Conductive network remodeling method based on SBS conductive fibers, conductive composite fibers prepared by using method and preparation method thereof

A conductive composite fiber and conductive fiber technology, applied in the direction of conductive/antistatic filament manufacturing, fiber treatment, synthetic fiber, etc., can solve the problems of low fiber strength, poor conductivity, and cortical structure resistance, etc., to improve electrical performance and ensure The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A kind of conductive network remodeling method based on SBS conductive fiber, comprises the steps:

[0057] 1) Preparation of ethyl acetate mixture

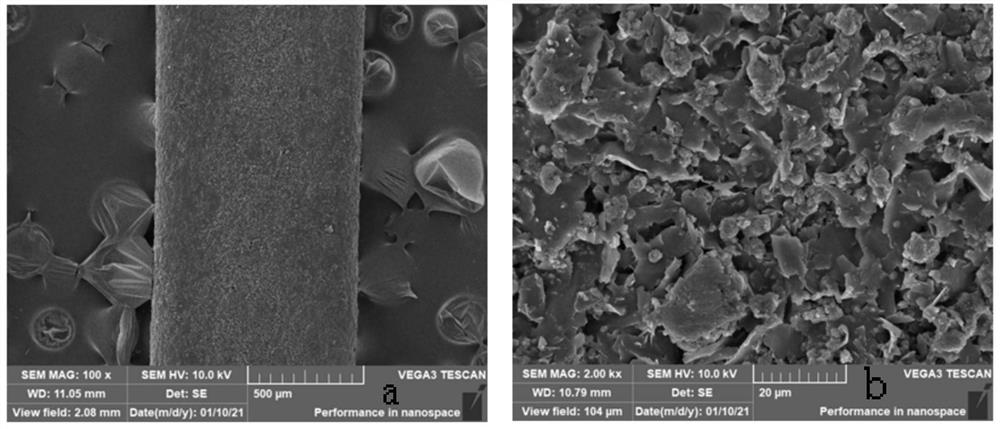

[0058] Add graphene and carboxyl carbon nanotubes into ethyl acetate solution to obtain ethyl acetate mixed solution, sonicate for 0.8h, and magnetically stir for 1h;

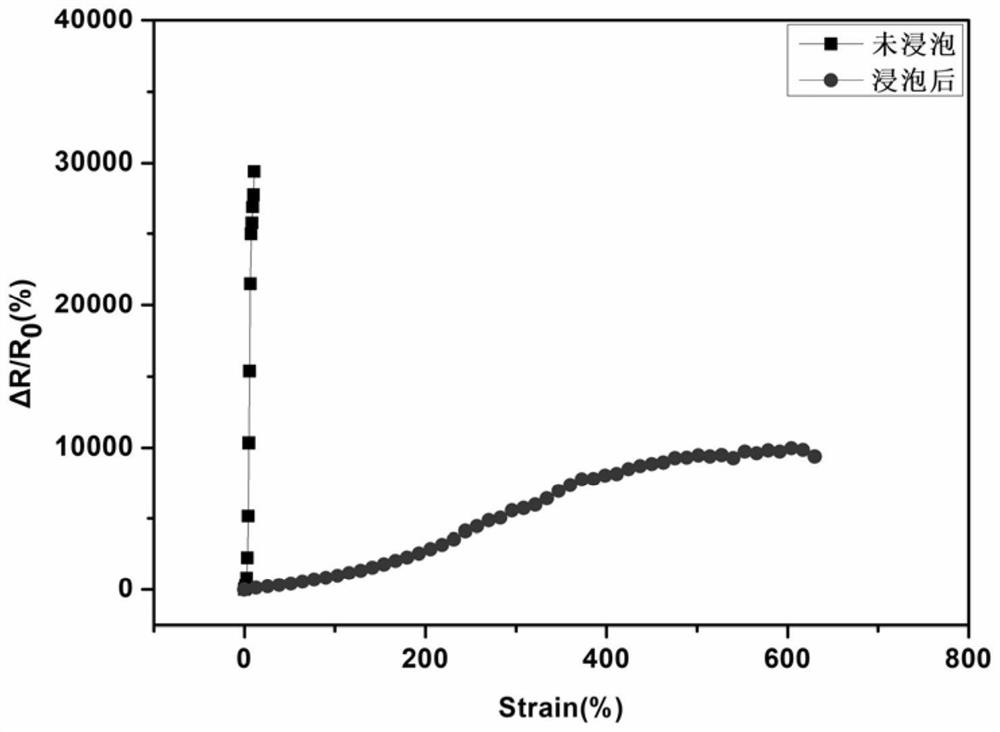

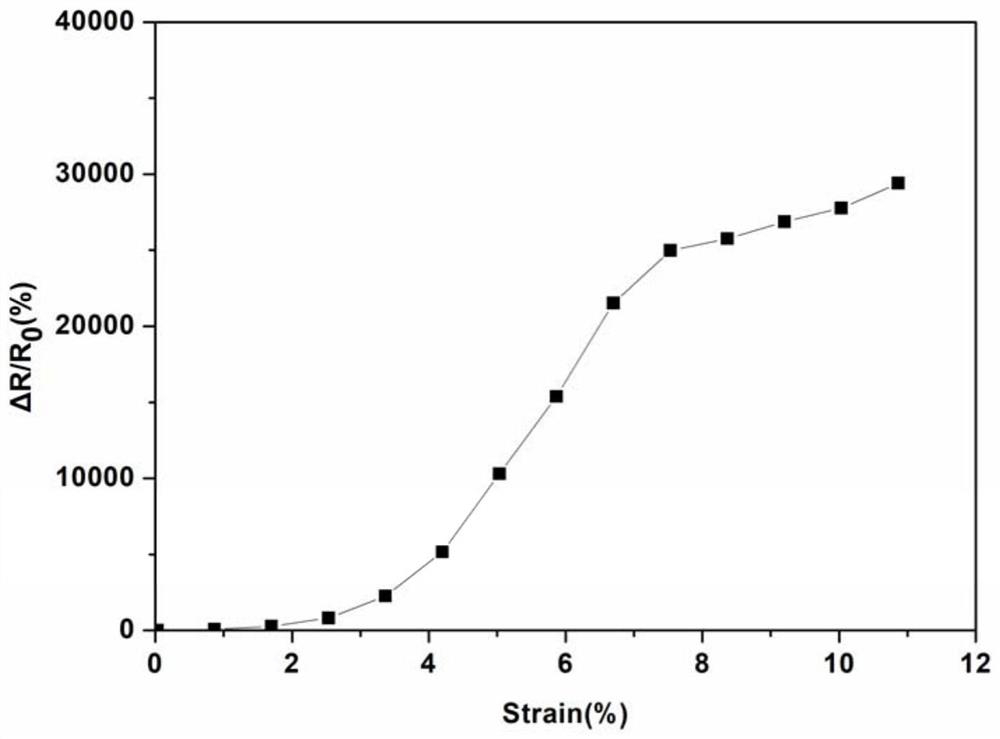

[0059] 2) Soak the SBS conductive fiber in the ethyl acetate mixture prepared in step 1) for 10 seconds, take it out, and dry it; the conductive material is the same as that contained in the conductive layer of the SBS conductive fiber. That is, in the present embodiment, the conductive layer of the SBS conductive fiber contains two kinds of conductive particles of graphene and carbon nanotubes, so the ethyl acetate mixed solution also contains two kinds of conductive materials of graphene and carbon nanotubes, and the graphene The weight ratio is 2.5 wt%, and the weight ratio of carbon nanotubes is 3.5 wt%.

[0060] In this embodiment, in order to obtain...

Embodiment 2

[0087] A kind of conductive network remodeling method based on SBS conductive fiber, comprises the steps:

[0088] 1) Preparation of ethyl acetate mixture

[0089] adding graphene and carboxyl carbon nanotubes to ethyl acetate solution to obtain ethyl acetate mixed solution, ultrasonic treatment for 1 h, and magnetic stirring for 1 h;

[0090] 2) Soak the SBS conductive fiber in the ethyl acetate mixture prepared in step 1) for 12 seconds, take it out, and dry it; the conductive material is the same as that contained in the conductive layer of the SBS conductive fiber. That is, in the present embodiment, the conductive layer of the SBS conductive fiber contains two kinds of conductive particles of graphene and carbon nanotubes, so the ethyl acetate mixed solution also contains two kinds of conductive materials of graphene and carbon nanotubes, and the graphene The weight ratio is 3wt%, and the weight ratio of carbon nanotubes is 4wt%.

[0091] In this embodiment, in order to...

Embodiment 3

[0119] A kind of conductive network remodeling method based on SBS conductive fiber, comprises the steps:

[0120] 1) Preparation of ethyl acetate mixture

[0121] Graphene and carboxyl carbon nanotubes are added to ethyl acetate solution to obtain ethyl acetate mixed solution, ultrasonic treatment for 1.5h, magnetic stirring for 1.2h; in ethyl acetate mixed solution, the weight ratio of graphene is 3.5wt %, the weight ratio of the carbon nanotubes is 4.5wt%.

[0122] 2) Soak the SBS conductive fiber in the ethyl acetate mixture prepared in step 1) for 15 seconds, take it out, and dry it; the conductive material is the same as that contained in the conductive layer of the SBS conductive fiber. That is, in the present embodiment, the conductive layer of the SBS conductive fiber contains two kinds of conductive particles of graphene and carbon nanotubes, so the ethyl acetate mixed solution also contains two kinds of conductive materials of graphene and carbon nanotubes, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com