A kind of low-carbon high-clean diesel vehicle fuel and preparation method thereof

A diesel vehicle, clean technology, applied in the liquid carbon-containing fuel, fuel, petroleum industry and other directions, can solve the problems of low temperature starting of vehicle diesel, engine block wear, low flash point of vehicle diesel, etc., to reduce carbon deposition , the effect of low production cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

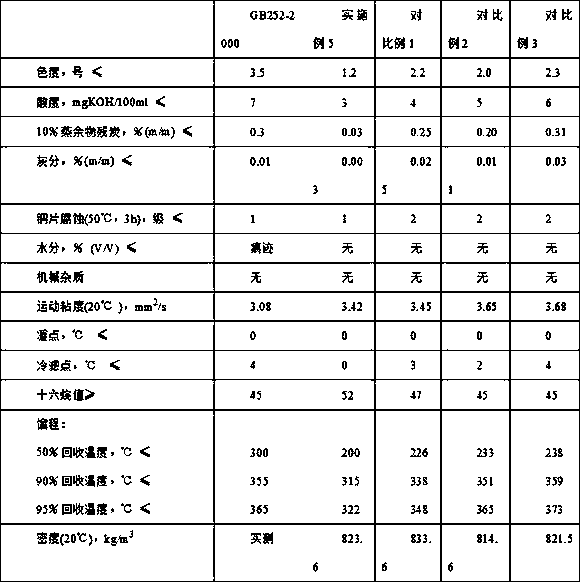

Examples

Embodiment 1

[0016] In the embodiment of the present invention, a low-carbon high-clean diesel vehicle fuel is composed of the following raw materials in parts by weight: 10 parts of methanol, 33 parts of diesel oil, 5 parts of sodium bisulfite formaldehyde, 11 parts of itaconic acid, and acetylacetone 3 parts of cerium, 1 part of nano zinc oxide.

[0017] Diesel oil, itaconic acid and nano-zinc oxide were mixed, and sealed and stirred at a temperature of 73°C for 35 minutes to prepare mixture A. Mix methanol, sodium bisulfoxylate formaldehyde and cerium acetylacetonate, and stir at 62°C for 1.2h to prepare mixture B. Mix mixture A and mixture B, heat to 65° C. and stir for 10 minutes, then sonicate at this temperature for 42 minutes with an ultrasonic power of 1000 W to prepare a fuel.

Embodiment 2

[0019] In the embodiment of the present invention, a low-carbon high-clean diesel vehicle fuel is composed of the following raw materials in parts by weight: 20 parts of methanol, 41 parts of diesel oil, 12 parts of sodium bisulfite formaldehyde, 19 parts of itaconic acid, and acetylacetone 7 parts of cerium, 3 parts of nano zinc oxide.

[0020] Diesel oil, itaconic acid and nano-zinc oxide were mixed, and sealed and stirred at a temperature of 73°C for 40 minutes to prepare mixture A. Mix methanol, sodium bisulfoxylate formaldehyde and cerium acetylacetonate, and stir at 62°C for 1.2h to prepare mixture B. Mix mixture A and mixture B, heat to 65° C. and stir for 10 minutes, then sonicate at this temperature for 42 minutes with an ultrasonic power of 1000 W to prepare a fuel.

Embodiment 3

[0022] In the embodiment of the present invention, a low-carbon high-clean diesel vehicle fuel is composed of the following raw materials in parts by weight: 12 parts of methanol, 35 parts of diesel oil, 7 parts of sodium bisulfite formaldehyde, 13 parts of itaconic acid, acetylacetone 4 parts of cerium, 1.5 parts of nano zinc oxide.

[0023] Diesel oil, itaconic acid and nano-zinc oxide were mixed, and sealed and stirred at a temperature of 73°C for 38 minutes to prepare mixture A. Mix methanol, sodium bisulfoxylate formaldehyde and cerium acetylacetonate, and stir at 62°C for 1.2h to prepare mixture B. Mix mixture A and mixture B, heat to 65° C. and stir for 10 minutes, then sonicate at this temperature for 42 minutes with an ultrasonic power of 1000 W to prepare a fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com