Method for preparing polyacrylonitrile nano-fibers by circulation and coaxial electrospinning of surface active agent solution

A technology of surfactant and coaxial electrospinning, which is applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of high surface tension and insufficient formation of high-quality nanofibers, and achieve uniform distribution, small diameter, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

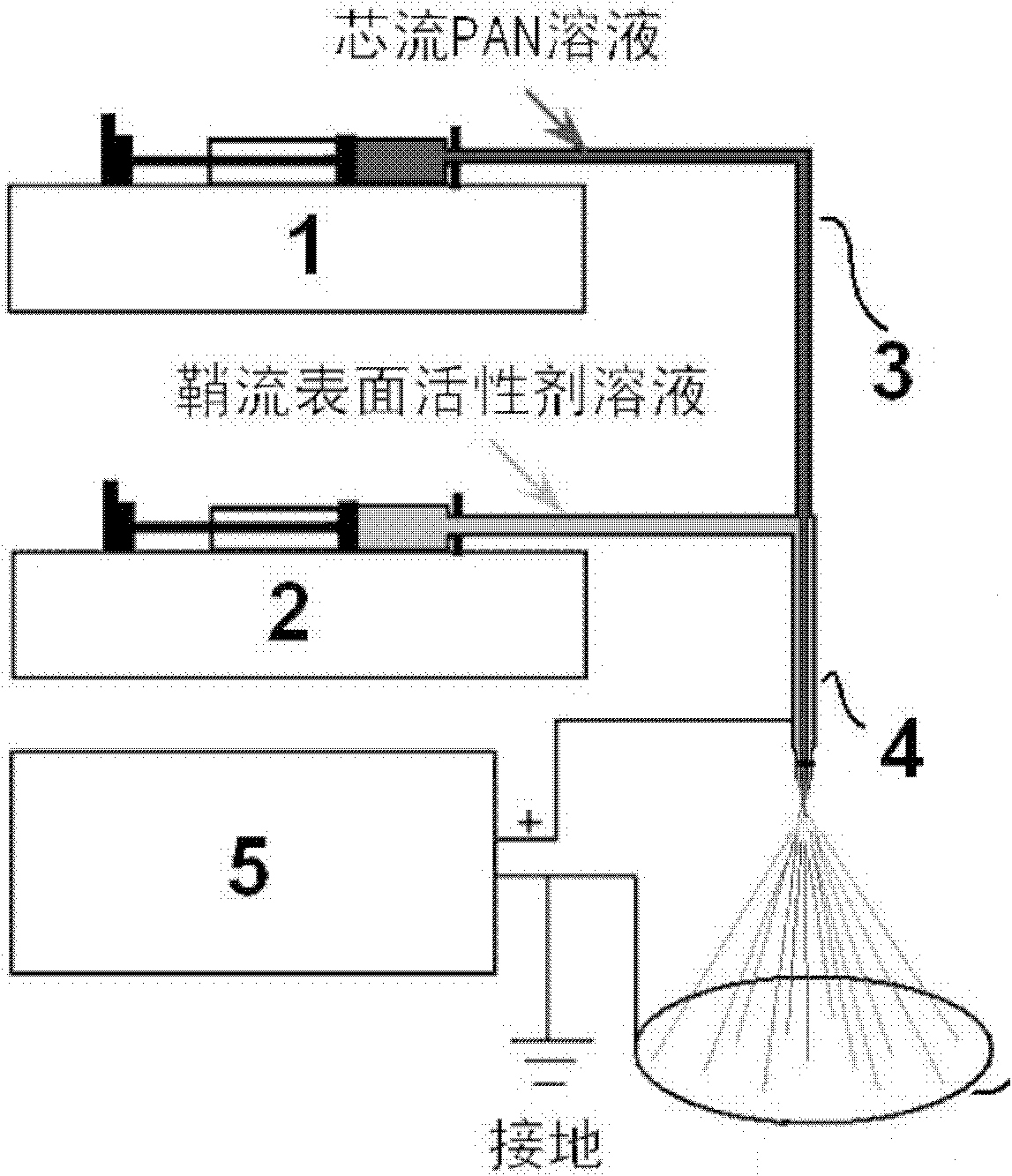

[0021] Embodiment 1:: the single spinning of 14%w / v (mass volume ratio) polyacrylonitrile (PAN)

[0022] A flattened stainless steel injection needle (inner diameter 0.3 mm) was used as the metal conduit 3 for spraying thin streams, connected to a high-voltage power supply (ZGF2000, Shanghai Sute Electric Co., Ltd.), and the flow of the core / sheath fluid was passed through an axial flow syringe pump (Cole- Parmer ∞ company) to regulate, nanofiber adopts fiber receiving plate 6 to receive.

[0023] Disperse 14.0g of PAN powder in 100ml of N,N-dimethylformamide (DMF) at room temperature, then shake overnight in a constant temperature shaker at 50°C to prepare a yellow translucent spinning solution, which is High-voltage electrospinning was performed to prepare nanofibrous membranes. Other process parameters are as follows: the flow rate is 1.0mL / h, the distance between the receiving plate and the spinneret is 15cm, and the voltage is 12kV. The ambient temperature is (23±1)°C,...

Embodiment 2

[0025] Embodiment 2: With the N,N-dimethylformamide solution of 4% w / v nonionic surfactant Triton X-100 as the sheath fluid, the surfactant solution circulation is carried out through two single-channel axial flow syringe pumps. Preparation of PAN Fibers by Axial Electrospinning

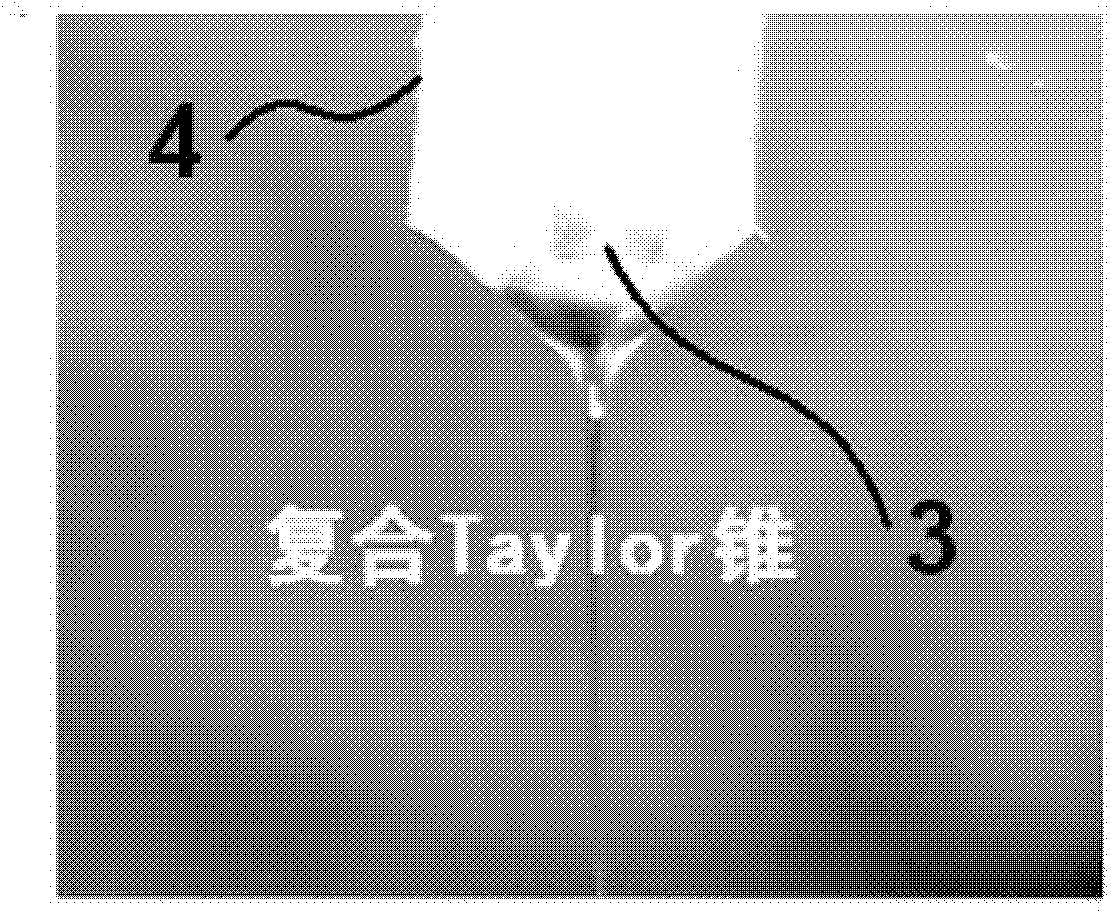

[0026] With the N,N-dimethylformamide solution of 4%w / v nonionic surfactant Triton X-100 as the sheath fluid, the PAN solution in Example 1 as the core fluid, using such as figure 1 A self-assembled coaxial spinning head was used to prepare PAN fibers by coaxial electrospinning with surfactant solution circulation, and the core / sheath liquid flow was regulated by two single-channel axial flow syringe pumps. The specific parameters of other process conditions are: the sheath / core liquid flow rate is 0.4 / 2mL / h, the distance between the receiving plate and the spinneret is 15cm, and the voltage is 12kV. The ambient temperature is (23±1)°C, and the ambient humidity is 62±4%.

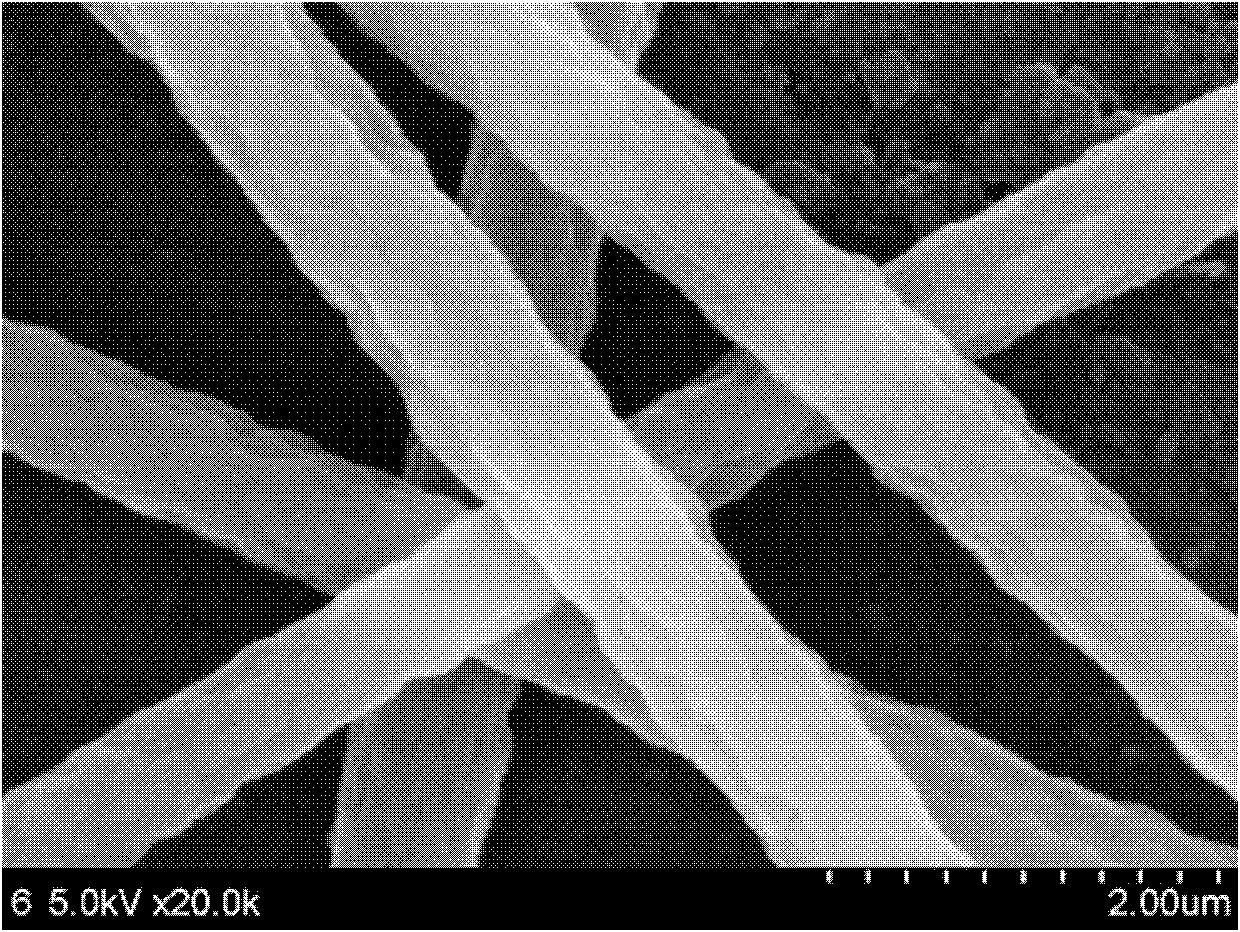

[0027] Field scanning ele...

Embodiment 3

[0028] Embodiment 3: With the N,N-dimethylformamide solution of 1% w / v nonionic surfactant Triton X-100 as the sheath fluid, the surfactant solution was circulated simultaneously through two single-channel axial flow syringe pumps. Preparation of PAN Fibers by Axial Electrospinning

[0029] The N,N-dimethylformamide solution of 1% w / v nonionic surfactant Triton X-100 is used as the sheath liquid, and the others are the same as in Example 2, and the surfactant solution is prepared by two single-channel axial flow syringe pumps. PAN fibers were prepared by circulating coaxial electrospinning.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com