Preparation method of double-quantum dot modified flower-like three-dimensional graphene and photocatalytic material

A technology of double quantum dots and graphene, which is applied in the fields of photoelectric catalysis and hydrogen production, can solve the problems of high photo-generated electron-hole pair recombination rate, low utilization rate of sunlight, and small specific surface area of nanoparticle structure, so as to reduce the recombination rate. efficiency, high light sensitivity, strong corrosion resistance and light stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

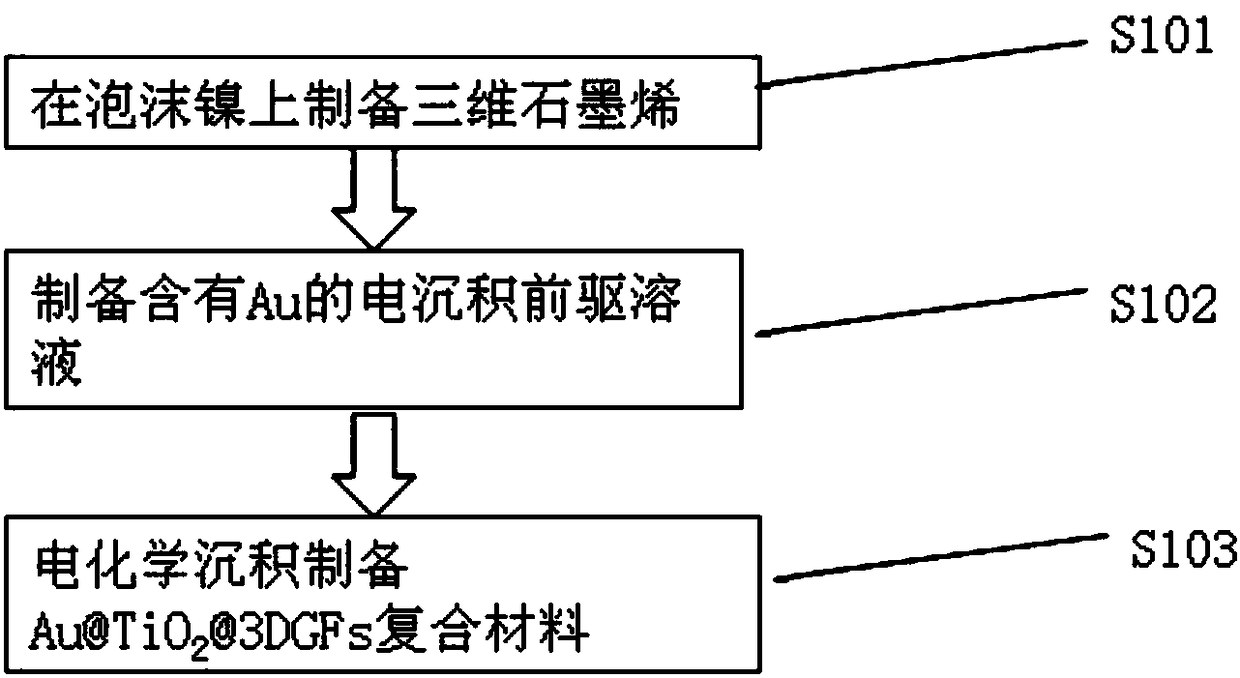

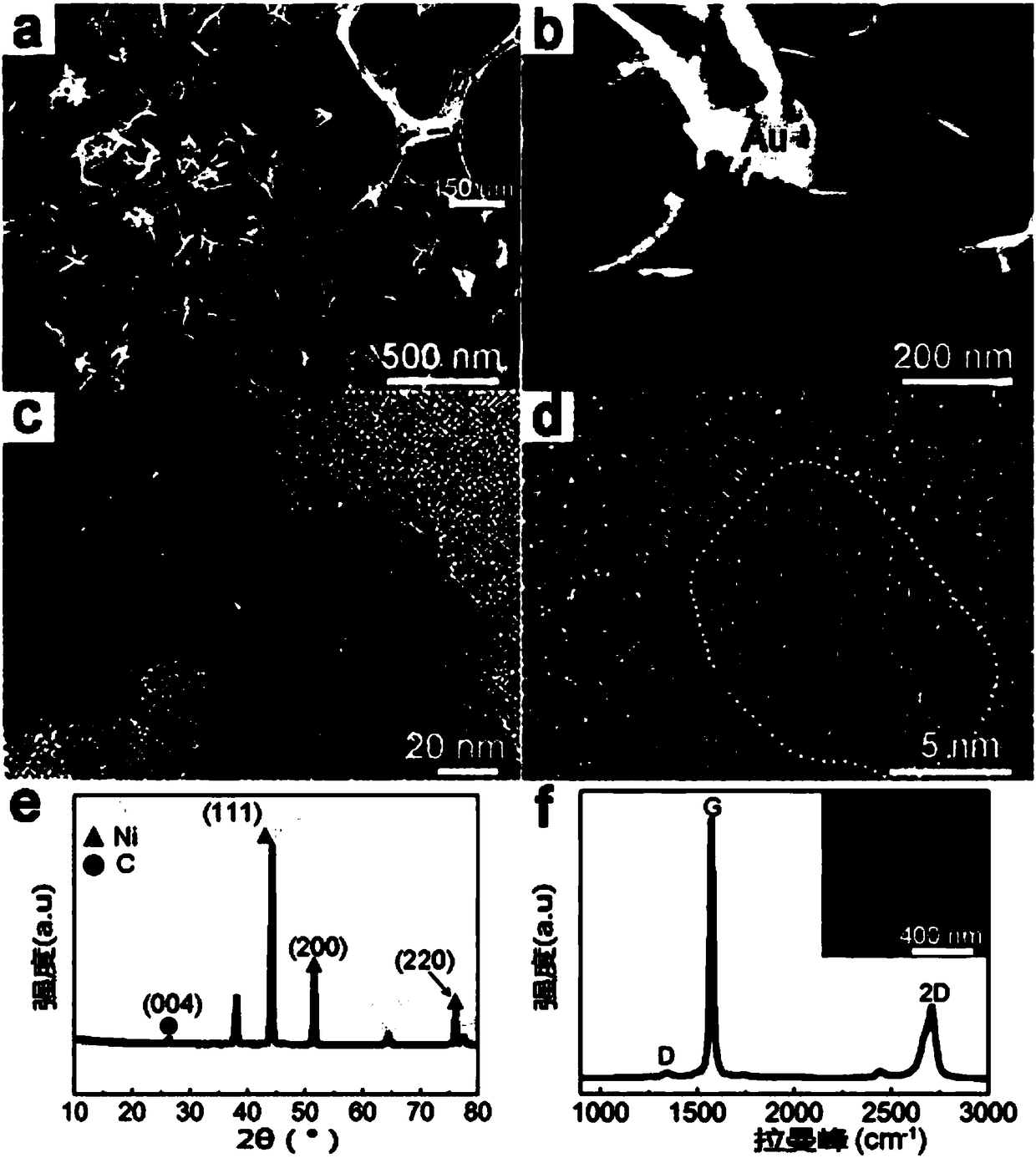

[0026] Such as figure 1 As shown, the present invention provides double quantum dots modified flower-shaped three-dimensional graphene (Au@TiO 2 The preparation method of @3DGFs) includes steps:

[0027] S101: Preparation of three-dimensional graphene on foam nickel;

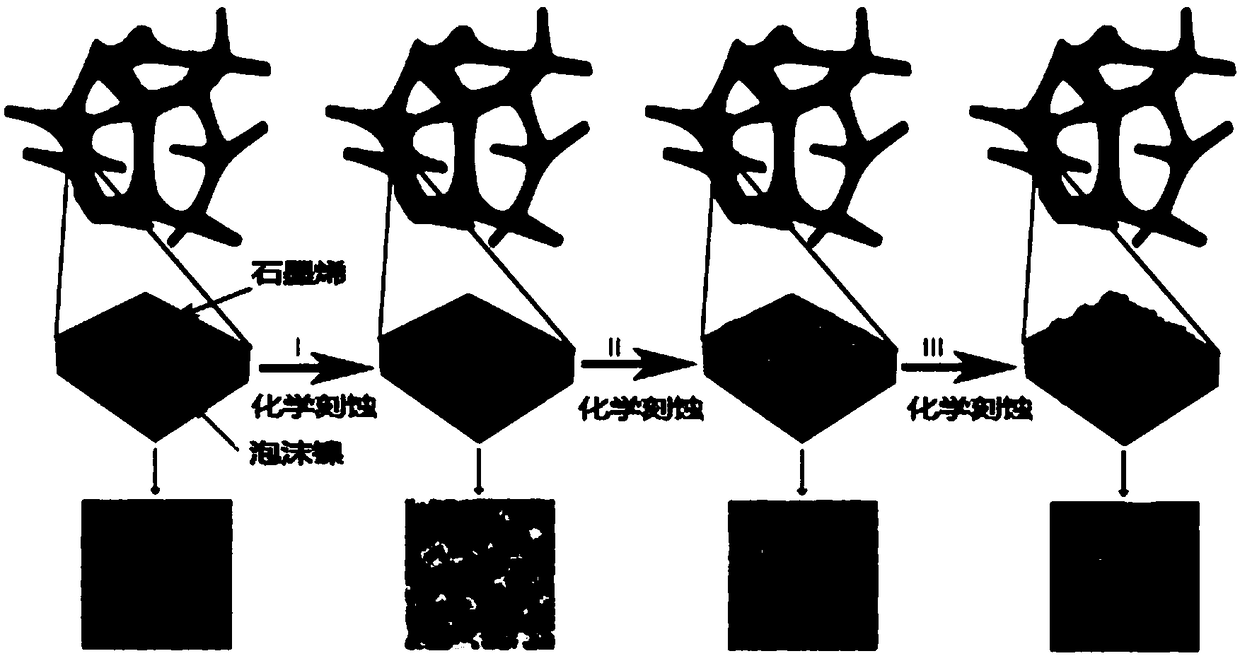

[0028] Using foamed nickel as a template for the three-dimensional graphene growth support, put the cut into pieces of foamed nickel into a quartz tube furnace; make the nickel foam material in Ar (300-800sccm) and H 2 (100-400sccm) in a tube furnace under the environment, heat to 800-1100℃, and anneal for 5-30min to clean and remove the oxide layer on the surface of the foam nickel; then the CH with a flow rate of 1-20sccm 4 Pass into the reaction tube furnace under a certain ambient pressure to make it equivalent to the concentration of 0.1 vol%-2 vol% of the total gas flow. After the reaction gas reacts for 3-10min, the sample is in Ar (300-800sccm) and H 2 (100-400sccm), rapidly cool to room temperature at a rate ...

Embodiment 1

[0035] Prepare three-dimensional graphene on foam nickel by chemical vapor deposition method;

[0036] Using foamed nickel as a template for the three-dimensional graphene growth support, put the cut into pieces of foamed nickel into a quartz tube furnace; make the nickel foam material in Ar (500sccm) and H 2 (200sccm) in a tube furnace under the environment, heat it to 1000℃, and anneal for 10min to clean and remove the oxide layer on the surface of the foam nickel; then the CH with a flow rate of 5sccm 4 Pass into a reaction tube furnace under a certain ambient pressure to make it equivalent to a concentration of 0.7 vol% of the total gas flow. After the reaction gas reacts for 5 minutes, the sample is in Ar (500sccm) and H 2 (200sccm) and rapidly cool to room temperature at a rate of 200°C / min in an environment of (200sccm); that is, a three-dimensional graphene sample on the foamed nickel surface is obtained;

[0037] Preparation of electrodeposition precursor solution containin...

Embodiment 2

[0043] S101, using chemical vapor deposition to prepare three-dimensional graphene on foam nickel;

[0044] Using foamed nickel as a template for the three-dimensional graphene growth support, put the cut into pieces of foamed nickel into a quartz tube furnace; make the nickel foam material in Ar (500sccm) and H 2 (200sccm) in a tube furnace under the environment, heat it to 1000℃, and anneal for 10min to clean and remove the oxide layer on the surface of the foam nickel; then the CH with a flow rate of 5sccm 4 Pass into a reaction tube furnace under a certain ambient pressure to make it equivalent to a concentration of 0.7 vol% of the total gas flow. After the reaction gas reacts for 5 minutes, the sample is in Ar (500sccm) and H 2 (200sccm) and rapidly cool down to room temperature at a rate of 250°C / min; obtain a three-dimensional graphene sample on the foamed nickel surface;

[0045] S102, preparing an electrodeposition precursor solution containing Au;

[0046] First, 300 μL of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com