Sweet dumpling type formed sulfur-resistant low-temperature denitration catalyst as well as preparation method and application thereof

A denitration catalyst and catalyst technology, which are used in catalyst protection, molecular sieve catalysts, chemical instruments and methods, etc., to achieve the effects of good gas flow, reduced pressure drop, and excellent low-temperature activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

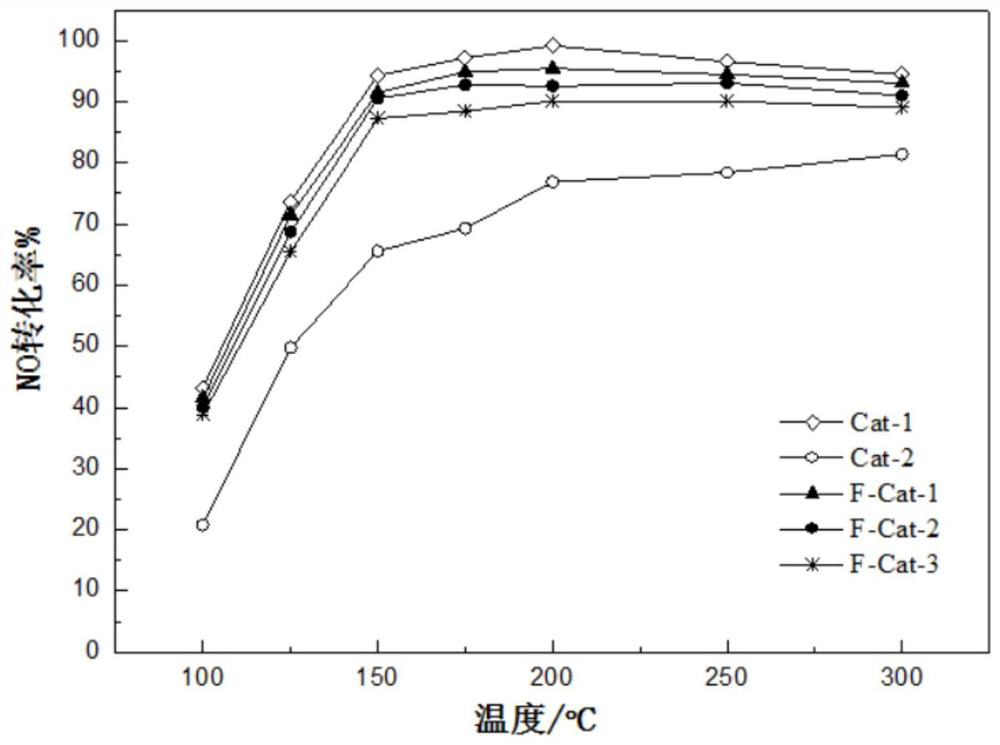

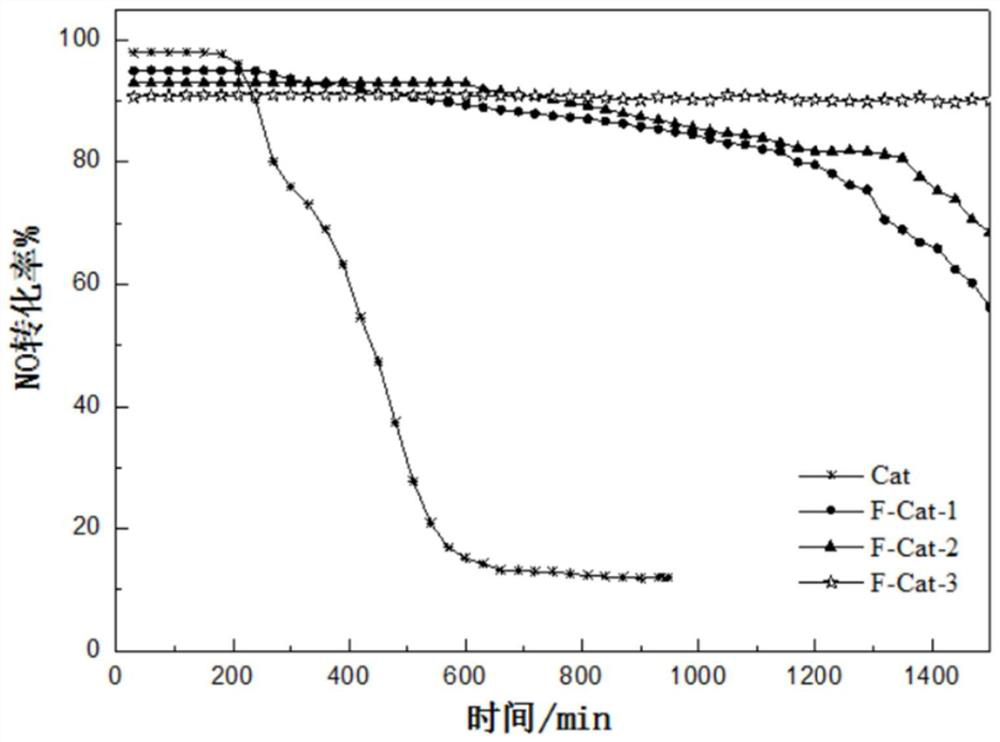

Embodiment 1

[0112] 20 g of catalyst pellets Cat-1 were used as core pellets. Mix the catalyst core pellets with 20g of titanium oxide powder, 5.4g of silica sol, and 0.6g of squash powder and roll them into catalyst pellets (referred to as F-Cat-1). In the catalyst, the mass ratio of molecular sieve, active component and protective layer is 10:3.3:13.

Embodiment 2

[0114] 20 g of catalyst pellets Cat-1 were used as core pellets. Mix catalyst core pellets with 35g of titanium oxide powder, 6.04g of silica sol, and 0.73g of turnip powder and roll them into catalyst pellets (referred to as F-Cat-2). In the catalyst, the mass ratio of molecular sieve, active component and protective layer is 10:3.3:23.4.

Embodiment 3

[0116] 20 g of catalyst pellets Cat-1 were used as core pellets. Mix catalyst core pellets with 100g of titanium oxide powder, 15.86g of solid silica gel, and 3g of starch and evenly roll them into catalyst pellets (referred to as F-Cat-3). In the catalyst, the mass ratio of molecular sieve, active component and protective layer is 10:3.3:66.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com