Preparation method of low-carbon clean fuel

A low-carbon clean fuel technology, applied in liquid carbon-containing fuel, fuel, petroleum industry, etc., can solve the problems of low-temperature start-up of vehicle diesel, low flash point of vehicle diesel, engine cylinder wear and other problems, and achieve no mechanical Wear, reduce carbon deposits, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

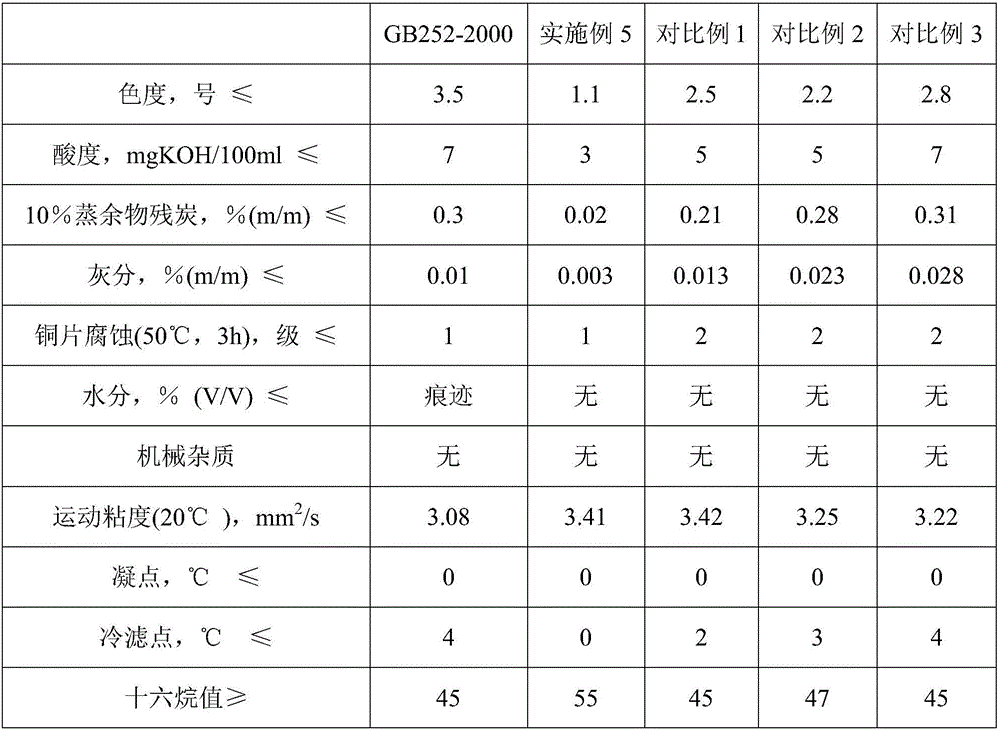

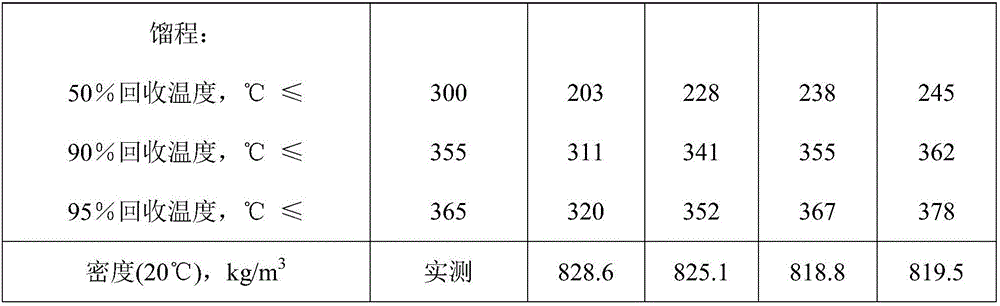

Examples

Embodiment 1

[0016] In the embodiment of the present invention, a low-carbon clean fuel is composed of the following raw materials in parts by weight: 37 parts of ethanol, 28 parts of diesel oil, 3 parts of fish float glue, 9 parts of cerium acetylacetonate, and 2 parts of nano-zinc oxide.

[0017] Diesel oil, fish float glue and cerium acetylacetonate were mixed, and sealed and stirred at a temperature of 79 ° C for 57 minutes to prepare mixture A. Ethanol was mixed with nanometer zinc oxide, and stirred at a temperature of 68° C. for 1.3 h to prepare mixture B. Mixture A and mixture B were mixed, heated to 62°C and stirred for 22 minutes, and then ultrasonically treated at this temperature for 1.3h with an ultrasonic power of 900W to prepare a fuel.

Embodiment 2

[0019] In the embodiment of the present invention, a low-carbon clean fuel is composed of the following raw materials in parts by weight: 45 parts of ethanol, 36 parts of diesel oil, 7 parts of fish float glue, 13 parts of cerium acetylacetonate, and 4 parts of nano-zinc oxide.

[0020] Diesel oil, fish float glue and cerium acetylacetonate were mixed, and sealed and stirred at a temperature of 79 ° C for 57 minutes to prepare mixture A. Ethanol was mixed with nanometer zinc oxide and stirred at 68° C. for 1.4 h to prepare mixture B. Mixture A and mixture B were mixed, heated to 62°C and stirred for 22 minutes, and then ultrasonically treated at this temperature for 1.3h with an ultrasonic power of 900W to prepare a fuel.

Embodiment 3

[0022] In the embodiment of the present invention, a low-carbon clean fuel is composed of the following raw materials in parts by weight: 39 parts of ethanol, 30 parts of diesel oil, 4 parts of fish float glue, 10 parts of cerium acetylacetonate, and 2.5 parts of nano-zinc oxide.

[0023] Diesel oil, fish float glue and cerium acetylacetonate were mixed, and sealed and stirred at a temperature of 79 ° C for 57 minutes to prepare mixture A. Ethanol was mixed with nano zinc oxide, and stirred at 68° C. for 1.35 h to prepare mixture B. Mixture A and mixture B were mixed, heated to 62°C and stirred for 22 minutes, and then ultrasonically treated at this temperature for 1.3h with an ultrasonic power of 900W to prepare a fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com