Preparation method of Beta-type molecular sieve resistant to propylene poisoning

A beta type, molecular sieve technology, applied in the field of composite catalyst synthesis and performance research, can solve the problems of catalyst carbon deposition and deactivation, and achieve the effect of wide reaction temperature window and excellent low temperature activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

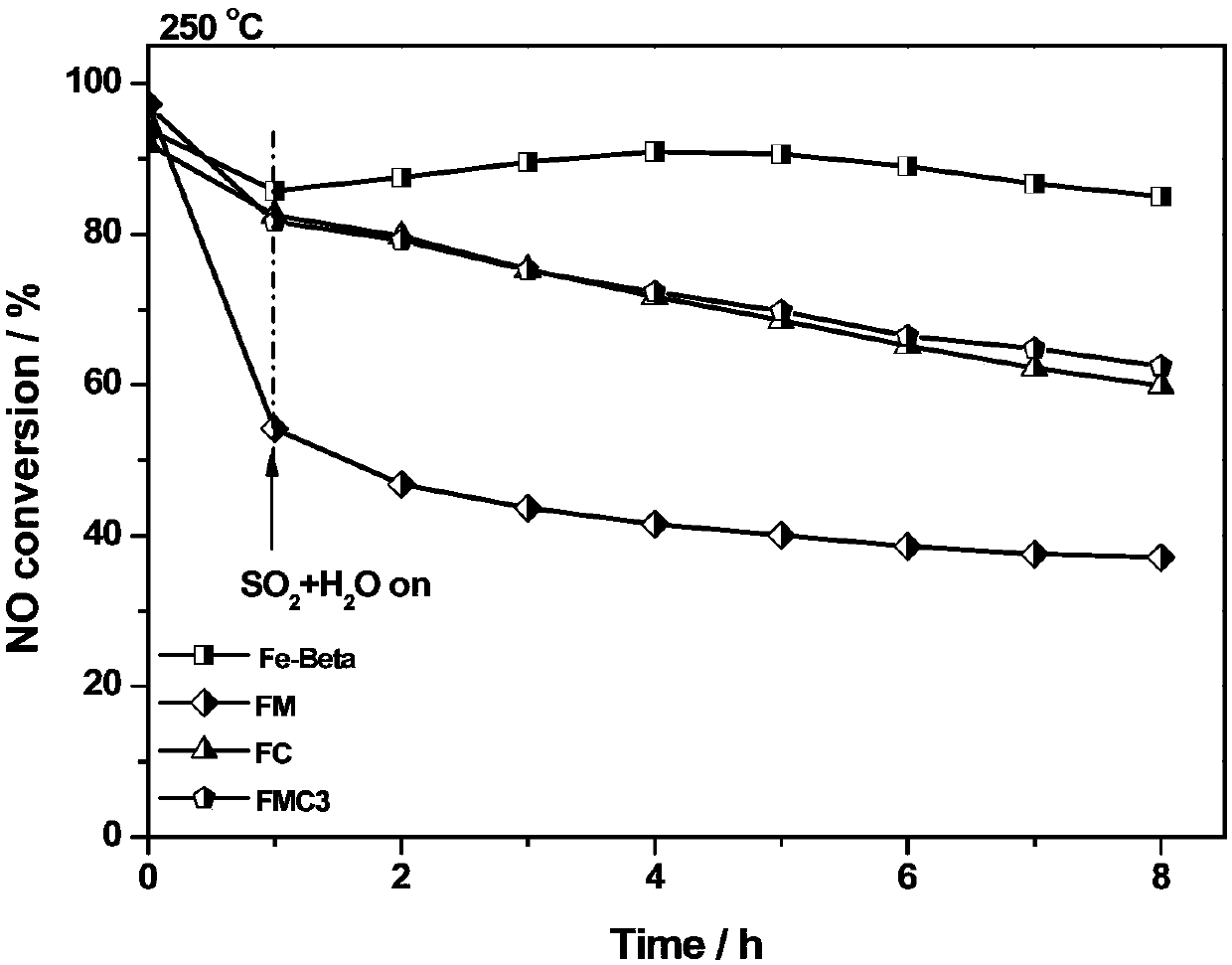

[0026] Example 1 Fe-Beta+MnO x (FM) preparation and activity evaluation

[0027] 1) Preparation of Fe-Beta:

[0028] A series of Fe-Beta catalysts were prepared by equal-volume impregnation method with ferrocene toluene solution using template-free Beta molecular sieves (Si / Al≈9) as supports. The specific steps are as follows: first, put Na-Beta molecular sieves in 0.5mol / L ammonium nitrate solution, stir vigorously at 80°C for 4h, then suction filter, wash, and dry at 120°C for 8-12h, and the obtained sample is used again with the same After exchange of concentrated ammonium nitrate solution, NH 4 -Beta molecular sieve; then, accurate measurement of NH 4 -Toluene saturated adsorption capacity of Beta molecular sieve, add the required amount of ferrocene to the corresponding toluene to make a solution, and then slowly add the ferrocene toluene solution to the NH 4 -Beta molecular sieve, stir evenly, stand at room temperature for more than 50h; finally calcinate the obtaine...

Embodiment 2

[0034] Example 2 Fe-Beta+CeO 2 Preparation and Activity Evaluation of (FC)

[0035] The steps and process conditions of this embodiment are all the same as in Example 1, the difference is that the CeO 2 (Tianjin Huahong New Material Co., Ltd.) to replace MnO x , thus preparing Fe-Beta+CeO 2 (FC) catalyst.

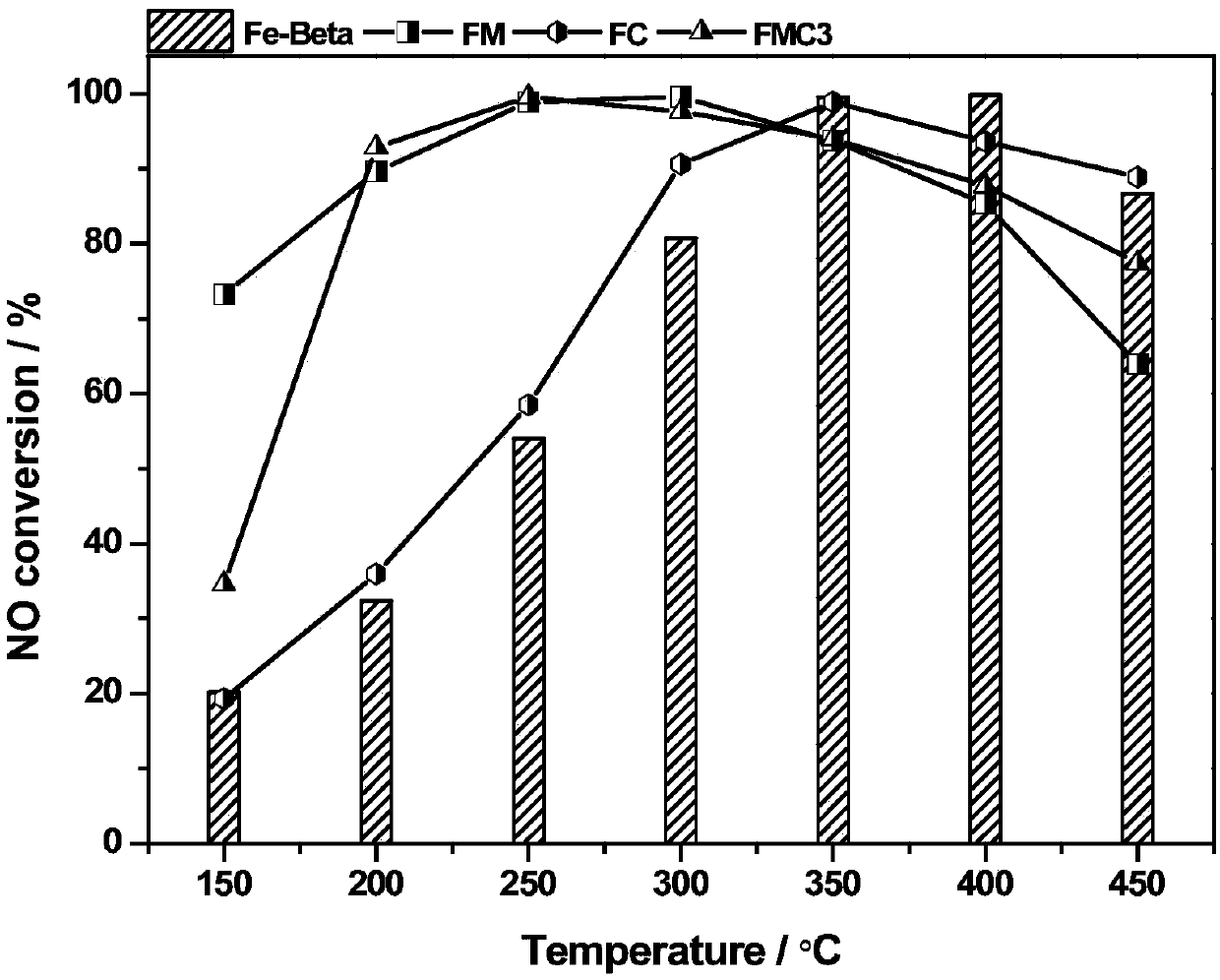

[0036] With CeO 2 The activity of the catalyst FC as an auxiliary agent increases slightly between 200 and 300°C, but the range is not obvious. However, the catalyst has better activity at high temperature, and the activity between 300 and 450°C is above 90%.

Embodiment 3

[0041] Example 3 Fe-Beta+MnO x / CeO 2 (FMC3) preparation and activity evaluation

[0042] The steps and process conditions of this embodiment are all the same as in Example 1, the difference is that the MnO x / CeO 2 replace MnO x (wherein, MnO x / CeO 2 The preparation method is the same as that of Comparative Example 1), thereby preparing Fe-Beta+MnO x / CeO 2 (FMC3) catalyst.

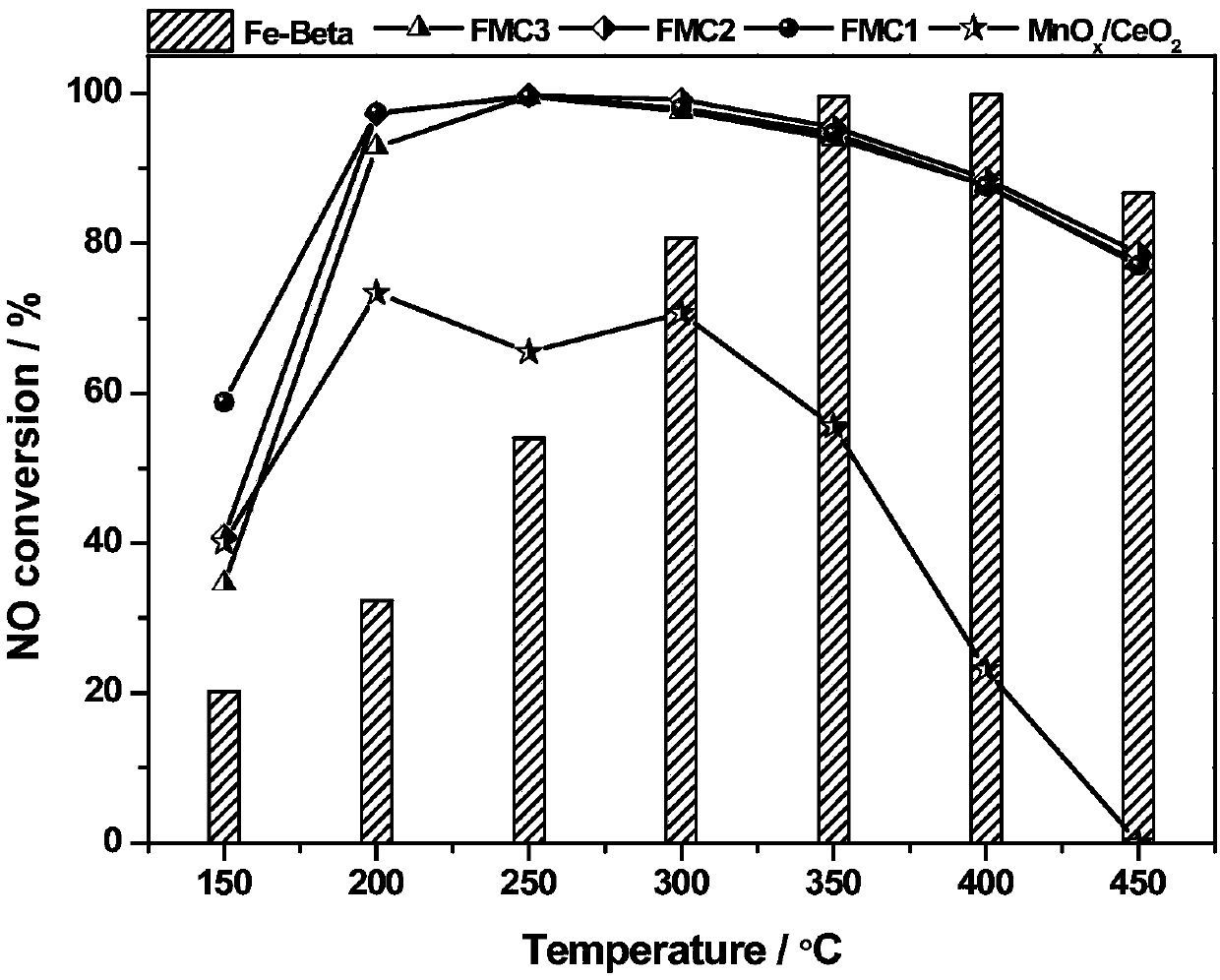

[0043] When the MnO x / CeO 2 When used as an auxiliary agent, the activity of the catalyst at 150°C is increased from 19% to 35%, and it can maintain a conversion rate of more than 90% between 200 and 400°C. Compared with pure Fe-Beta or MnO x / CeO 2 The activity of the catalyst is much higher than that of the catalyst, which shows that the catalyst prepared by the mechanical mixing method can obtain the ideal result and effectively increase the NH content of propylene in the atmosphere. 3 - Activity of molecular sieves in SCR reactions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com