Process for preparing water-soluble ceria nanocrystalline

A cerium dioxide, water-soluble technology, applied in the field of preparation of water-soluble CeO2 nanocrystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

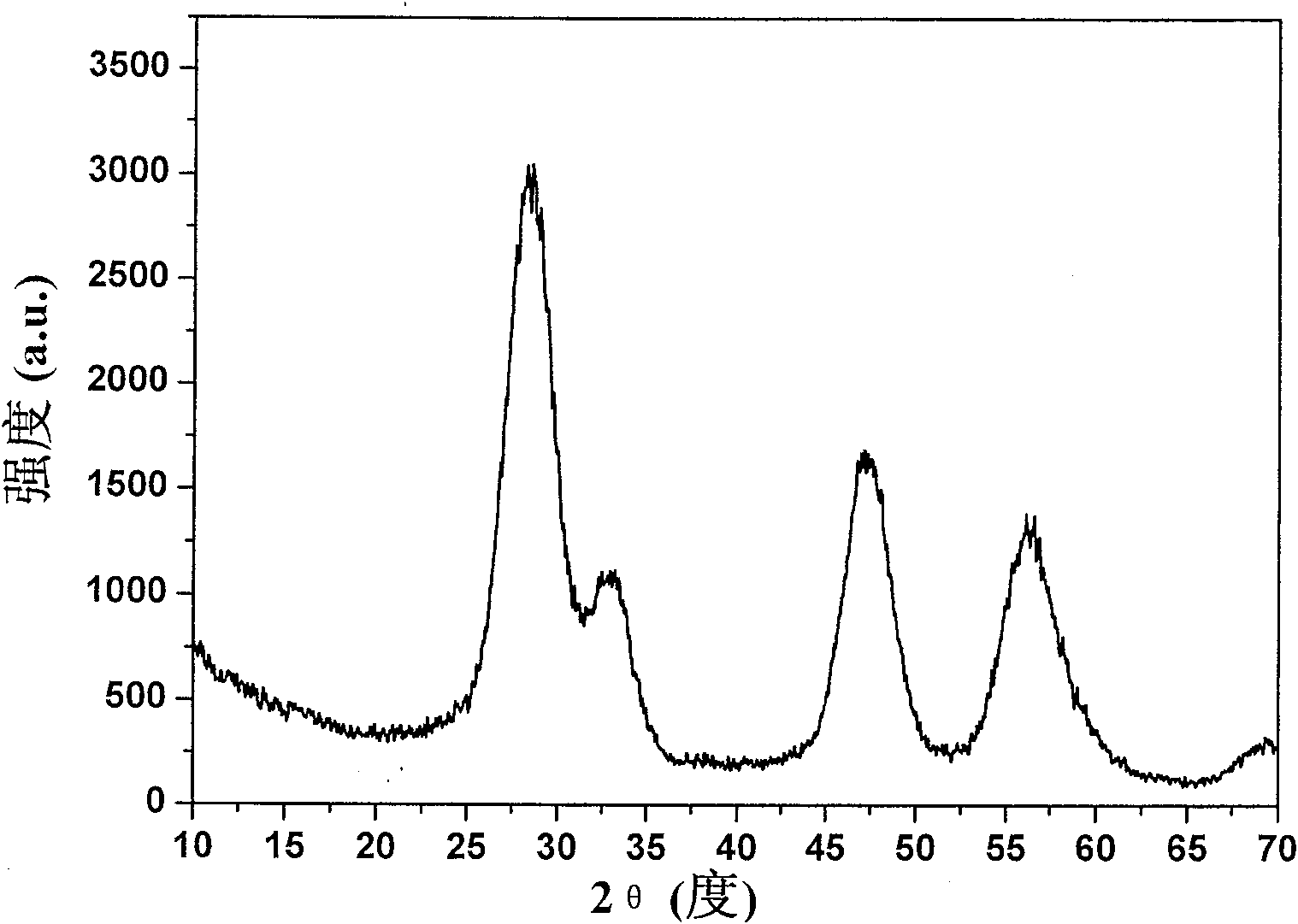

[0018] Embodiment 1: take by weighing the Ce(acac) of 2mmol 3 ·H 2 O, add in the two-neck round bottom flask of 100ml, then add the 2-pyrrolidone of 20ml. Insert a thermometer into one neck of the bottle and a water-cooled reflux condenser into the other neck. The mixture was heated to 75°C, Ce(acac) 3 Dissolve in 2-pyrrolidone to obtain 0.1mol / L 2-pyrrolidone solution of cerium acetylacetonate, heat the solution to 240°C and reflux for 60min, remove the heating mantle, and cool to room temperature to obtain water-soluble CeO 2 Transparent brown sol of nanoparticles. Add 200ml of methanol to the solution, there is water-soluble CeO 2 The precipitation of nanoparticles is separated out, and the precipitation is centrifuged, and the precipitation is washed 5 times with acetone (each consumption 50ml), and the precipitation is washed with N 2 Flow drying for 4h, to obtain light yellow water-soluble CeO 2 Nanoparticles. If a certain amount of deionized water or 2-pyrrolidon...

Embodiment 2

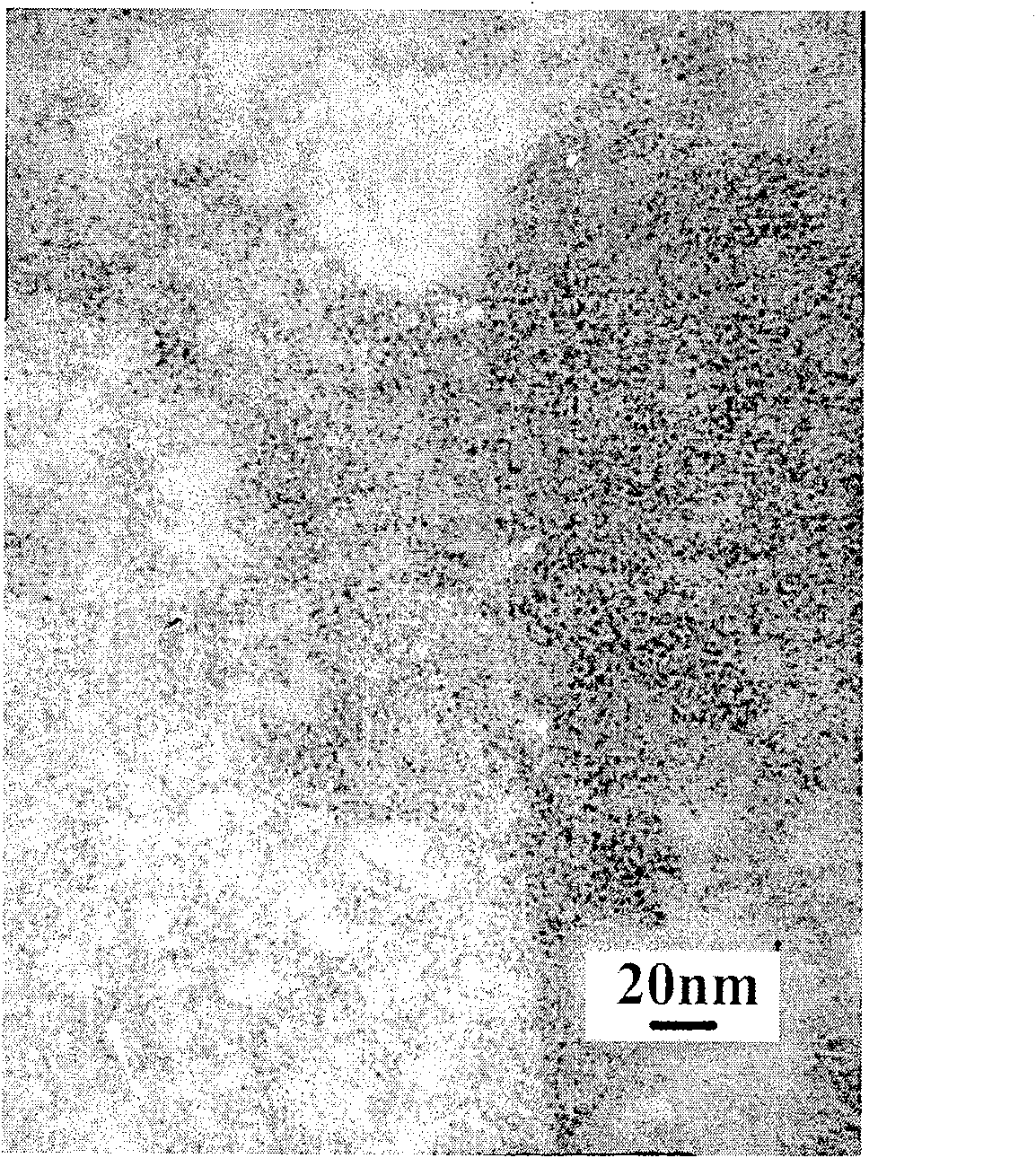

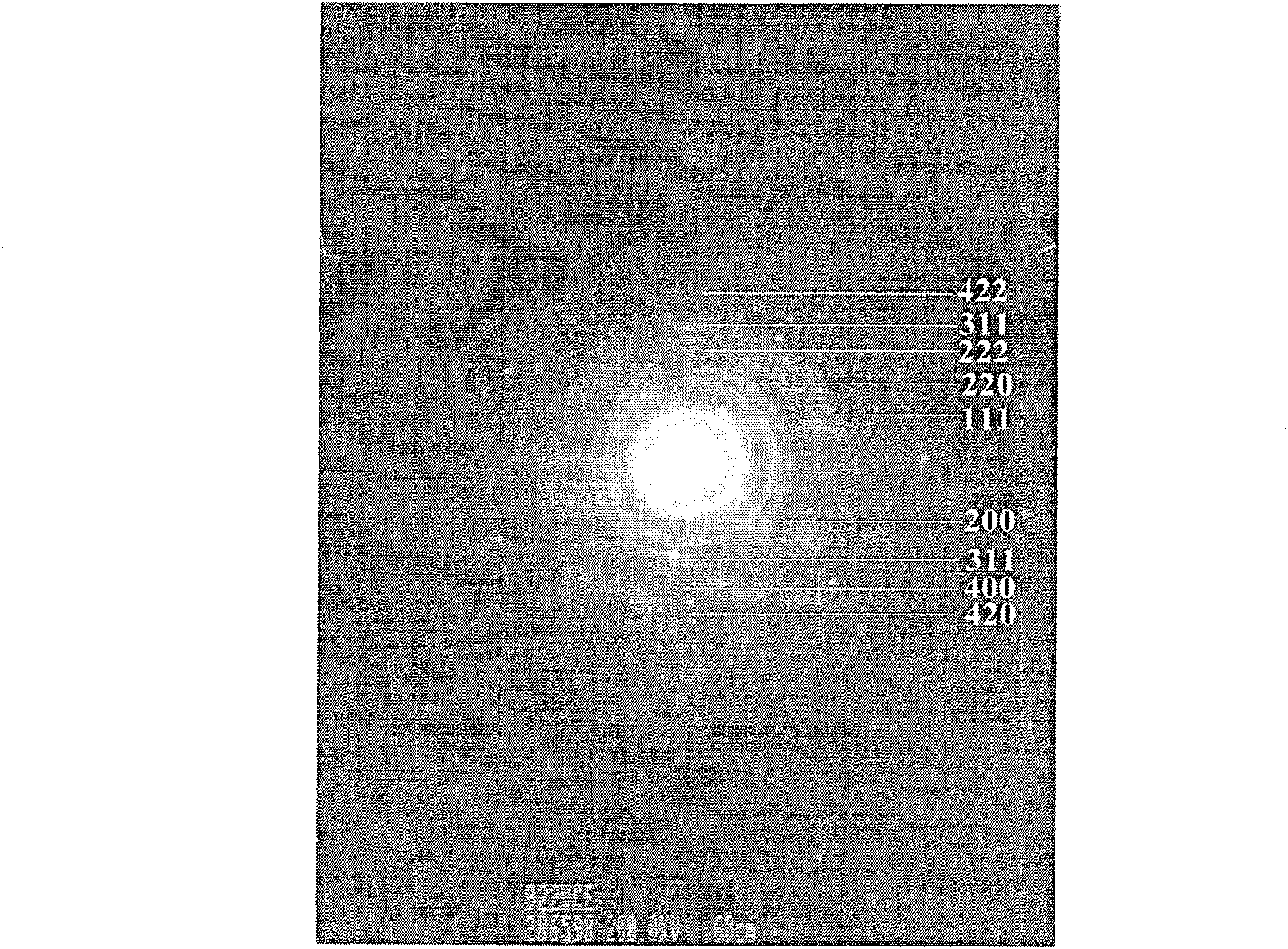

[0019] Embodiment 2: take by weighing the Ce (acac) of 4mmol 3 ·H 2 O, add in the two-neck round bottom flask of 100ml, then add the 2-pyrrolidone of 20ml. Insert a thermometer into one neck of the bottle and a water-cooled reflux condenser into the other neck. The mixture was heated to 85°C, Ce(acac) 3 Dissolve in 2-pyrrolidone to obtain 0.2mol / L 2-pyrrolidone solution of cerium acetylacetonate, heat the solution to 225°C and reflux for 120min, remove the heating mantle and cool to room temperature to obtain water-soluble CeO 2 Transparent brown sol of nanoparticles. Add 300ml of methanol to the solution, there is water-soluble CeO 2 The nanoparticles were precipitated, and the precipitate was centrifuged, washed with acetone (80ml each time) for 5 times, and dried at 50°C for 10h to obtain light yellow water-soluble CeO 2 Nanoparticles. The prepared water-soluble CeO 2 The diameter of the nanoparticles is about 10 nm, and the particles are spherical.

Embodiment 3

[0020] Embodiment 3: take by weighing the Ce(acac) of 3mmol 3 ·H 2 O, add in the two-neck round bottom flask of 100ml, then add the 2-pyrrolidone of 20ml. Insert a thermometer into one neck of the bottle and a water-cooled reflux condenser into the other neck. The mixture was heated to 80°C, Ce(acac) 3 Dissolve in 2-pyrrolidone to obtain 0.15mol / L 2-pyrrolidone solution of cerium acetylacetonate, heat the solution to 230°C and reflux for 100min, remove the heating mantle, and cool to room temperature to obtain water-soluble CeO 2 Transparent brown sol of nanoparticles. Add 300ml of methanol to the sol, there is water-soluble CeO 2 The nanoparticles were precipitated, and the precipitate was centrifuged, washed with acetone (80ml each time) for 5 times, and dried at 60°C for 5h to obtain light yellow water-soluble CeO 2 Nanoparticles. The prepared water-soluble CeO 2 The diameter of the nanoparticles is about 8 nm, and the particles are spherical.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com