Preparation method of poly-p-phenylene ethylene derivative micro-nano fiber

A poly-p-phenylene vinylene and micro-nano fiber technology, which is applied in fiber processing, fiber chemical characteristics, spinning solution preparation, etc., can solve the problems of polymer residue, complicated device, affecting the performance of optoelectronic devices, etc., and achieve strong polarization. , the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

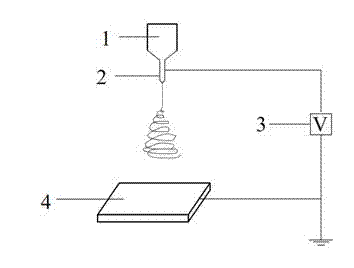

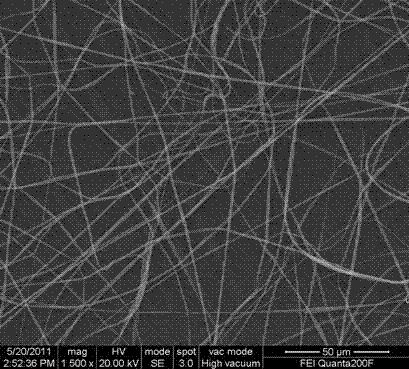

[0027] MDMO-PPV with a weight average molecular weight of 200,000 was dissolved in 5 mL of chloroform to form a solution with a concentration of 10 wt.%, and a uniform solution was obtained by stirring and ultrasonic dispersion. Then 2 mL of tert-butanol was gradually added under vigorous stirring. After completion, continue to stir for a period of time and perform ultrasonic dispersion to obtain a uniform electrospinning solution. Micro-nanofilaments were produced by electrospinning.

Embodiment 2

[0029] BEH-PPV with a weight average molecular weight of 400,000 was dissolved in 5 mL of dichloroethane to prepare a solution with a concentration of 6 wt.%, and a uniform solution was obtained by stirring and ultrasonic dispersion. Afterwards, 1 mL of ethanol was gradually added under vigorous stirring. After completion, continue to stir for a period of time and perform ultrasonic dispersion to obtain a uniform electrospinning solution. Micro-nanofilaments were produced by electrospinning.

Embodiment 3

[0031] Dissolve poly[2,5-2(3′,7′-dimethyloctyloxy)-1,4-phenyleneethylene] with a weight average molecular weight of 300,000 in 5mL of dichloroethane to make a concentration of 8wt .% solution, a homogeneous solution was obtained by stirring and ultrasonic dispersion. Then 1 mL of isopropanol was gradually added under vigorous stirring. After completion, continue to stir for a period of time and perform ultrasonic dispersion to obtain a uniform electrospinning solution. Micro-nanofilaments were produced by electrospinning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com