Low hydroxyl value tung oil polyol and preparation method thereof

A tung oil polyol, low hydroxyl value technology, applied in the field of polyurethane materials, can solve the problems of easy side reactions, high reactivity of epoxy groups, poor selectivity, etc., to avoid cross-linking side reactions, renewable raw materials, biological good degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

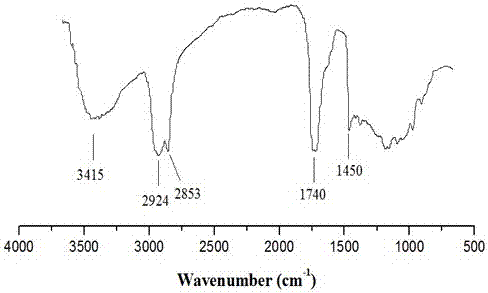

Image

Examples

Embodiment 1

[0028] Add 500g of tung oil, 80g of formic acid (85wt% solution), 0.5g of concentrated sulfuric acid, and 150g of n-hexanoic acid into a 2000mL three-neck flask, heat up to 40°C and stir well. Then, 325g of 30wt% hydrogen peroxide solution was slowly added dropwise under vigorous stirring, and the rate of addition was controlled to keep the reaction temperature at about 50°C. After the reaction system was separated into layers, the water phase was removed, and the oil phase was washed with 10 wt% sodium bicarbonate aqueous solution until neutral, and then the product was washed with hot water at 70°C for 3 times. The washed product was distilled at 2000 Pa and 80°C for 2 hours to obtain tung oil polyol.

[0029] Take 250g of the above-prepared tung oil polyol, add 1.25g of sodium hydroxide into the reaction kettle and mix evenly, gradually raise the temperature to 120°C under the protection of nitrogen, add 760g of propylene oxide within 7.5h, and then continue the reaction fo...

Embodiment 2

[0031] Add 500g of tung oil, 100g of formic acid (85wt% solution), 0.25g of concentrated sulfuric acid, and 250g of n-hexanoic acid into a 2000mL three-neck flask, heat up to 45°C and stir well. Then, 380g of 30wt% hydrogen peroxide solution was slowly added dropwise under vigorous stirring conditions, and the dropping rate was controlled to keep the reaction temperature at about 65°C. After the reaction system was separated into layers, the water phase was removed, and the oil phase was washed with 10 wt% sodium bicarbonate aqueous solution until neutral, and then the product was washed with hot water at 70°C for 3 times. The washed product was distilled at 2000 Pa and 80°C for 2 hours to obtain tung oil polyol.

[0032] Take 250g of the above-prepared tung oil polyol, add 1.25g of potassium hydroxide into the reaction kettle and mix evenly. After gradually raising the temperature to 140°C under the protection of nitrogen, add 760g of ethylene oxide within 7.5h, then continue...

Embodiment 3

[0034] Add 500g of tung oil, 55g of formic acid (85wt% solution), 4g of concentrated sulfuric acid, and 100g of n-hexanoic acid into a 2000mL three-neck flask, heat up to 35°C and stir well. Then, 285g of 30wt% hydrogen peroxide solution was slowly added dropwise under vigorous stirring, and the dropping rate was controlled to keep the reaction temperature at about 40°C. After the reaction system was separated into layers, the water phase was removed, and the oil phase was washed with 10 wt% sodium bicarbonate aqueous solution until neutral, and then the product was washed with hot water at 70°C for 3 times. Distill the washed product at 1000-3000Pa and 80°C for 2h to obtain tung oil polyol.

[0035] Take 250g of the above-prepared tung oil polyol, add 1.25g of lithium hydroxide into the reaction kettle and mix evenly. After gradually raising the temperature to 90°C under the protection of nitrogen, add 510g of butylene oxide within 5h, and then continue the reaction for 6h to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com