Manganese-cerium composite oxide low-temperature denitration catalyst with hollow multi-shell microsphere structure

A composite oxide and low-temperature denitrification technology, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of vanadium-titanium-based catalysts, catalyst poisoning, Temperature drop and other problems, to achieve the effect of improving low-temperature denitrification performance, good denitrification activity, and long contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Prepare 20ml of a mixed solution containing Ce ions and Mn ions, wherein the concentration of Ce ions is 0.029mol / L, and the concentration of Mn ions is 0.019mol / L. At the same time, 60ml of glucose solution of 0.53mol / L is prepared, and then the mixed solution is added to Stir evenly into the glucose solution;

[0020] (2) transfer the homogeneously mixed solution into a reaction kettle, and conduct a hydrothermal reaction at 180° C. for 20 hours;

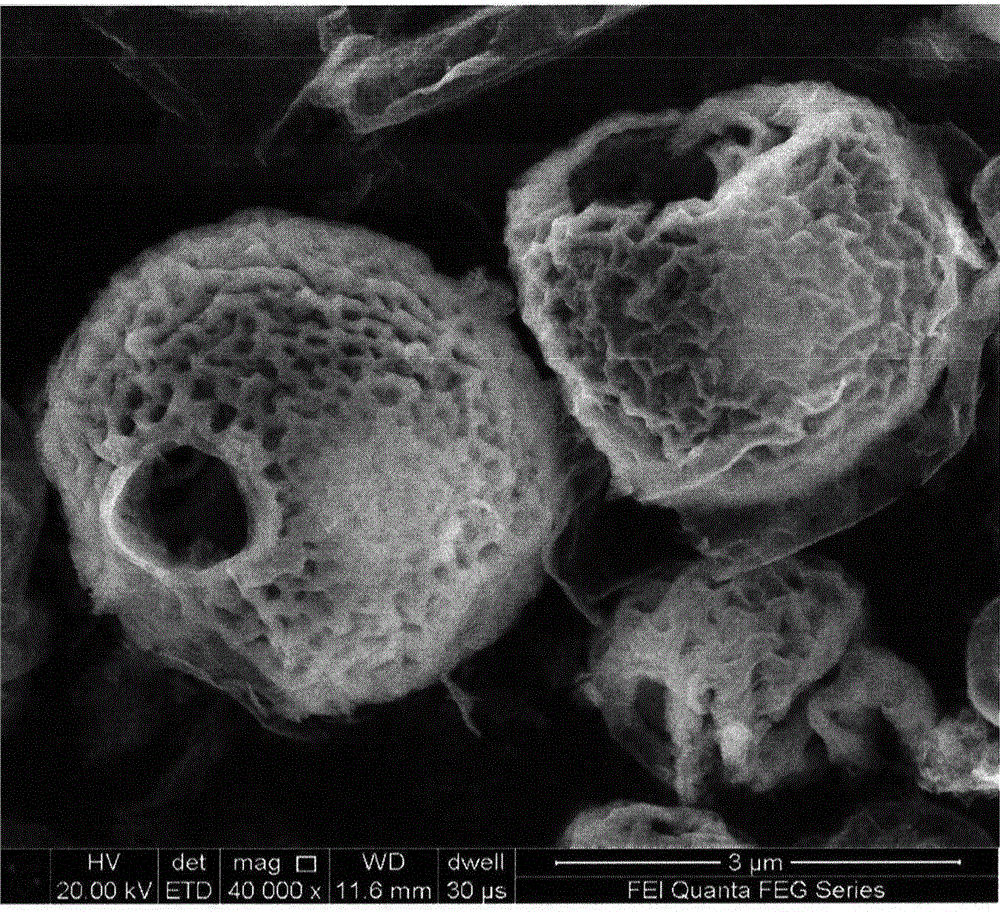

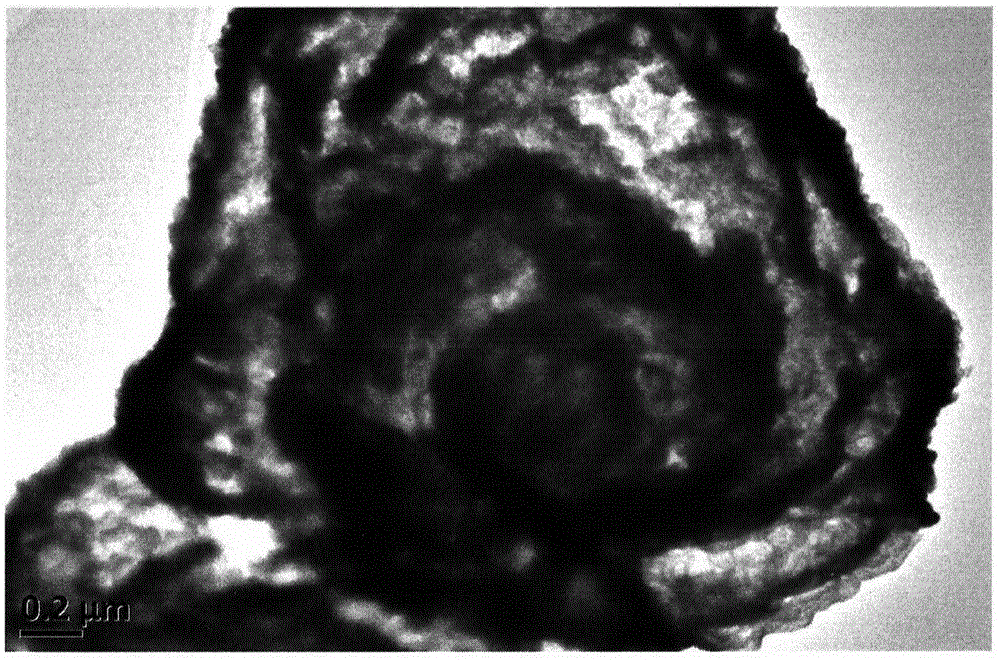

[0021] (3) After naturally cooling to room temperature, the product of the hydrothermal reaction was washed three times with water and ethanol respectively, then dried at 80°C, and then calcined at 400°C in a muffle furnace for 7.5 hours to obtain a hollow Manganese-cerium composite oxide with multi-shell microsphere structure.

[0022] The microsphere Mn: (Mn+Ce) = 0.4, the diameter of the microsphere is 3 μm after testing, and the specific surface area is 180m 2 / g. Catalyst activity test adopts fixed bed reactor, ...

Embodiment 2

[0024] (1) Prepare 20ml of a mixed solution containing Ce ions and Mn ions, wherein the concentration of Ce ions is 0.029mol / L, and the concentration of Mn ions is 0.067mol / L. At the same time, 60ml of glucose solution of 0.53mol / L is prepared, and then the mixed solution is added to Stir evenly into the glucose solution;

[0025] (2) transfer the homogeneously mixed solution into a reaction kettle, and conduct a hydrothermal reaction at 180° C. for 20 hours;

[0026] (3) After naturally cooling to room temperature, the product of the hydrothermal reaction was washed three times with water and ethanol respectively, then dried at 80°C, and then calcined at 400°C in a muffle furnace for 7.5 hours to obtain a hollow Manganese-cerium composite oxide with multi-shell microsphere structure.

[0027] The microsphere Mn: (Mn+Ce) = 0.7, the diameter of the microsphere is 2.5 μm after testing, and the specific surface area is 112m 2 / g. Catalyst activity test adopts fixed bed reactor...

Embodiment 3

[0029] (1) Prepare 20ml of a mixed solution containing Ce ions and Mn ions, wherein the concentration of Ce ions is 0.029mol / L, and the concentration of Mn ions is 0.0072mol / L. At the same time, 60ml of glucose solution of 0.53mol / L is prepared, and then the mixed solution is added to Stir evenly into the glucose solution;

[0030] (2) transfer the homogeneously mixed solution into a reaction kettle, and conduct a hydrothermal reaction at 180° C. for 20 hours;

[0031] (3) After naturally cooling to room temperature, the product of the hydrothermal reaction was washed three times with water and ethanol respectively, then dried at 80°C, and then calcined at 400°C in a muffle furnace for 7.5 hours to obtain a Manganese-cerium composite oxide with multi-shell microsphere structure.

[0032] The microsphere Mn: (Mn+Ce) = 0.2, the diameter of the microsphere is 2.7 μm after testing, and the specific surface area is 115m 2 / g. Catalyst activity test adopts fixed bed reactor, inle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com