Aluminum zirconate-doped lithium titanium phosphate two-component surface-modified ferric fluoride positive electrode material and preparation method thereof

A technology of aluminum zirconate and surface modification, which is applied in the direction of battery electrodes, electrochemical generators, electrical components, etc., can solve the problems of high conversion reaction, high reaction activation energy, and poor economy, so as to improve the electrochemical performance. performance, overcoming the effect of extremely low ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

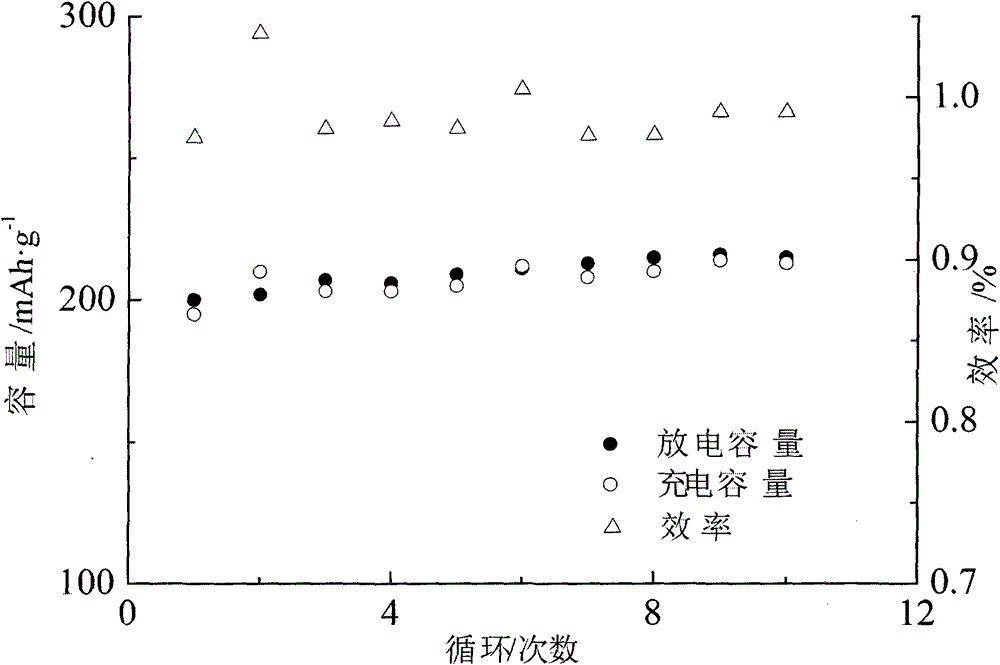

[0019] Embodiment 1: Al 2 o 3 : SiO 2 : TiO 2 : NH 4 h 2 PO 4 : Li 2 CO 3 Mix evenly in a ratio of 0.05:0.2:1.9:2.8:0.65 (molar ratio), add 3.5% of 95% ethanol, and ball mill in a ball mill at a speed of 110 rpm for 12 hours. After the ball milling, the pressure is 15Pa at 65°C Dry in a vacuum oven for 2.5 hours, take it out, and re-grind it in an agate mortar for 15 minutes. The ground powder is heated to 650°C at a rate of 6°C / min and kept for 6 hours to make Li 1.3 Al 0.1 Ti 1.9 Si 0.2 P 2.8 o 12 Solid electrolyte powder. Fe(NO 3 ) 3 9H 2 O and ammonium fluoride (1.0:3.1 molar ratio) with 3.2% by weight Li 1.3 Al 0.1 Ti 1.9 Si 0.2 P 2.8 o 12 Solid electrolyte powder, 0.6% by weight of Tween-80 and 0.6% by weight of aluminum-zirconium coupling agent of brand name C are ball milled at room temperature for 5 hours under the protection of high-purity nitrogen in a high-energy ball mill. Under the protection of the mixed gas of % hydrogen and 95% argon, th...

Embodiment 2

[0020] Embodiment 2: Al 2 o 3 : SiO 2 : TiO 2 : NH 4 h 2 PO 4 : Li 2 CO 3 Mix evenly in a ratio of 0.05:0.2:1.9:2.8:0.65 (molar ratio), add 8% of 95% ethanol, and ball mill in a ball mill at a speed of 450 rpm for 45 hours. After the ball milling, the pressure is 80Pa at 75°C Dry in a vacuum oven for 8 hours, take it out and re-grind it in an agate mortar for 25 minutes. The ground powder is heated to 900°C at a rate of 25°C / min and kept for 15 hours to make Li 1.3 Al 0.1 Ti 1.9 Si 0.2 P 2.8 o 12 Solid electrolyte powder. FeCl 3 ·6H 2 O and ammonium fluoride (1.0:3.6 molar ratio) with 13% by weight Li 1.3 Al 0.1 Ti 1.9 Si 0.2 P 2.8 o 12 The solid electrolyte powder, 2.8% by weight of span-60 and 3.0% by weight of the aluminum-zirconium coupling agent of the trade name CPM are ball milled at room temperature for 20 hours under the protection of high-purity nitrogen in a high-energy ball mill, and the material is taken out at 5% Under the protection of the ...

Embodiment 3

[0021] Embodiment 3: Al 2 o 3 : SiO 2 : TiO 2 : NH 4 h 2 PO 4 : Li 2 CO 3 Mix evenly in the ratio of 0.05:0.2:1.9:2.8:0.65 (molar ratio), add 5% of 95% ethanol, and ball mill in a ball mill at a speed of 200 rpm for 25 hours. After the ball milling, the pressure is 60Pa at 70°C Dry in a vacuum oven for 7 hours, take it out and re-grind it in an agate mortar for 20 minutes. The ground powder is heated to 750°C at a rate of 20°C / min and kept for 12 hours to make Li 1.3 Al 0.1 Ti 1.9 Si 0.2 P 2.8 o 12 Solid electrolyte powder. Will Fe 2 (SO 4 ) 3 9H 2 O and ammonium fluoride (molar ratio 1.0:3.5) with 7% by weight Li 1.3 Al 0.1 Ti 1.9 Si 0.2 P 2.8 o 12 Solid electrolyte powder, 2.0% by weight of tx-10 and 2.1% by weight of the commercial brand of aluminum-zirconium coupling agent CPG are ball milled at room temperature for 15 hours under the protection of high-purity nitrogen in a high-energy ball mill, and the material is taken out at 5% Under the protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com