Preparation method of graphene fiber

A graphene fiber and fiber technology, which is applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of difficult to control the morphology of graphene fibers, poor environmental friendliness, and many process steps, and achieve stable mechanical properties, convenient operation, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 Continuous graphene fiber 1 # preparation method

[0045] The third-generation continuous SiC fiber (in this embodiment, the third-generation continuous SiC fiber has a fiber diameter of 10.3 μm, a tensile strength of 1820 MPa, a modulus of 331 GPa, and a density of 2.95 g / cm 3 ) is placed in a graphite furnace, continuously evacuated to a vacuum degree of less than 30Pa, heated to 1800°C at a heating rate of 600°C / hour and then kept for 10 hours to obtain a continuous graphene fiber 1 # . The resulting continuous graphene fiber 1 # The tensile strength of the fiber is 375MPa, the modulus is 34GPa, and the density is 1.60g / cm 3 .

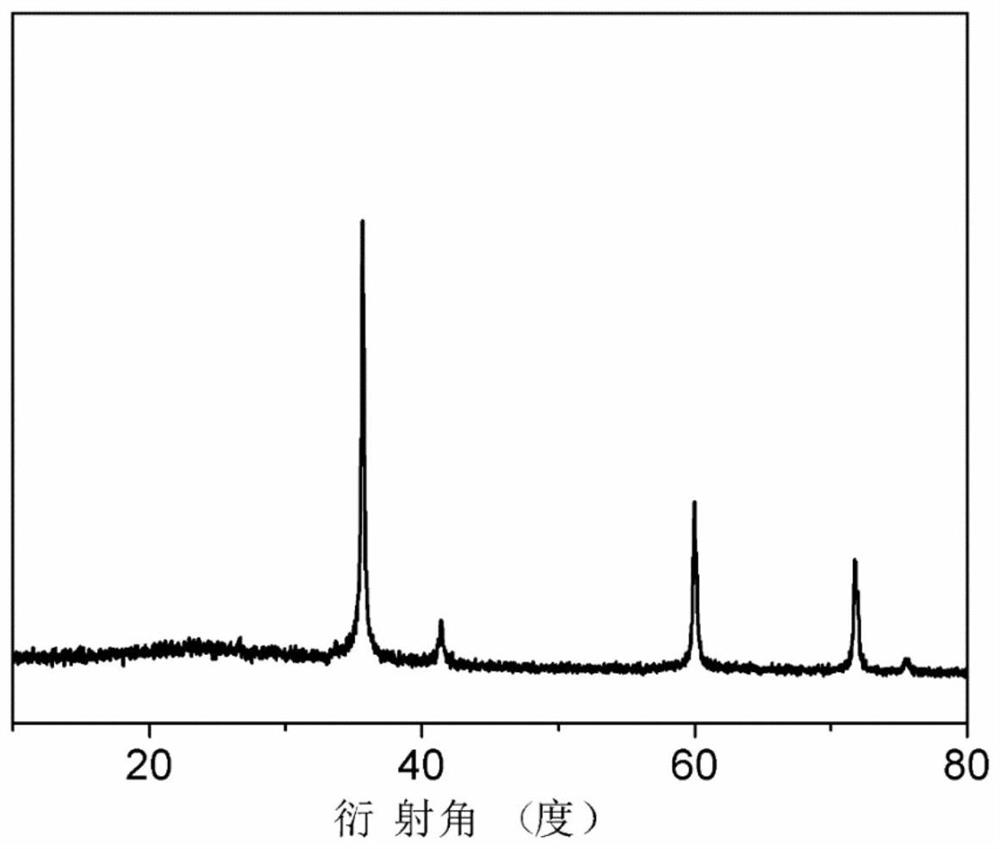

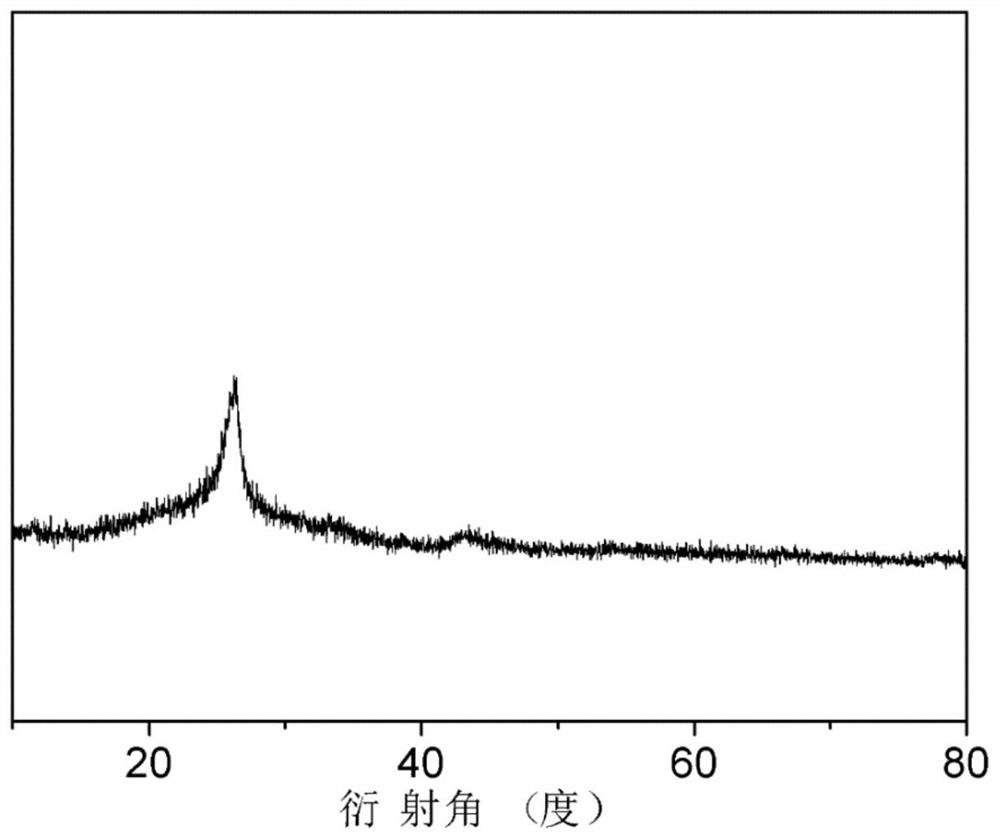

[0046] figure 1 It is the X-ray diffraction spectrum of the third-generation continuous SiC fiber used in the preferred embodiment 1 of the present invention, in which the peaks with diffraction angles of 35.6, 41.4, 60.0, 71.8 and 75.5 degrees correspond to the peaks of 3C-SiC grains respectively (111), (200), (220), (311)...

Embodiment 2

[0048] Embodiment 2 continuous graphene / silicon carbide composite fiber 1 # preparation method

[0049] The third-generation continuous SiC fiber (in this embodiment, the third-generation continuous SiC fiber has a fiber diameter of 10.3 μm, a tensile strength of 1820 MPa, a modulus of 331 GPa, and a density of 2.95 g / cm 3 ) placed in a graphite furnace, evacuated to a vacuum degree of less than 1Pa, heated to 1800°C at a heating rate of 300°C / hour and then kept for 1 hour to obtain a continuous graphene / silicon carbide composite fiber 1 # , the tensile strength of the fiber is 622MPa, the modulus is 195GPa, and the density is 2.49g / cm 3 .

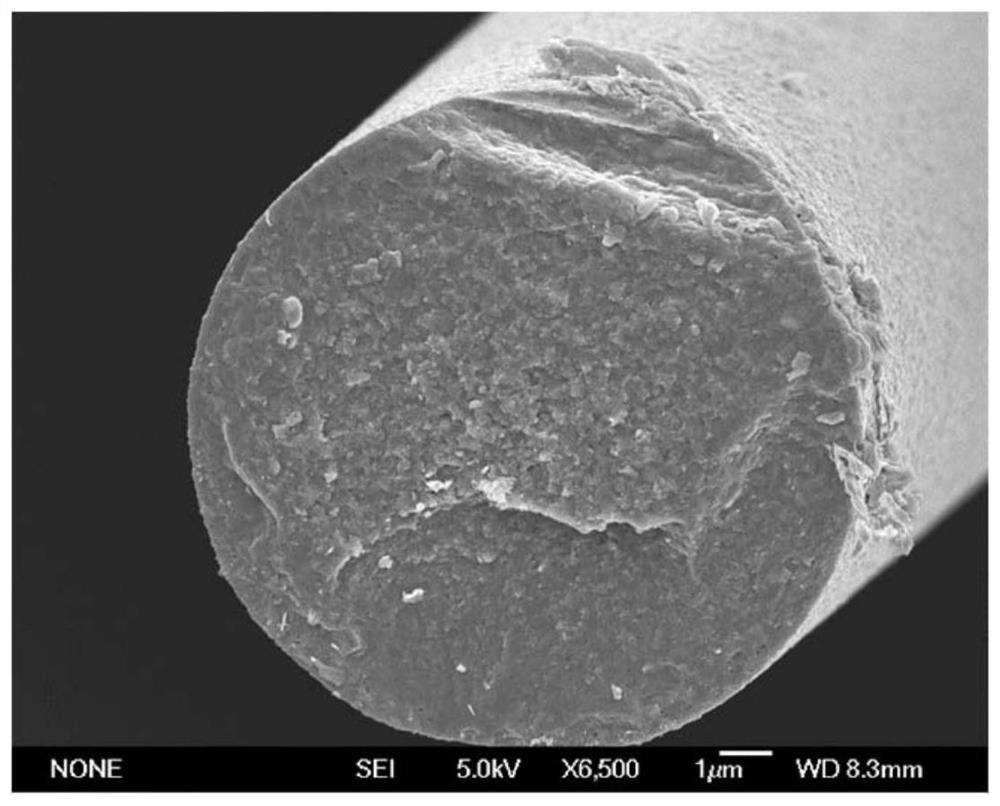

[0050] Figure 7 It is a cross-sectional scanning electron micrograph of the continuous graphene / silicon carbide composite fiber prepared in preferred embodiment 2 of the present invention, Figure 8 It is a surface scanning electron micrograph of the continuous graphene / silicon carbide composite fiber prepared in preferred embodiment ...

Embodiment 3

[0051] Embodiment 3 continuous graphene fiber 2 # preparation method

[0052] The third-generation continuous SiC fiber (in this embodiment, the third-generation continuous SiC fiber has a fiber diameter of 10.3 μm, a tensile strength of 1820 MPa, a modulus of 331 GPa, and a density of 2.95 g / cm 3 ) is placed in a graphite furnace, evacuated to a vacuum degree of less than 1000Pa, heated to 1800°C at a heating rate of 400°C / hour and then kept for 8 hours to obtain a continuous graphene fiber 2 # . The tensile strength of the fiber is 473MPa, the modulus is 45GPa, and the density is 1.61g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com