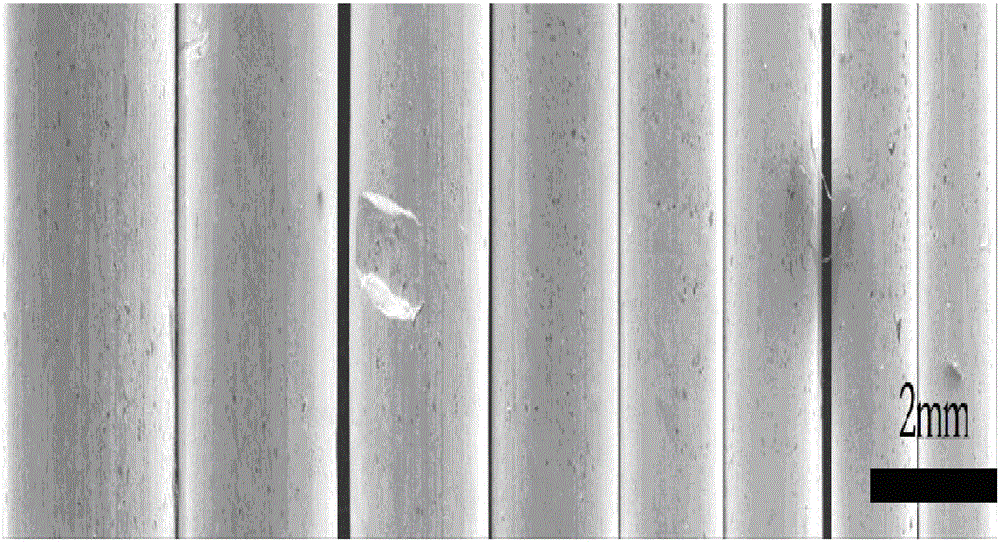

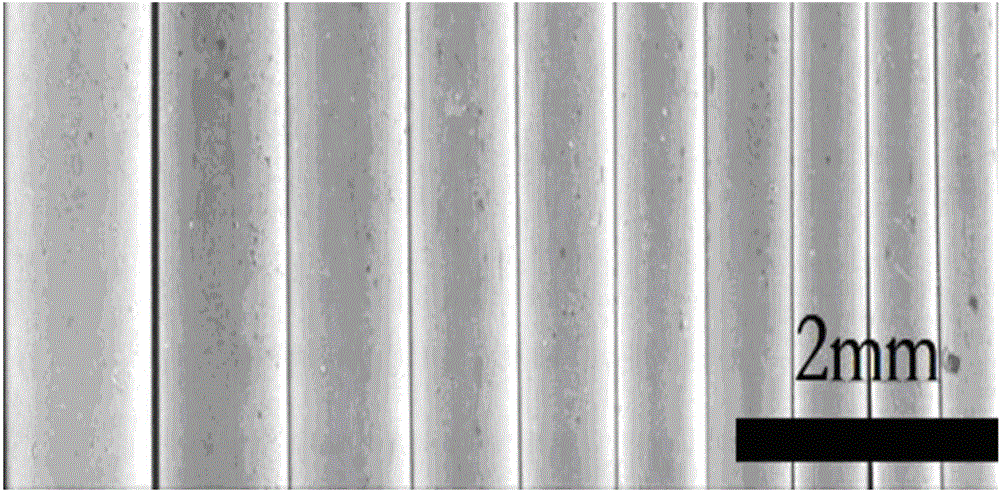

Examples

specific Embodiment approach 1

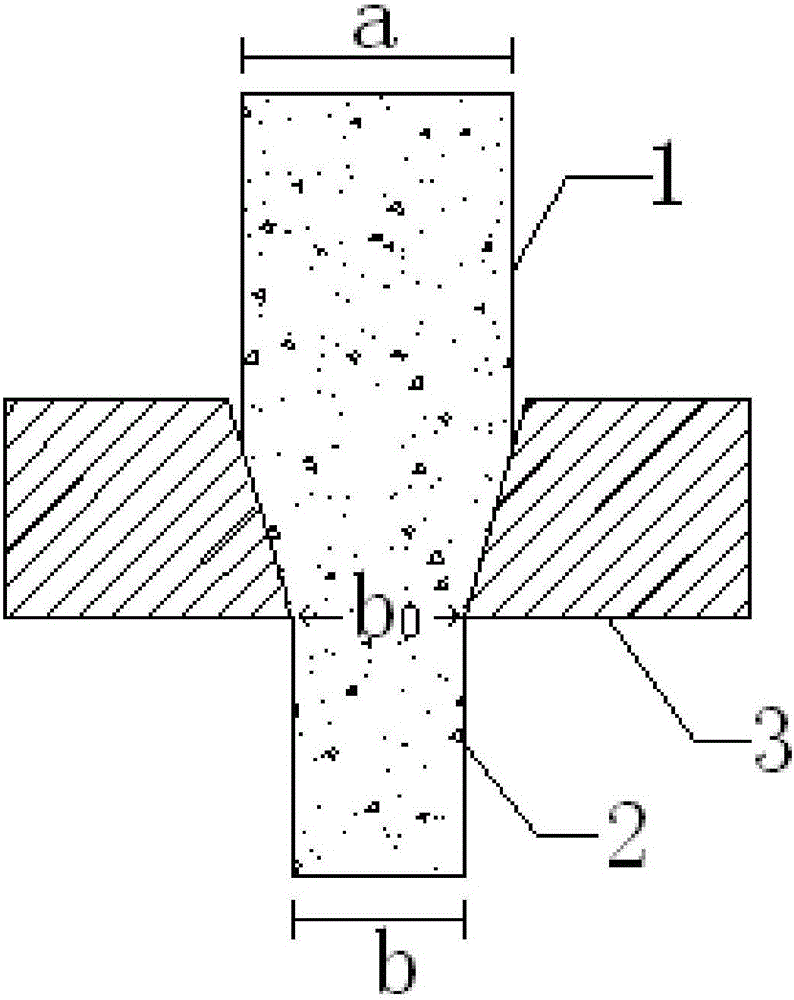

[0037] Specific embodiment 1: The method for preparing CuZnAl or CuZn alloy continuous fiber by cold drawing in this embodiment is realized according to the following steps:

[0038] 1. Preparation of original ingot

[0039] According to molecular formula Cu x Zn y al z or Cu x Zn y The mass fraction of each element in the formula, weigh pure copper, zinc and aluminum and mix them, or weigh pure copper and zinc and mix them, put them into a quartz tube with an inner diameter of 7-8mm and one end sealed, and reduce the pressure inside the quartz tube to 3×10 -2 ~5×10 -2 After Pa, seal the unsealed end of the quartz tube, then put the sealed quartz tube vertically into the resistance furnace, heat the air resistance furnace to 1240-1260°C and keep it warm for 40-60min, after completion, take out the quartz tube and place it side by side In water at room temperature, crush the quartz tube to obtain an original ingot with a diameter of 7-8mm;

[0040] 2. The original ingot...

specific Embodiment approach 2

[0055] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the molecular formula Cu described in step one x Zn y al z where x=70.9, y=25.35; z=3.75. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0056] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the purity of pure copper in step 1 is 99.99%, the purity of zinc is 99.99%, and the purity of aluminum is 99.99%. Other steps and parameters are the same as one of the specific embodiments 1 to 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com