Method for preparing YBCO superconducting composite film

A composite film, superconducting technology, applied in the usage of superconducting elements, the manufacture/processing of superconducting devices, superconducting devices, etc., can solve the problem of inability to evaluate superconducting properties, reduce production costs, and improve current-carrying capacity. , the effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Weigh yttrium acetate, barium acetate and copper acetate to be 0.005mol, 0.01mol and 0.015mol respectively, mix the yttrium acetate, barium acetate and copper acetate and dissolve them in 100ml deionized water containing 10mol% trifluoroacetic acid to prepare into solution;

[0029] (2) After the solution prepared in step (1) was stirred by a magnetic stirrer for 1 h, the solvent was evaporated by a rotary evaporator to obtain a gel;

[0030] (3) Add 30mL of methanol into the gel prepared in step (2), stir it with a magnetic stirrer for 0.5h, and then use a rotary evaporator to evaporate the solvent to further remove impurities such as water to obtain a very pure gel. glue;

[0031] (4) adding the gel prepared in step (3) into 20ml of methanol to make Y, Ba and Cu three kinds of metal total ion concentration is the precursor solution of 1.5mol / L;

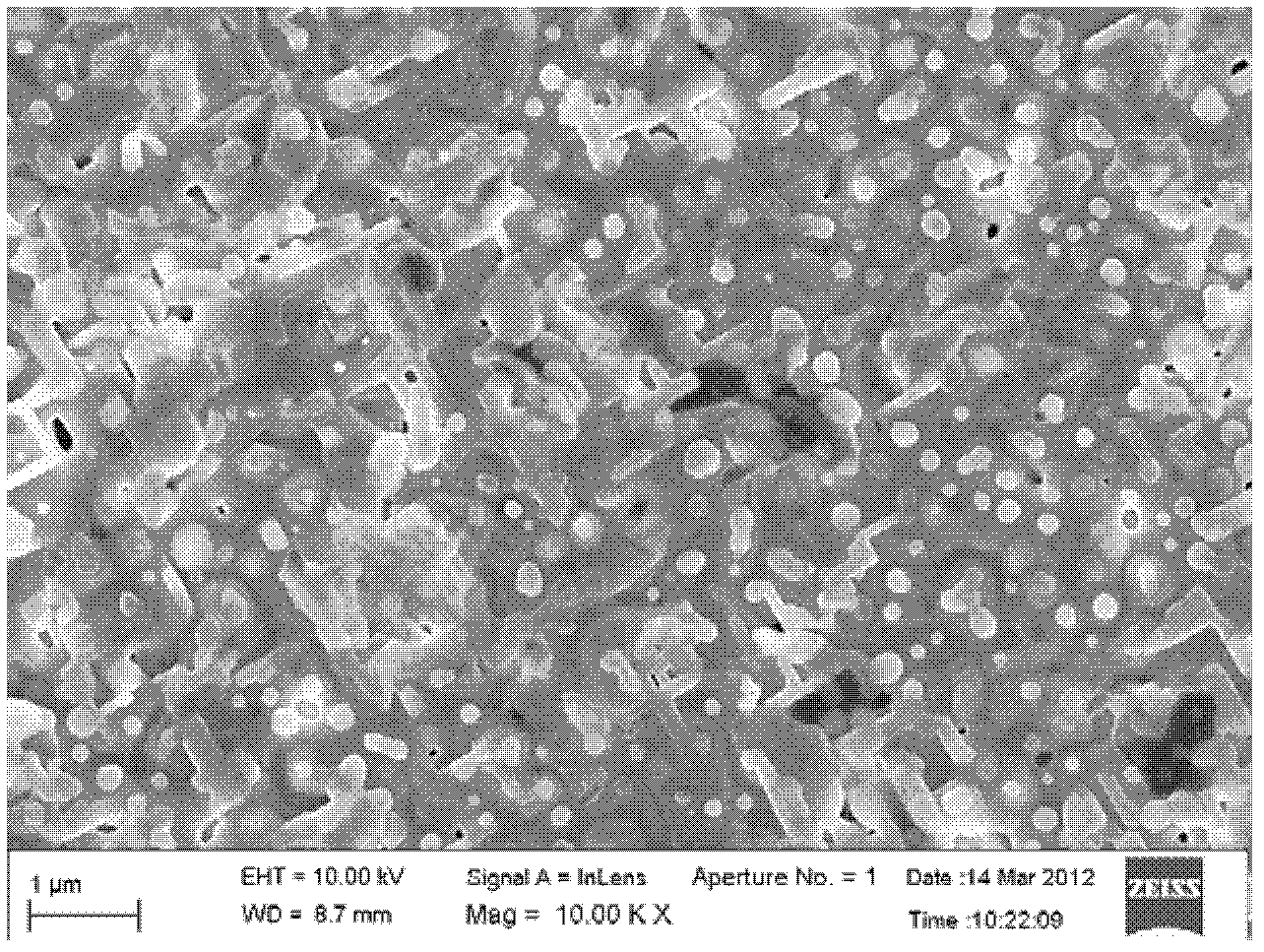

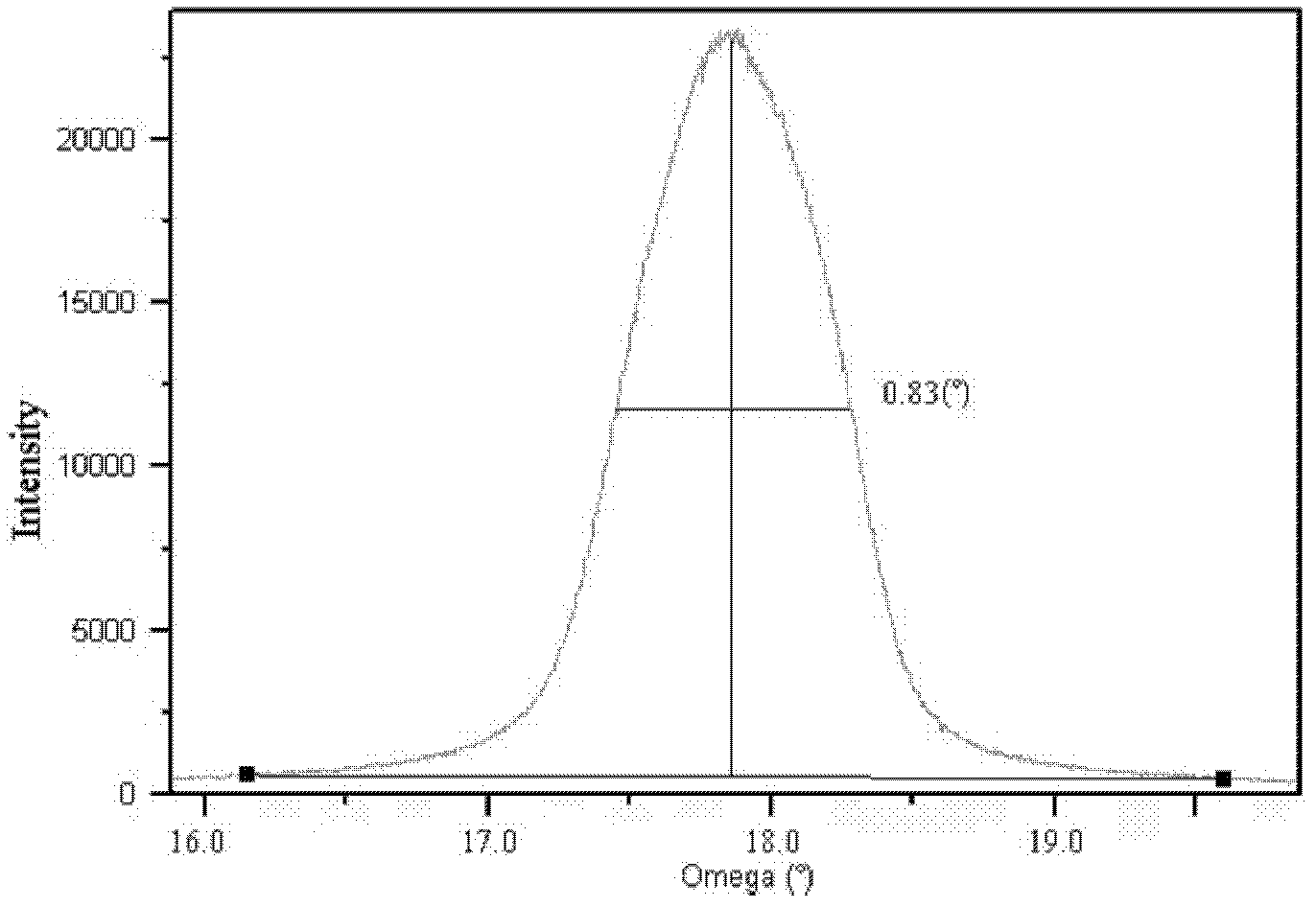

[0032] (5) Spin-coat the precursor solution prepared in step (4) on the strontium titanate single crystal substrate a...

Embodiment 2

[0040] (1) Weigh yttrium acetate, barium acetate and copper acetate to be 0.01mol, 0.02mol and 0.03mol respectively, mix the yttrium acetate, barium acetate and copper acetate and dissolve in 200ml deionized water containing 20mol% trifluoroacetic acid to prepare into solution;

[0041] (2) After the solution prepared in step (1) was stirred by a magnetic stirrer for 2 hours, the solvent was evaporated by a rotary evaporator to obtain a gel;

[0042] (3) Add 60mL of methanol to the gel prepared in step (2), and then stir it with a magnetic stirrer for 1 hour, then use a rotary evaporator to evaporate the solvent to further remove impurities such as moisture to obtain a very pure gel ;

[0043] (4) adding the gel prepared in step (3) into 30ml of methanol to make Y, Ba and Cu three kinds of metal total ion concentration is the precursor solution of 2mol / L;

[0044] (5) The precursor solution prepared in step (4) was spin-coated on the lanthanum aluminate single crystal substr...

Embodiment 3

[0052] (1) Weigh yttrium acetate, barium acetate and copper acetate to be 0.015mol, 0.03mol and 0.045mol respectively, mix the yttrium acetate, barium acetate and copper acetate and dissolve them in 300ml deionized water containing 30mol% trifluoroacetic acid to prepare into solution;

[0053] (2) After the solution prepared in step (1) was stirred for 3 hours by a magnetic stirrer, the solvent was evaporated by a rotary evaporator to obtain a gel;

[0054] (3) Add 90mL of methanol into the gel prepared in step (2), stir with a magnetic stirrer for 1.5h, and then use a rotary evaporator to evaporate the solvent to further remove impurities such as moisture to obtain a very pure gel. glue;

[0055] (4) adding the gel prepared in step (3) into 30ml of methanol to make Y, Ba and Cu three kinds of metal total ion concentration is the precursor solution of 3.0mol / L;

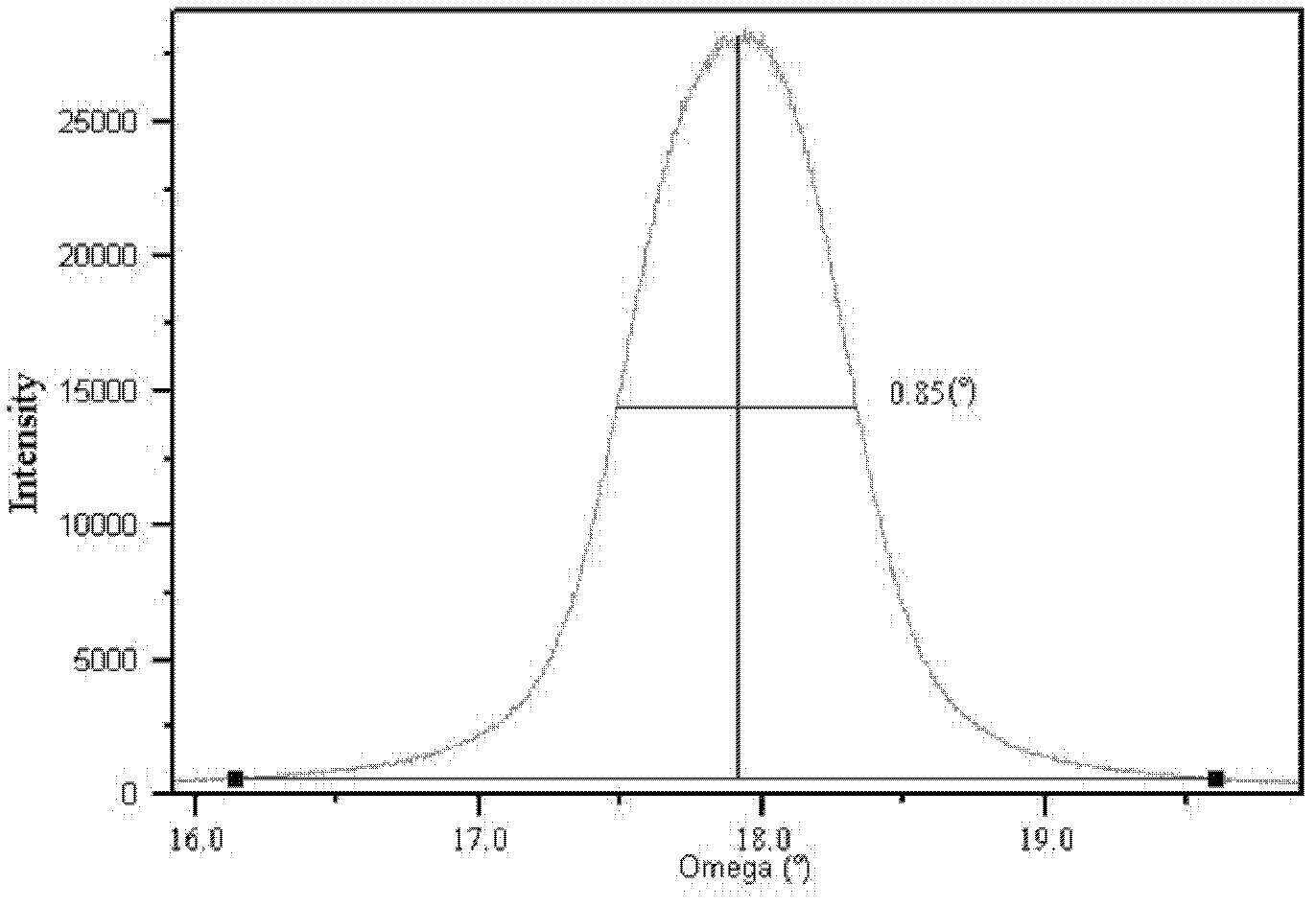

[0056] (5) Spin-coat the precursor solution prepared in step (4) on the magnesium oxide single crystal substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com