Method for preparing composite oxides mischcrystal jelly glue with gadolinium oxide adulterating cerium oxide

A composite oxide and cerium oxide technology, which is applied in solid electrolyte fuel cells, electrochemical generators, final product manufacturing, etc., can solve unavoidable problems and achieve the effects of improving sintering activity, simple preparation process, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of a composite oxide solid solution gel doped with gadolinium oxide cerium oxide, which comprises the steps of:

[0027] 1) Selection of raw materials: each raw material is weighed according to the following weight: cerium acetylacetonate hydrate [Ce(CH 3 COCHCOCH 3 ) 3 ·3H 2 O] 1.554g, gadolinium acetylacetonate hydrate [Gd(CH 3 COCHCOCH 3 ) 3 ·3H 2 O] 0.355g, methanol 25.37g, N, N-dimethylformamide 0.415g; described methanol, N, N-dimethylformamide are analytically pure, with a purity greater than 98wt%;

[0028] 2) Add cerium acetylacetonate hydrate [Ce(CH 3 COCHCOCH 3 ) 3 ·3H 2 O], gadolinium acetylacetonate hydrate [Gd(CH 3 COCHCOCH 3 ) 3 ·3H 2 O], methanol and N, N-dimethylformamide, stirred at room temperature for 1.5 hours (without adding deionized water);

[0029] 3) Pour the stable and clear sol solution into a glass petri dish, cover the petri dish and put it in an oven, gelatinize, dehydrate and dealcoholize at 68°C for 24...

Embodiment 2

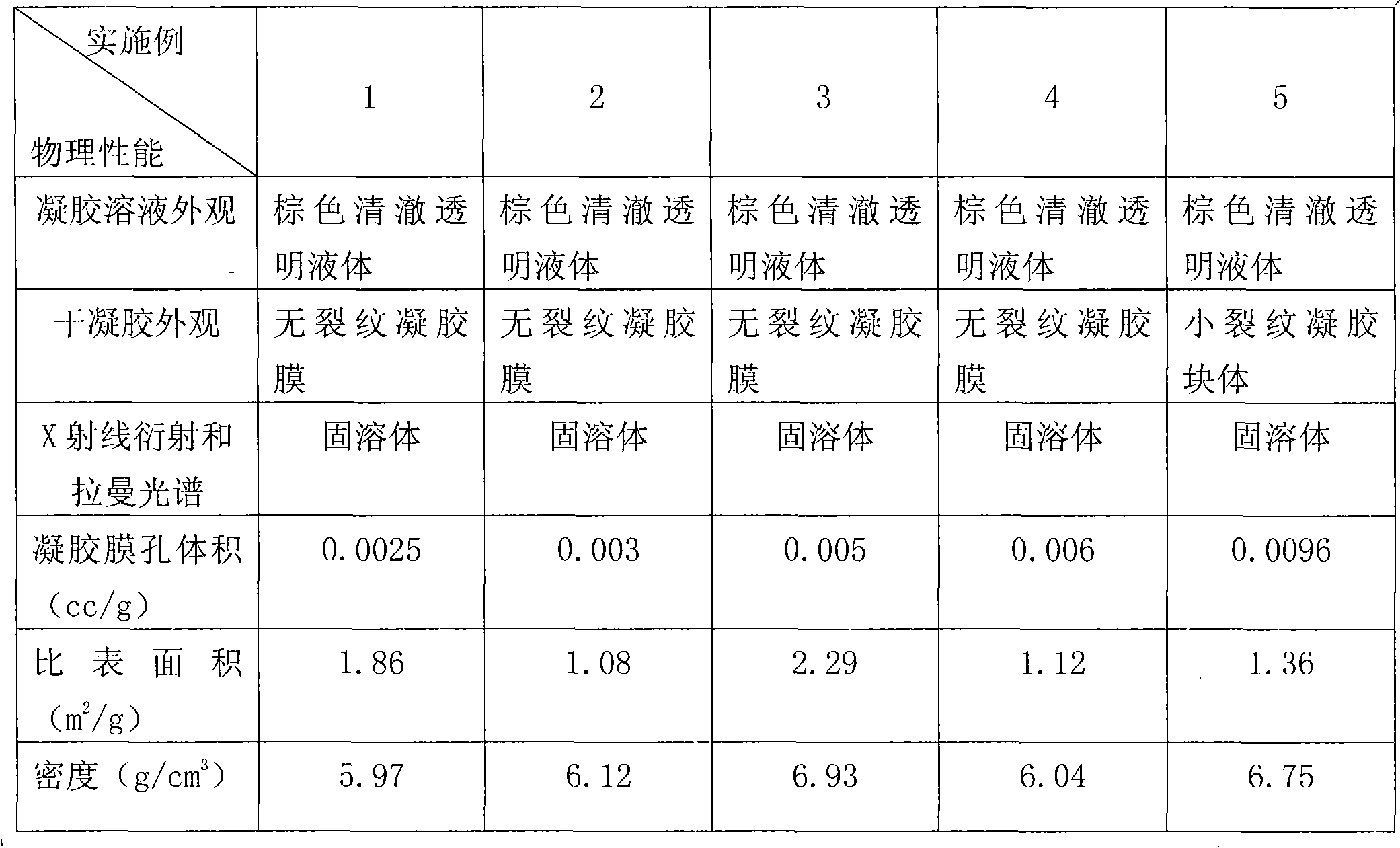

[0034] The preparation method is the same as in Example 1, except that in step 2) of Example 1, no deionized water is replaced with 0.315 g of deionized water. The test results of its basic physical properties are shown in Table 1.

Embodiment 3

[0036] A preparation method of a composite oxide solid solution gel doped with gadolinium oxide cerium oxide, which comprises the steps of:

[0037] 1) Selection of raw materials: each raw material is weighed according to the following weight: cerium acetylacetonate hydrate [Ce(CH 3 COCHCOCH 3 ) 3 ·3H 2 O] 1.554g, gadolinium acetylacetonate hydrate [Gd(CH 3 COCHCOCH 3 ) 3 ·3H 2 O] 0.355g, methanol 25.37g, N, N-dimethylformamide 0.415g, deionized water 0.315g; described methanol, N, N-dimethylformamide are analytically pure, with a purity greater than 98wt%;

[0038] 2) Add cerium acetylacetonate hydrate [Ce(CH 3 COCHCOCH 3 ) 3 ·3H 2 O], gadolinium acetylacetonate hydrate [Gd(CH3 COCHCOCH 3 ) 3 ·3H 2 O], methanol and N,N-dimethylformamide, add deionized water and stir at room temperature for 1 hour;

[0039] 3) Pour the stable and clear sol solution into a glass petri dish, cover the petri dish and put it in an oven, gelatinize, dehydrate and dealcoholize at 65°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com