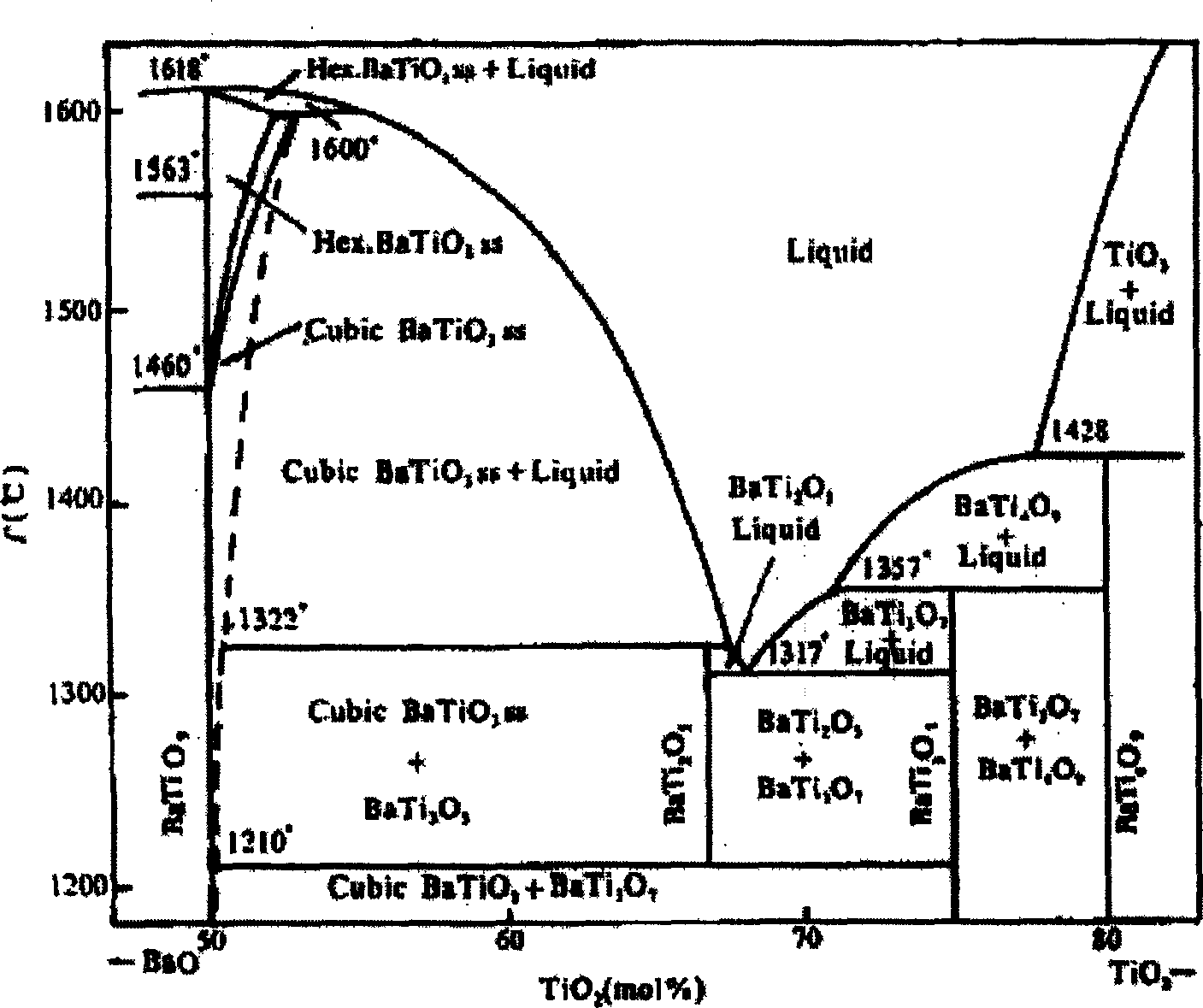

Process for laser preparation of hexagonal phase barium titanate ceramic

A phase barium titanate and laser technology, which is applied in the field of preparation of hexagonal phase barium titanate ceramics, can solve the problems of impurity pollution, difficult control of the sintering process, long sintering time, etc., and achieve high repeatability, pollution-free sintering, and short preparation time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

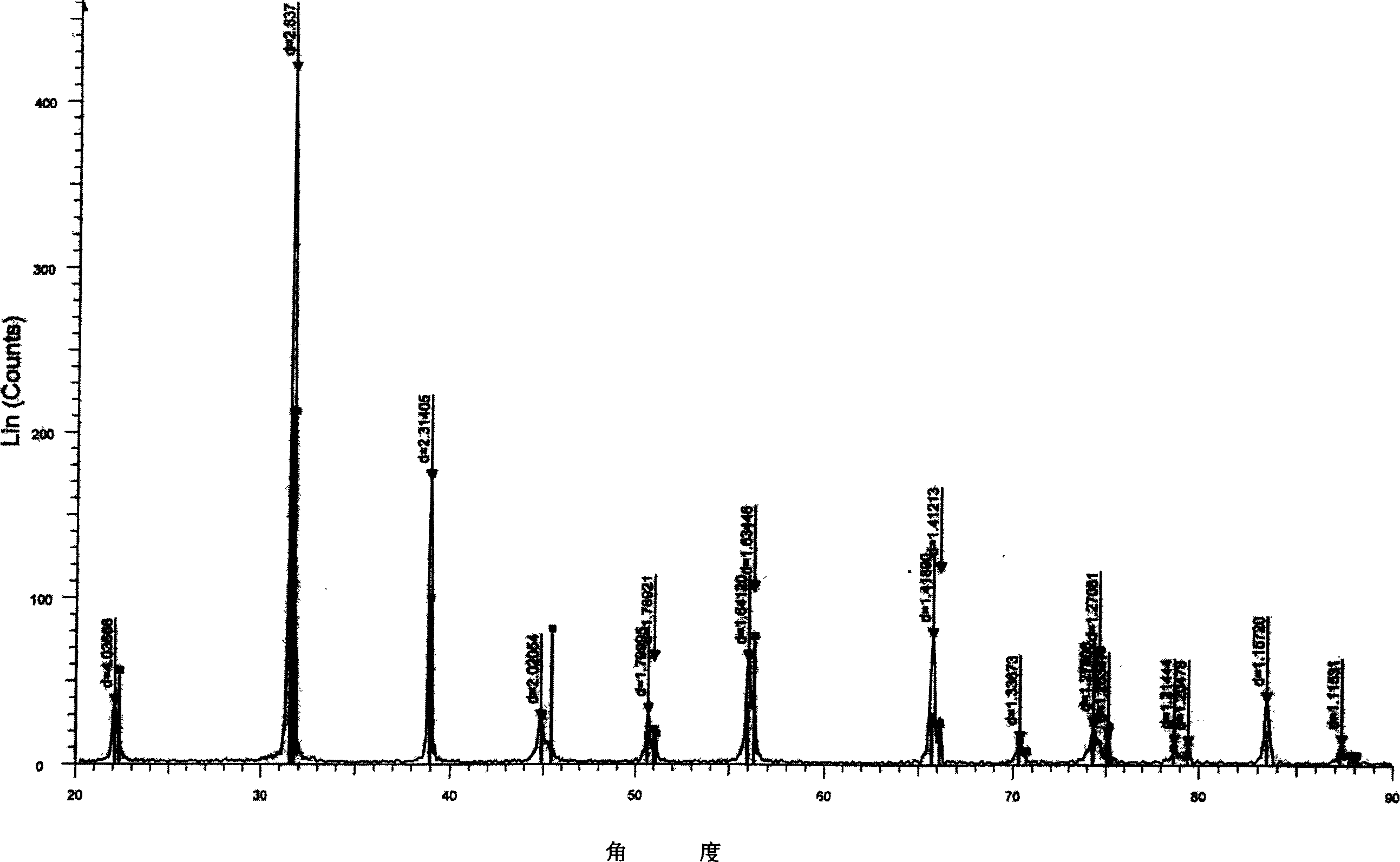

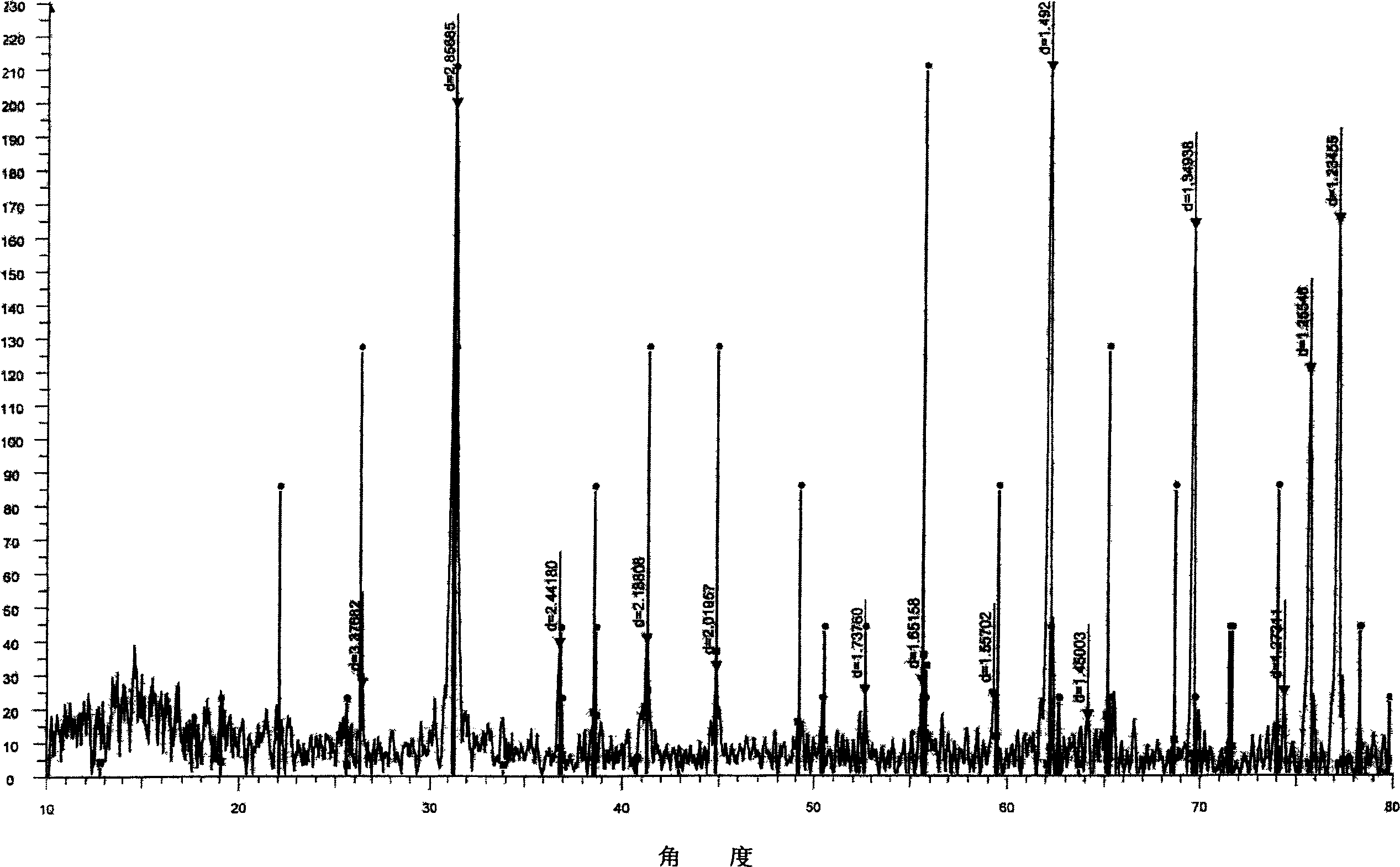

Embodiment 1

[0027] Example 1: BaTiO is irradiated with German Rofin-sina RS2500 laser 3 Ceramic body; firstly, continuously increase the laser power density from 0 to sintering power density value of 466w / cm within 60s 2 , the rotation speed of the rotary table is 120° / s, after 20s of sintering time, then reduce the laser power to zero within 60s; the laser is turned off. The sample cools down to porcelain.

Embodiment 2

[0028] Example 2: BaTiO is irradiated with German Rofin-sina RS2500 laser 3 Ceramic body; firstly, within 50s, continuously increase the laser power density from 0 to the sintering power density value of 528w / cm 2 , the rotation speed of the rotary table is 90° / s, after 30s of sintering time, then reduce the laser power to zero within 50s; the laser is turned off. The sample cools down to porcelain.

Embodiment 3

[0029] Example 3: BaTiO is irradiated with German Rofin-sina RS2500 laser 3 Ceramic body; firstly, within 50s, continuously increase the laser power density from 0 to the sintering power density value of 590w / cm 2 , the rotation speed of the rotary table is 90° / s, after 25s of sintering time, then reduce the laser power to zero within 50s; the laser is turned off. The sample cools down to porcelain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com