Patents

Literature

33results about How to "Considerable reversible capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

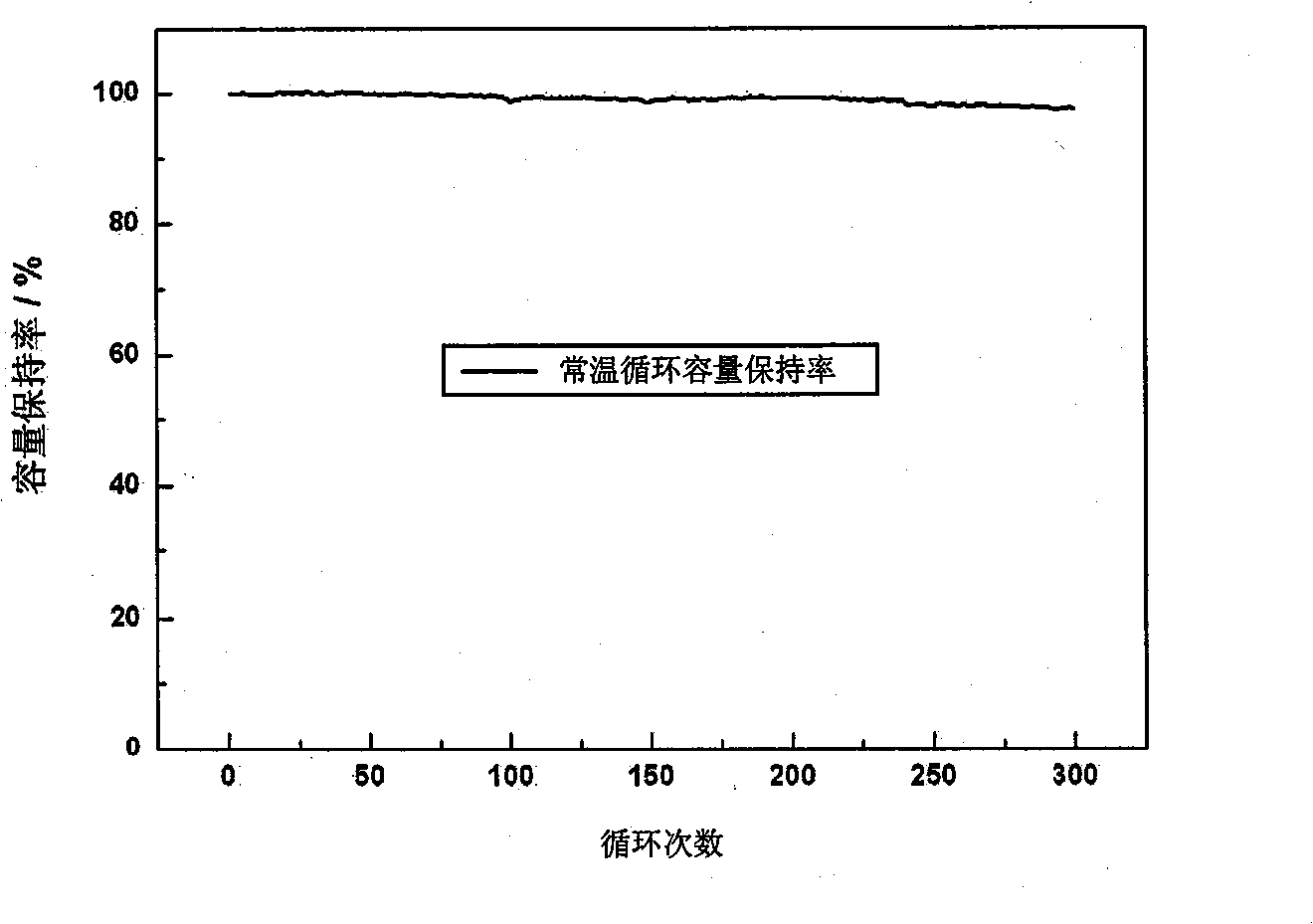

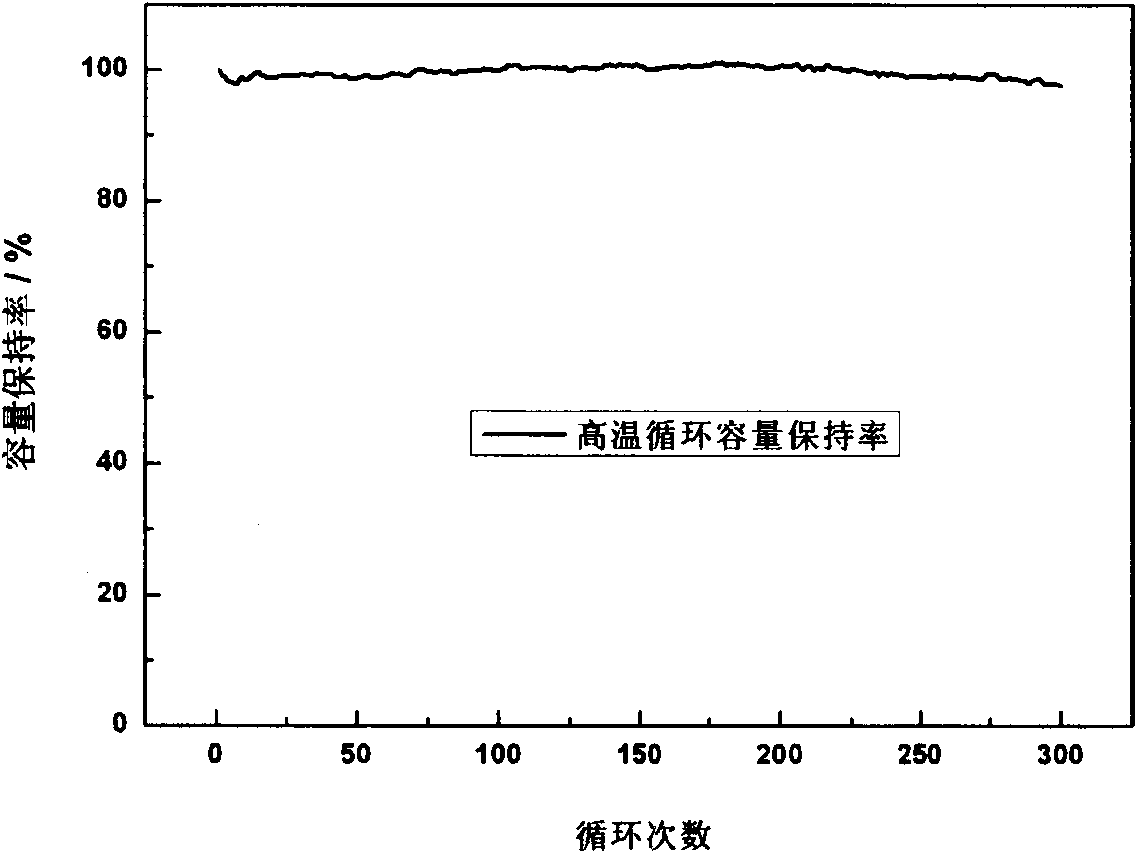

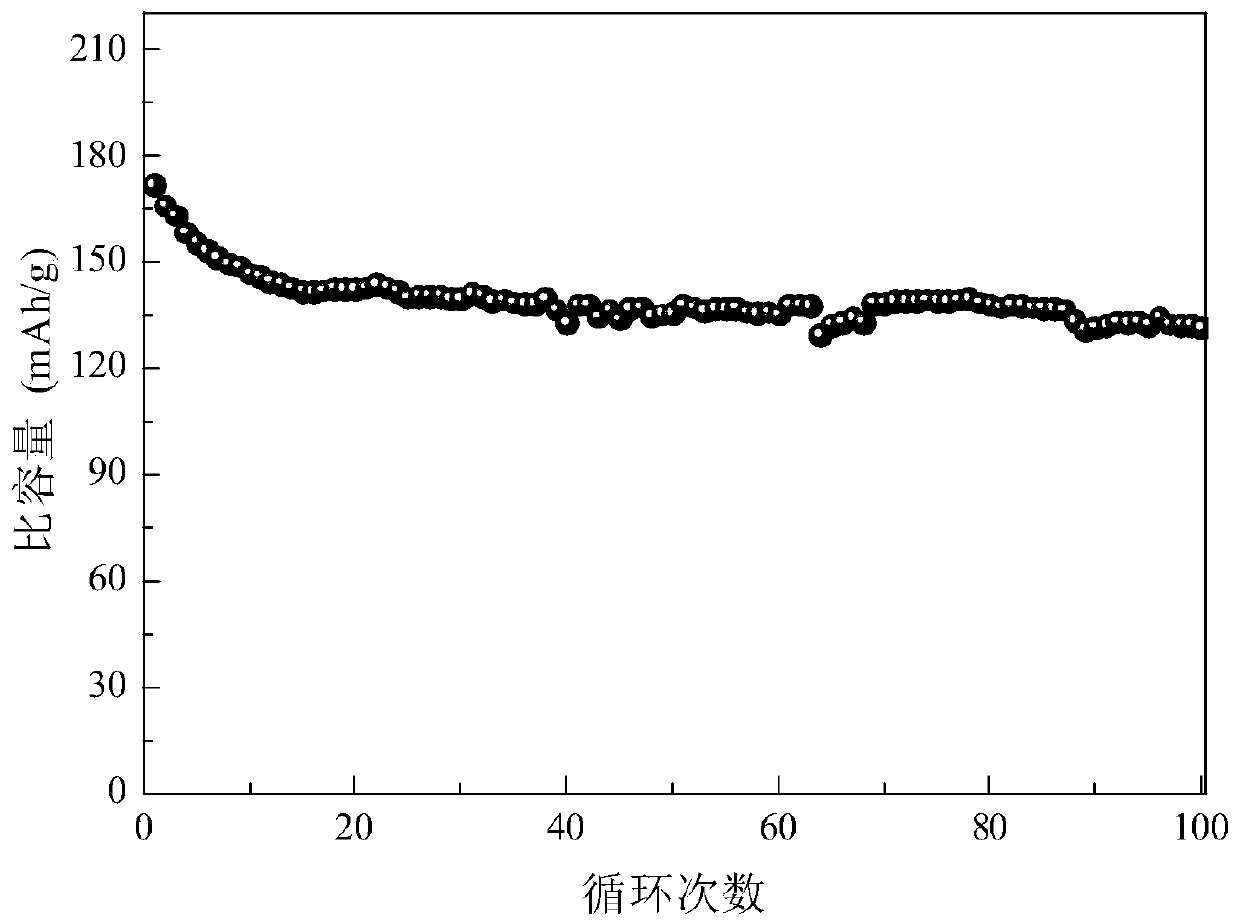

Preparation method of lamellar lithium manganese battery

ActiveCN101964428ALow costGood high temperature performanceFinal product manufactureCell electrodesLithium electrodeCooking & baking

Owner:BTR NEW MATERIAL GRP CO LTD

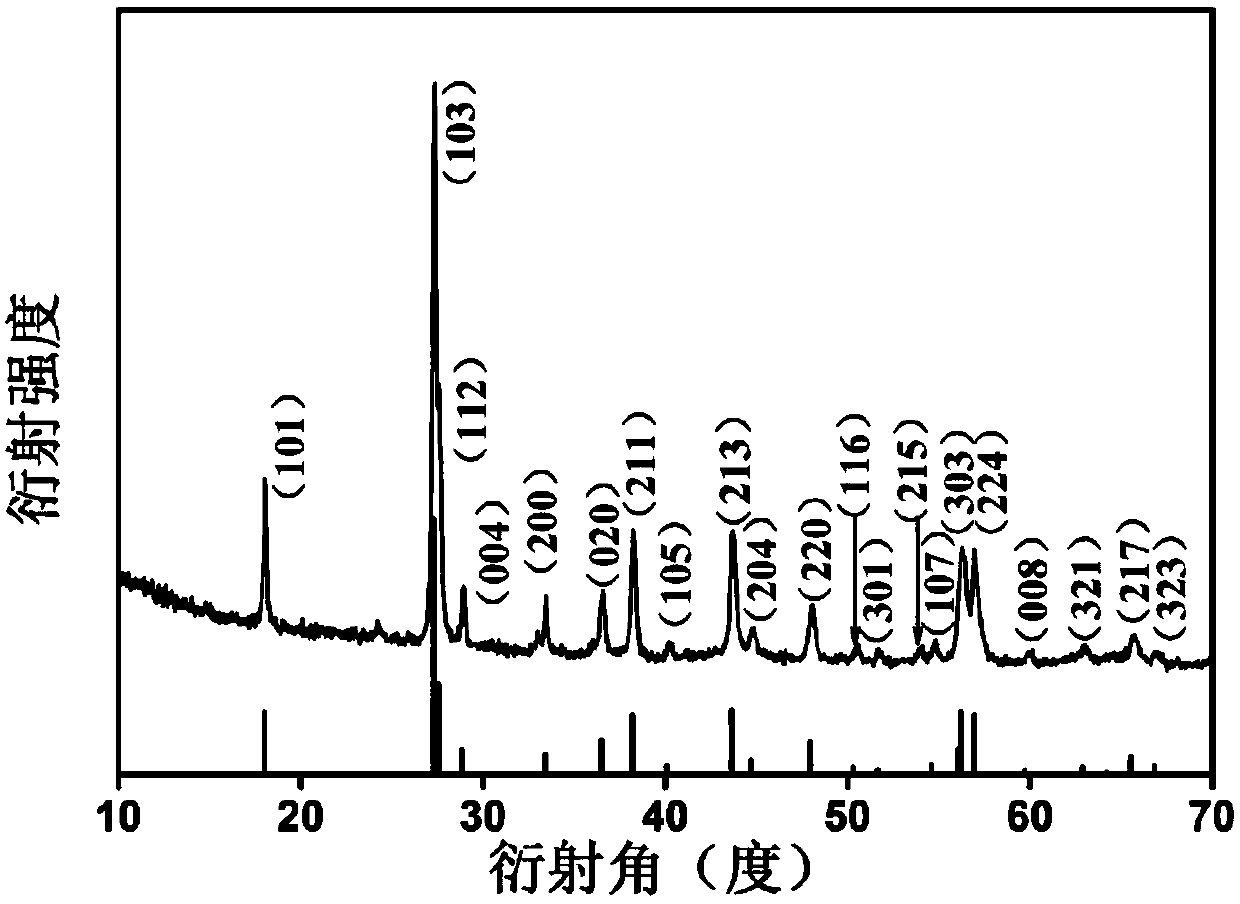

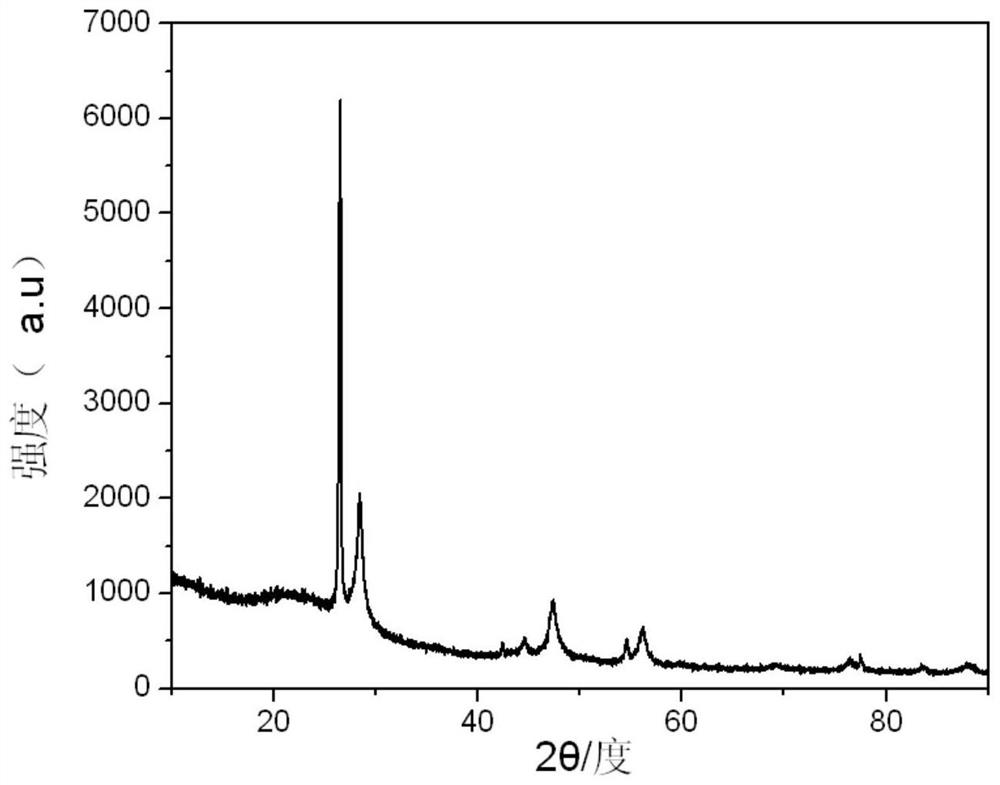

Method for preparing fluorizated lithium vanadium phosphate as lithium-ion battery anode material by using spray pyrolysis method

InactiveCN102079517ASimple manufacturing processGood dispersionCell electrodesPhosphorus compoundsHydrazine compoundCrystallinity

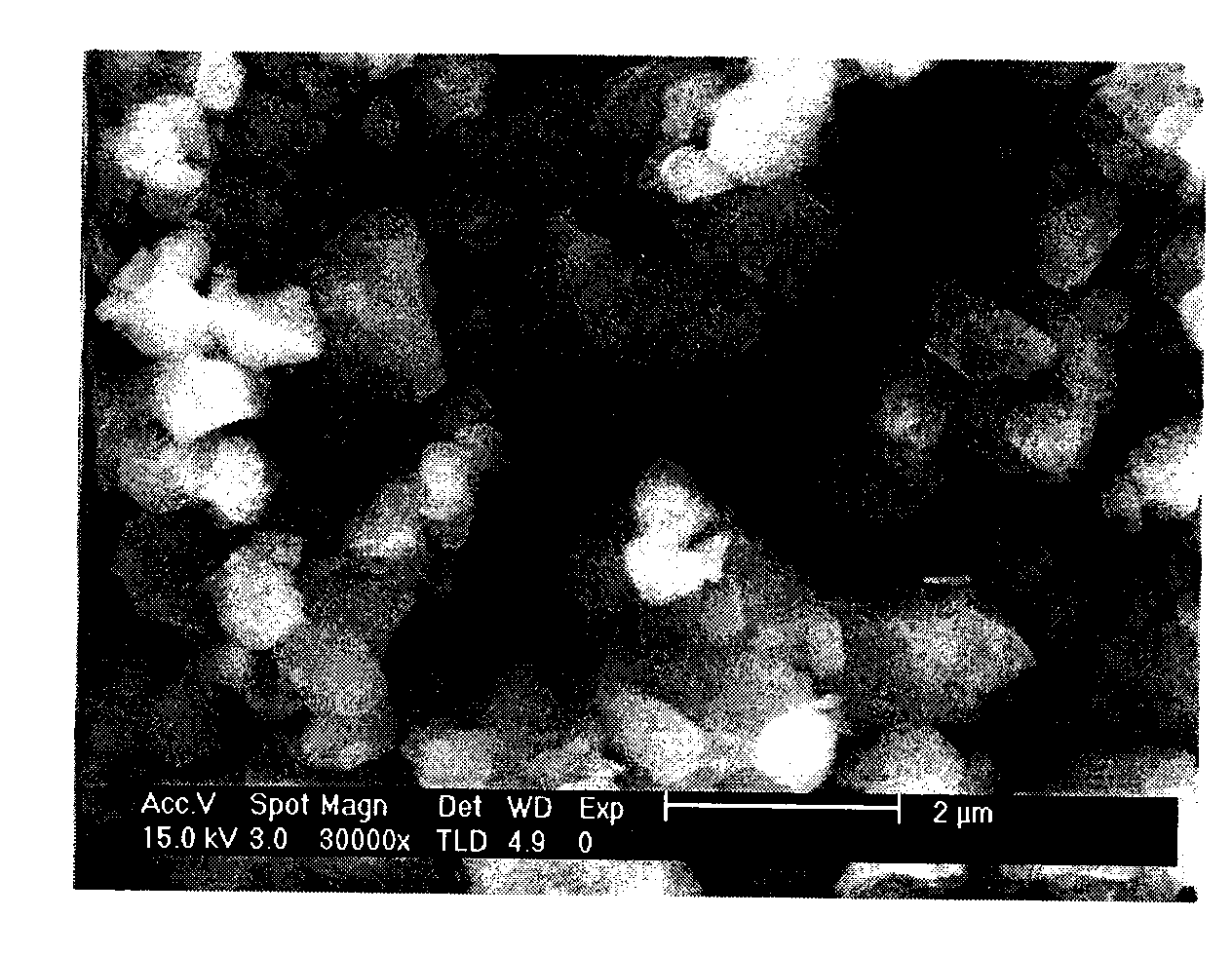

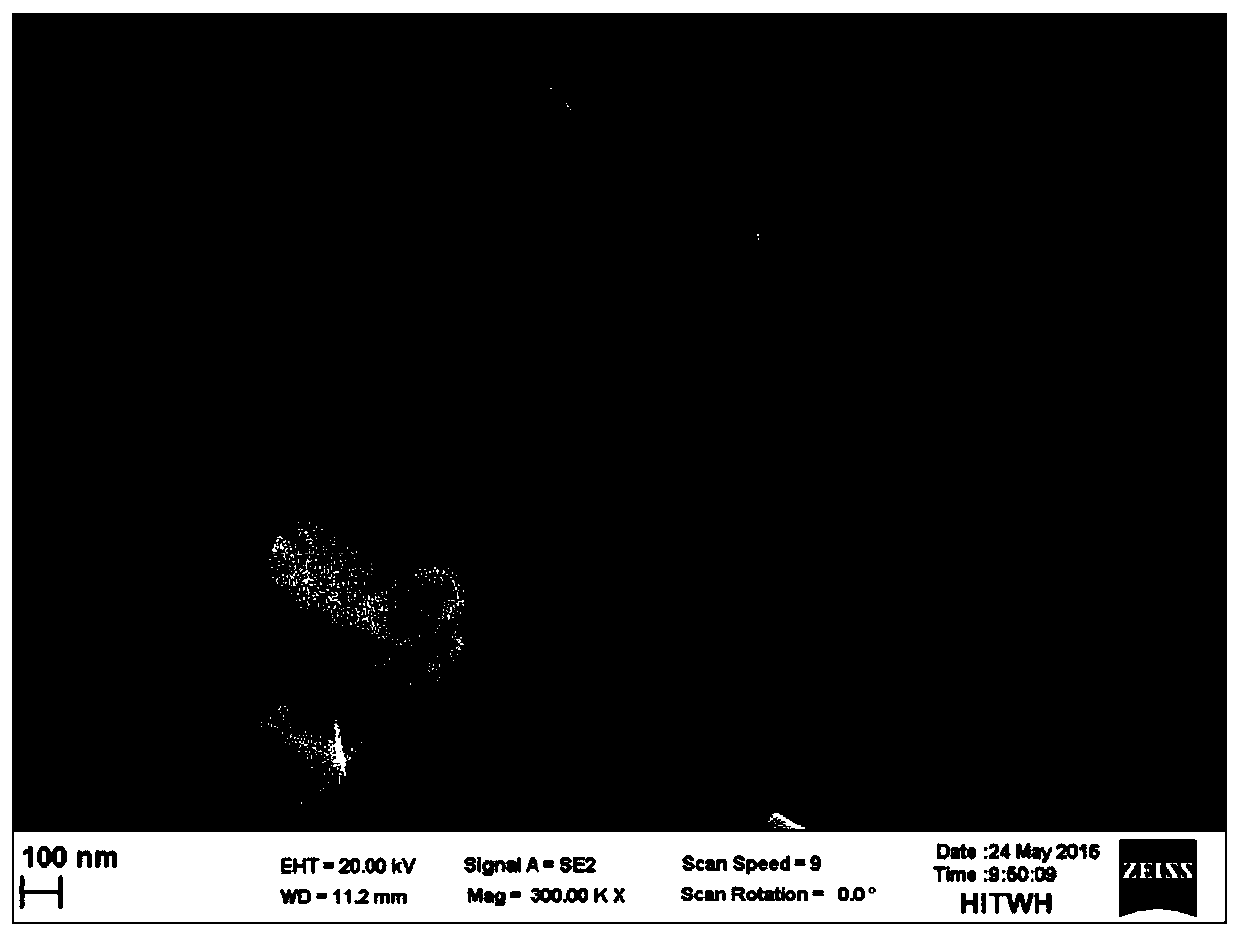

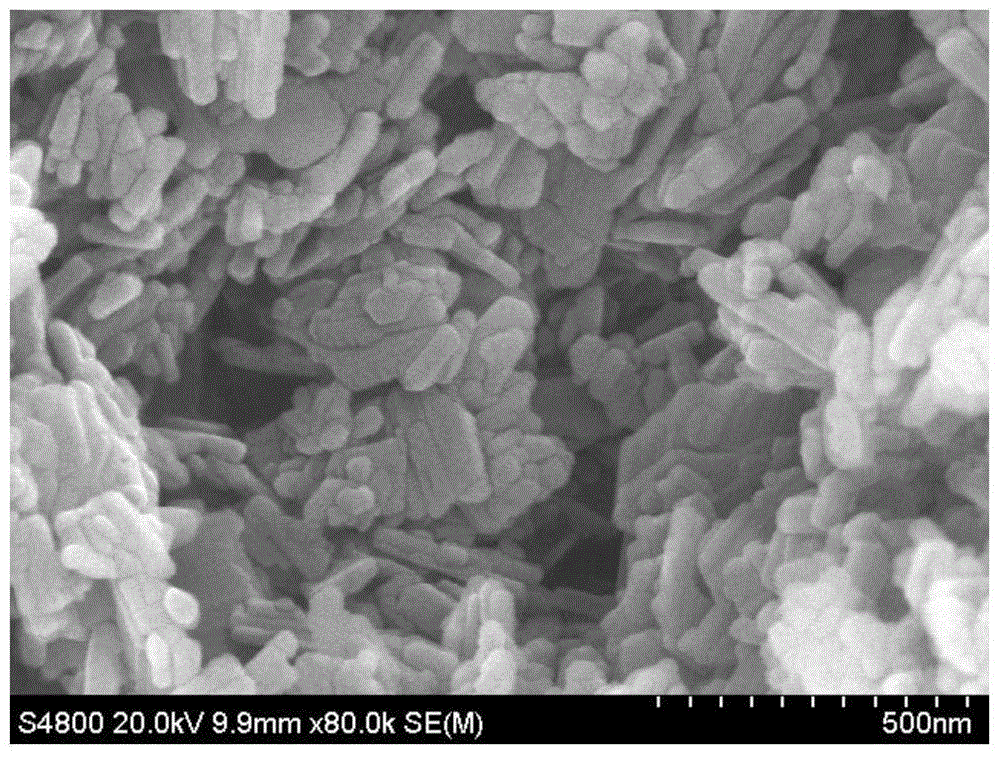

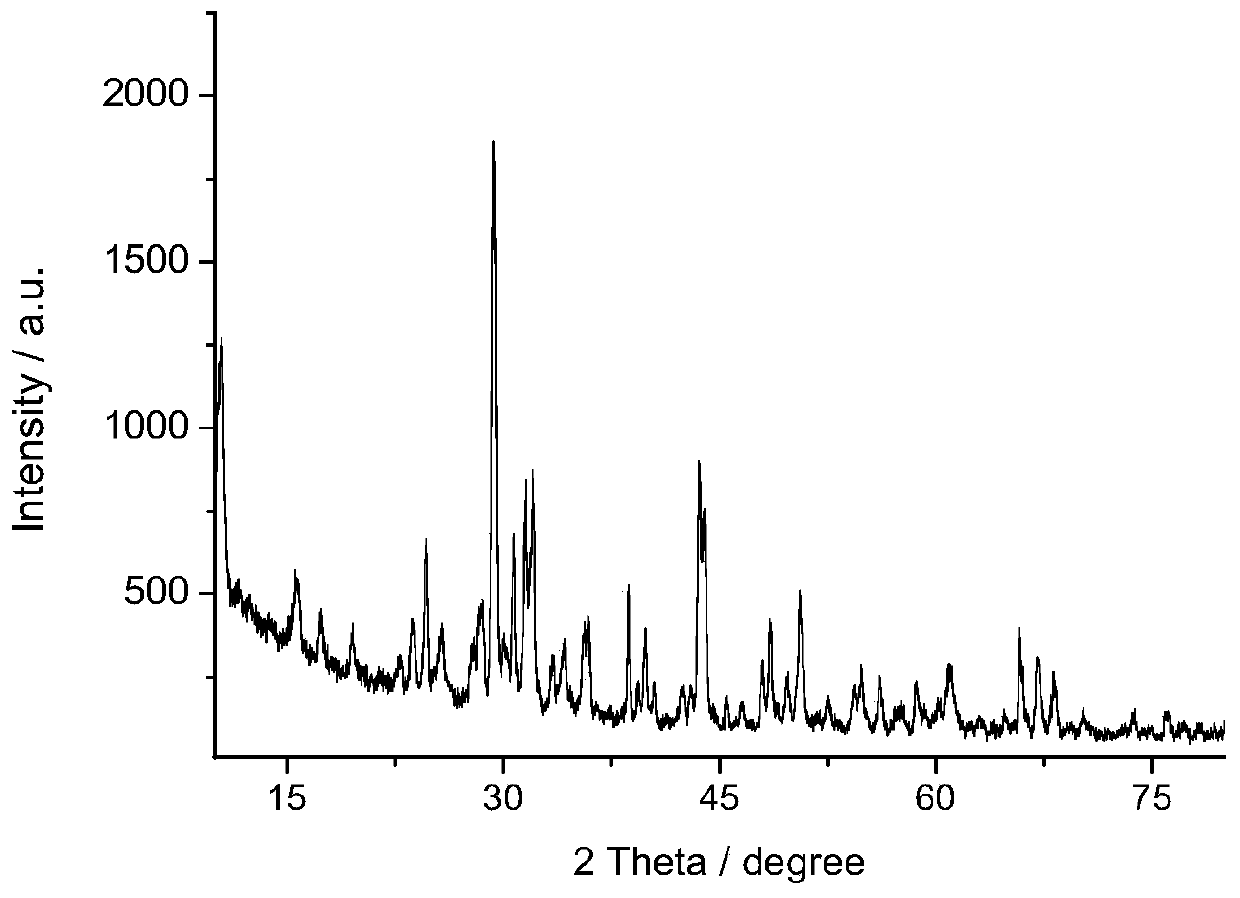

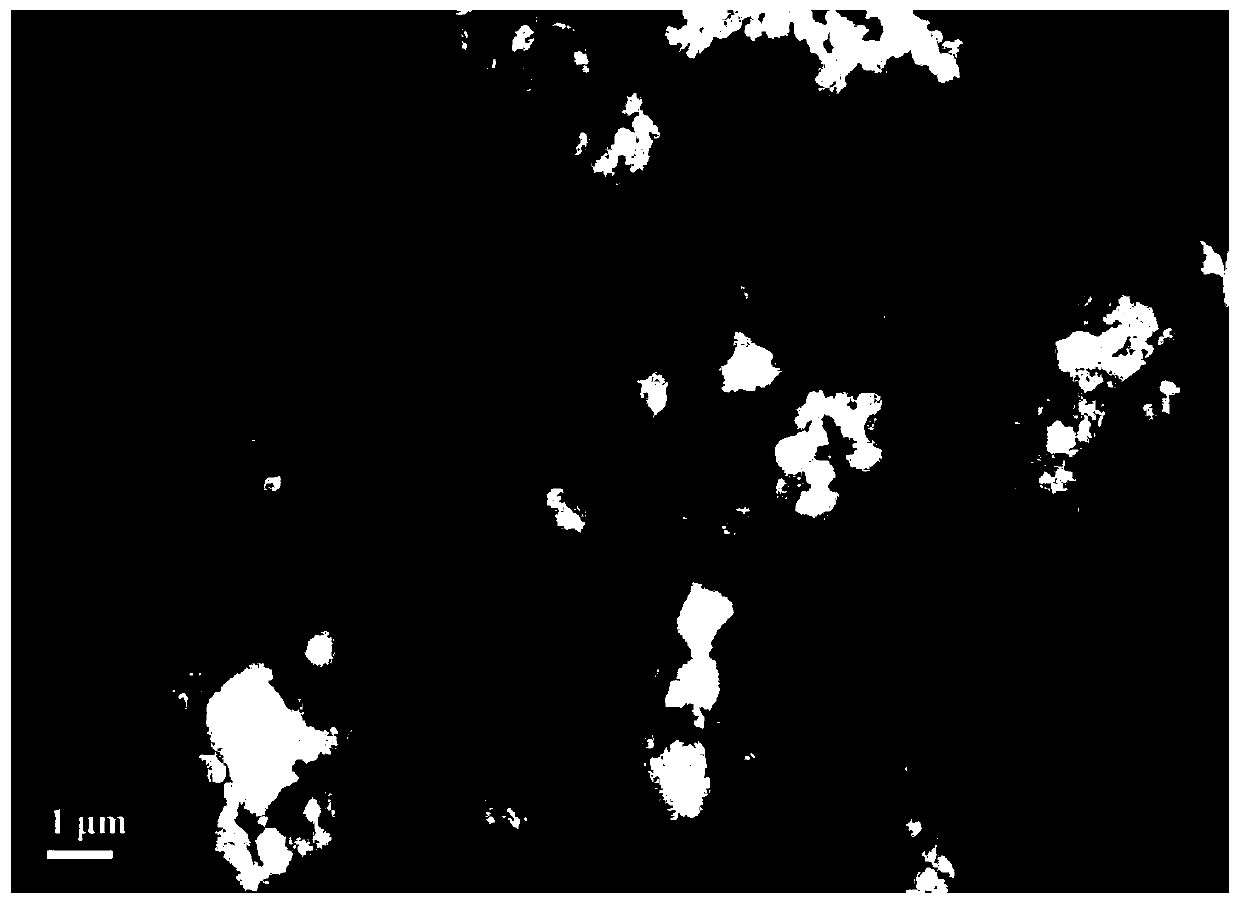

The invention discloses a method for preparing fluorizated lithium vanadium phosphate as a lithium-ion battery anode material by using a spray pyrolysis method. The preparation method comprises the following steps of: respectively adding a phosphate source, a vanadium source, a lithium source, a fluorine source, hydrazine hydrate and additives in a certain stoichiometric proportion to water, stirring for 30min to uniformly mix after adding each substance, and finally, forming a mixed solution with the metal ion concentration of 0.2-1.0mol / L; then, putting the mixed solution in a hydrogen airflow spray dryer, spraying and drying at 200-300 DEG C and collecting the product to obtain precursor powder; and tabletting the precursor powder at the pressure of 20MPa, then, sintering at 600-800 DEG C for 10h under hydrogen protection and naturally cooling to a room temperature to obtain LiVPO4F. The method has low raw material cost, simple operation process, strong controllability and high reproduction, effectively shortens the synthesis period of the material and saves the production cost. The fluorizated lithium vanadium phosphate synthesized by applying the method has the grain diameter of 60-500nm, good grain dispersibility, high crystallinity degree, higher reversible capacity and favorable cycle life, can meet various needs of the practical applications of the lithium-ion battery and can be directly used for the mass production of the lithium-ion battery anode material.

Owner:NINGBO UNIV

Negative electrode for lithium batteries

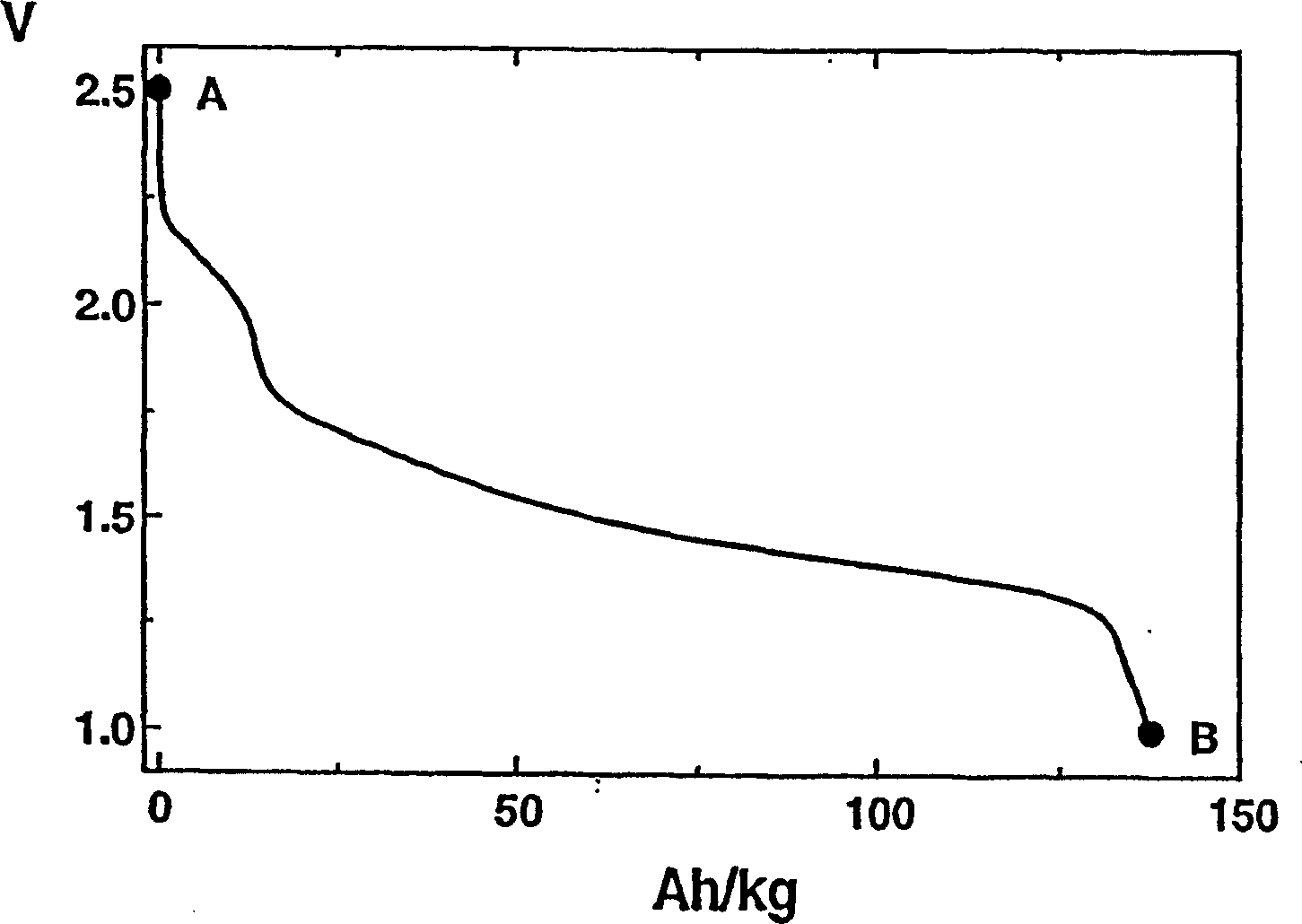

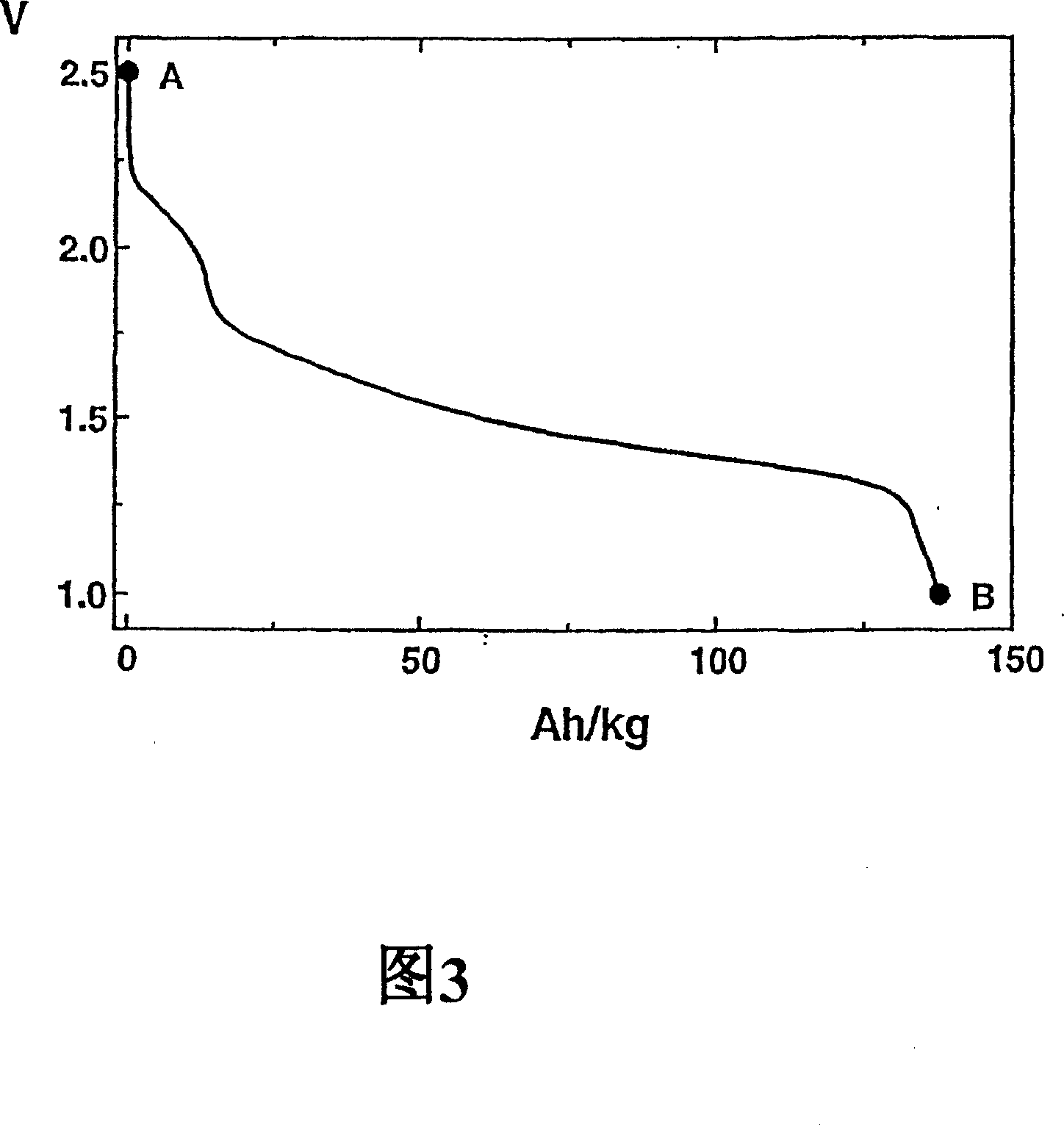

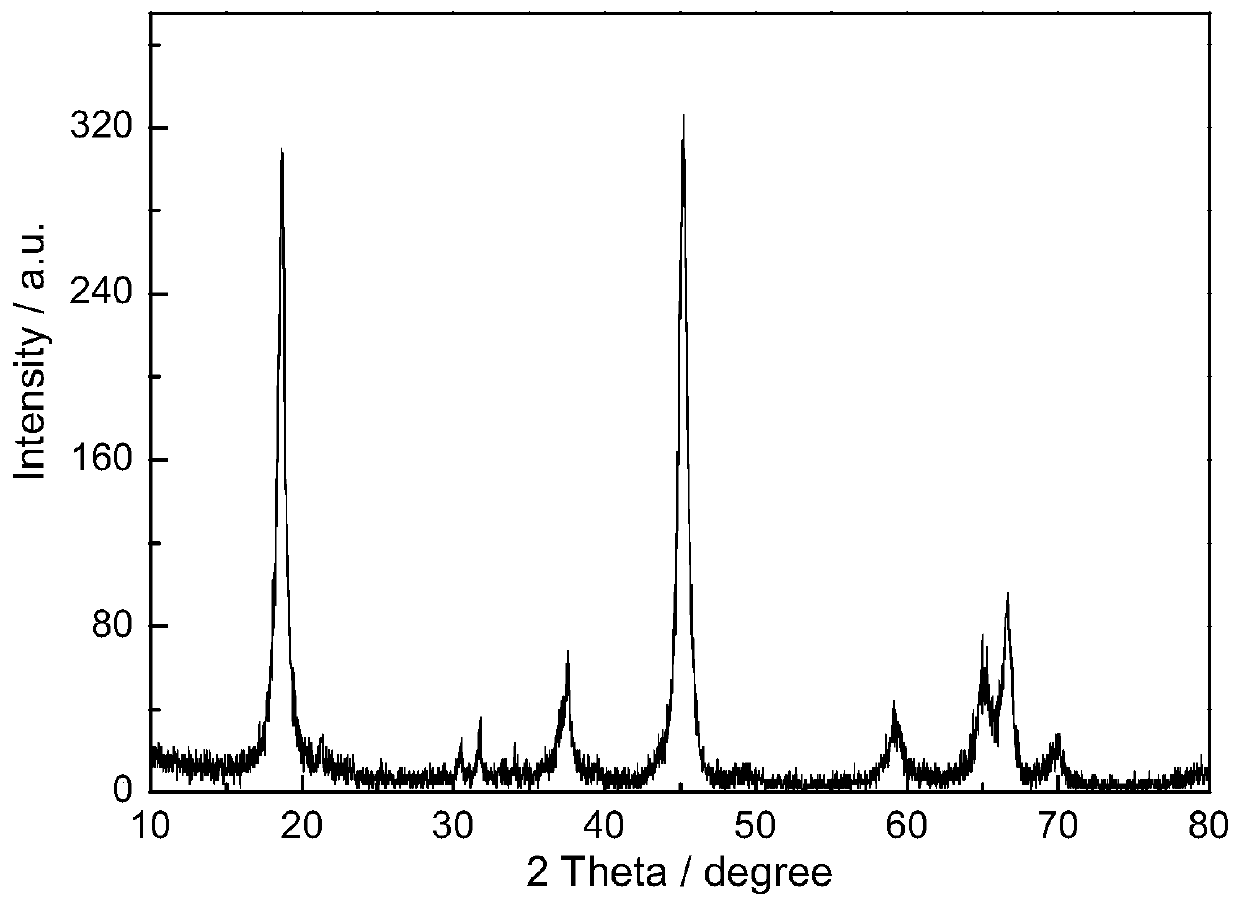

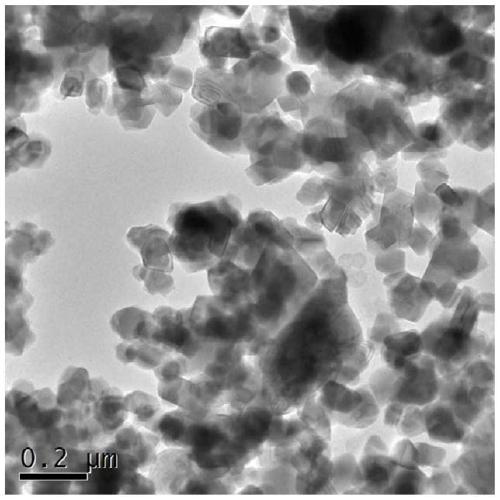

InactiveCN1784802ASynthesis temperature is lowConsiderable reversible capacityAlkali titanatesNegative electrodesHigh current densityLithium oxide

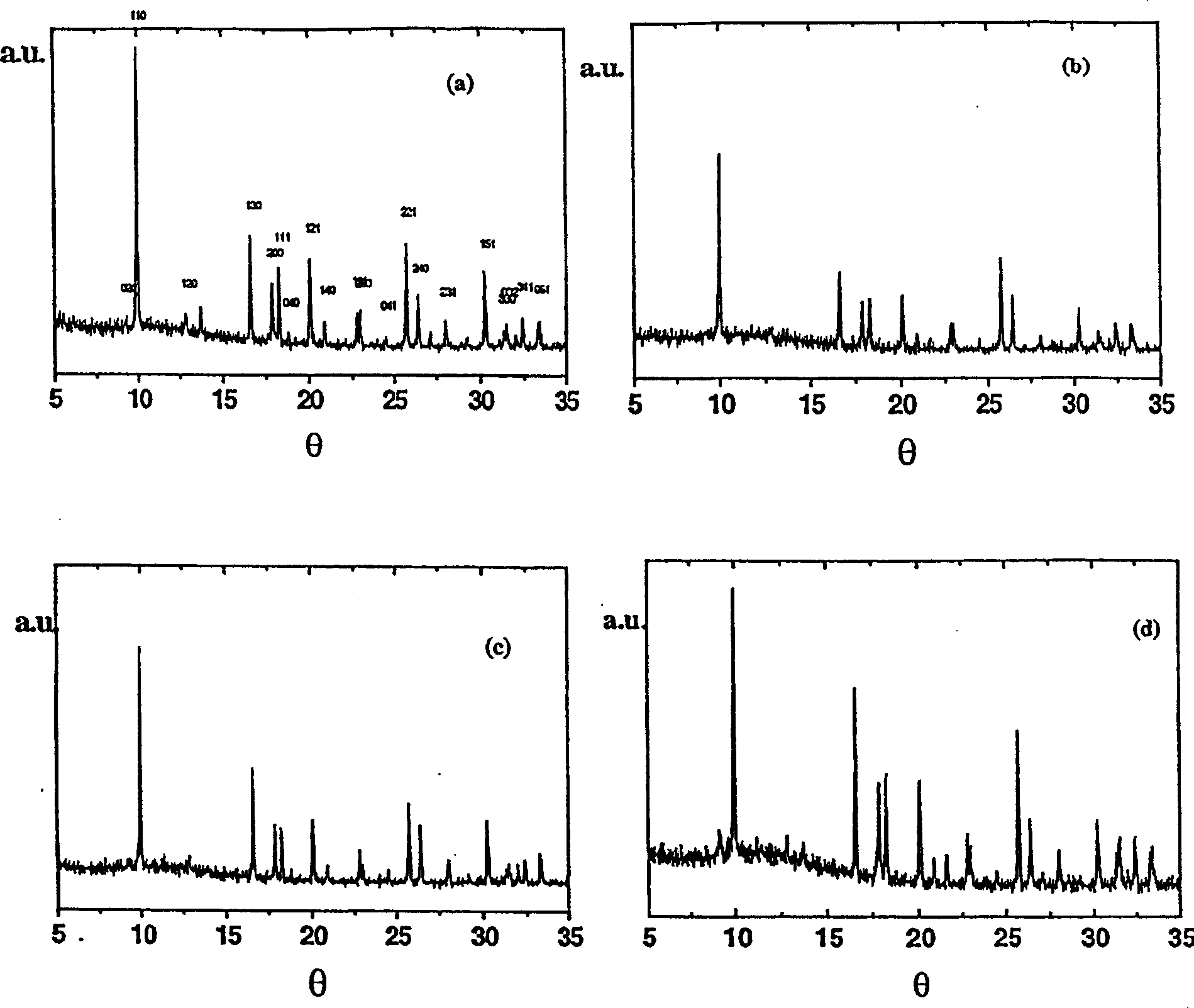

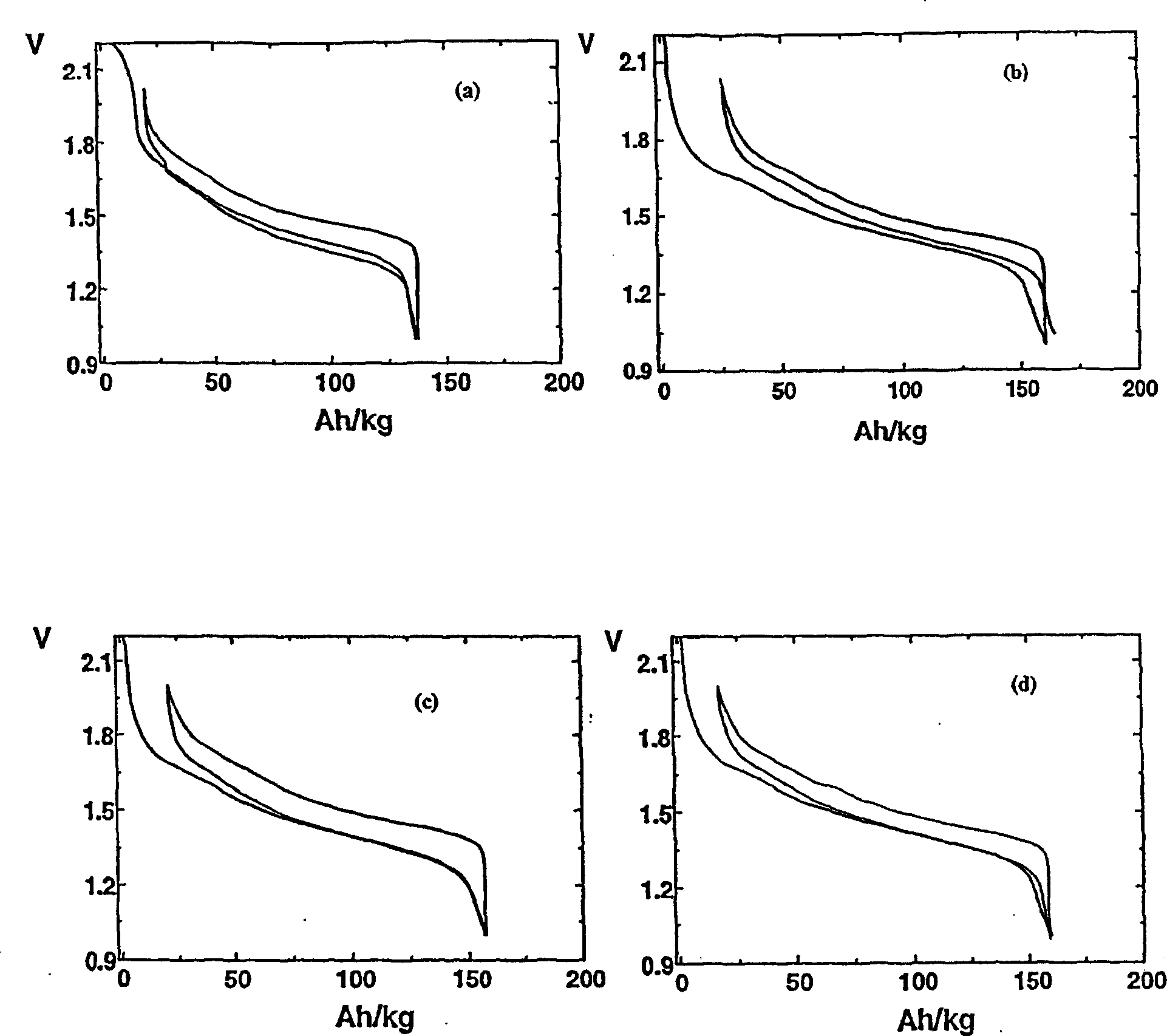

An active material for high-voltage negative electrodes (>1V vs. Li) of secondary rechargeable lithium batteries is disclosed. Chemical composition is represented by the general formula Li2+vTi3−WFeXMyM′ZO7−α, where M and M′ are metal ions having an ionic radius between 0.5 and 0.8 A and forming an octahedral structure with oxygen, like Ti3+, Co2+, Co3+, Ni2+, Ni3+, Cu2+, Mg2+, Al3+, In3+, Sn4+, Sb3+, Sb5+, α is related to the formal oxidation numbers n and n′ of M and M′ by the relation 2α=v+4w−3x−ny−n′z and the ranges of values are −0.5≦̸V≦̸0.5, 0≦̸w≦̸0.2, x>0, y+z>0 and x+y+z≦̸0.7. The structure is related to that of ramsdellite for all the compositions. The negative active material is prepared by ceramics process wherein lithium oxide, titanium oxide, iron oxide, M and / or M′ oxide are used as starting material for synthesis. Inorganic or organic solid precursors of the oxides can also be used instead. After reactant dispersion the mixture is fired. The resulting electrochemically active material provides low working voltage and capacity with excellent cycling capabilities at both low and high current densities.

Owner:UMICORE AG & CO KG +1

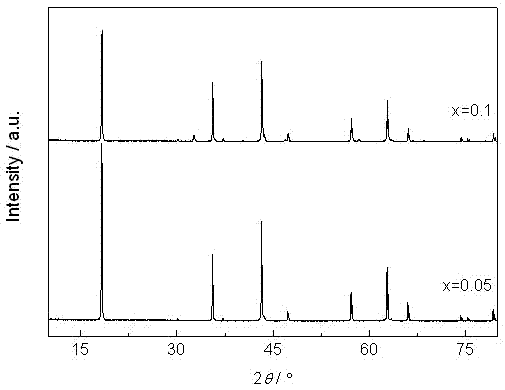

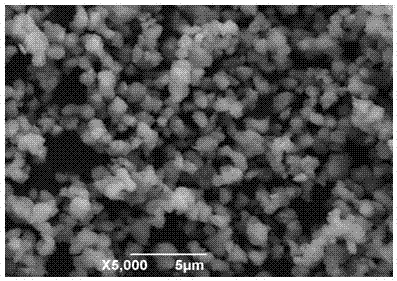

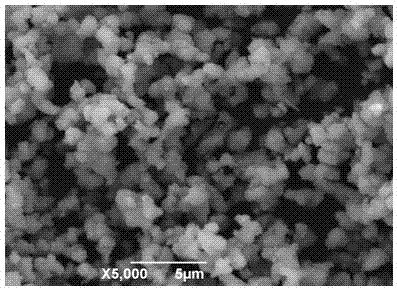

Preparation method of wide potential window negative electrode material of lithium ion battery

InactiveCN102368556ASimple manufacturing processImprove controllabilityCell electrodesElectrical batteryPhysical chemistry

The invention which provides a preparation method of a wide potential window negative electrode material of a lithium ion battery belongs to the technical field of lithium ion batteries. The preparation method of the invention comprises the following steps: 1, mixing a lanthanum source, TiO2 with different crystal forms, and a lithium source, and grinding for 6-12h in a ball mill to obtain a mixture; and 2, putting the mixture in a muffle furnace, reacting for 12-24h at 800-950DEG C, and naturally cooling to room temperature to obtain the wide potential window negative material Li4La5-xLaxO12of the lithium ion battery, wherein x is 0.05 or 0.1. The negative electrode material prepared in the invention has a wide potential window, a good reversible capacity, an excellent rate performance and a stable cycle life, so the material which has a high practical use value allows practical requirements of various applications of the lithium ion battery to be effectively satisfied. In addition, the method of the invention has the characteristics of simplified preparation technology, high controllable reappearance, low production cost and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

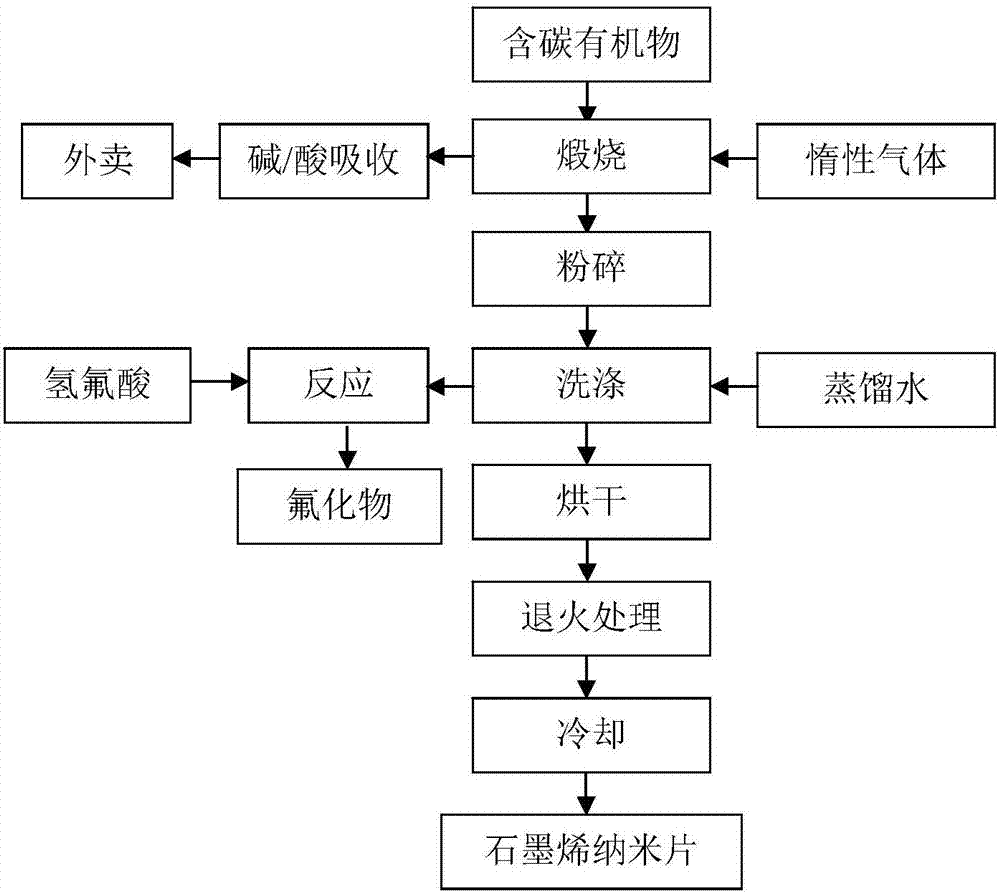

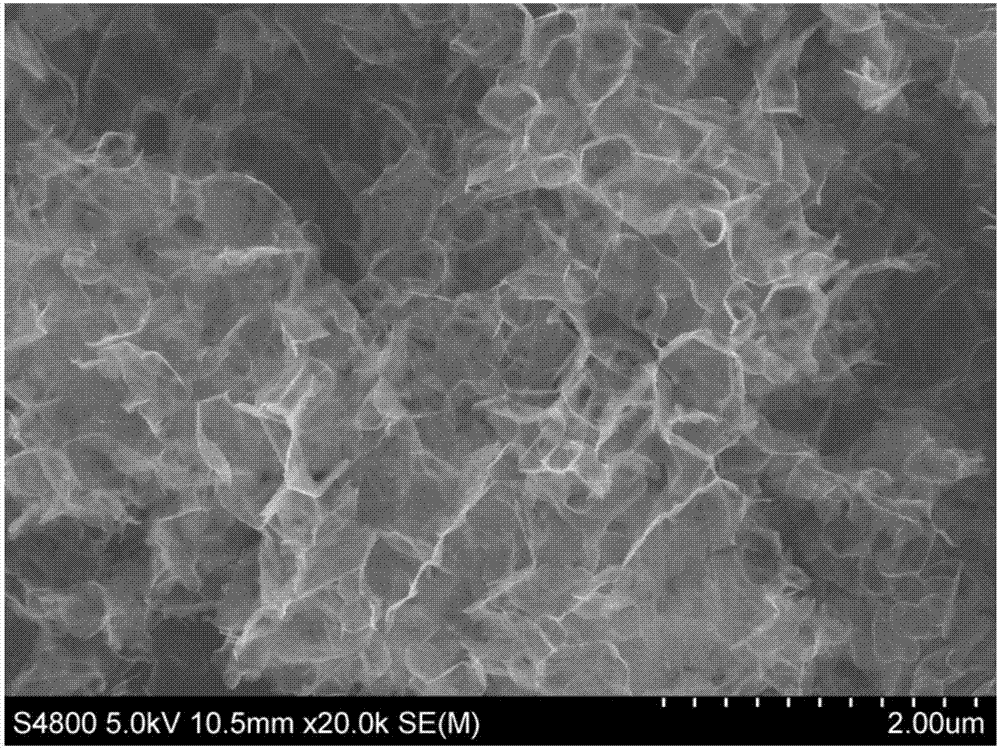

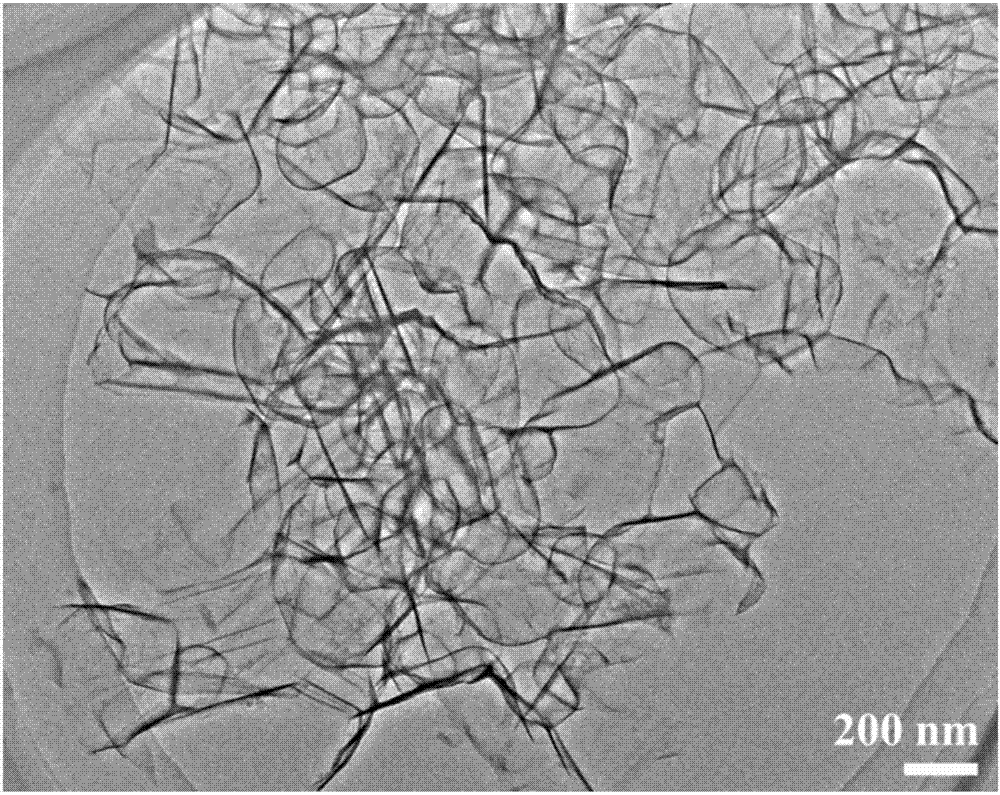

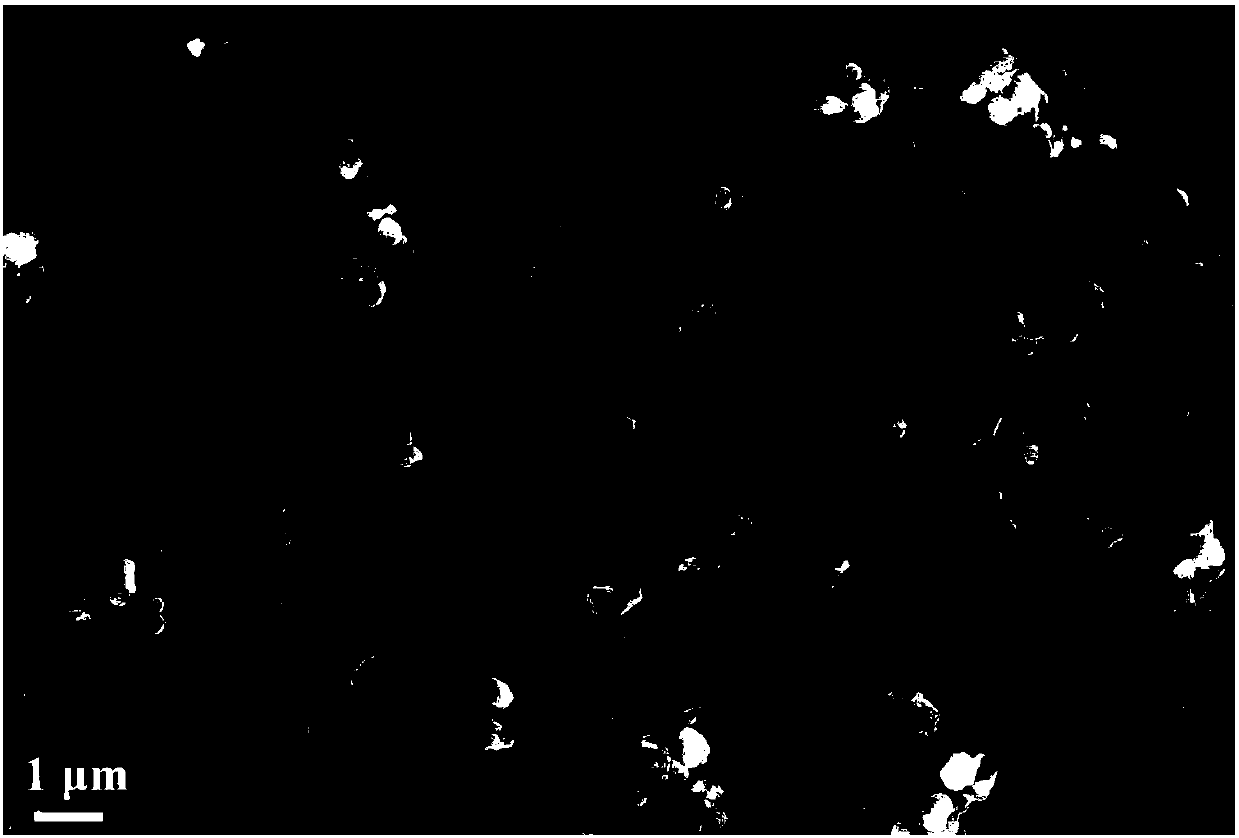

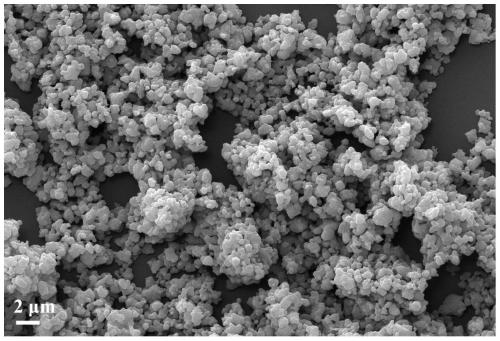

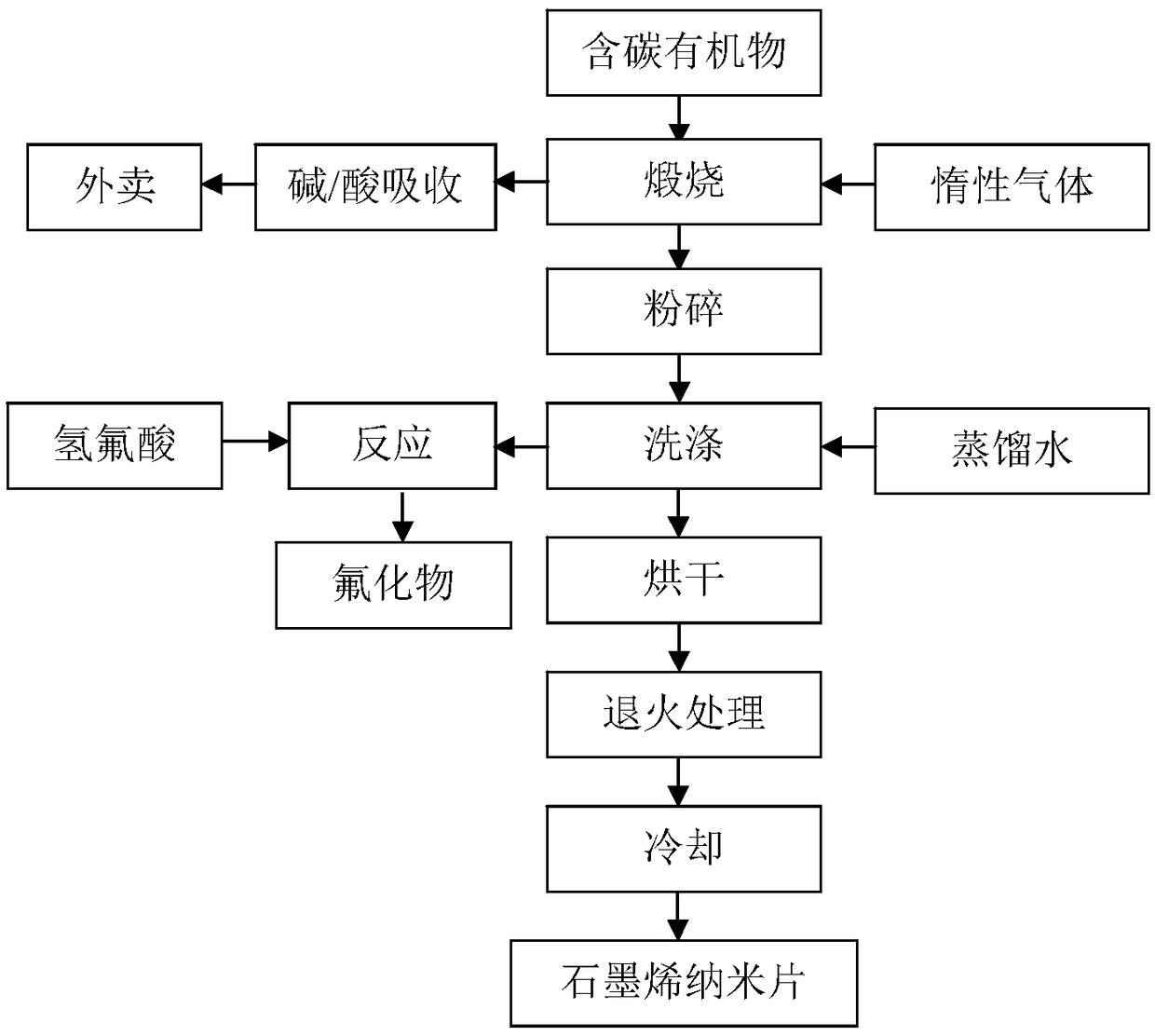

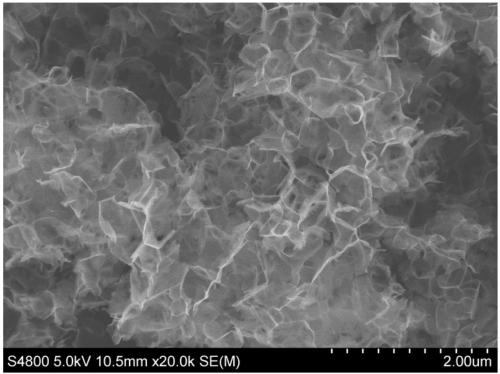

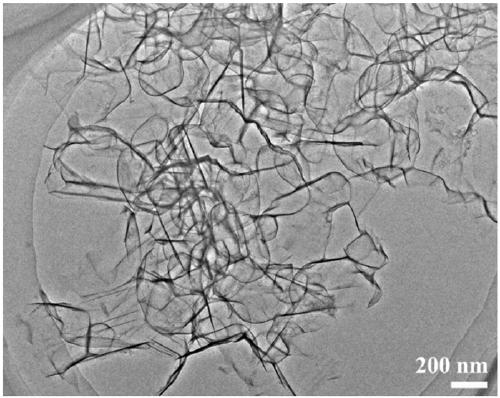

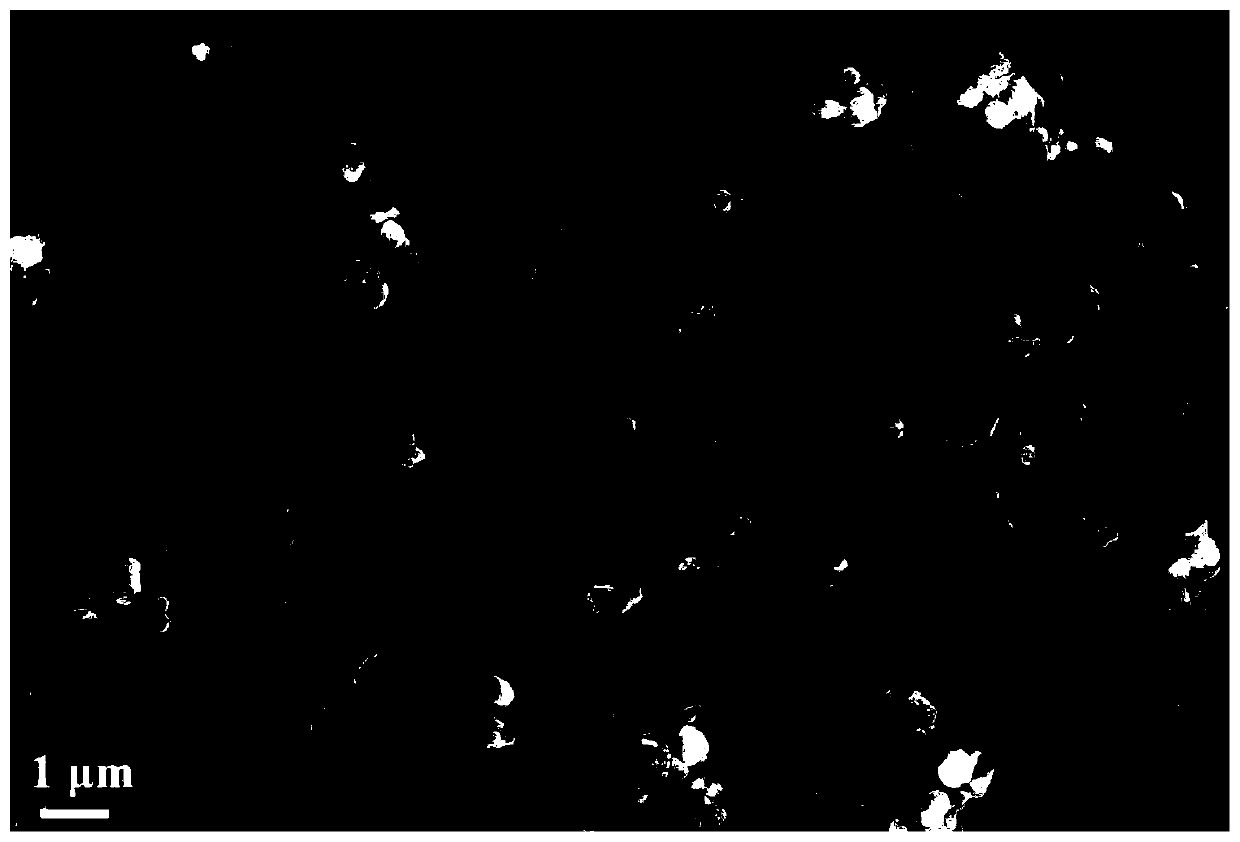

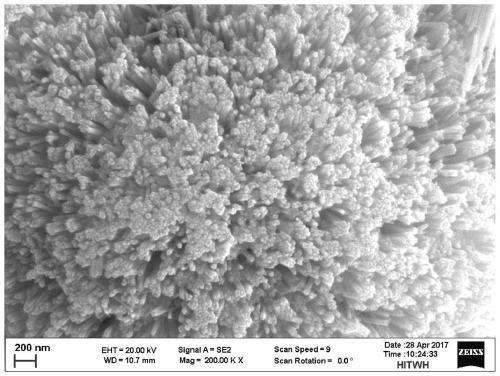

Network-like graphene nanometer material as well as preparation method and application thereof

ActiveCN107128902AReduce pollutionIncrease profitMaterial nanotechnologyCell electrodesOrganic matterGraphene

The invention relates to a network-like graphene nanometer material as well as a preparation method and application thereof. The preparation method of the network-like graphene nanometer material comprises the following steps: 1) calcining a carbon source organic matter at the temperature of 500-1000 DEG C so as to obtain a calcined matter; 2) adding water into the calcined matter for washing, and filtering so as to obtain filter residues; and 3) annealing the filter residues at the temperature of 200-1600 DEG C in a protective atmosphere, thereby obtaining the product. According to the network-like graphene nanometer material disclosed by the invention, the carbon source organic matter serves as a raw material, and the nanometer material is prepared through calcining, washing and secondary high-temperature annealing, an extra template and a template dissolving process are not involved, the process flow is simple, the equipment requirement is low, and industrial production is easily realized. Moreover, the network-like graphene nanometer material has wide interlayer spacing and excellent conductivity and presents excellent sodium storage performance.

Owner:DO FLUORIDE CHEM CO LTD

Preparation method of lithium sodium titanate negative electrode material with multistage structure

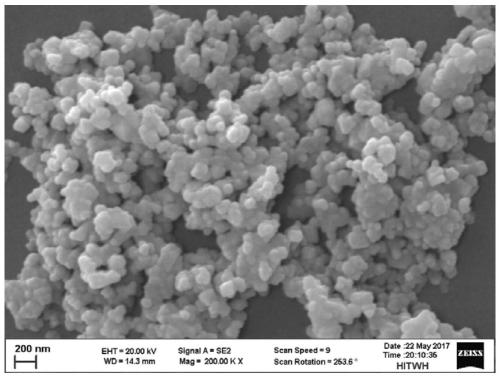

ActiveCN107742718AStable structureCompact structureCell electrodesSecondary cellsDispersityHigh rate

The invention discloses a preparation method of a lithium sodium titanate negative electrode material with a multistage structure, and belongs to the technical field of lithium ion batteries. The method comprises the following specific steps: dissolving tetrabutyl titanate, lithium acetate and sodium nitrate in an alcohol solution, adding citric acid to serve as a chelating agent, then adding an amine compound, stirring to form gel, and performing vacuum drying; then mixing gamma-LiAlO2 with the dried gel, performing ball milling, performing preheating treatment in the air, then performing ball milling and calcining to obtain a Na2Li2Ti6O14@gamma-LiAlO2 material; putting the Na2Li2Ti6O14@gamma-LiAlO2 material into distilled water, performing ultrasonic treatment and adding sodium dodecyl benzene sulfonate; and pouring a dissolved pyrrole solution into the mixture, stirring, adding an initiator, centrifuging, washing and drying to obtain a target product. The synthesized negative electrode material has the advantages of uniform and consistent particles, high dispersity and high degree of crystallinity; with a stable multistage composite structure, the negative electrode material hasconsiderable wide-potential-window reversible capacity, high rate performance and stable cycle life.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

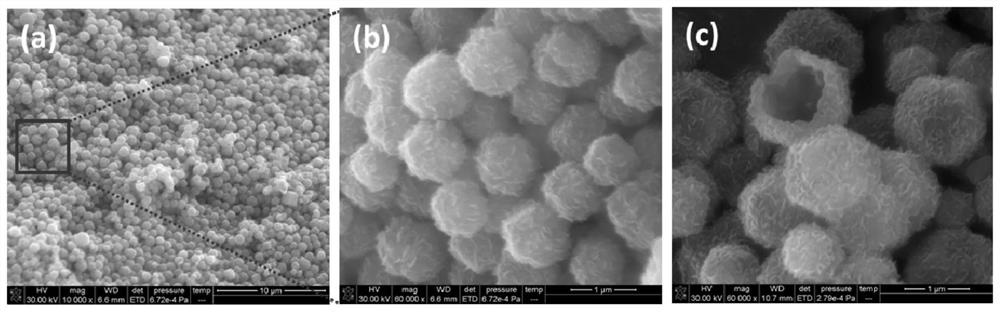

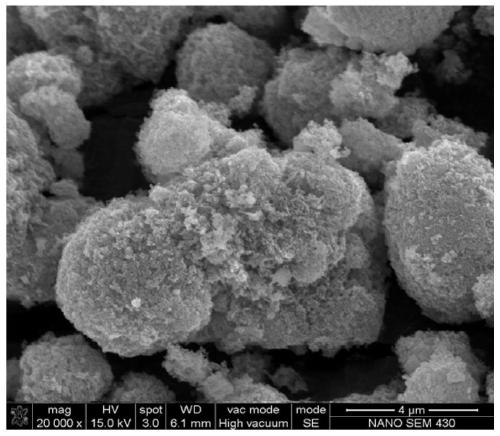

Polypyrrole coated MoS2/C composite material and preparation method thereof

ActiveCN112786870AImprove pulverizationPromote aggregationMaterial nanotechnologyNegative electrodesHydration reactionPolypyrrole

The invention discloses a polypyrrole coated MoS2 / C composite material and a preparation method thereof. The preparation method of the composite material comprises the following steps: 1), dissolving sodium molybdate dehydrate and thiourea in ethanol, then adding polyvinylpyrrolidone, uniformly performing stirring, then putting the mixture into a high-pressure kettle, and carrying out heat preservation reaction at the temperature of greater than or equal to 150 DEG C to obtain hollow nanospheres assembled by MoS2 / C; and 2), uniformly mixing the hollow nanospheres assembled by MoS2 / C with an oxidizing agent, taking the obtained mixture as a raw material, taking pyrrole as a coating source, taking a high-pressure kettle as a reaction chamber, and carrying out heat preservation reaction under a heating or non-heating condition under the condition that the mixture and pyrrole are not in contact with each other, thereby obtaining a polypyrrole coated MoS2 / C composite material. The composite material is in a hollow spherical shape and has excellent Li<+> storage performance and reversible capacity, and the preparation method is simpler and more environmentally friendly.

Owner:GUANGXI NORMAL UNIV

Preparation method of multilevel structure titanate negative electrode material for lithium ion battery

ActiveCN107749471AStable structureEvenly dispersedMaterial nanotechnologyCell electrodesMuffle furnaceCarbon nanotube

The invention discloses a preparation method of a multilevel structure titanate negative electrode material for a lithium ion battery, and belongs to the technical field of lithium ion batteries. Themethod concretely comprises the following steps: dispersing a sodium source and a titanium source in a glycol and anhydrous ethanol mixed solution to form a solution A; dissolving a barium source in an aqueous solution of anhydrous ethanol to form a solution B; mixing and stirring the solution A and the solution B, heating the obtained solution until evaporative drying is achieved, placing the obtained precursor in a muffle furnace, and carrying out pre-calcining, ball milling and calcining to obtain a BaNa2Ti6O14 material; dispersing the material in an acetone solution, adding carbon nano-tubes, and stirring and heating the obtained solution until the solution is completely volatilized in order to obtain BaNa2Ti6O14-CNT; and carrying out mixing and ball-milling on the BaNa2Ti6O14-CNT andcarbon fibers, and sintering the obtained mixture in nitrogen to obtain the target product. The titanate negative electrode material obtained in the invention has a stable multilevel composite structure, so the titanate negative electrode material has the advantages of considerable wide potential window reversible capacity, excellent rate performances and stable cycle life.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

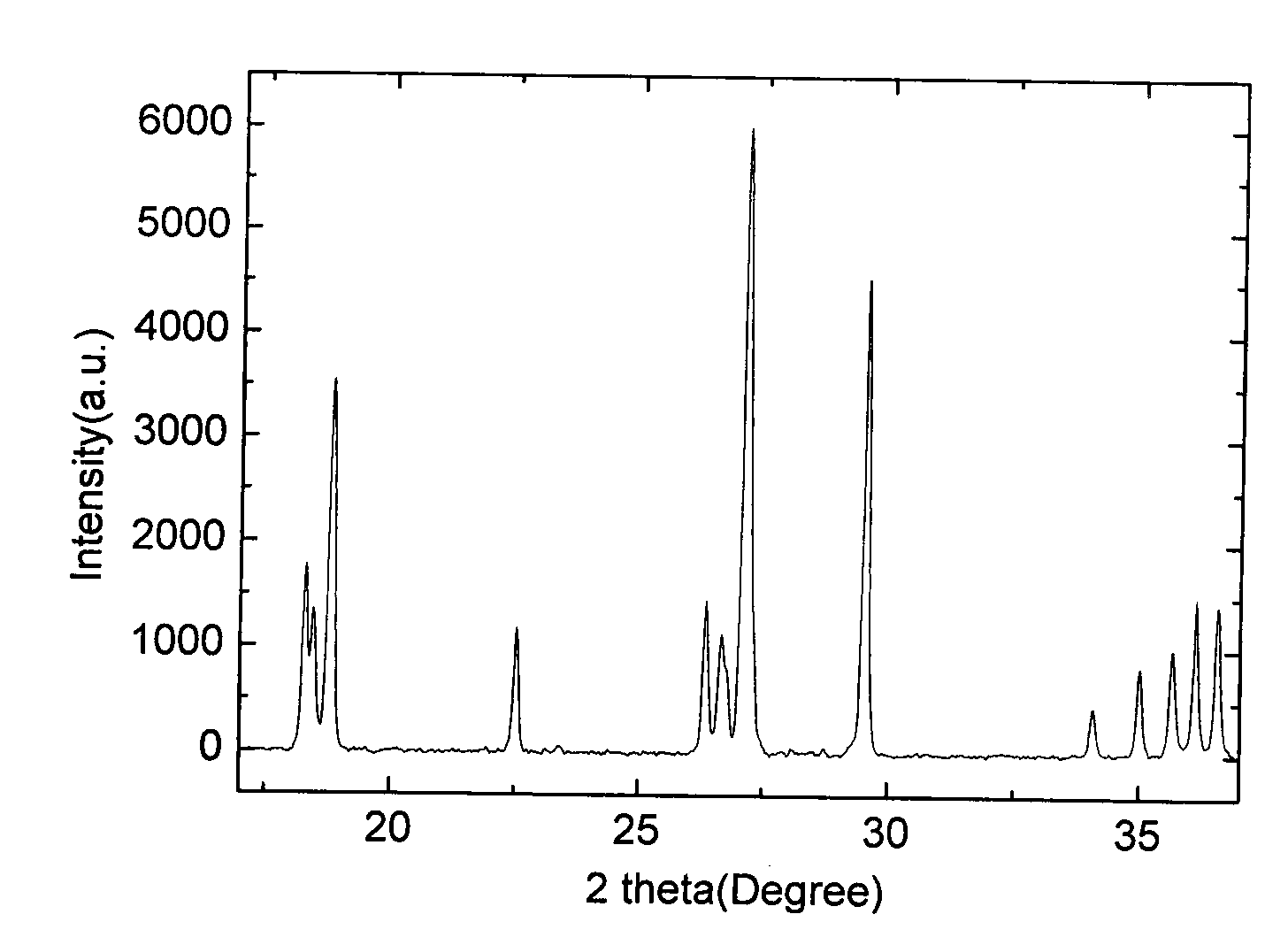

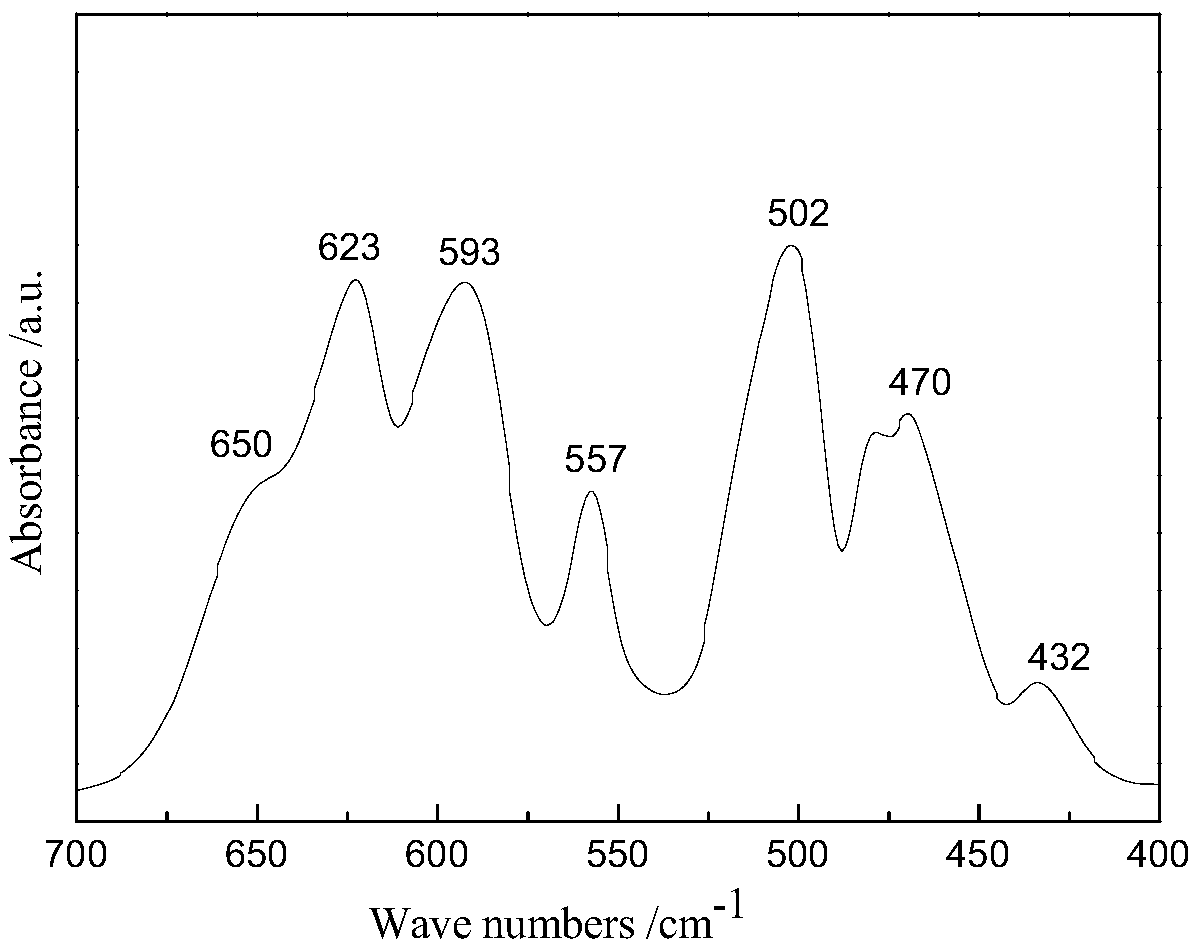

Preparation method of spherical porous lithium-ion battery high-voltage cathode material

InactiveCN105514412AImprove electrochemical performanceUniform particlesCell electrodesSecondary cellsHigh energyHigh pressure

The invention discloses a preparation method of a spherical porous lithium-ion battery high-voltage cathode material and belongs to the technical field of lithium-ion batteries. The chemical formula of the material is LiNi0.5Mn1.5O4-Li3xLa(2 / 3)-xTiO3, wherein 0.05<x<0.15, and the mass fraction of the Li3xLa(2 / 3)-xTiO3 is 5%. The material is prepared by adopting an organic solvent assisted coprecipitation method. The preparation method is wide in raw material source, simple and convenient to operate, good in controllability and high in reproducibility, and the long-time high-energy-consumption high-temperature sintering process is avoided. The prepared material has the porous spherical characteristics, is small in granule, uniform in particle size distribution, high in crystallinity and better in rate performance, is of a P4332 structure and can be used as the high-performance lithium-ion battery high-voltage cathode material.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Preparation method of lithium ion battery anode material with high multiplying power

InactiveCN102364731ASimple manufacturing processImprove controllabilityCell electrodesNiobiumRoom temperature

The invention provides a preparation method of a lithium ion battery anode material with high multiplying power, belonging to the technical field of lithium ion batteries. The preparation method comprises the following steps of: mixing a lithium source, a manganese source, a nickel source and a niobium source according to a certain stoichiometric ratio, grinding for 5-10h in a ball mill to obtain a mixture, putting the mixture into a muffle furnace, heating to 850-950 DEG C at a temperature rise speed of 5-10DEG C / min, reacting for 15-24h at 850-950 DEG C, and then naturally cooling to room temperature to obtain an LiMn1.425Ni0.525Nb0.05O4 anode material. The anode prepared by the preparation method disclosed by the invention has considerable reversible volume, excellent multiplying power and stably cycle life, thereby having higher actual usage value and being capable of effectively meeting actual requirements of various applications of lithium ion batteries. In addition, the preparation method disclosed by the invention has the characteristics of simplified preparation process, high controllable repeatability, low production cost and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

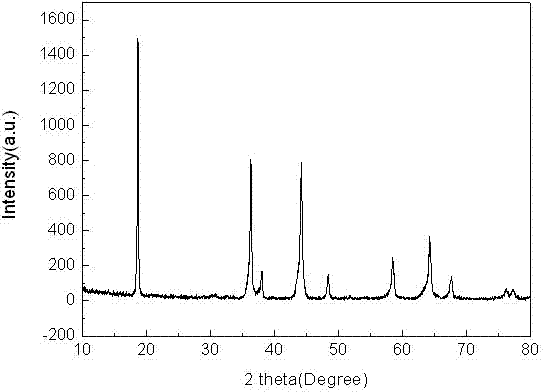

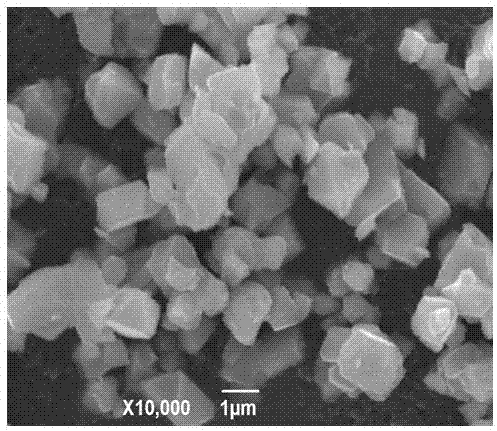

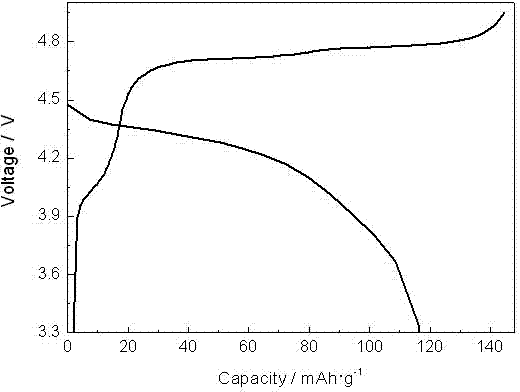

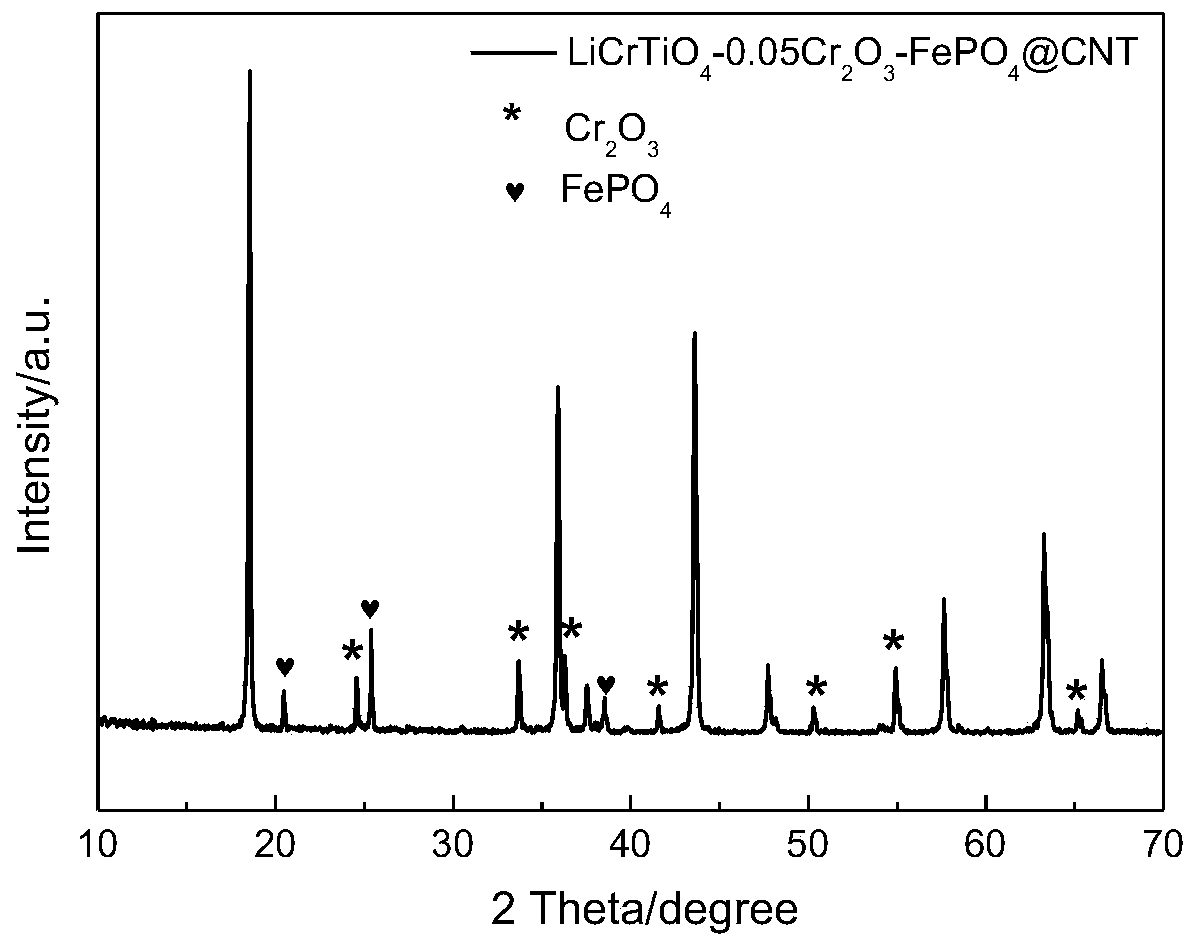

Preparation method of titanate composite negative electrode material for lithium ion battery

ActiveCN110176584AUniform particlesGood dispersionSecondary cellsNegative electrodesWater bathsCrystallinity

The invention discloses a preparation method of a titanate composite negative electrode material for a lithium ion battery. The preparation method comprises the following steps of dissolving a titanium source and a chromium source in an ethanol aqueous solution, adding citric acid under a stirring condition, adding the ethanol aqueous solution comprising a lithium source, performing water bath heating to form a gel state, performing drying and grinding, placing the product in a muffle furnace for pre-burning, and cooling to a room temperature to obtain a LiCrTiO<4-a<Cr2O3 precursor; dissolvingthe LiCrTiO<4-a<Cr2O3 precursor and FePO4 in absolute ethyl alcohol, performing uniform stirring and drying, cooling to the room temperature, placing the product in a ball-milling machine for ball-milling, performing sieving, placing the product in the muffle furnace for calcination, and cooling to the room temperature to obtain a LiCrTiO<4-a>Cr2O3-FePO4 electrode material; and dispersing the electrode material in an acetone solution, adding CNT, performing stirring, allowing a liquid to be completely volatilized to obtain the titanate composite negative electrode material for the lithium ionbattery. The preparation method has the advantages of wide raw materials, good controllability and high reproducibility and is simple and convenient to operate, the obtained material is relatively small in particle, uniform in grain size distribution and high in crystallinity, so that the material preparation cost is reduced, and the electrochemical performance of the material is improved.

Owner:NANJING GUOXUAN BATTERY CO LTD

Negative electrode for lithium batteries

InactiveCN100359723CSynthesis temperature is lowConsiderable reversible capacityAlkali titanatesNegative electrodesHigh current densityLithium oxide

An active material for high-voltage negative electrodes (>1V vs. Li) of secondary rechargeable lithium batteries is disclosed. Chemical composition is represented by the general formula Li2+vTi3−WFeXMyM′ZO7−α, where M and M′ are metal ions having an ionic radius between 0.5 and 0.8 A and forming an octahedral structure with oxygen, like Ti3+, Co2+, Co3+, Ni2+, Ni3+, Cu2+, Mg2+, Al3+, In3+, Sn4+, Sb3+, Sb5+, α is related to the formal oxidation numbers n and n′ of M and M′ by the relation 2α=v+4w−3x−ny−n′z and the ranges of values are −0.5≰V≰0.5, 0≰w≰0.2, x>0, y+z>0 and x+y+z≰0.7. The structure is related to that of ramsdellite for all the compositions. The negative active material is prepared by ceramics process wherein lithium oxide, titanium oxide, iron oxide, M and / or M′ oxide are used as starting material for synthesis. Inorganic or organic solid precursors of the oxides can also be used instead. After reactant dispersion the mixture is fired. The resulting electrochemically active material provides low working voltage and capacity with excellent cycling capabilities at both low and high current densities.

Owner:UMICORE AG & CO KG +1

A kind of preparation method of chromium-titanium-based lithium-ion battery multi-level structure negative electrode material

ActiveCN107732207BStable structureCompact structureCell electrodesSecondary cellsPhysical chemistryCarbon nanotube

The invention discloses a preparation method of a negative electrode material of the multistage structure of a chromium-titanium-based lithium-ion battery, and belongs to the technical field of lithium-ion batteries. The method includes the steps that a titanium source, a lithium source and a chromium source are dissolved in an alcohol solution, organic acid is added and serves as a chelating agent, stirring is conducted until gel is formed, and vacuum drying is conducted; alpha-LiALO2 prepared in advance is mixed with a precursor, pre-high-temperature treatment is conducted in the air, then ball-milling is conducted, and calcination is conducted at 800 DEG C to obtain Li5Cr7Ti6O25-LiAlO2; after mixing and ball-milling are conducted on the Li5Cr7Ti6O25-LiAlO2 and a nitrified carbon nano tube, the mixture is treated in an inert atmosphere, and an obtained product is the Li5Cr7Ti6O25@alpha-LiAlO2@CNT. The negative electrode material compounded through the method has even and uniform particles, the diversity is high, the crystallinity degree is high, and the negative electrode material has the stable multistage composite structure, so that the negative electrode material has considerable reversible capacity of wide potential windows, high rate performance, stable cycle life and a very high actual use value.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A kind of preparation method of multi-level structure titanate negative electrode material for lithium ion battery

ActiveCN107749471BStable structureCompact structureMaterial nanotechnologyCell electrodesLithium-ion batteryMuffle furnace

The invention discloses a preparation method of a multilevel structure titanate negative electrode material for a lithium ion battery, and belongs to the technical field of lithium ion batteries. Themethod concretely comprises the following steps: dispersing a sodium source and a titanium source in a glycol and anhydrous ethanol mixed solution to form a solution A; dissolving a barium source in an aqueous solution of anhydrous ethanol to form a solution B; mixing and stirring the solution A and the solution B, heating the obtained solution until evaporative drying is achieved, placing the obtained precursor in a muffle furnace, and carrying out pre-calcining, ball milling and calcining to obtain a BaNa2Ti6O14 material; dispersing the material in an acetone solution, adding carbon nano-tubes, and stirring and heating the obtained solution until the solution is completely volatilized in order to obtain BaNa2Ti6O14-CNT; and carrying out mixing and ball-milling on the BaNa2Ti6O14-CNT andcarbon fibers, and sintering the obtained mixture in nitrogen to obtain the target product. The titanate negative electrode material obtained in the invention has a stable multilevel composite structure, so the titanate negative electrode material has the advantages of considerable wide potential window reversible capacity, excellent rate performances and stable cycle life.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

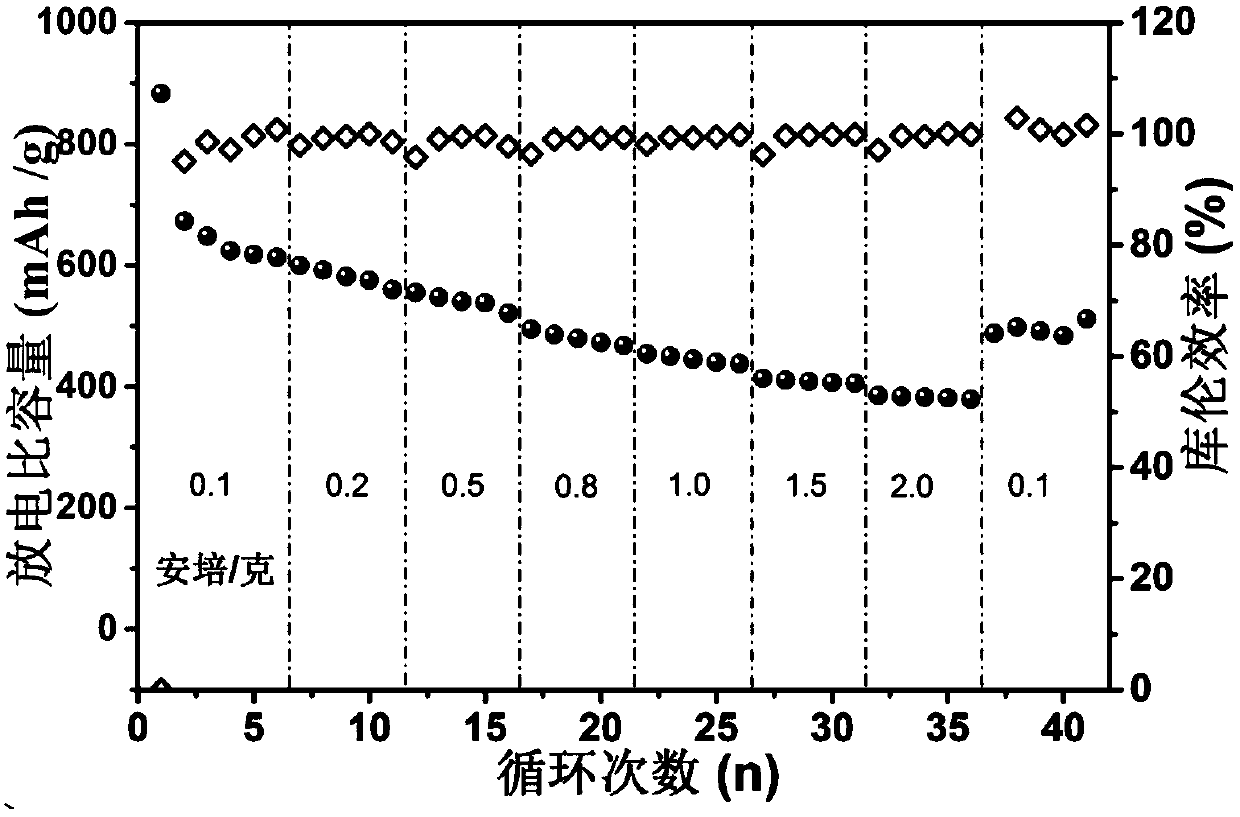

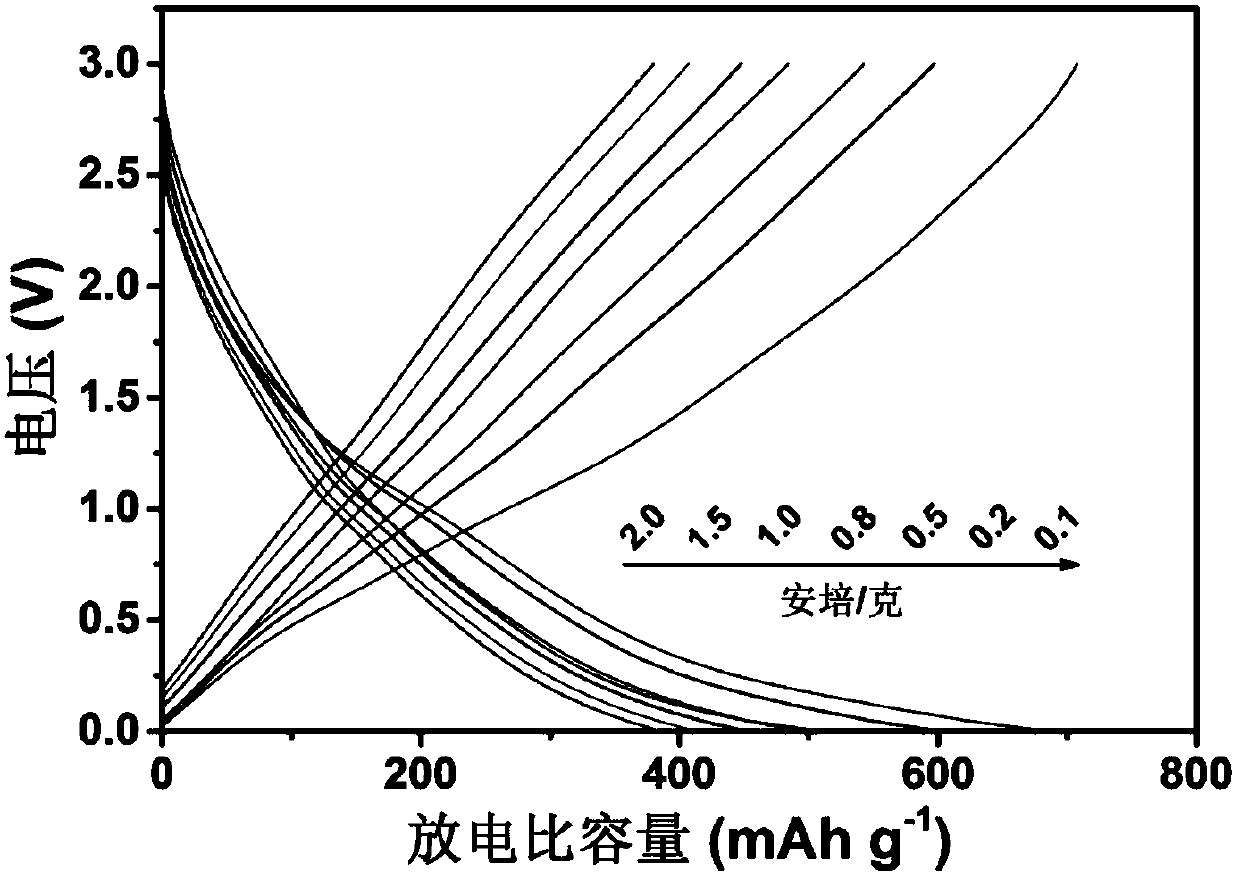

Preparation method of v2(po4)o/c material, negative electrode and method for making lithium ion battery

ActiveCN106602005BReduce manufacturing costThe method is simple and controllableCell electrodesSecondary cellsOXALIC ACID DIHYDRATEElectrical battery

The invention relates to a preparation method of V2(PO4)O / C material, a negative electrode of a lithium ion battery, prepared from the V2(PO4)O / C material prepared thereby and a method for preparing the negative electrode. The preparation method comprises the steps of dissolving V2O5 and oxalic acid in deionized water, forming a blue transparent solution in an oil bath condition, and adding ammonium dihydrogen phosphate and glucose into the solution; adding ethylene glycol into the solution to obtain a mixed solution; and performing hydrothermal reaction on the mixed solution to obtain a solid precipitant, wherein the feeding mole ratio of the V2O5, the oxalic acid and the ammonium dihydrogen phosphate is 1:3:1. The invention also provides the negative electrode of a lithium ion battery, prepared from the V2(PO4)O / C material prepared by the method and the method for preparing the negative electrode. The V2(PO4)O / C material, acetylene black and a lithium polyacrylic acid aqueous solution are mixed according to a certain weight proportion and are used for coating a copper foil to prepare an electrode membrane used as the negative electrode of the lithium ion battery. By the technical scheme of the invention, compared with an existing negative electrode material such as lithium titanate and nitride, the V2(PO4)O / C material shows excellent reversible capacity, rate performance and cycle stability when the V2(PO4)O / C material is used as a lithium ion negative electrode material.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

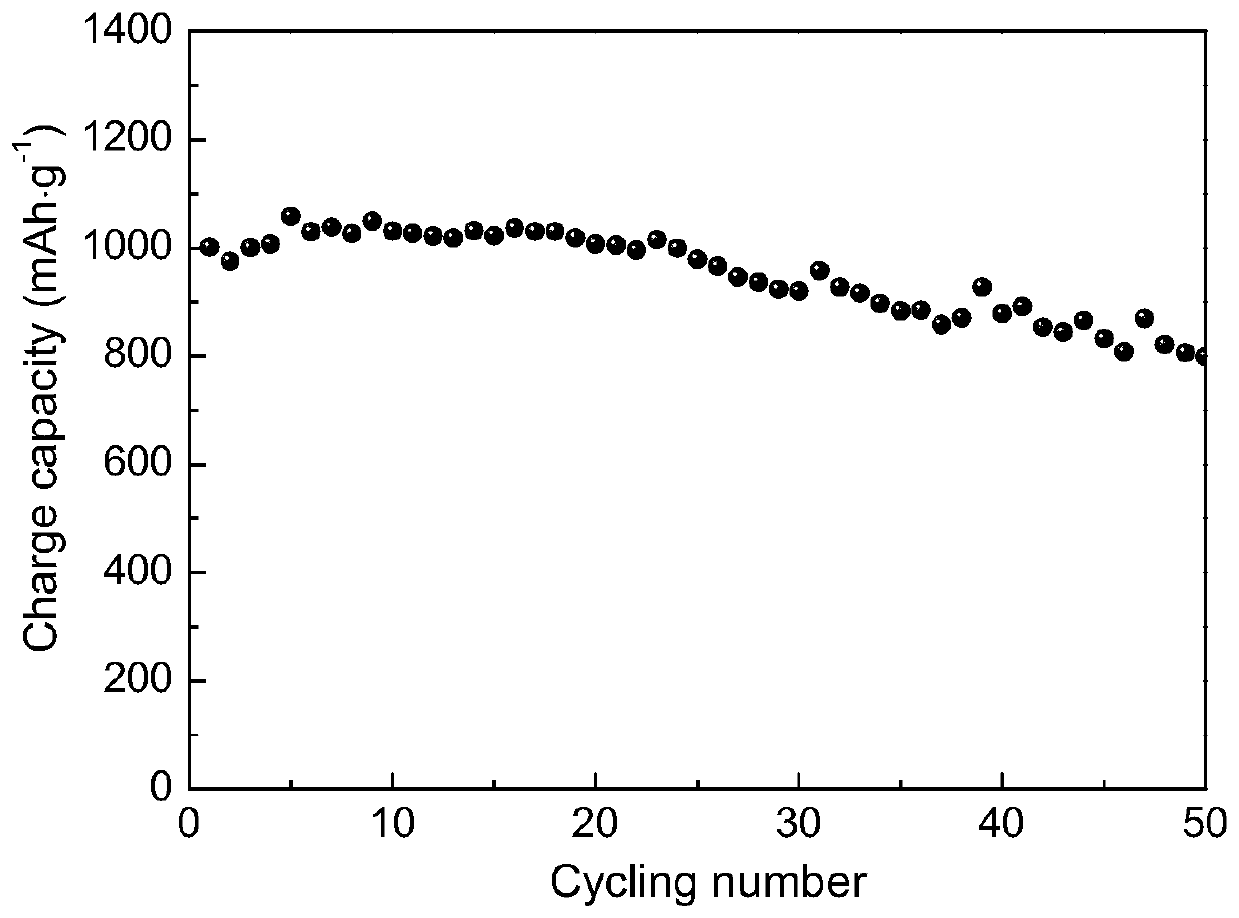

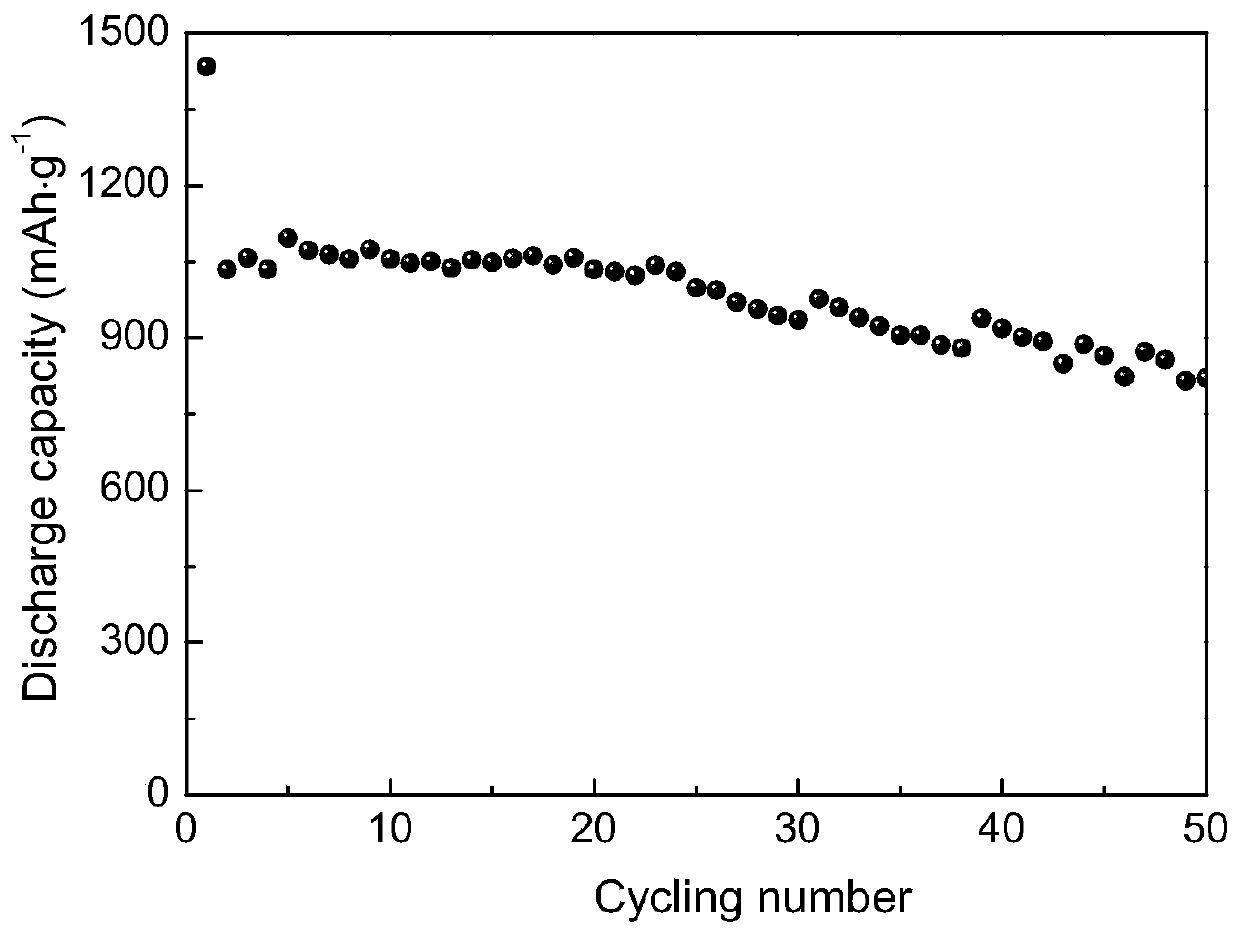

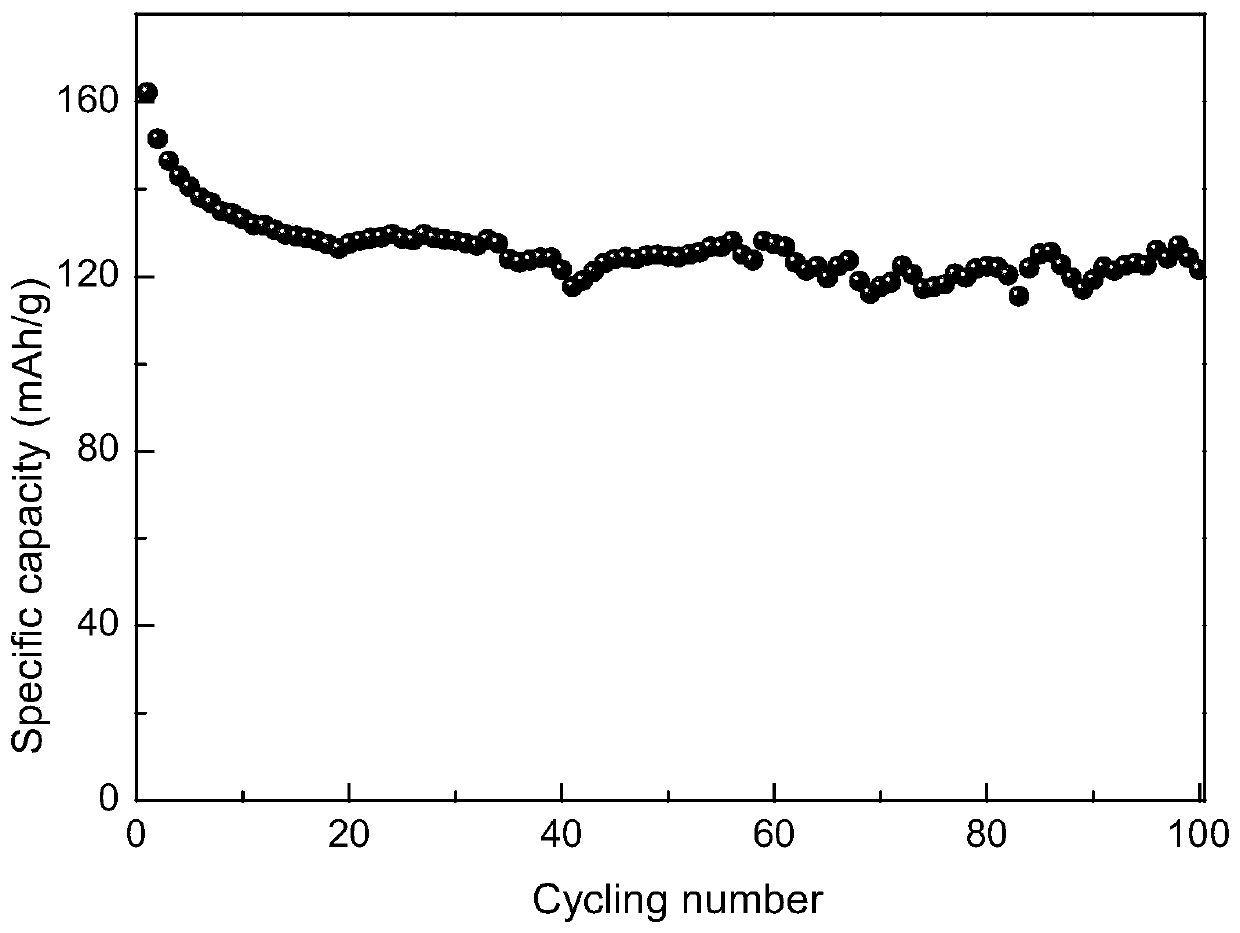

High-rate lithium ion battery cathode material and preparation method and application thereof

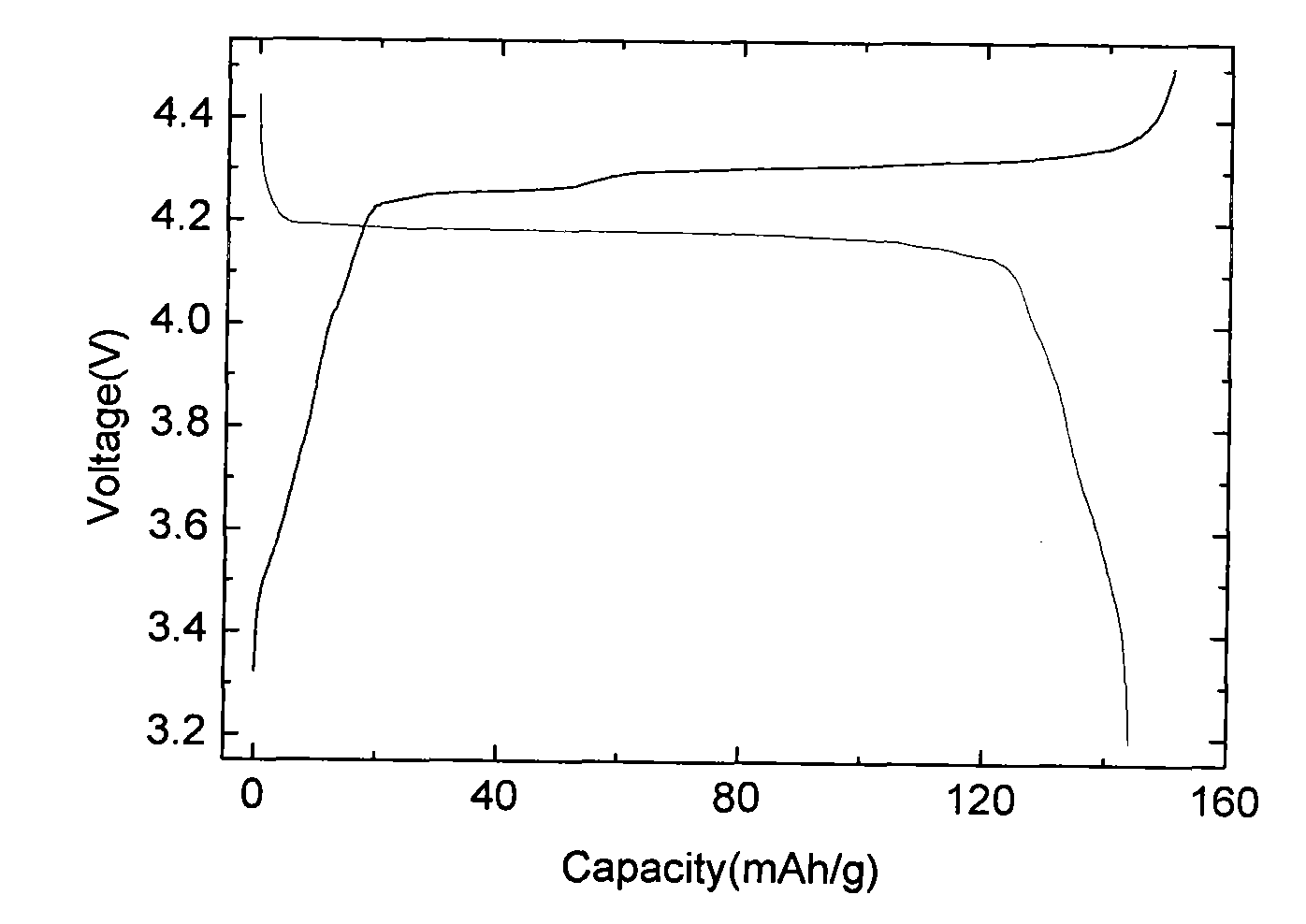

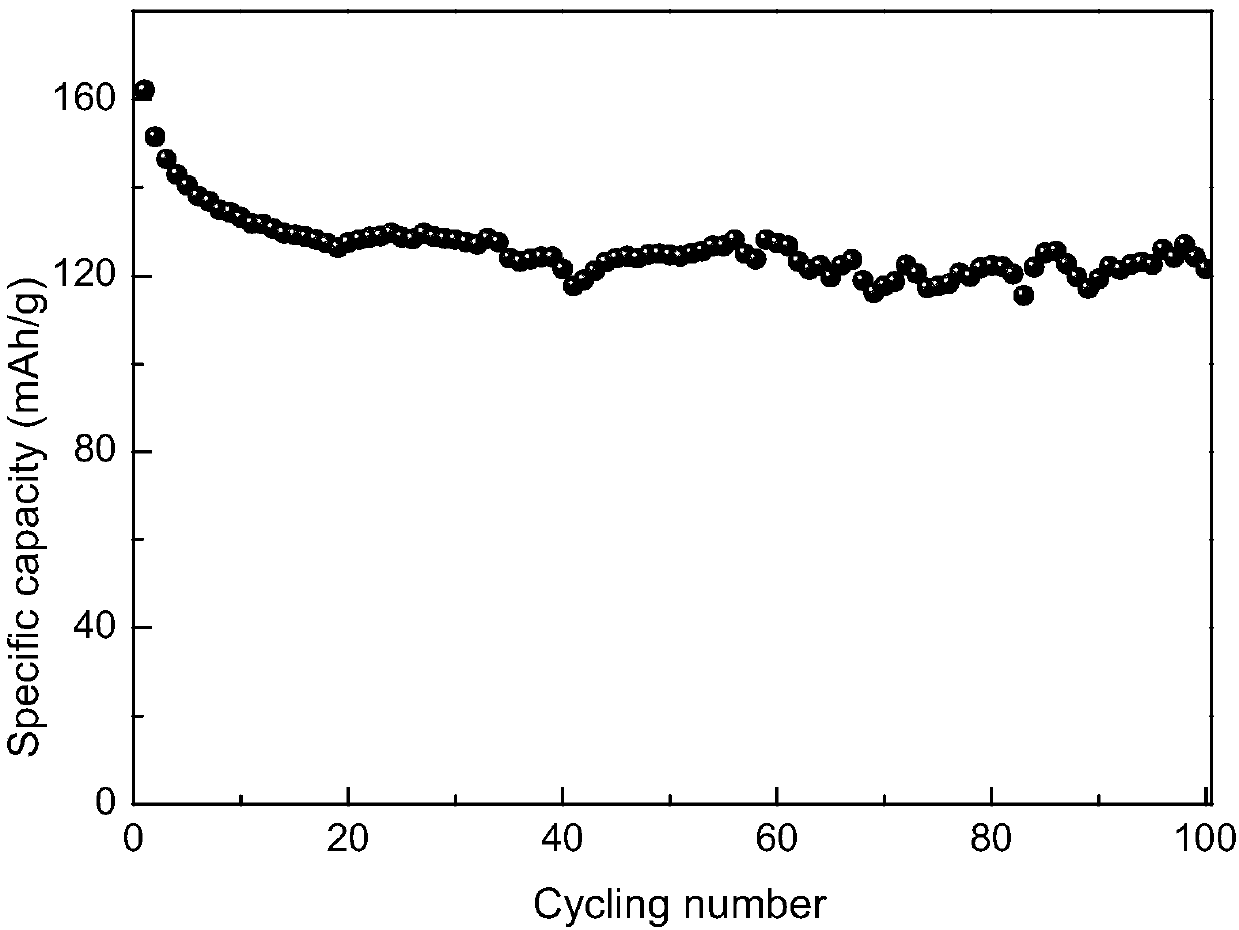

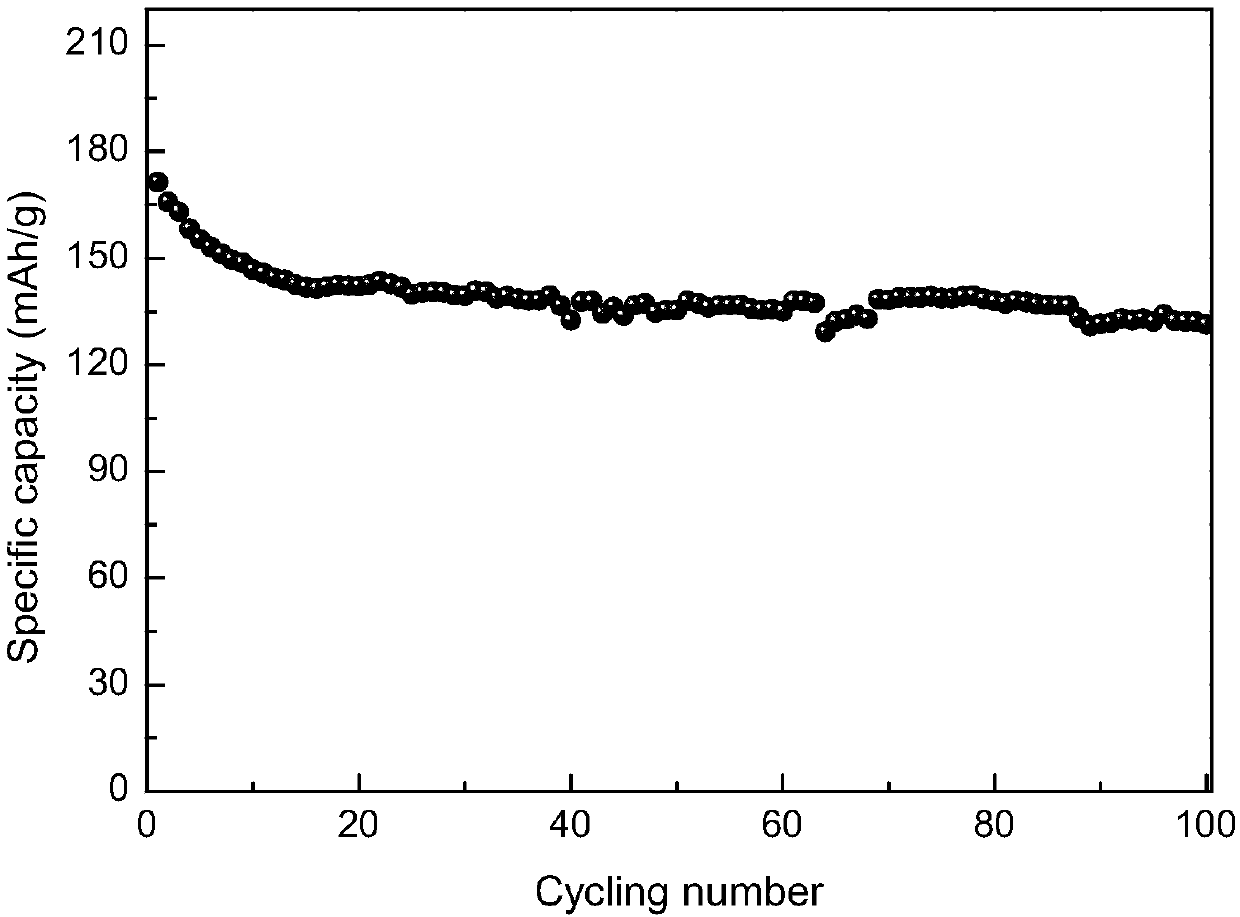

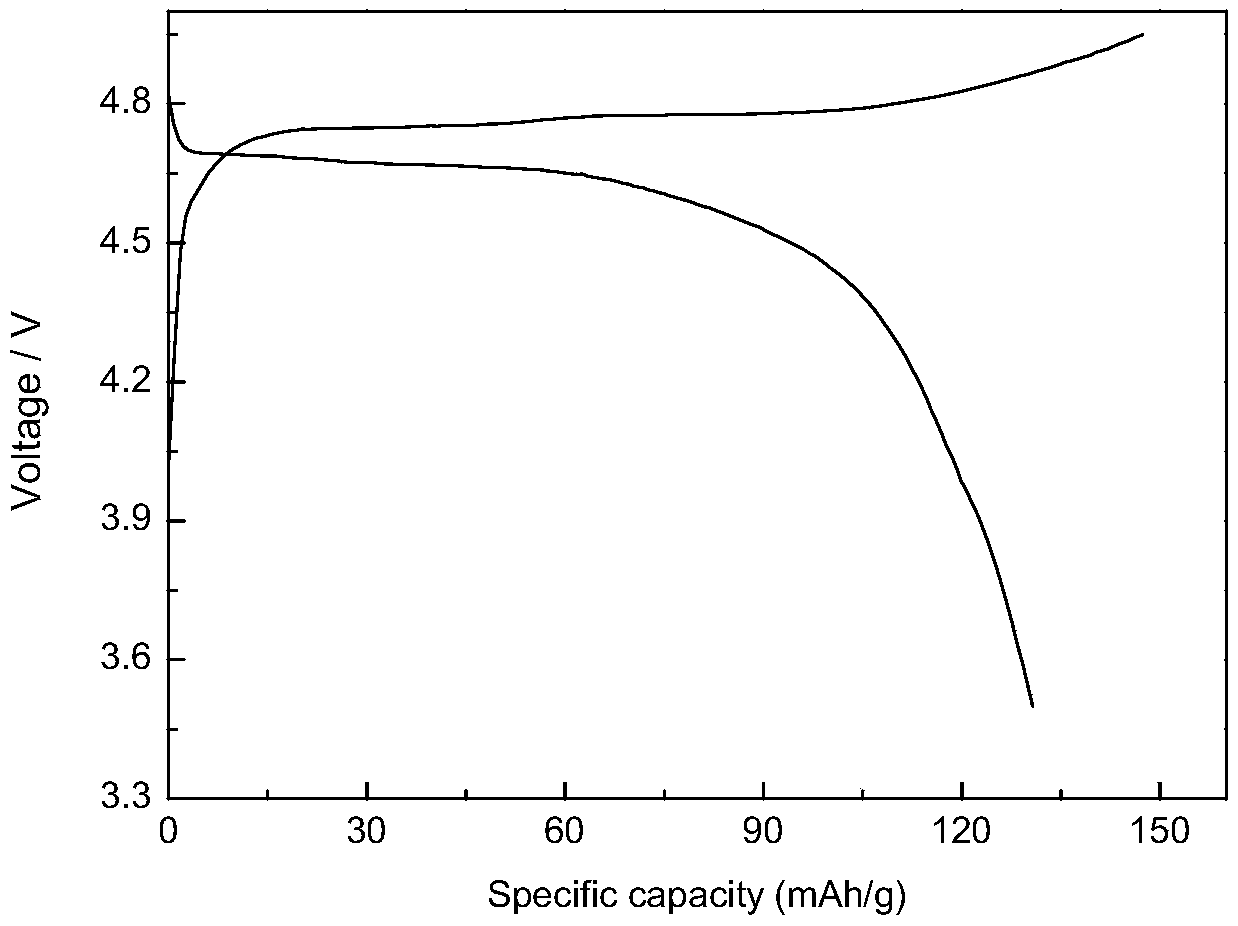

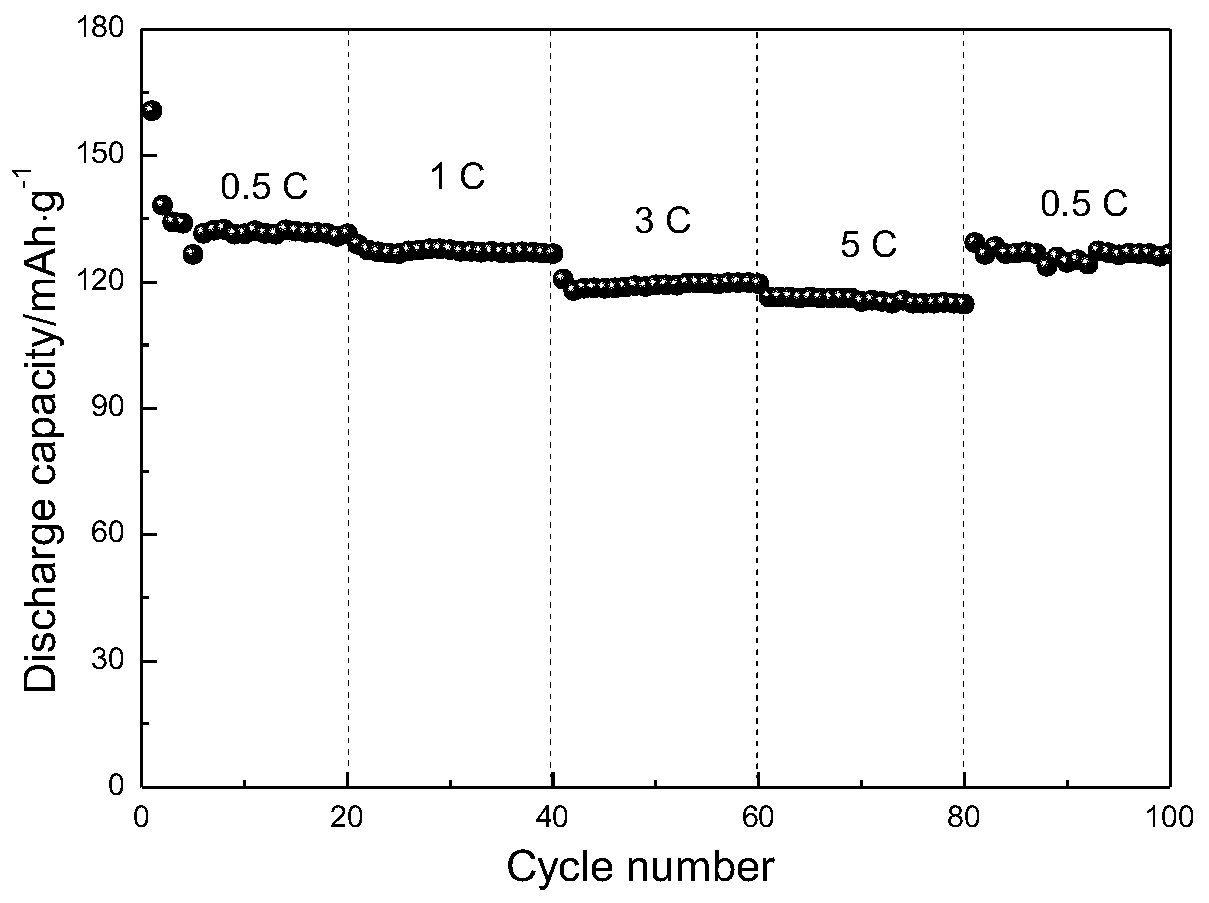

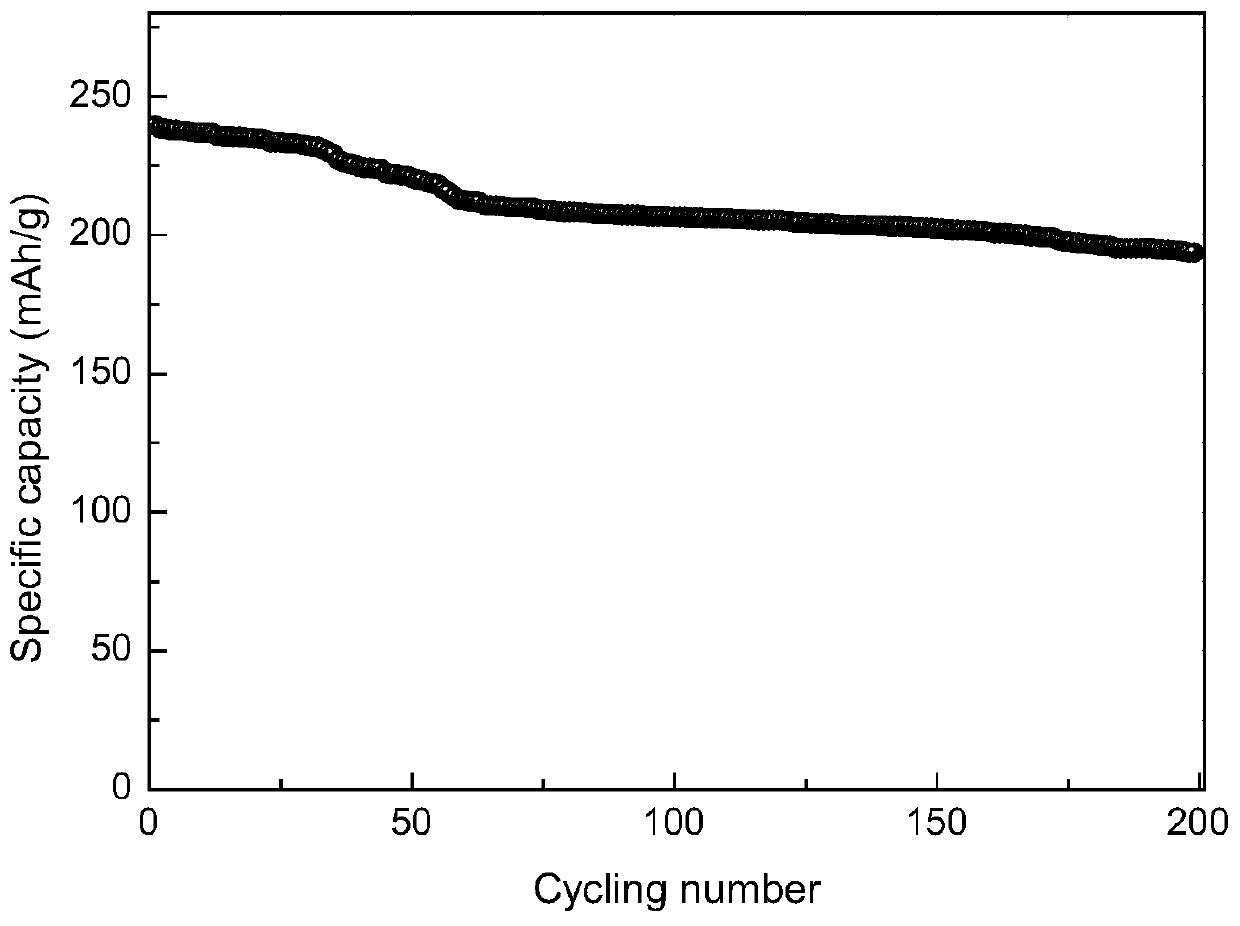

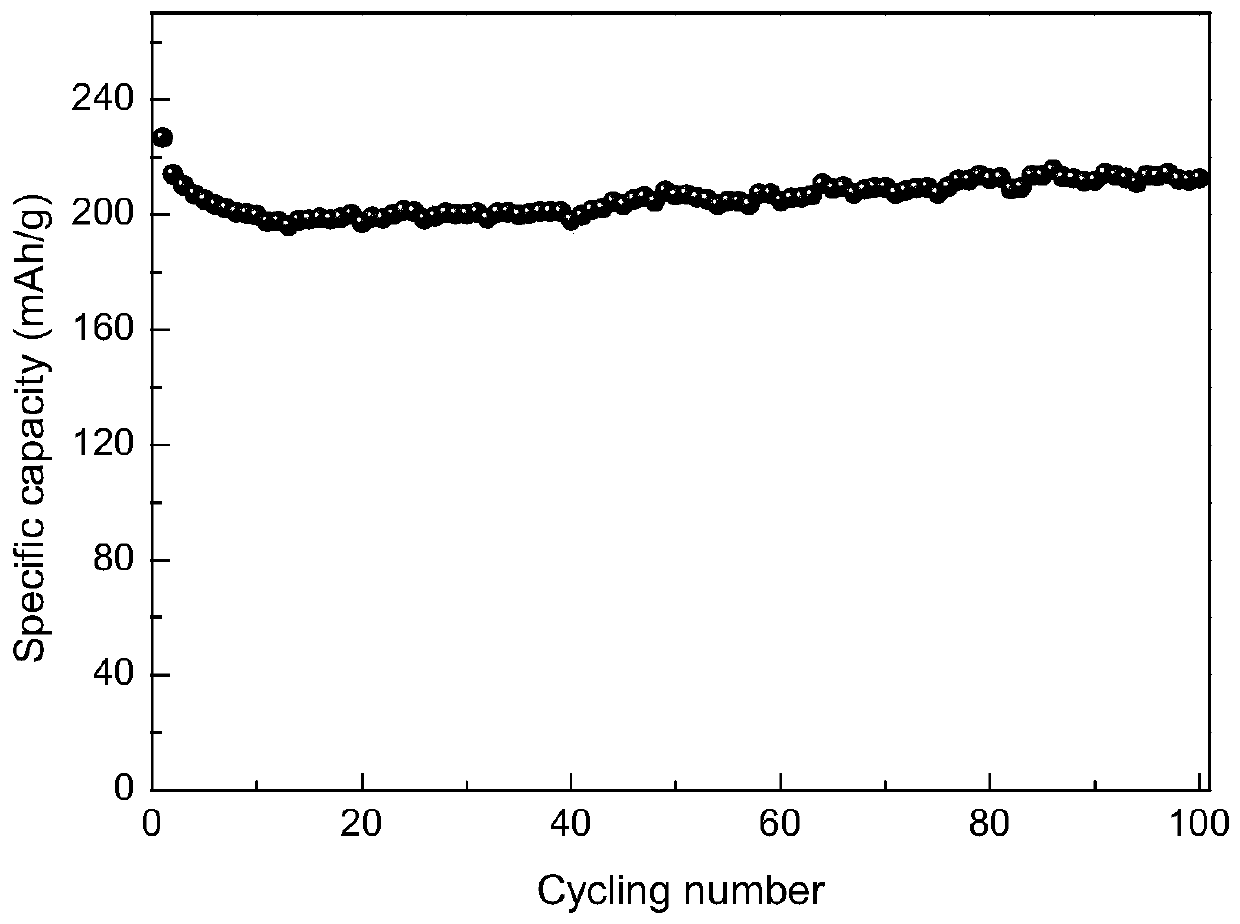

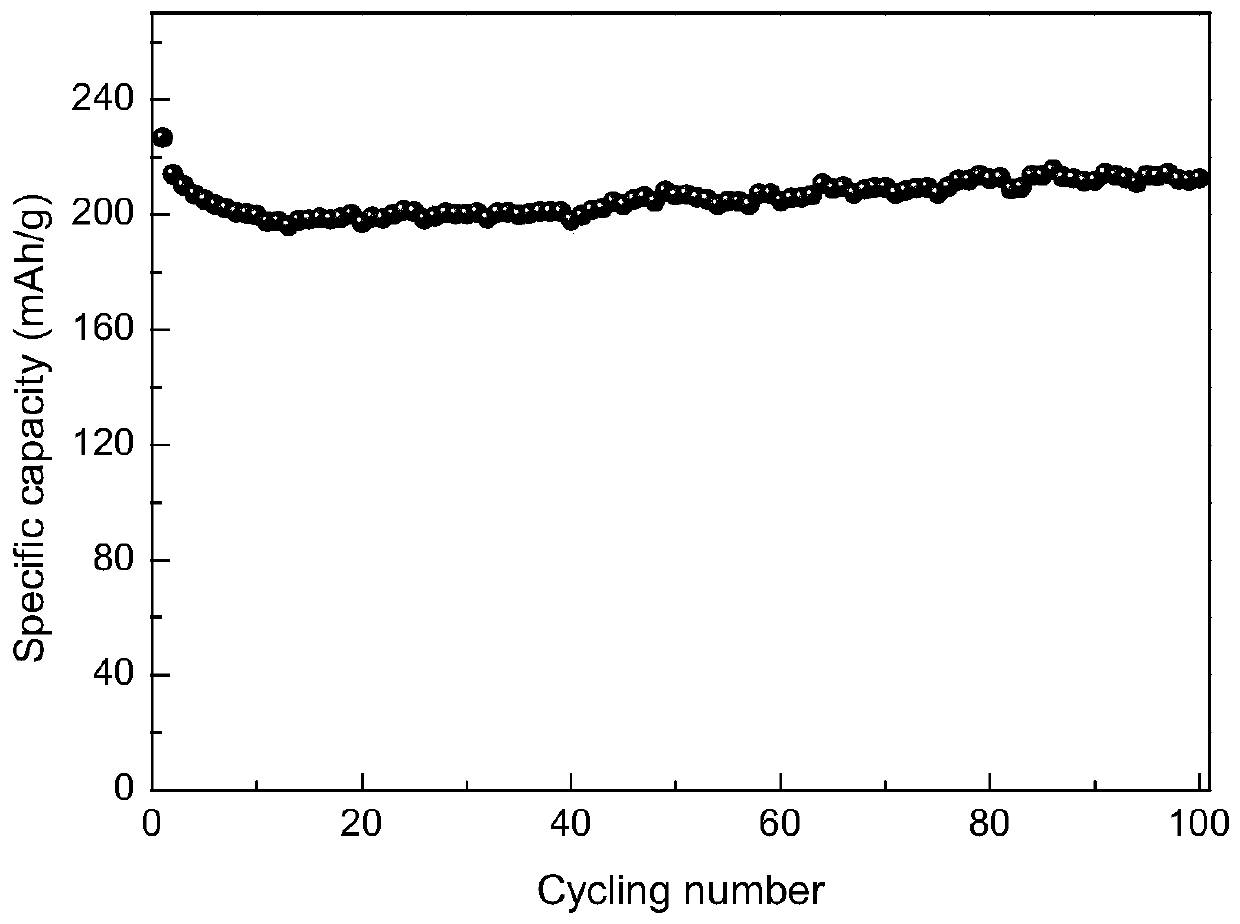

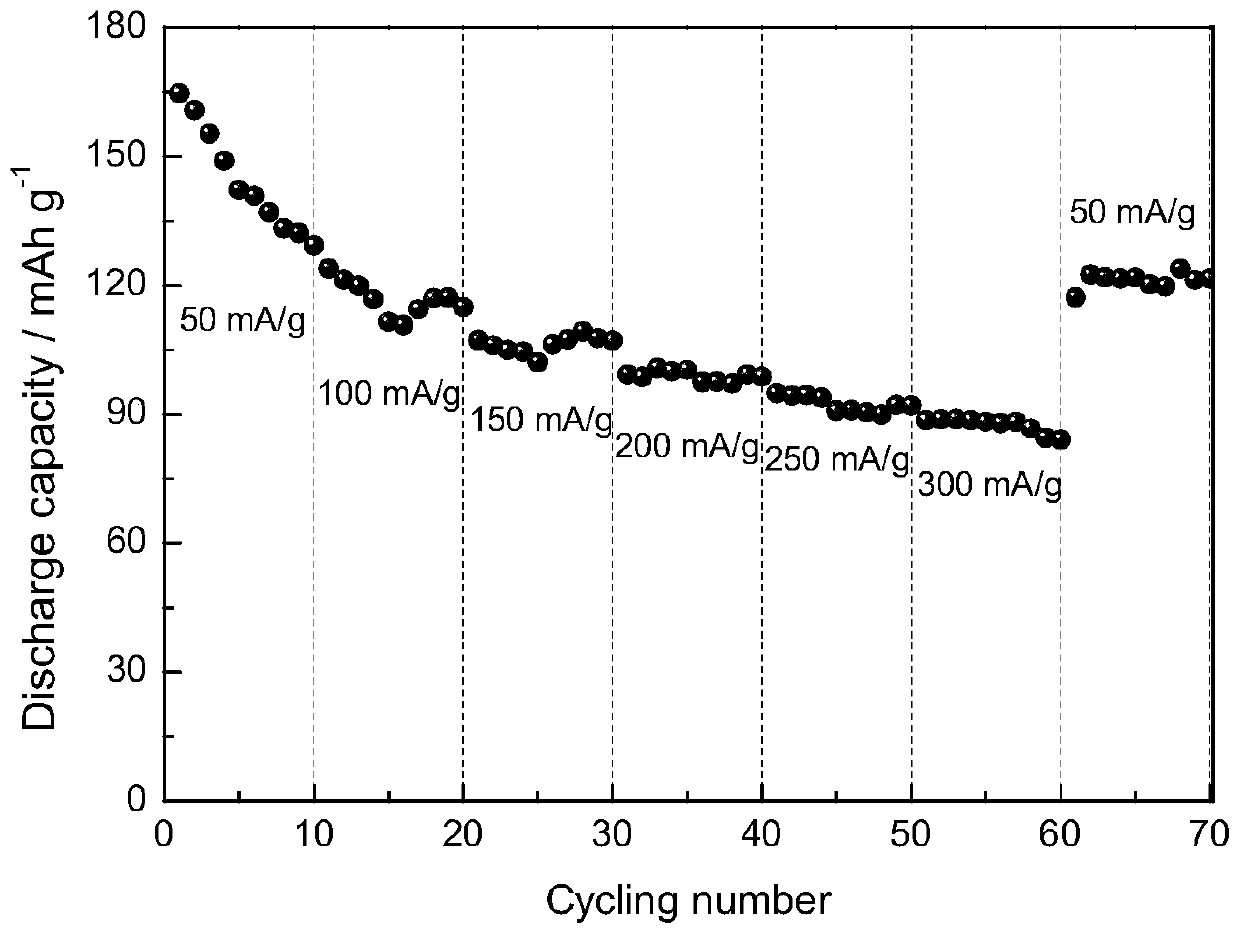

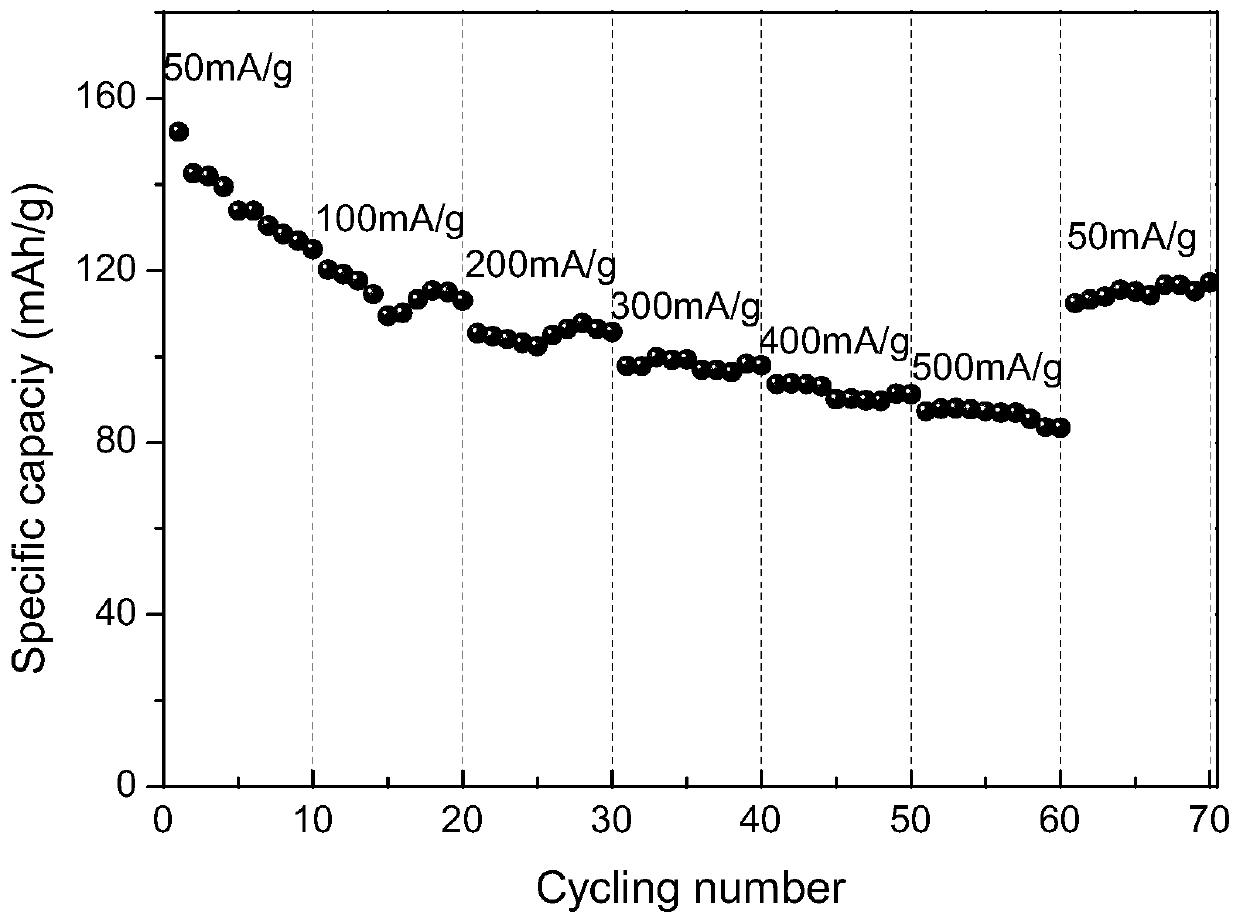

InactiveCN102891299BImprove electrochemical performanceConsiderable reversible capacityHybrid capacitor electrodesCell electrodesElectrical batterySmart grid

The invention discloses a lithium nickel cobalt manganese oxide sosoloid material and a preparation method thereof, and application of the lithium nickel cobalt manganese oxide sosoloid material serving as a cathode material of a high-rate and high-capacity secondary battery and a super capacitor. The chemical formula of the material is Li1+sigmaNixCoyMn1-x-yO2, wherein sigma is more than 0.0 and less than or equal to 12, x is more than 0.0 and less than or equal to 0.6, y is more than or equal to 0 and less than 0.5, and 1-x-y is more than 0.0 and less than or equal to 0.5. The invention also discloses a preparation method for the material. The method comprises the following steps of: preparing a precursor by a coprecipitation method; and obtaining the material by two-step solid phase sintering. The invention also discloses the material serving as the cathode material and application of the current lithium ion battery in compatibility with a mixed super capacitor. Compared with the prior art, the lithium nickel cobalt manganese oxide sosoloid material has the advantages that high-rate and high-capacity high charging and discharging cyclic performance is realized, and industrialization is easy to implement; discharging is executed by 1.6A / g(10C) current; a complete charging and discharging cycle is executed for more than 60 times within 2.5 to 4.3V; and the final discharging is 120mAh / g higher than the capacity. The material obtained by the invention can be used in the conventional lithium ion battery market and can be used for power supplies of an electric tool, an electric automobile and an intelligent power grid.

Owner:GUANGDONG KEPRIME ENERSTORE

A kind of wide potential window negative electrode material, its preparation method and application

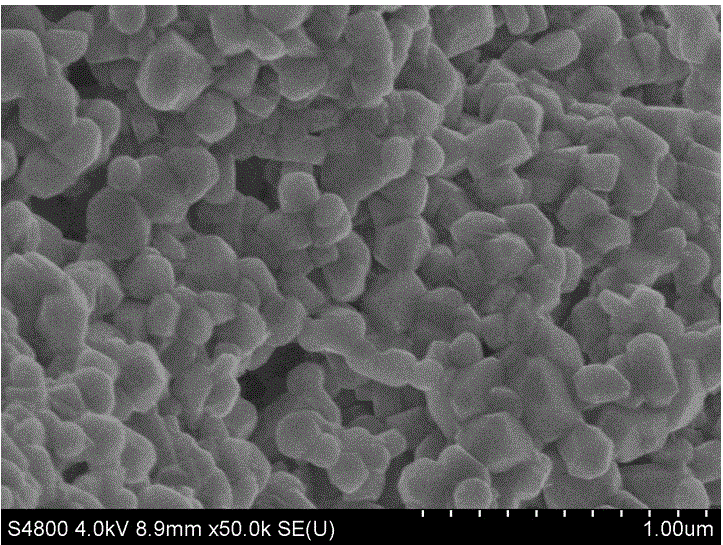

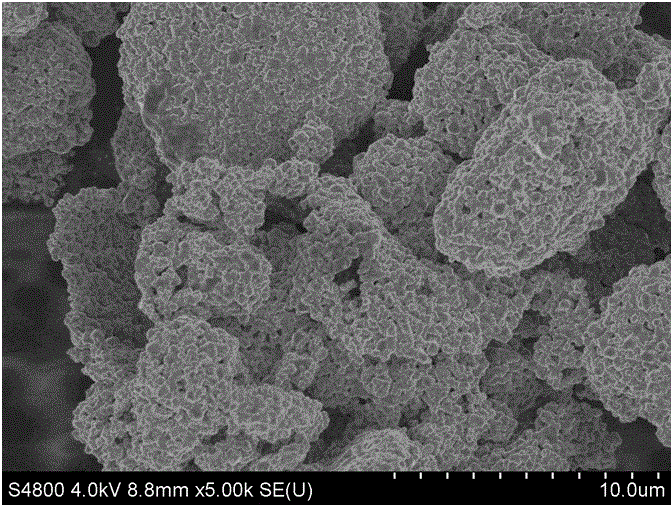

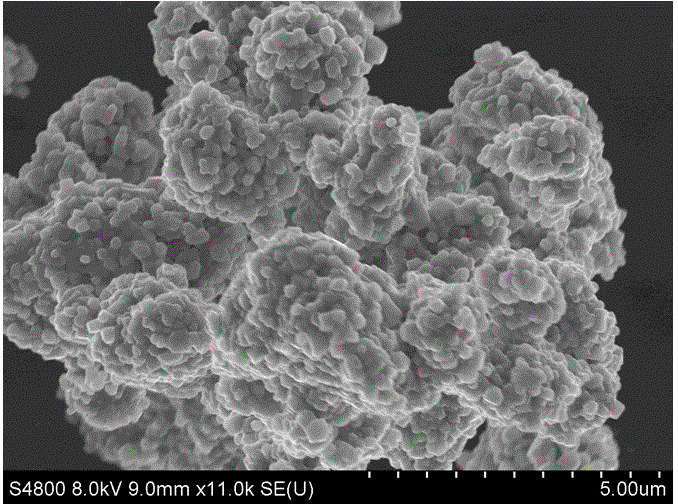

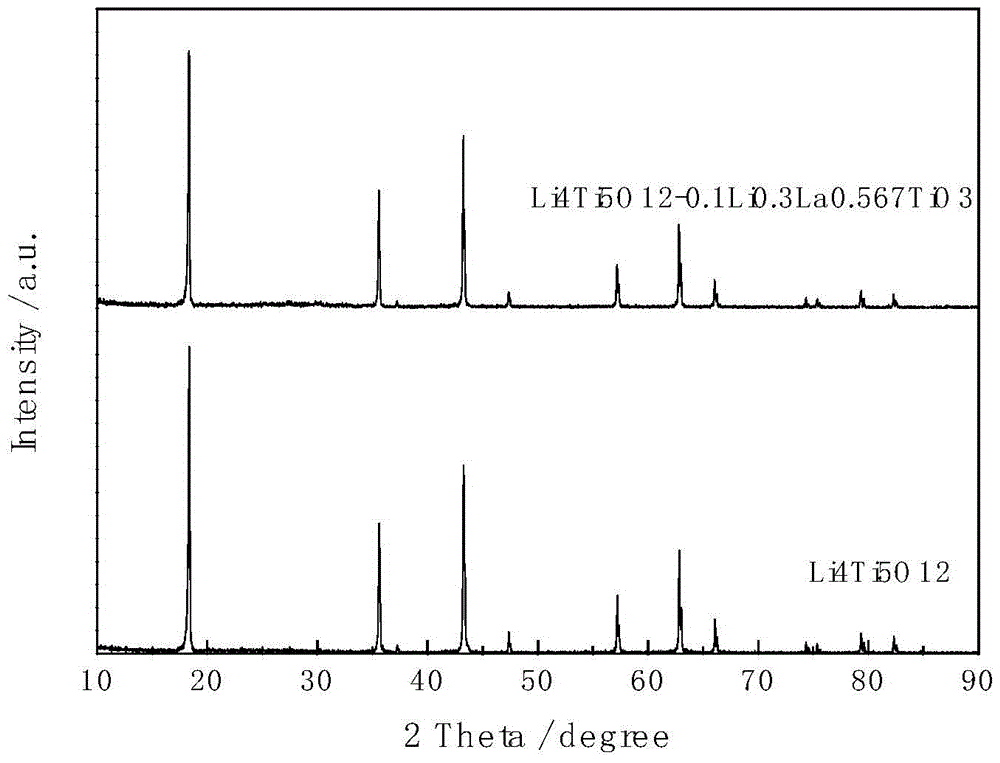

InactiveCN103985839BUniform particlesGood dispersionCell electrodesSecondary cellsOrganic solventReaction temperature

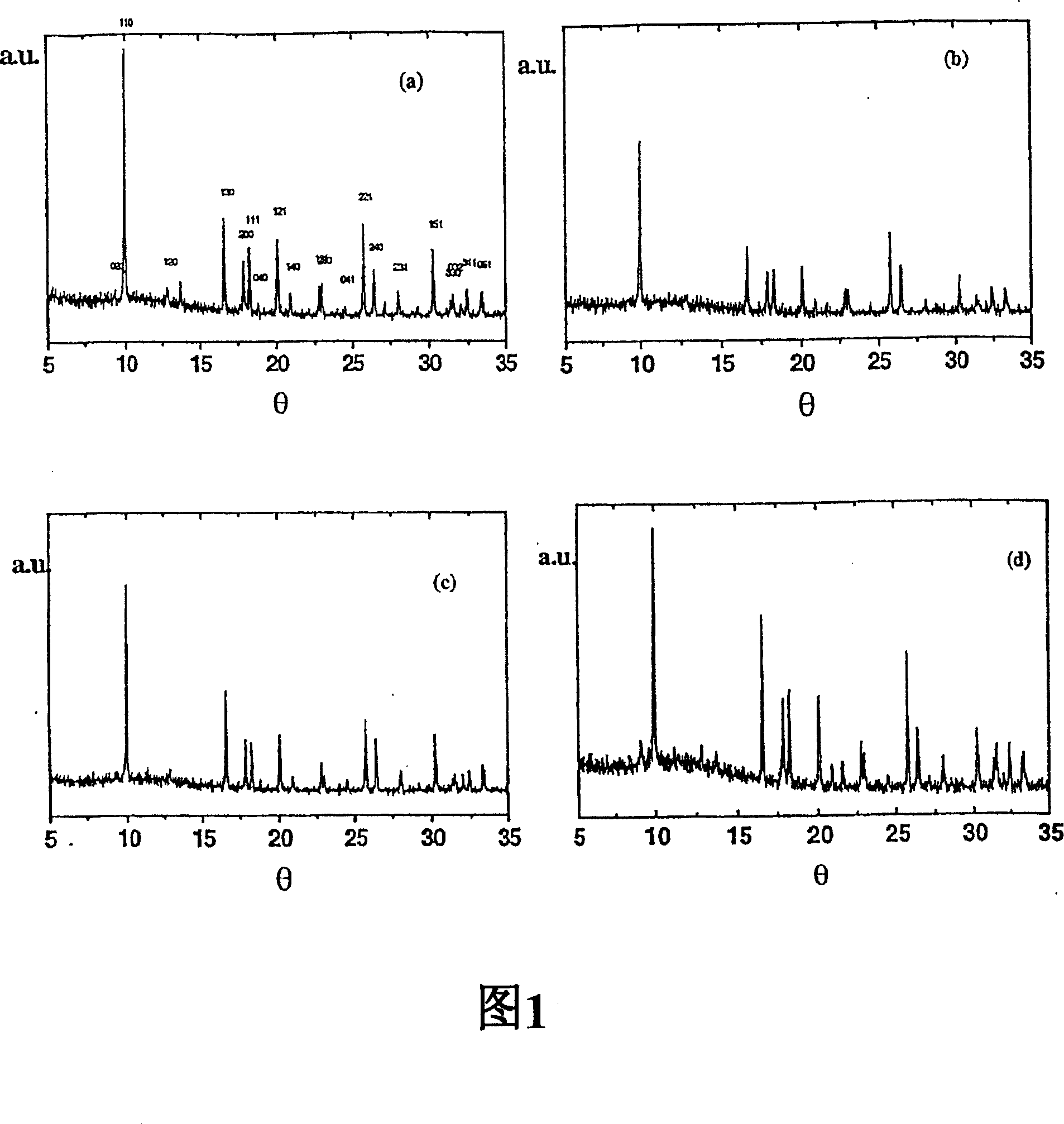

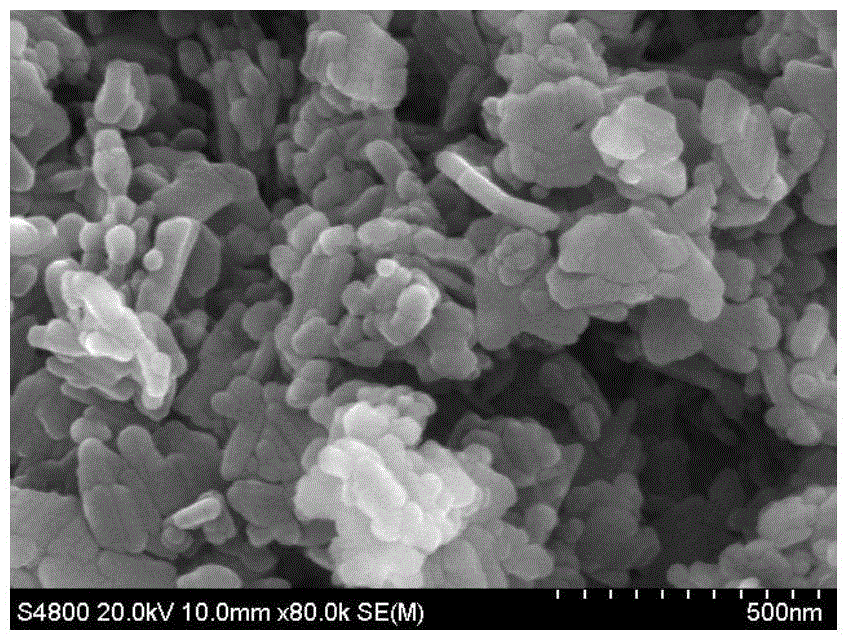

The invention provides a broad potential window negative electrode material. The material has a chemical formula: aLi4Ti5O12-bLi3xLa(2 / 3)-xTiO3 (3%<=b:a<=15%, 0.05<=x<=0.15). The negative electrode material has the advantages of uniform particles, good dispersibility, and high crystallization degree. Materials in different morphologies and particle sizes can be obtained through adjusting the organic solvent species, reaction temperature, and reaction time.

Owner:HEILONGJIANG UNIV

A kind of preparation method of chromium-based lithium ion battery composite negative electrode material

ActiveCN107742710BStable structureCompact structureMaterial nanotechnologyCell electrodesFiberCarbon fibers

The invention discloses a preparation method of a chromium-based lithium ion battery composite anode material, which belongs to the technical field of lithium ion batteries. The specific steps of themethod are as follows: titanium source, lithium source and chromium source are dissolved in an alcoholic solution, organic acid is added, amide is then added, agitation is carried out until gel is formed, preheating treatment is carried out after drying, calcination is carried out under 800 DEG C, and thereby Li5Cr7Ti6O25 is obtained; Li5Cr7Ti6O25 is added into a ferric nitrate solution and dispersed, and an ammonium dihydrogen phosphate solution is then dripped into the solution; suction filtration, washing and drying are carried out, so that an Li5Cr7Ti6O25-FePO4 precursor is obtained; carbon fibers are added into concentrated nitric acid, and after agitation and washing by water, nitrified carbon fibers are obtained; after the nitrified carbon fibers and the precursor are ball-milled and dried, roasting is carried out, and thereby a target product is obtained. The Li5Cr7Ti6O25 composite anode material has the characteristics of uniform grain size and stable and dense structure, andhas a stable multi-level composite structure, and such a structure ensures that the chromium-based lithium ion battery composite anode material has the characteristics of high capacity and long service life.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A kind of preparation method of lithium ion battery composite negative electrode material

ActiveCN107221659BImprove controllabilityGood reproducibilityCell electrodesSecondary cellsElectrical batteryOrganosolv

The invention discloses a preparation method of a lithium ion battery composite anode material and belongs to the technical field of lithium ion batteries. The molecular formula of the lithium ion battery composite anode material is BaNa2Ti6O14-aLi3xLa2 / 3-xTiO3(LLTO), wherein a is more than or equal to 0.1 and less than or equal to 0.4, and x is more than or equal to 0.05 and less than or equal to 0.15. The preparation method comprises the following concrete steps: putting a barium source, a sodium source and a titanium source into a ball milling tank, carrying out ball milling, then putting into a muffle furnace for pre-sintering, cooling, carrying out ball milling in a ball milling machine, sieving, then putting into the muffle furnace for roasting, cooling, and carrying out ball milling, so that an anode material precursor is obtained; and dissolving a lithium source, a lanthanum source, a titanium source and the anode material precursor into an organic solvent, stirring, then transferring into a closed reaction kettle, carrying out heat preservation, cooling, carrying out suction filtration, drying, and putting the obtained mixture into the muffle furnace to be roasted, so that the BaNa2Ti6O14-aLi3xLa2 / 3-xTiO3(LLTO) composite anode material is obtained. The preparation method disclosed by the invention has the advantages that raw material sources are wide, the operation is simple, the controllability is good, the reproducibility is high, and the obtained material is smaller in particle, uniform in particle size distribution and high in degree of crystallinity, so that preparation cost of the material is reduced and the electrochemical performance of the material is also improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

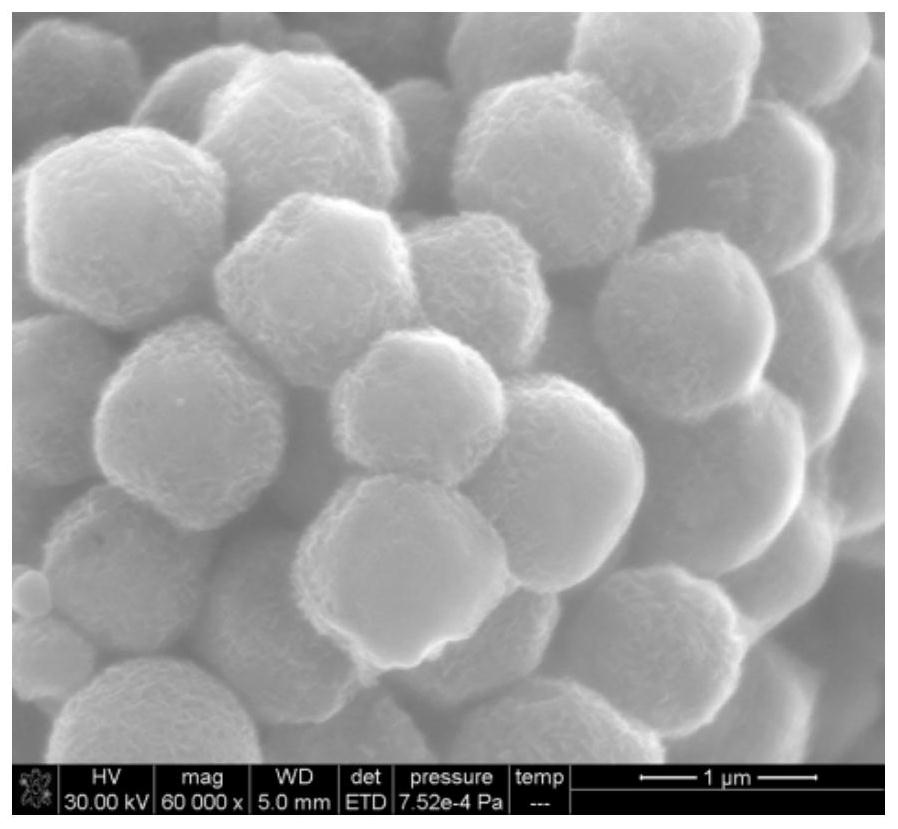

A kind of preparation method of spherical n-doped c-coated metal oxide negative electrode material with multi-level structure

ActiveCN108258223BUniform particle sizeStable structureCell electrodesSecondary cellsPyrrolidinonesCrystallinity

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A kind of preparation method of barium sodium titanate composite negative electrode material for lithium ion battery

ActiveCN107768635BStable structureCompact structureCell electrodesSecondary cellsBarium titanateSodium titanate

The invention discloses a preparation method of a sodium barium titanate composite negative material for a lithium ion battery, which belongs to the technical field of a lithium ion battery. The method comprises the following steps: dissolving sodium nitrate and barium nitrate into an alcohol aqueous solution, adding organic acid, and marking as a solution A; dissolving TiCl4 in the alcohol solution, and marking as a solution B; mixing the solution A and the solution B, stirring, and evaporating the liquid; then pre-burning in a muffle furnace, sintering, cooling to room temperature, ball milling to obtain a BaNa2Ti6O14 material; placing the BaNa2Ti6O14 material into a beaker, adding a surfactant and deionized water, ultrasonically dispersing, and then stirring; and then adding pyrrole andacid solution, adding oxidant, stirring in an icy water bath, washing, and obtaining the BaNa2Ti6O14@PPy composite negative material. The negative material is uniform in particle size, stable and compact in structure, remarkable in wide potential window reversibility, excellent in rate capacity and stable in cycling life.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A kind of network graphene nanomaterial and its preparation method and application

ActiveCN107128902BReduce pollutionIncrease profitMaterial nanotechnologyCell electrodesOrganic matterCvd graphene

Owner:DO FLUORIDE CHEM CO LTD

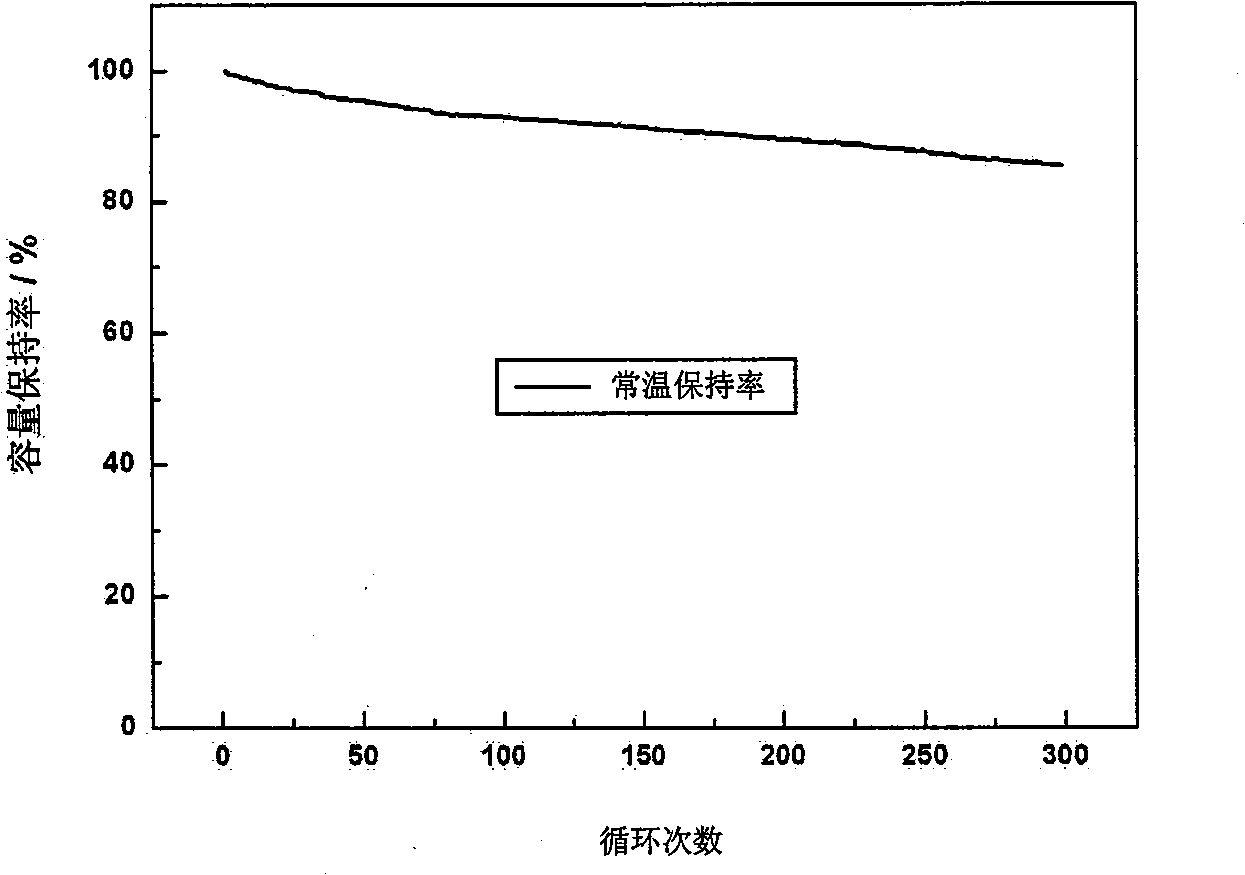

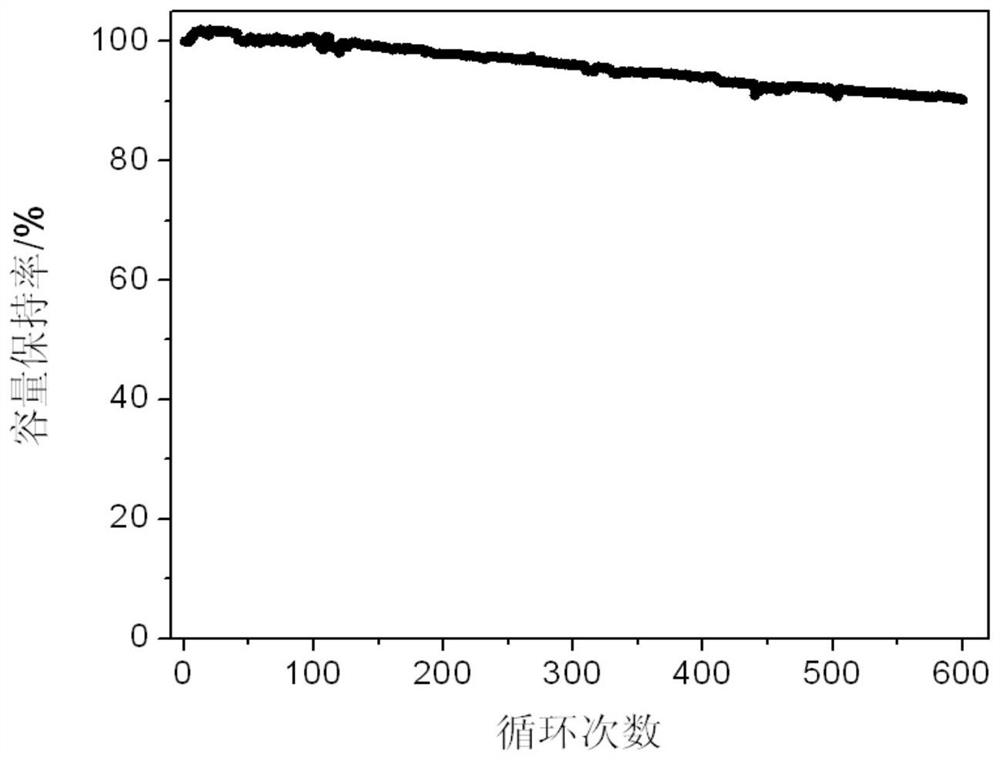

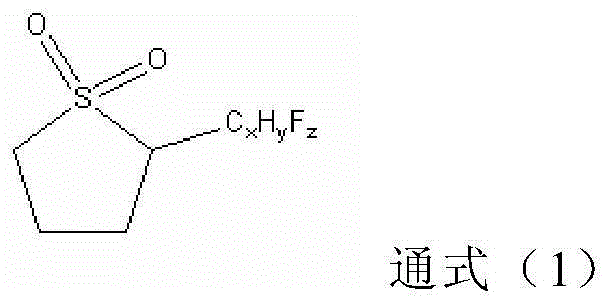

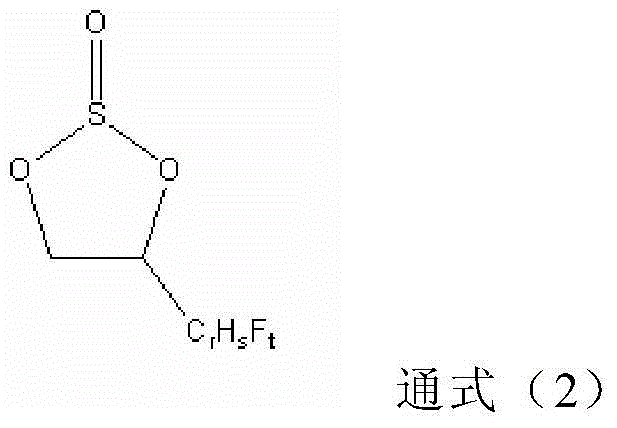

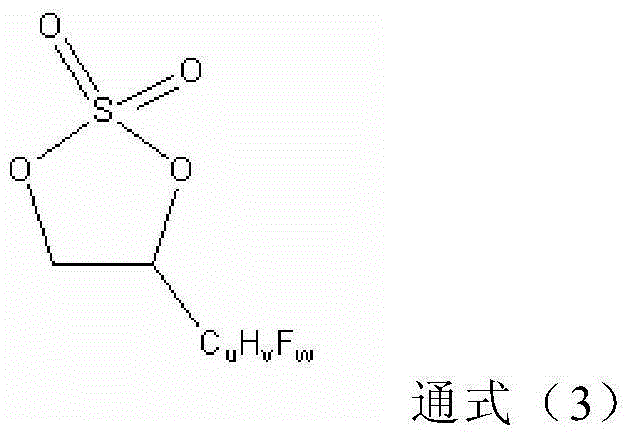

Lithium ion battery

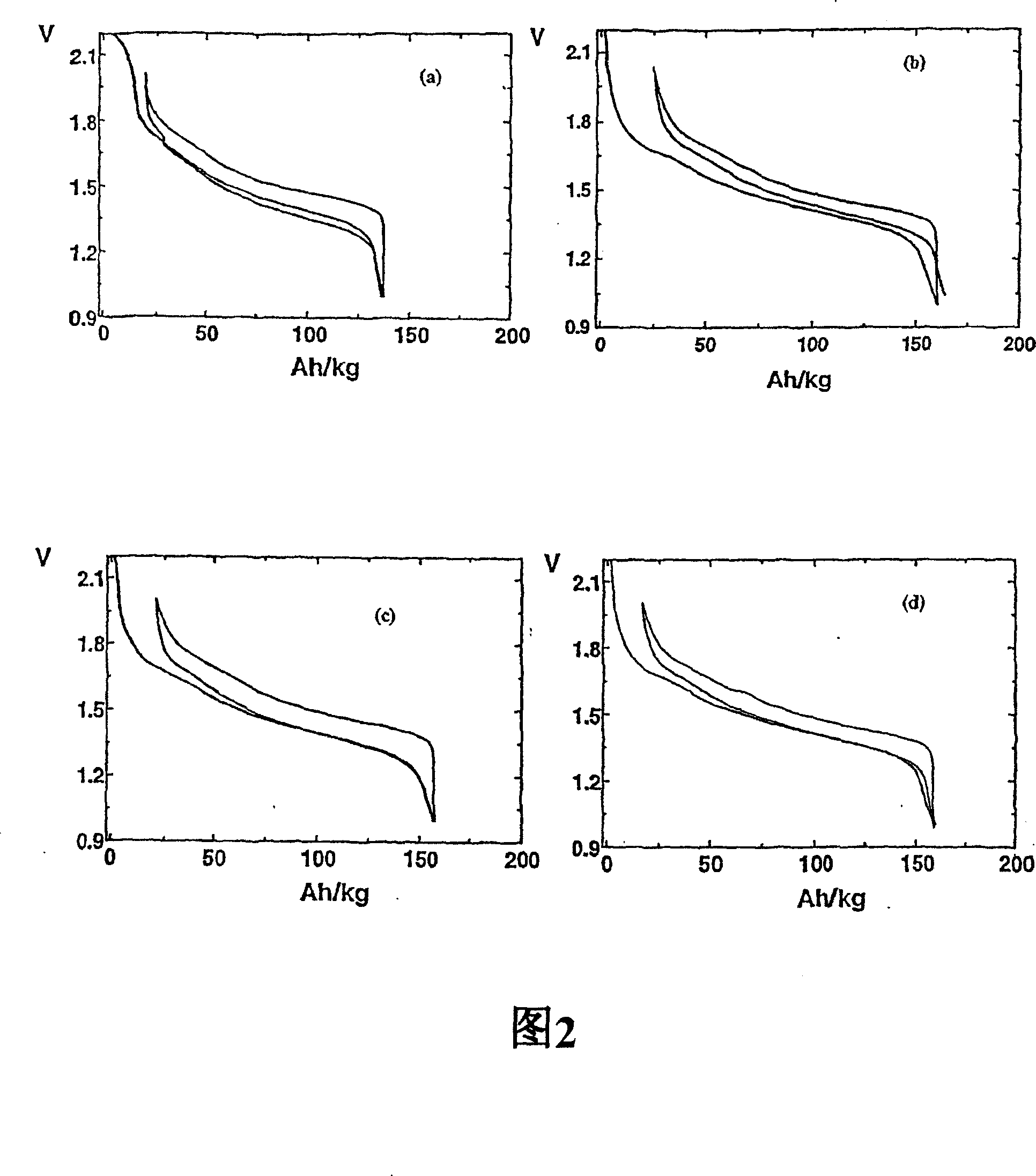

InactiveCN104362368ALow costConsiderable reversible capacityCell electrodesElectrolyte accumulators manufactureSulfolaneManganese

The invention discloses a lithium ion battery which comprises a positive electrode, a negative electrode and an electrolyte. The electrolyte comprises lithium salt and a solvent. The lithium ion battery is characterized in that an active material of the positive electrode is lithium-rich manganese-based solid solution; an active material of the negative electrode is lithium titanate; and the solvent contains fluorocarbonic ester and contains one or more additives selected from fluoromethyl sulfolane or its derivative, fluoromethyl glycol sulfite or its derivative and fluoromethyl ethylene sulfate or its derivative. A general formula of the lithium-rich manganese-based solid solution is xLi2MnO3.(1-x)LiMO2, wherein x is less than 1.8 and greater than 1.6; M is any one selected from Ni, Co, Mn, Cr, Ni0.5Mn0.5 and Ni1 / 3Mn1 / 3Co1 / 3. The lithium salt is one or more selected from LiPF6, LiBF4, LiClO4, LiAsF6, LiBOB and LiCF3SO3. Reversible capacity is greater than 250 mAh / g. Energy density is greater than that of other traditional cathode materials, and high-temperature performance is excellent.

Owner:QINGDAO QIANYUN HIGH TECH NEW MATERIAL

A kind of preparation method of sodium lithium titanate negative electrode material with hierarchical structure

ActiveCN107742718BStable structureCompact structureCell electrodesSecondary cellsElectrical batterySodium titanate

The invention discloses a preparation method of a lithium sodium titanate negative electrode material with a multistage structure, and belongs to the technical field of lithium ion batteries. The method comprises the following specific steps: dissolving tetrabutyl titanate, lithium acetate and sodium nitrate in an alcohol solution, adding citric acid to serve as a chelating agent, then adding an amine compound, stirring to form gel, and performing vacuum drying; then mixing gamma-LiAlO2 with the dried gel, performing ball milling, performing preheating treatment in the air, then performing ball milling and calcining to obtain a Na2Li2Ti6O14@gamma-LiAlO2 material; putting the Na2Li2Ti6O14@gamma-LiAlO2 material into distilled water, performing ultrasonic treatment and adding sodium dodecyl benzene sulfonate; and pouring a dissolved pyrrole solution into the mixture, stirring, adding an initiator, centrifuging, washing and drying to obtain a target product. The synthesized negative electrode material has the advantages of uniform and consistent particles, high dispersity and high degree of crystallinity; with a stable multistage composite structure, the negative electrode material hasconsiderable wide-potential-window reversible capacity, high rate performance and stable cycle life.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

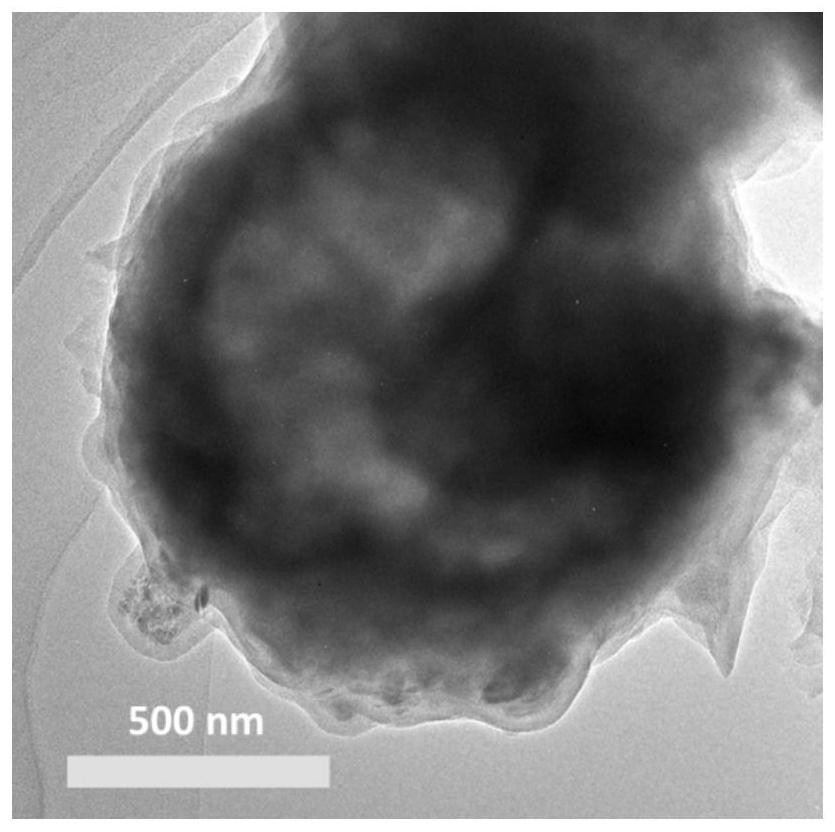

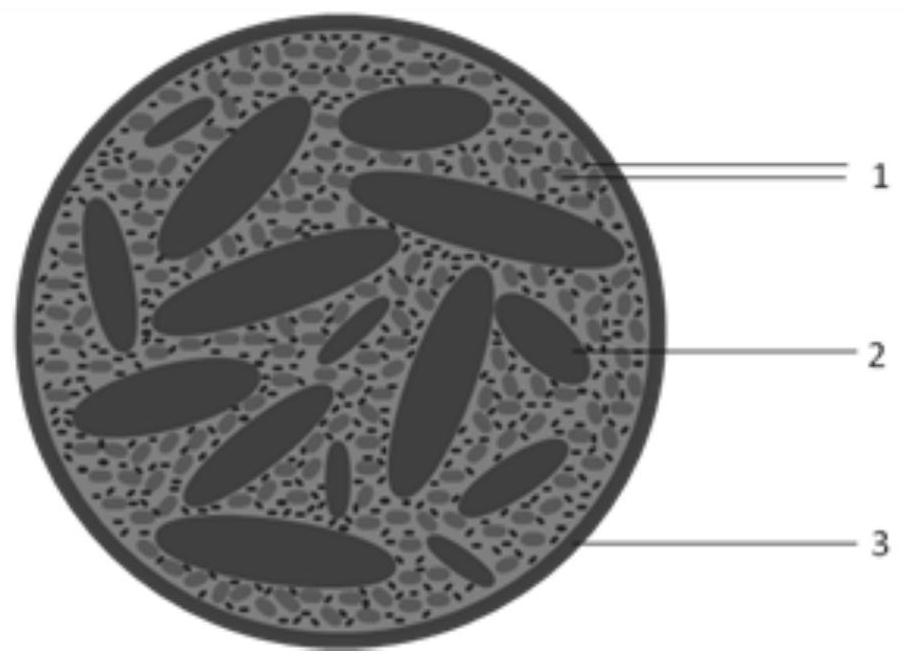

Core-shell type composite negative electrode material as well as preparation method and application thereof

PendingCN111952550AImprove conductivityImprove bindingNegative electrodesLi-accumulatorsCarbon coatingBattery cell

Owner:BTR NEW MATERIAL GRP CO LTD +1

Lithium ion battery and preparation method thereof

ActiveCN103022555BLow costIncrease energy densityFinal product manufactureCell electrodesSulfolaneHigh energy

The invention relates to a lithium ion battery and a preparation method thereof. The lithium ion battery comprises a positive pole, a negative pole and electrolyte, wherein the electrolyte comprises lithium salt and a solvent; an active material of the positive pole is a rich lithium manganese base solid solution; an active material of the negative pole is lithium titanate; and the solvent comprises additives of one or more selected from fluoro carbonic ester, fluoro methyl sulfolane or derivatives of the fluoro methyl sulfolane, fluoro methyl sulphurous acid vinyl ester or derivatives of the luoro methyl sulphurous acid vinyl ester, and fluoro methyl sulfuric acid vinyl ester or derivatives of the fluoro methyl sulfuric acid vinyl ester. The preparation method comprises the following steps of: preparing a positive pole piece; preparing a negative pole piece; coiling or overlapping the obtained positive and negative pole pieces and a diaphragm so as to prepare a battery cell; putting into a shell or wrapping by a membrane; drying; injecting the electrolyte and sealing an opening; standing and forming; and subsequently aging, degassing, sealing, capacity dividing and detecting so as to obtain the lithium ion battery. The battery has the characteristics of high energy density, high security, low cost and long service life.

Owner:WUXI FUHONG TECH +1

A kind of preparation method of double metal oxide composite negative electrode material with multi-level structure

ActiveCN107732206BStable structureCompact structureMaterial nanotechnologyCell electrodesIce waterActive agent

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A modified n, p co-doped lithium titanate negative electrode material and preparation method thereof

ActiveCN111403724BImprove conductivityUniform particle sizeCell electrodesSecondary cells servicing/maintenanceSodium phosphatesElectrical battery

The invention provides a modified N, P co-doped lithium titanate negative electrode material and a preparation method thereof, and specifically relates to the technical field of lithium ion battery negative electrode materials. 2 O and anatase are mixed to obtain a precursor. Put the precursor and anhydrous sodium hypophosphite in a tube furnace and feed NH 3 and N 2 The mixed gas is heated to 800°C to obtain a nitrogen and phosphorus co-doped lithium titanate material. Add petroleum pitch, inorganic substances, organic solvents, and nitrogen-phosphorus co-doped lithium titanate particles into a 100 mL round-bottomed flask, mix well, and remove the organic solvent by rotary evaporation. The mixture after removing the organic solvent was moved into a tube furnace, and passed through H 2 Mix gas with Ar and raise the temperature to 800-850°C and keep the temperature constant for 1h, then cool down to 400°C and keep the temperature for 1h. After cooling down to room temperature, use 1 mol / L hydrochloric acid to remove the inorganic substances in the mixture, centrifuge and wash, and then vacuum-dry for 12 hours to obtain the product. The invention can ensure uniform and dense dispersion of the entire composite material, thereby maintaining the stability and high conductivity of the electrode structure.

Owner:JIANGSU AOXIN TECH DEV

Nano-structure lithium battery positive electrode material and preparation method thereof

InactiveCN110890533AConsiderable reversible capacityImproved magnification performanceMaterial nanotechnologyCell electrodesNano structuringCross linker

The invention discloses a nano-structure lithium battery positive electrode material and a preparation method thereof. The nano-structure lithium battery positive electrode material is formed by co-doping a two-dimensional V2O5 nanosheet, zero-dimensional Ag nanoparticles and one-dimensional nano TiO2, wherein the weight ratio of Ag to TiO2 to V2O5 is (5-10): (10-20): 100. According to the invention, a liquid phase self-assembly method based on Van der Waals' force is adopted, and one-dimensional nano TiO2 and Ag nano particles are ingeniously and simply assembled on the surface of a V2O5 nanosheet. The self-assembly method has the characteristics of low cost, high efficiency and energy conservation, and can accurately control the load density and distribution of the nanorods and the nanoparticles. The Van der Waals' force-based liquid phase self-assembly method is adopted, and an external cross-linking agent is not introduced, so that the method has the advantages of low cost and mildness compared with a method for preparing the composite material by utilizing a complexing effect.

Owner:南通意华新材料科技有限公司

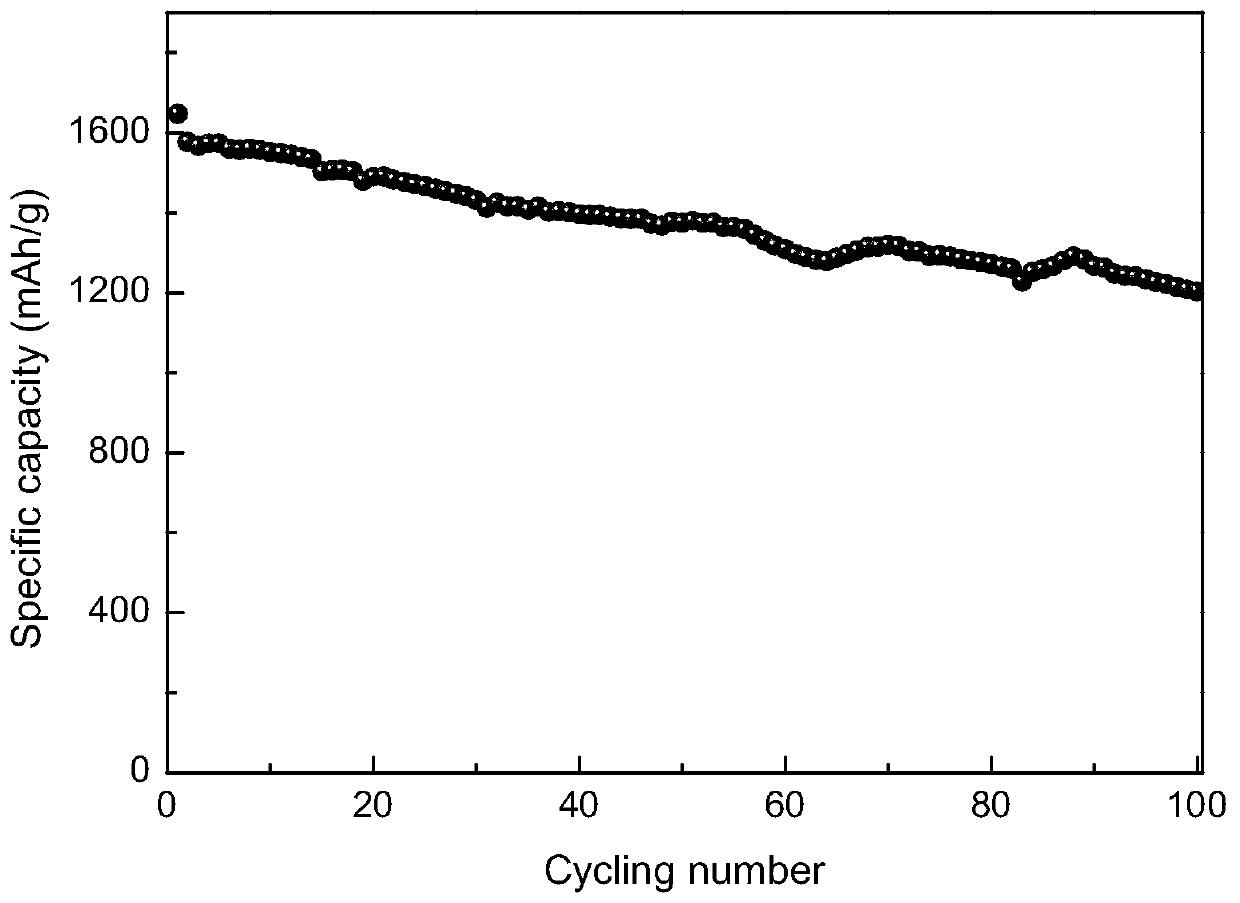

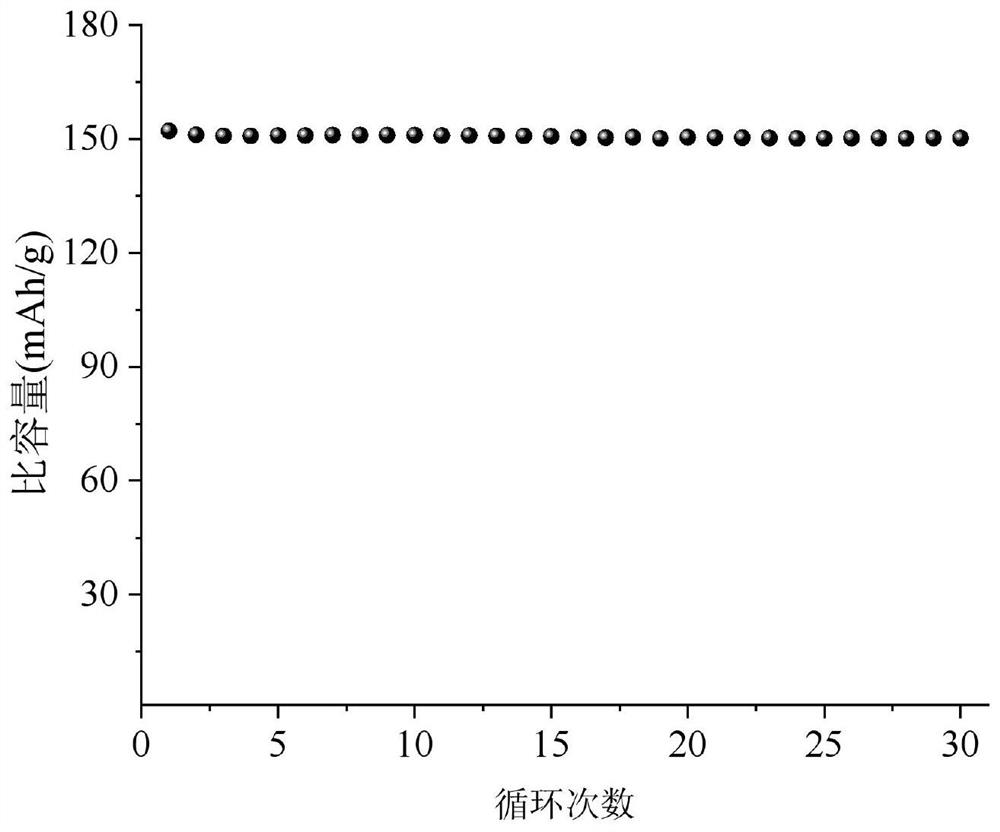

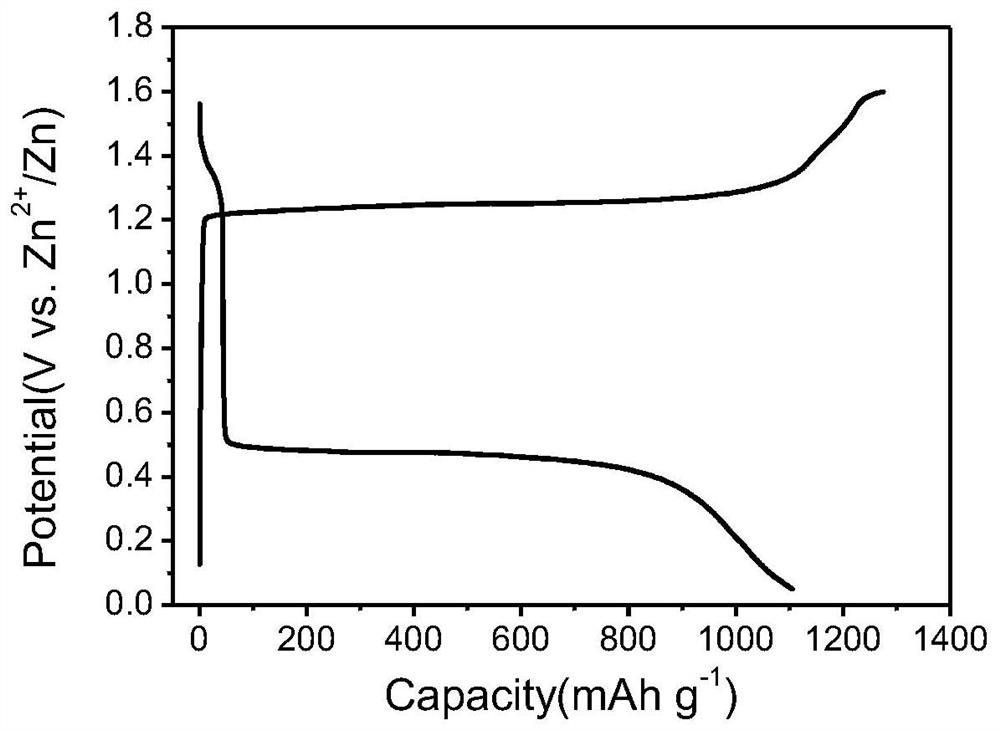

An aqueous solution-based zinc-based battery cathode material, its preparation and application

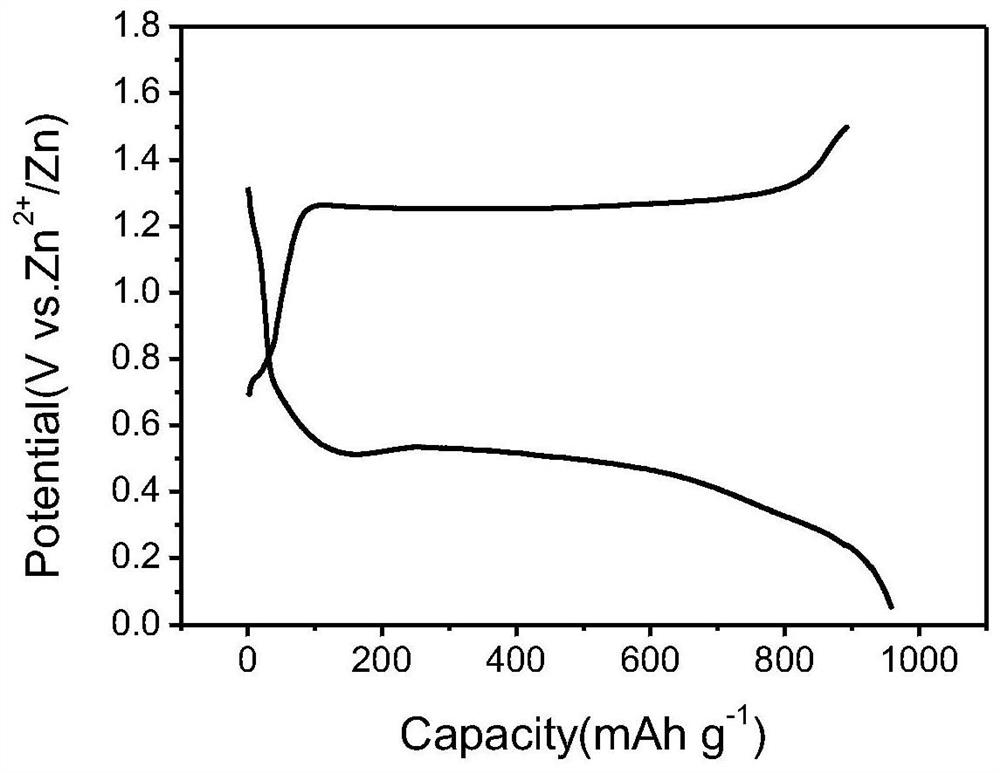

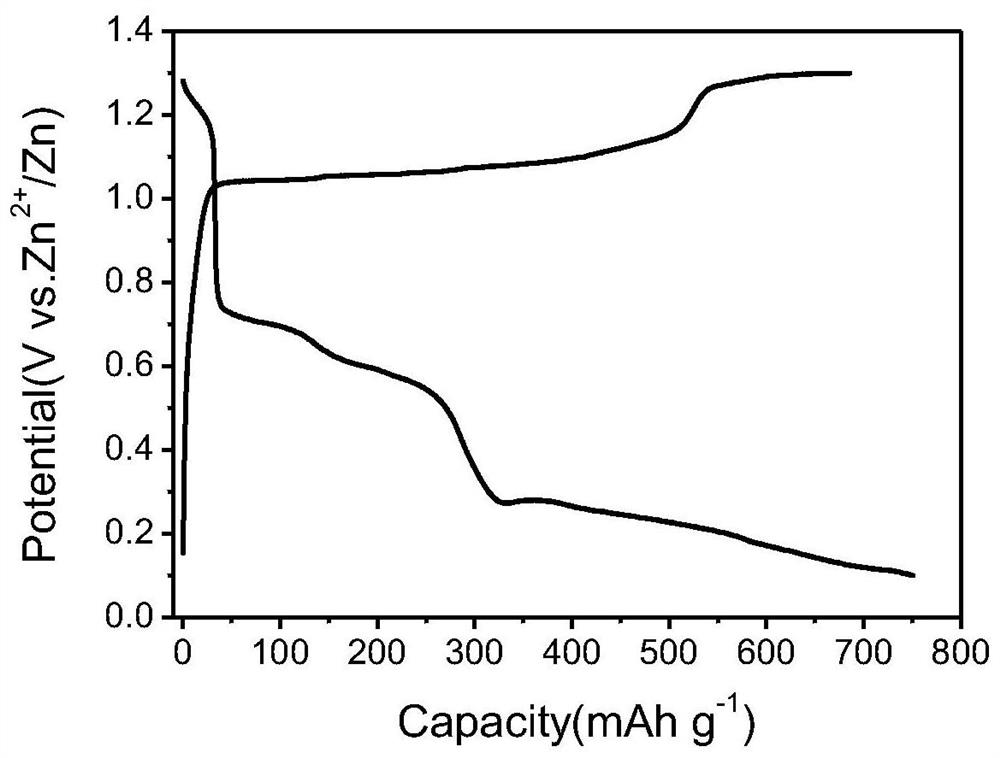

ActiveCN109888254BHigh reversible capacityIncrease energy densityCell electrodesSecondary cellsPhysical chemistryConductive materials

The invention belongs to the field of aqueous solution zinc-based batteries, and more specifically relates to an aqueous solution-based zinc-based battery cathode material, its preparation and application. The active material is elemental iodine, chalcogenide elements or compounds formed by chalcogenide elements; the conductive material is conductive and has a porous structure; wherein the conductive material not only plays a conductive role, but also utilizes its porous structure It can absorb or coat the active material, and prevent the active material from being dissolved and invalidated. It is used as a positive electrode material for zinc-based batteries based on aqueous solutions, especially as a positive electrode material for rechargeable aqueous zinc-based batteries, with high reversible capacity, energy density and cycle stability.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com