Three-level coaxial electro-spinning method for loading two sheath fluids without spinnability on core fluid

A coaxial electrospinning and fluid technology, applied in the direction of textiles and papermaking, artificial filaments made of cellulose derivatives, fiber chemical characteristics, etc., can solve the problems of limited materials, achieve uniform diameter distribution, smooth fiber surface , The effect of expanding the preparation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

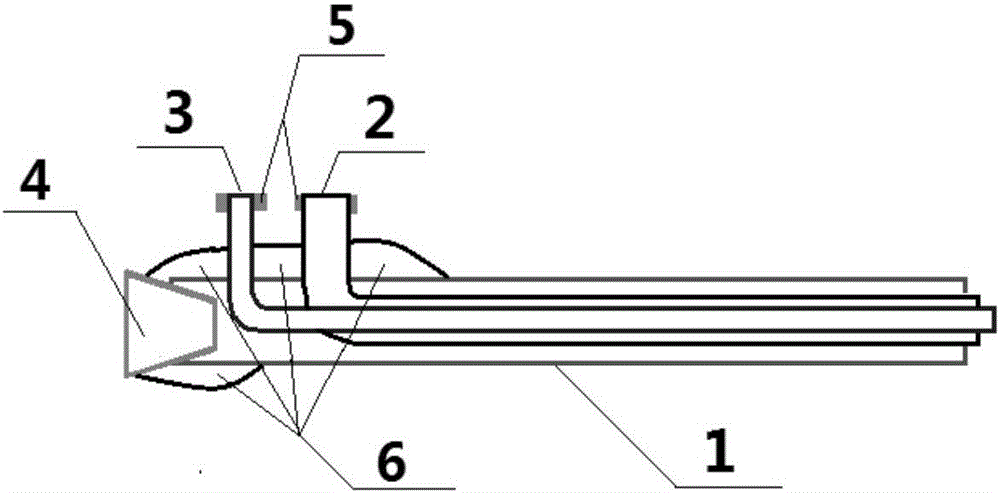

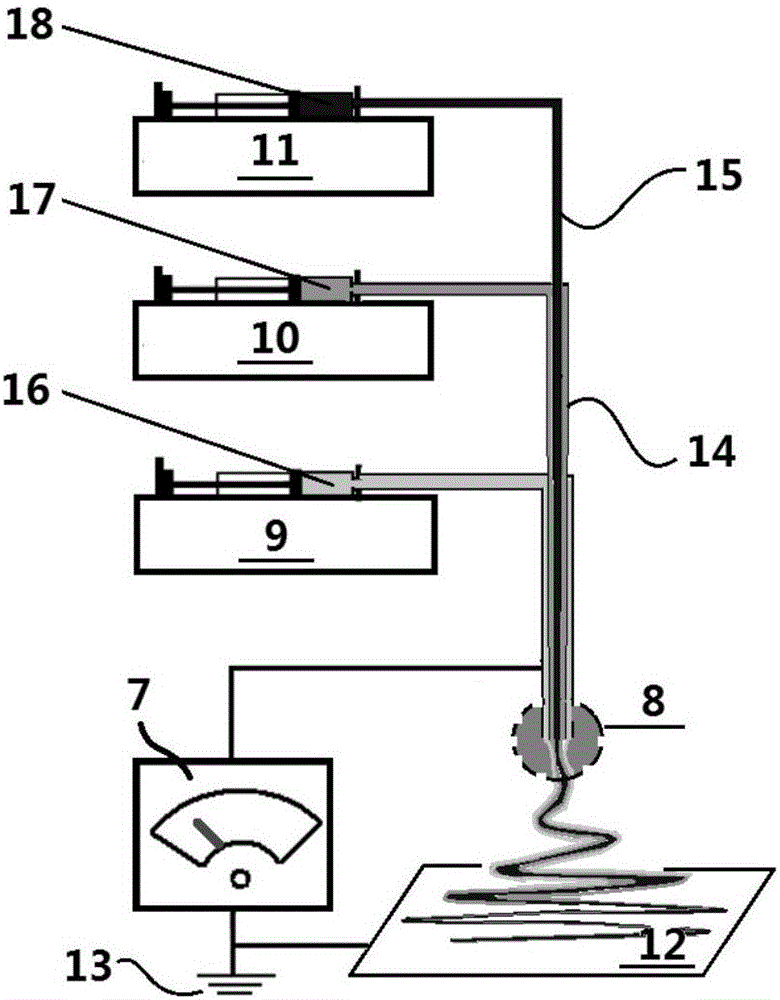

[0021] The three-stage coaxial spinning head used in the present invention is such as figure 1 As shown, it is composed of inner, middle and outer coaxial capillaries of different sizes, including: outer capillary 1, middle capillary 2, inner capillary 3, outer capillary 1 end rubber inlet joint 4, inner and middle capillary 2, 3 end of the lug joint 5 and adhesive epoxy 6 for fixing. The three-stage coaxial electrospinning technology implementation device is shown in the figure figure 2 As shown, it includes a high-voltage generator 7, a three-stage coaxial spinning head 8, an outer fluid injection pump 9, an intermediate fluid laminar injection pump 10, an inner fluid injection pump 11, a fiber receiving plate 12, a ground 13, and a middle layer The fluid conveys a high-elasticity silicone hose 14 , and the inner layer fluid conveys a high-elasticity silicone hose 15 .

[0022] The inner layer fluid injection pump 11 and the intermediate fluid injection pump 10 are respec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com