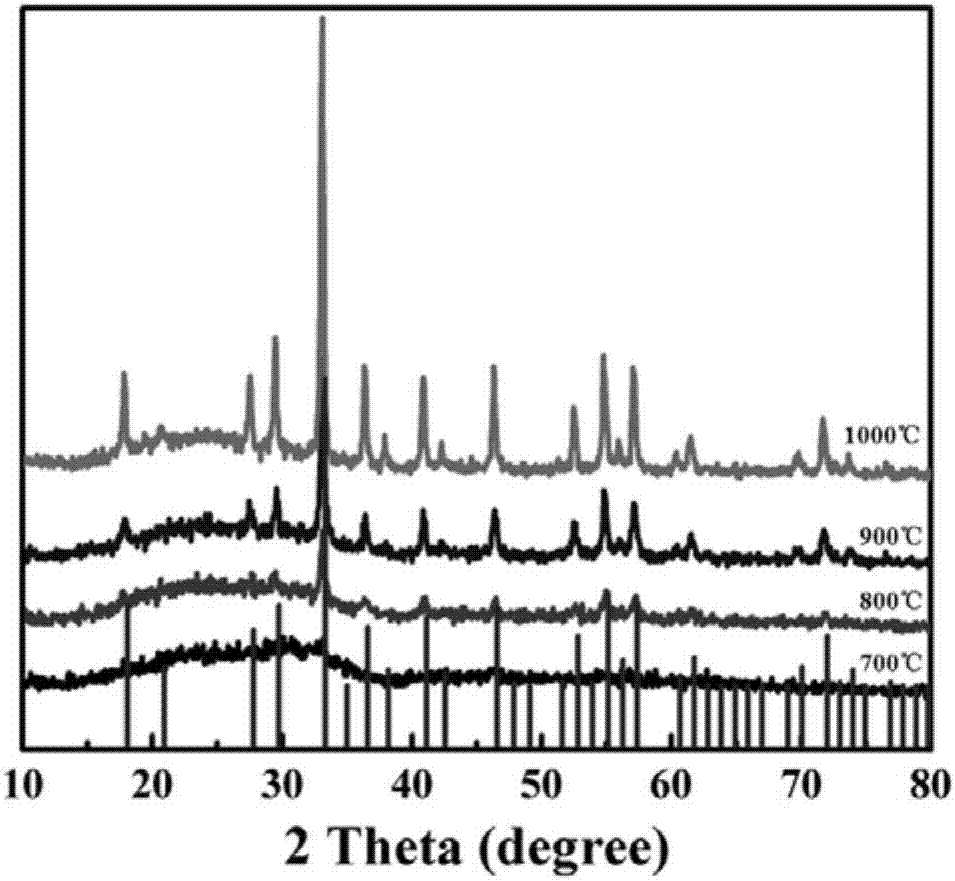

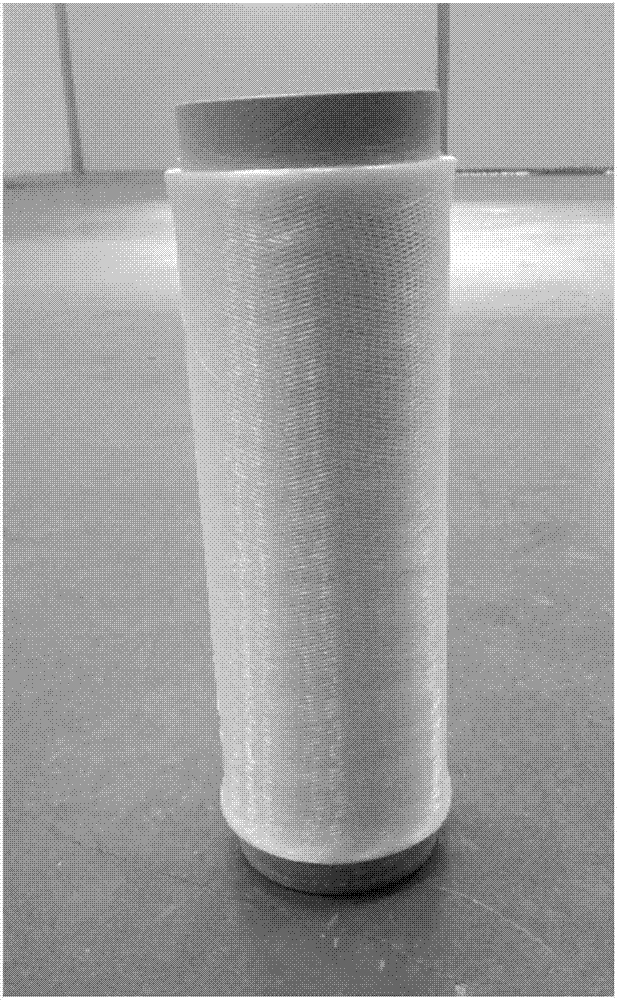

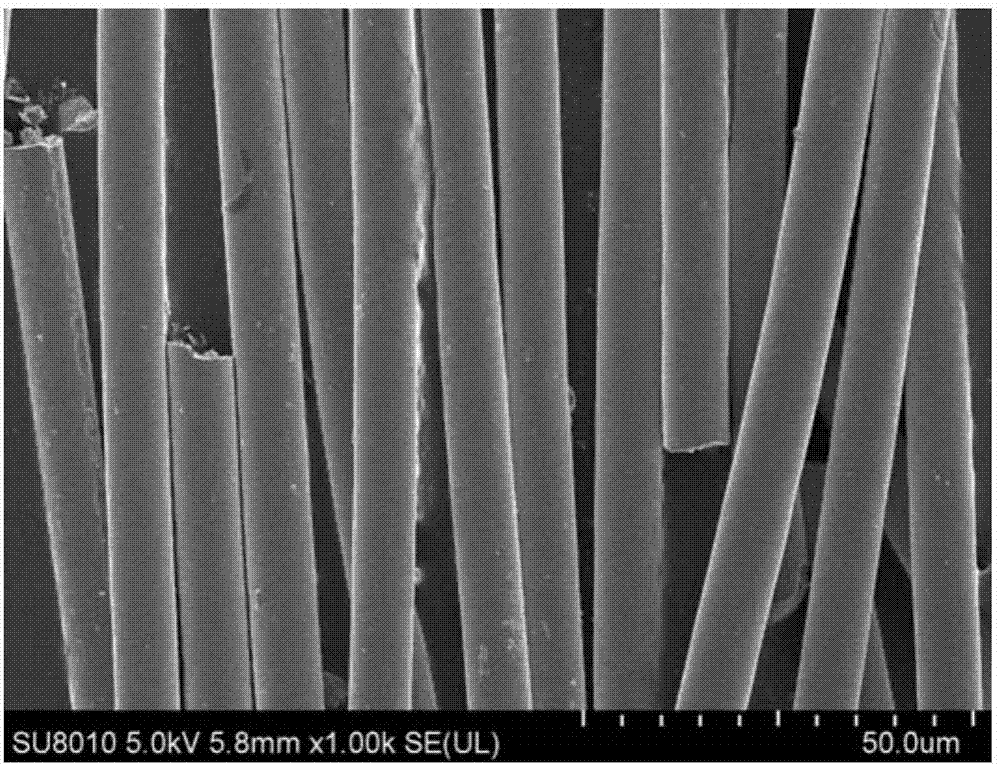

Preparation method of continuous fiber of yttrium aluminum garnet

A technology of yttrium aluminum garnet and continuous fiber, which is applied in the direction of spinning solution preparation, fiber chemical characteristics, chemical instruments and methods, etc., can solve the problems of low production efficiency, time-consuming, fiber length discussion, etc., and achieve short production cycle , Improving spinning performance and stabilizing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A kind of preparation method of yttrium aluminum garnet continuous fiber, comprises steps as follows:

[0050] (1) Preparation of spinnable precursor sol

[0051] 925.2g containing Al 13 The alumina sol (solid content is 22.04wt%) of colloidal particles is mixed with 419.6g gamma-AlOOH nano-dispersion liquid (solid content is 12.15wt%), utilizes disperser to stir until uniform, according to n (Al 2 o 3 ):n(Y 2 o 3 )=5:3 metering composition adds 2258.1g yttrium oxide sol (solid content is 15wt%), 35 ℃ of water baths stir, add 450g glacial acetic acid in stirring process, wherein the mol ratio of yttrium oxide and glacial acetic acid is 1:1.25, then Add 173g of dilute nitric acid to adjust the pH value to 2.0, add 39.6g of PVP solution, stir and mix evenly.

[0052] The aging temperature was set at 40 °C, and the aging process was carried out under the condition of a vacuum of 0.095 MPa. The mixed sol was aged to a viscosity of 500 Pa·s to obtain a precursor spinnab...

Embodiment 2

[0069] A kind of preparation method of yttrium aluminum garnet continuous fiber, comprises steps as follows:

[0070] (1) Preparation of spinnable precursor sol

[0071] 925.2g containing Al 13 The alumina sol (solid content is 22.04wt%) of colloidal particles is mixed with 419.6g gamma-AlOOH nano-dispersion liquid (solid content is 12.15wt%), utilizes disperser to stir until uniform, according to n (Al 2 o 3 ):n(Y 2 o 3 )=5:3 metering composition adds 2258.1g yttrium oxide sol (solid content is 15wt%), 35 ℃ of water baths stir, add 450g glacial acetic acid in stirring process, wherein the mol ratio of yttrium oxide and glacial acetic acid is 1:1.25, this When the pH value was 3.8, 98.9g of PVP solution was added, stirred and mixed evenly.

[0072] The aging temperature was set at 40°C, and the aging process was carried out under the condition of a vacuum of 0.095 MPa. The aging process was carried out under the condition of a vacuum of 0.095 MPa, and the mixed sol was ag...

Embodiment 3

[0077] A kind of preparation method of yttrium aluminum garnet continuous fiber, comprises steps as follows:

[0078] (1) Preparation of spinnable precursor sol

[0079] 925.2g containing Al 13 The alumina sol (solid content is 22.04wt%) of colloidal particles is mixed with 419.6g gamma-AlOOH nano-dispersion liquid (solid content is 12.15wt%), utilizes disperser to stir until uniform, according to n (Al 2 o 3 ):n(Y 2 o 3 )=5:3 metering composition adds 2258.1g yttrium oxide sol (solid content is 15wt%), 35 ℃ of water baths stir, add 486g glacial acetic acid in stirring process, wherein the mol ratio of yttrium oxide and glacial acetic acid is 1:1.35, then Add 195g of dilute nitric acid to adjust the pH value to 1.8, add 98.9g of PVP solution, stir and mix evenly.

[0080] The aging temperature was set at 40°C, and the aging process was carried out under the condition of a vacuum of 0.095 MPa. The mixed sol was aged to a viscosity of 520 Pa·s to obtain a precursor spinnabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com