Catalyst and preparation method and application thereof

A catalyst and modification technology, applied in separation methods, chemical instruments and methods, mechanical equipment, etc., can solve problems such as poor adsorption performance, expensive palladium, and inability to meet HC purification requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0135] Embodiment 1: prepare the catalyzer that contains front stage part and rear stage part

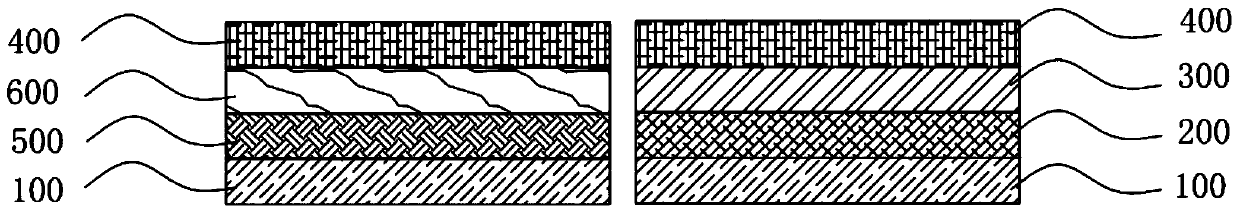

[0136] A catalyst with a structure such as figure 1 As shown, it contains a front-stage part and a rear-stage part, and the latter part includes a metal (iron and aluminum alloy) honeycomb matrix 100, a second carrier layer 200, a third noble metal layer 300, and a second noble metal layer 400 from bottom to top. ; The pre-stage part includes the metal honeycomb base 100, the first carrier layer 500, the first noble metal layer 600, and the second noble metal layer 400 from bottom to top; the distance between the pre-stage part and the back-stage part can be 220mm.

[0137] The second support layer 200 includes Ag-β molecular sieve and Ce 60 Zr 30 Y 5 La 5 , Ag-β zeolite and Ce 60 Zr 30 Y 5 La 5 The mass ratio of the Ag-modified β molecular sieve is 9:1, SiO 2 with Al 2 o 3 The molar ratio of Ag is 150:1, and the mass ratio of Ag in the modified β molecular sieve is 3%; ...

Embodiment 2

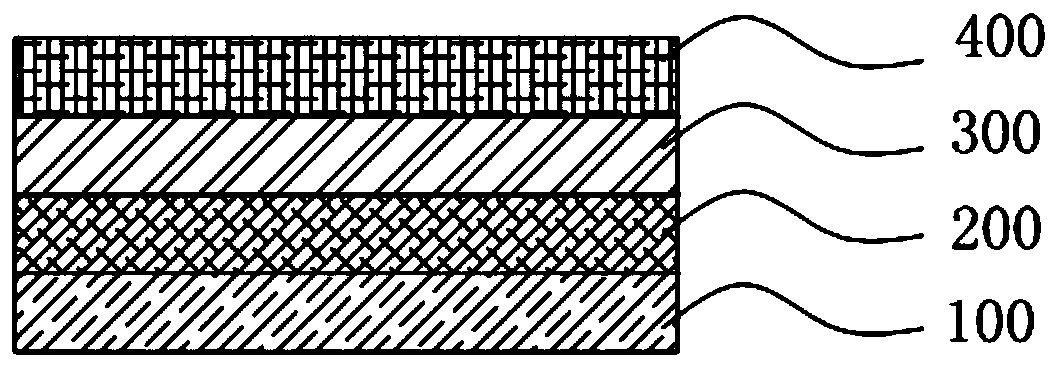

[0155] Compared with Example 1, the only difference of Example 2 is that the catalyzer made in Example 2 only contains the latter stage part, and the catalyzer structure schematic diagram made is as follows figure 2 As shown, the metal honeycomb base 100 , the second carrier layer 200 , the third noble metal layer 300 , and the second noble metal layer 400 are sequentially included from bottom to top.

Embodiment 3

[0157] Compared with Example 1, the only difference of Example 3 is that the catalyst prepared in Example 3 only contains the latter part, and the specification of the metal honeycomb matrix of the latter part is the mesh number 300cell / in 2 , Dimensions Φ63mm (diameter) × 90 (core length), volume 0.263L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com