Medium-low-temperature denitration catalyst with mesoporous cerium oxide as carrier and preparation method

A low-temperature denitrification and cerium oxide technology, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effects of easy operation, good application prospects, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

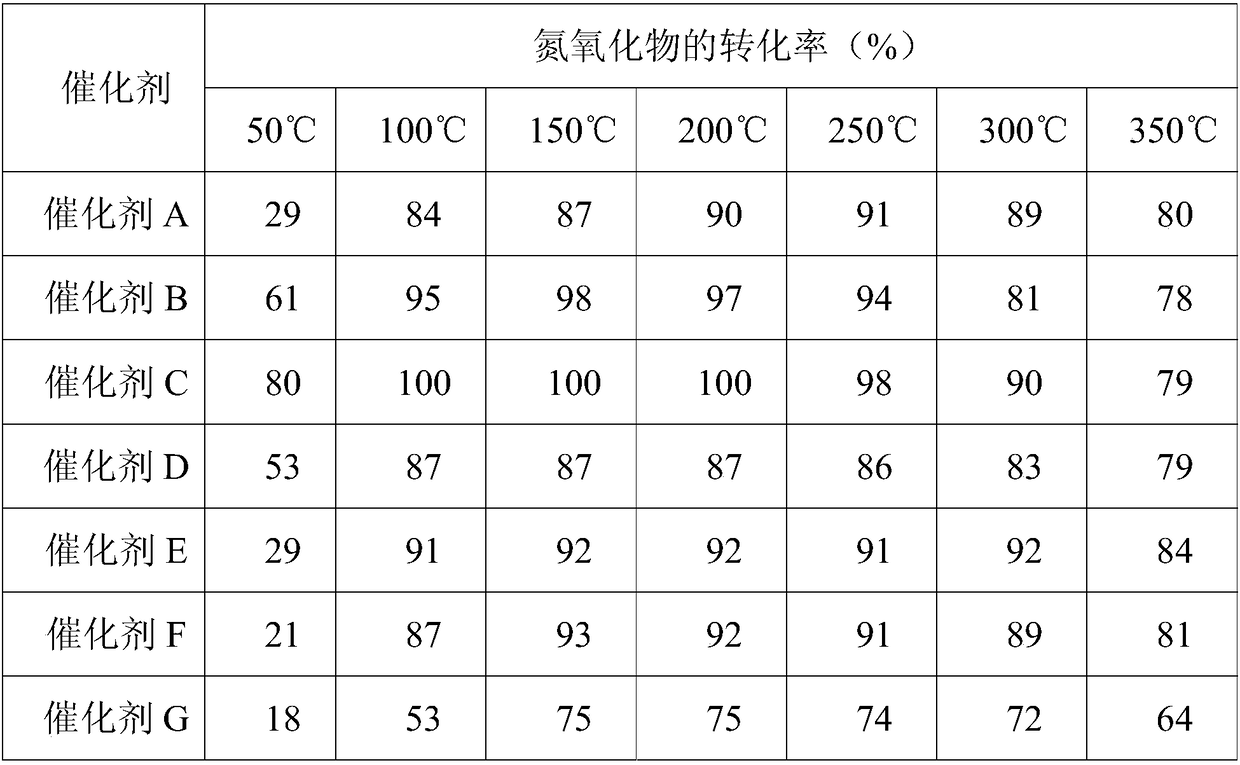

[0029] (1) 1.833g of cerium acetylacetonate hydrate and 2g of CTAB surfactant were mixed, and ball milled for 30 minutes with a ball mill; the medicine after ball milling was transferred to a 50mL polytetrafluoroethylene reaction kettle, and 0.5mL was added with a concentration of 2mol / L After aging treatment at 180°C for 24 h, the NaOH solution was naturally cooled to room temperature; the mesoporous cerium oxide precursor in the reaction kettle was taken out and dried in an oven, and the dried precursor was placed in a muffle furnace for 1 The heating rate of °C / min was raised to 500 °C, and baked at this temperature for 5 hours to obtain a mesoporous cerium oxide support; the obtained mesoporous cerium oxide support was recorded as CeO 2 -CTAB-C1 (CeO 2 -CTAB-C1 stands for CeO made from hydrated cerium acetylacetonate and CTAB 2 ), the specific surface area of the carrier is 161m 2 / g.

[0030] (2) Prepare the (NH 4 ) 6 h 2 W 12 o 40 ·yH 2 O solution, add equal m...

Embodiment 2

[0032] (1) 1.833g of cerium acetylacetonate hydrate and 1g of PVP surfactant were mixed, and ball milled for 30 minutes with a ball mill. Transfer the ball-milled medicine to a 50mL polytetrafluoroethylene reaction kettle, add 0.5mL NaOH solution with a concentration of 2mol / L, age at 100°C for 10h, and cool to room temperature naturally; take out the mesopores in the reaction kettle Place the cerium oxide precursor in an oven to dry, place the dried precursor in a muffle furnace, raise the temperature to 500°C at a heating rate of 2°C / min, and bake at this temperature for 2 hours to obtain mesoporous cerium oxide carrier. The obtained mesoporous cerium oxide support is denoted as CeO 2 -PVP-C1 (CeO 2 -PVP-C1 stands for CeO made from hydrated cerium acetylacetonate and PVP 2 ), the specific surface area of the carrier is 183m 2 / g.

[0033] (2) Prepare (NH 4 ) 6 h 2 W 12 o 40 ·yH 2 O solution, add equal mass of oxalic acid to inhibit the hydrolysis of tungsten ion...

Embodiment 3

[0035] (1) 1.506g of cerium isopropoxide and 2g of CTAB surfactant were mixed, and ball milled for 30 minutes with a ball mill. Transfer the ball-milled medicine to a 50mL polytetrafluoroethylene reaction kettle, add 0.5mL NaOH solution with a concentration of 2mol / L, age at 120°C for 12h, and cool naturally to room temperature; take out the mesopores in the reaction kettle Place the cerium oxide precursor in an oven to dry, place the dried precursor in a muffle furnace, raise the temperature to 550°C at a rate of 1°C / min, and bake at this temperature for 3 hours to obtain mesoporous cerium oxide carrier. The obtained mesoporous cerium oxide support is denoted as CeO 2 -CTAB-C2 (CeO 2 -CTAB-C2 stands for CeO made of cerium isopropoxide and CTAB 2 ), the specific surface area of the carrier is 134m 2 / g.

[0036] (2) Prepare (NH 4 ) 6 h 2 W 12 o 40 ·yH 2 O solution, add equal mass of oxalic acid to inhibit the hydrolysis of tungsten ions during the preparation proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com