A kind of high-strength and high-elastic vascular stent and preparation method thereof

A vascular stent and high-elasticity technology, applied in the field of high-strength and high-elastic vascular stent and its preparation, to achieve the effect of excellent vascular performance, mechanical properties and uniform appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

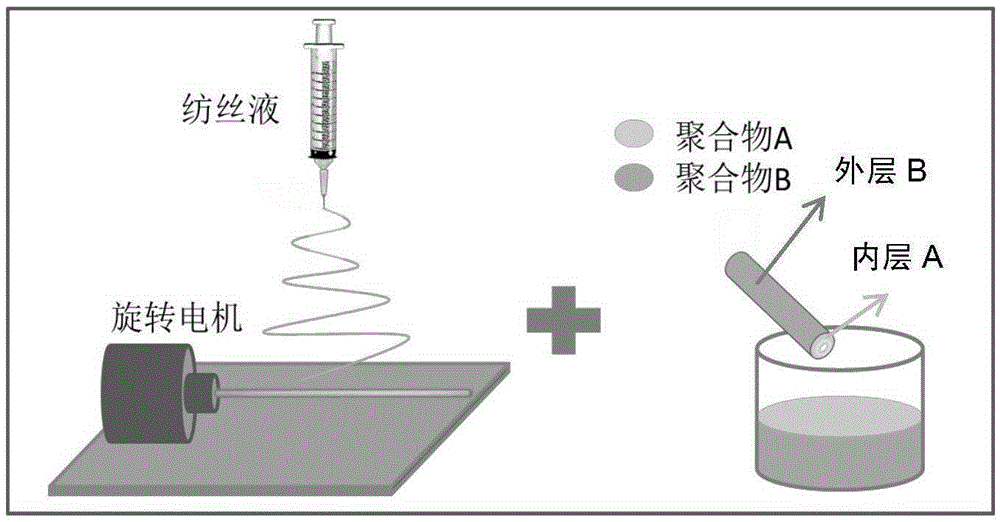

Method used

Image

Examples

Embodiment 1

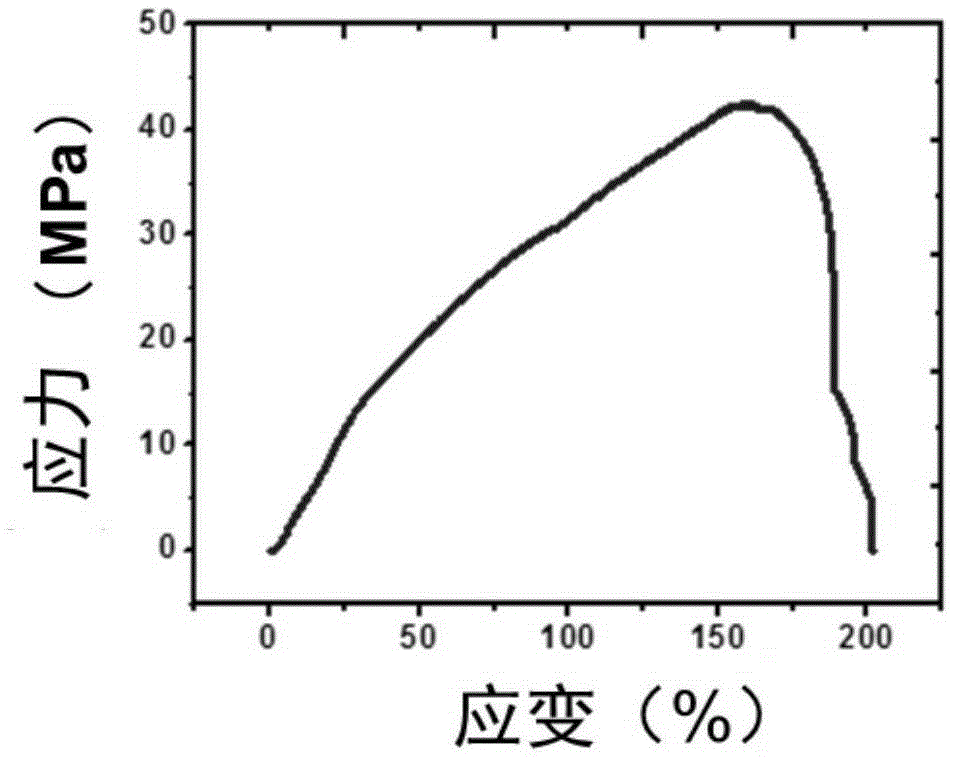

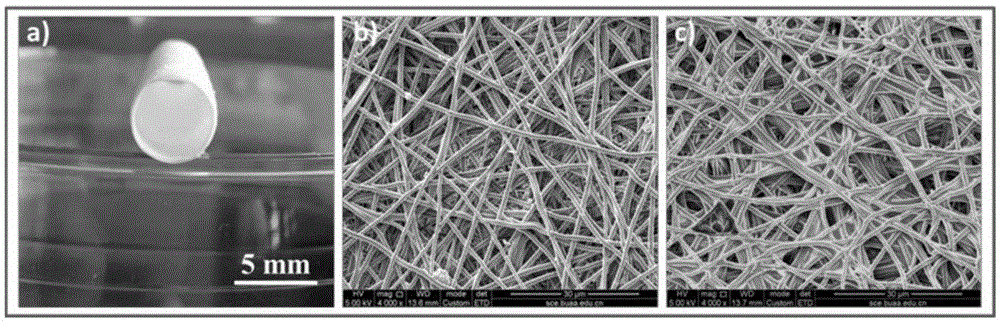

[0031] Pure polyurethane (PU, C 28 h 44 N 2 o 11 ), pure polylactic acid (PLA, (C 6 h 8 o 4 ) n ) and the mixture of the two are respectively dissolved in a mixed solvent (the mass ratio of acetone and N,N-dimethylformamide in the mixed solvent w / w=1:1), and prepared into three different proportions of 8wt% to 15wt% concentration A kind of spinning solution, as a precursor solution; the precursor solution is placed in a syringe pump equipped with a needle with a diameter of 0.5-0.9mm, and a voltage of 8-15kV is applied to carry out electrospinning when the working distance is 20cm, and it is received by aluminum foil Fibers can be used to obtain fiber membranes with different mechanical properties. After performance comparison, the fiber membrane with excellent mechanical properties and high porosity is polyurethane / polylactic acid composite fiber membrane. Therefore, the precursor solution is prepared by dissolving polyurethane / polylactic acid composite in a mixed solv...

Embodiment 2

[0034] Pure polycaprolactone (PCL, (C 6 h 10 o 2 ) n ), polylactic acid (PLA, (C 6 h 8 o 4 ) n ) and the mixture of the two are dissolved in a mixed solvent in which the mass ratio of acetone and N,N-dimethylformamide w / w=1:5 in the mixed solvent is formulated to be 8%-10% concentration by mass percentage Three kinds of spinning solutions in different proportions, that is, the precursor solution; the precursor solution is placed in a syringe pump equipped with a needle with a diameter of 0.2mm, and a voltage of 10-15kV is applied to carry out electrospinning when the working distance is 25cm. The aluminum foil receives the fiber, and the fiber membrane with different mechanical properties can be obtained. After comparison, the precursor solution with excellent mechanical properties and high porosity was obtained as the electrospinning solution of polymer B—PCL+PLA composite electrospinning solution.

[0035] Dissolve dextran in water to make an electrospinning solution...

Embodiment 3

[0037] Pure polycaprolactone (PCL, (C 6 h 10 o 2 ) n ), polylactic acid-glycolic acid copolymer (PLGA, 75:25) and the mixture of the two are respectively dissolved in the mixed solvent, and in the mixed solvent, acetone and N, N-dimethylformamide mass percentage w / w =1:4, prepared into electrospinning solutions with different concentrations of 8%-10% by mass; put the precursor solution in a syringe pump equipped with a needle with a diameter of 0.5-1.0mm, and apply a voltage of 10-25kV at the working distance Electrospinning is carried out when the diameter is 20 cm, and fiber membranes with different mechanical properties can be obtained by receiving fibers through aluminum foil, and finally the electrospinning solution of PCL+PLGA is selected.

[0038] Put polyvinylpyrrolidone (PVP, (C 6 h 9 NO) n ) was dissolved in ethanol to form an ethanol solution with a mass percentage of 9%, the electrospinning solution of polymer A was placed in a syringe pump equipped with a ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com