Flower cluster shaped calcium vanadate microsphere and preparation method thereof

A technology of calcium vanadate and microspheres, applied in the field of flower cluster-shaped calcium vanadate microspheres and preparation thereof, can solve the problems of poor quality of calcium vanadate, cumbersome preparation process, pressure on production cost and the like, and achieves easy implementation, The effect of simple process and high shape qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Configure three solutions or reagents

[0040] a. Calcium acetate is dissolved in ethylene glycol to form a reaction solution A, wherein the concentration of the calcium source is 0.1mol / L;

[0041] b. Sodium vanadate is dissolved in deionized water to form reaction solution B, wherein the concentration of vanadium source is 0.1mol / L;

[0042] c. PVP is dissolved in ethylene glycol to form reaction solution C, wherein the concentration of PVP is 0.15mol / L;

[0043] (2) Take 30ml of reaction solution A, add it dropwise to 30ml of reaction solution B, and magnetically stir to form a mixed solution. 10ml of solution C was added dropwise to 60ml of the mixed solution, and magnetically stirred. The above mixed system was moved to the reactor, and reacted at 180°C for 24h. The reaction products were washed three times with ethanol, centrifuged at 5000 rpm for 15 min respectively, dried at 60° C. for 5 h, and dispersed in ethanol solution for preservation.

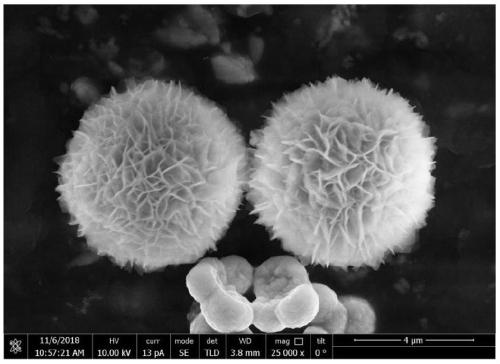

[0044] fi...

Embodiment 2

[0046] (1) Configure three solutions or reagents

[0047] a. Calcium acetate is dissolved in ethylene glycol to form a reaction solution A, wherein the concentration of the calcium source is 0.075mol / L;

[0048] b. Sodium vanadate is dissolved in deionized water to form reaction solution B, wherein the concentration of vanadium source is 0.15mol / L;

[0049] c. PVP is dissolved in ethylene glycol to form reaction solution C, wherein the concentration of PVP is 0.15mol / L;

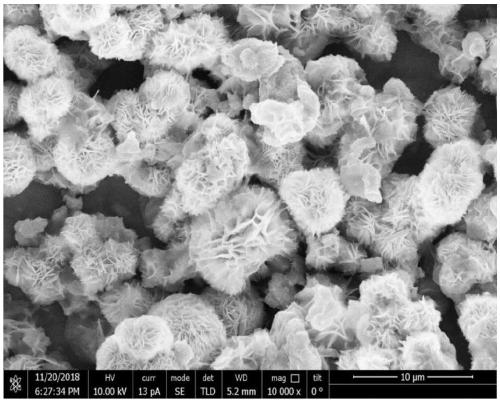

[0050] (2) Take 40ml of reaction solution A, add it dropwise to 20ml of reaction solution B, and magnetically stir to form a mixed solution. 10ml of reaction solution C was added dropwise to 60ml of the mixed solution, and magnetically stirred. The above mixed system was moved to the reactor, and reacted at 180°C for 24h. The reaction products were washed three times with ethanol, centrifuged at 5000 rpm for 15 min respectively, dried at 60° C. for 5 h, and dispersed in ethanol solution for preservation. ...

Embodiment 3

[0053] (1) Configure three solutions or reagents

[0054] a. Calcium acetate is dissolved in ethylene glycol solution to form reaction solution A, wherein the concentration of calcium source is 0.1mol / L;

[0055] b. Sodium vanadate is dissolved in deionized water to form reaction solution B, wherein the concentration of vanadium source is 0.1mol / L;

[0056] c. PVP is dissolved in ethylene glycol solution to form reaction solution C, wherein the concentration of PVP is 0.15mol / L;

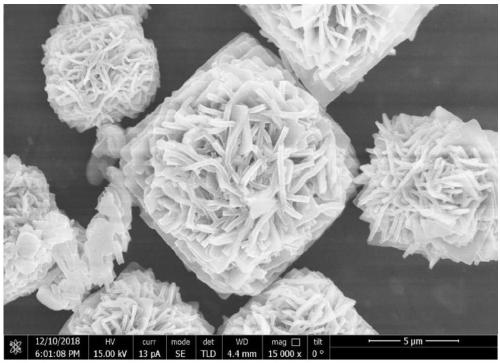

[0057] (2) Take 30ml of reaction solution A, add it dropwise to 30ml of reaction solution B, and magnetically stir to form a mixed solution. 10ml of reaction solution C was added dropwise to 60ml of the mixed solution, and magnetically stirred. The above mixed system was moved to a reaction kettle and reacted at 180°C for 36h. The reaction products were washed three times with ethanol, centrifuged at 5000 rpm for 15 min respectively, dried at 60° C. for 5 h, and dispersed in ethanol solution for pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com