Negative electrode for lithium batteries

A lithium battery and negative electrode technology, applied in the field of rechargeable lithium batteries, can solve the problems of not improving performance and limiting reversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

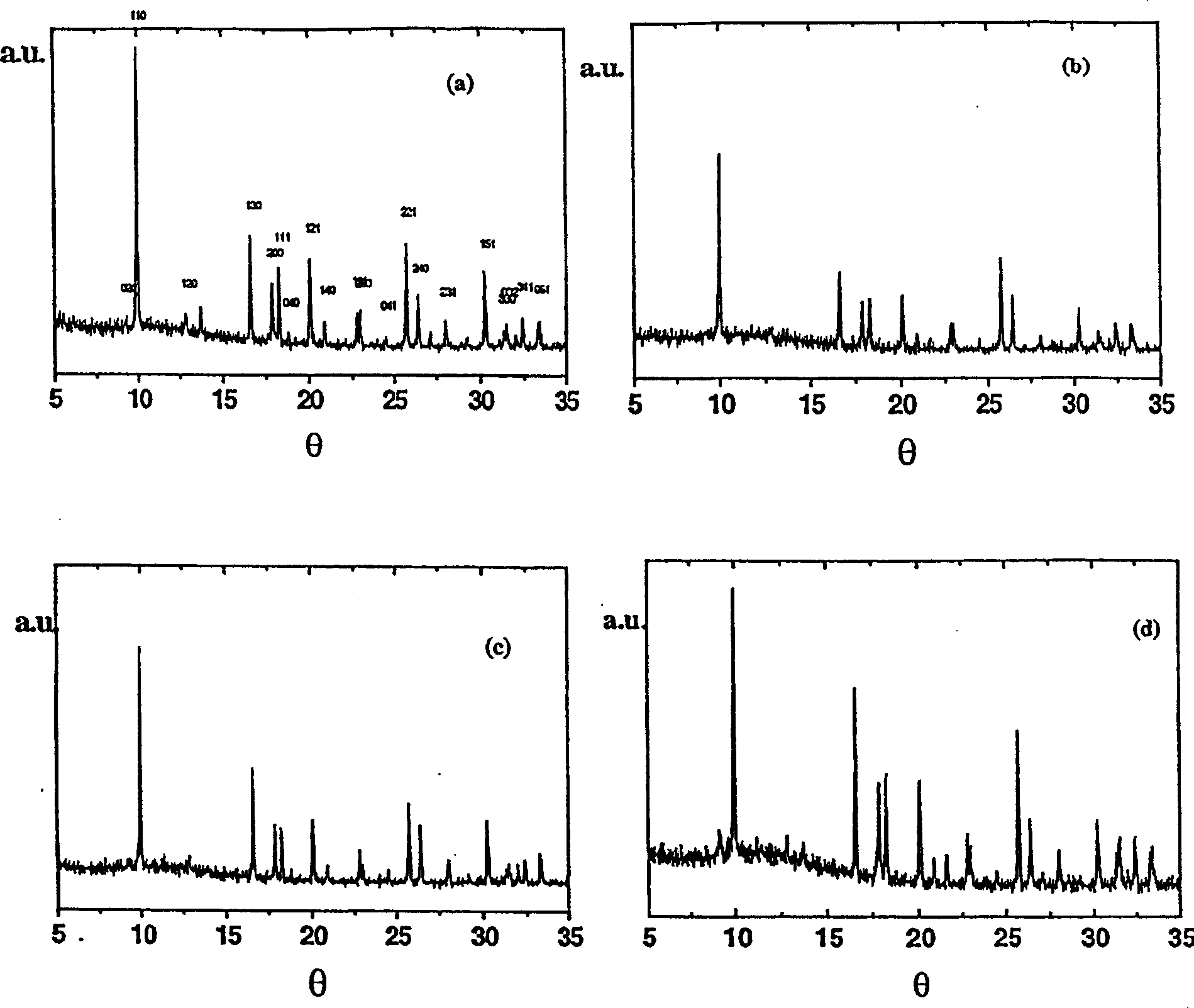

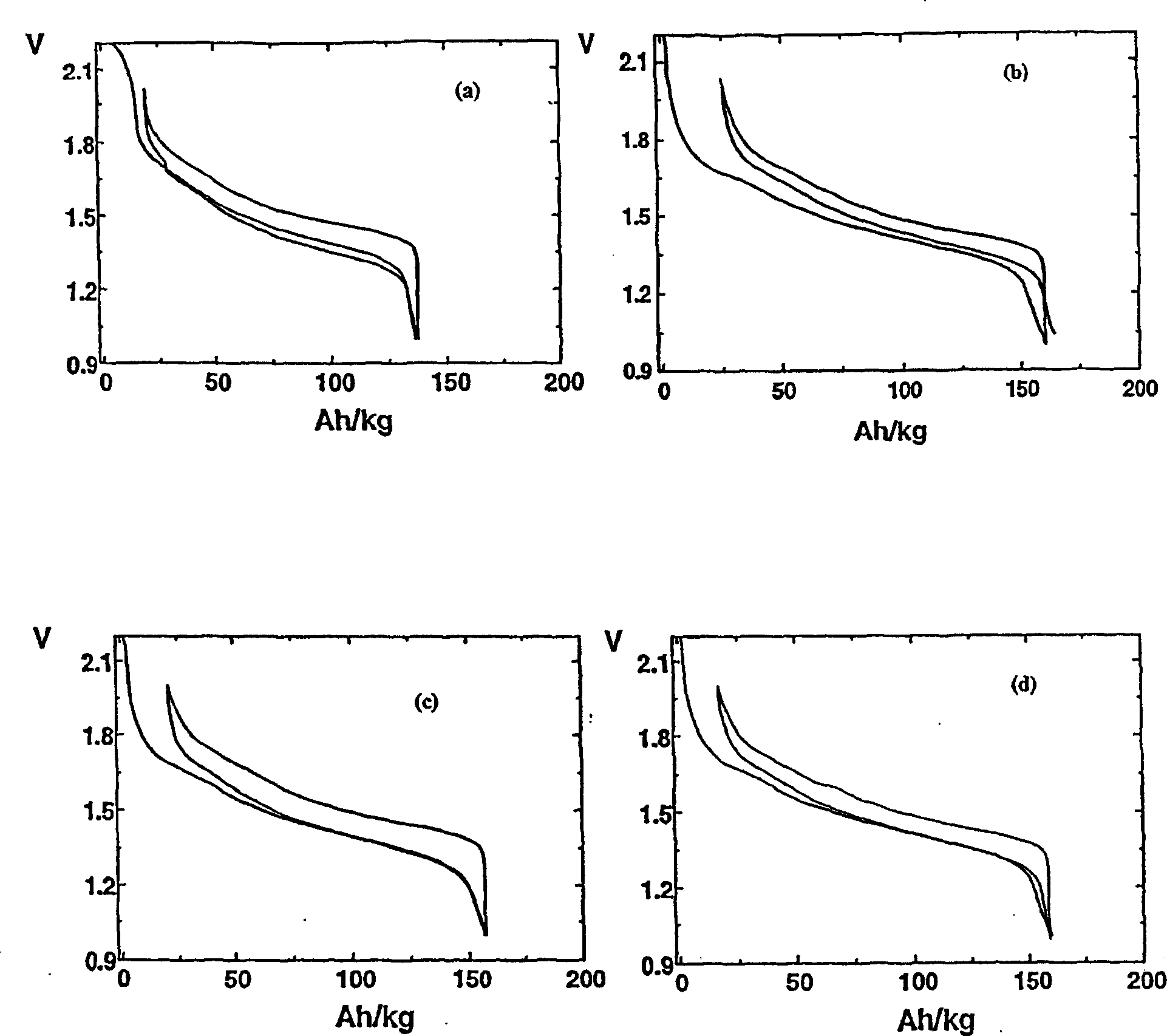

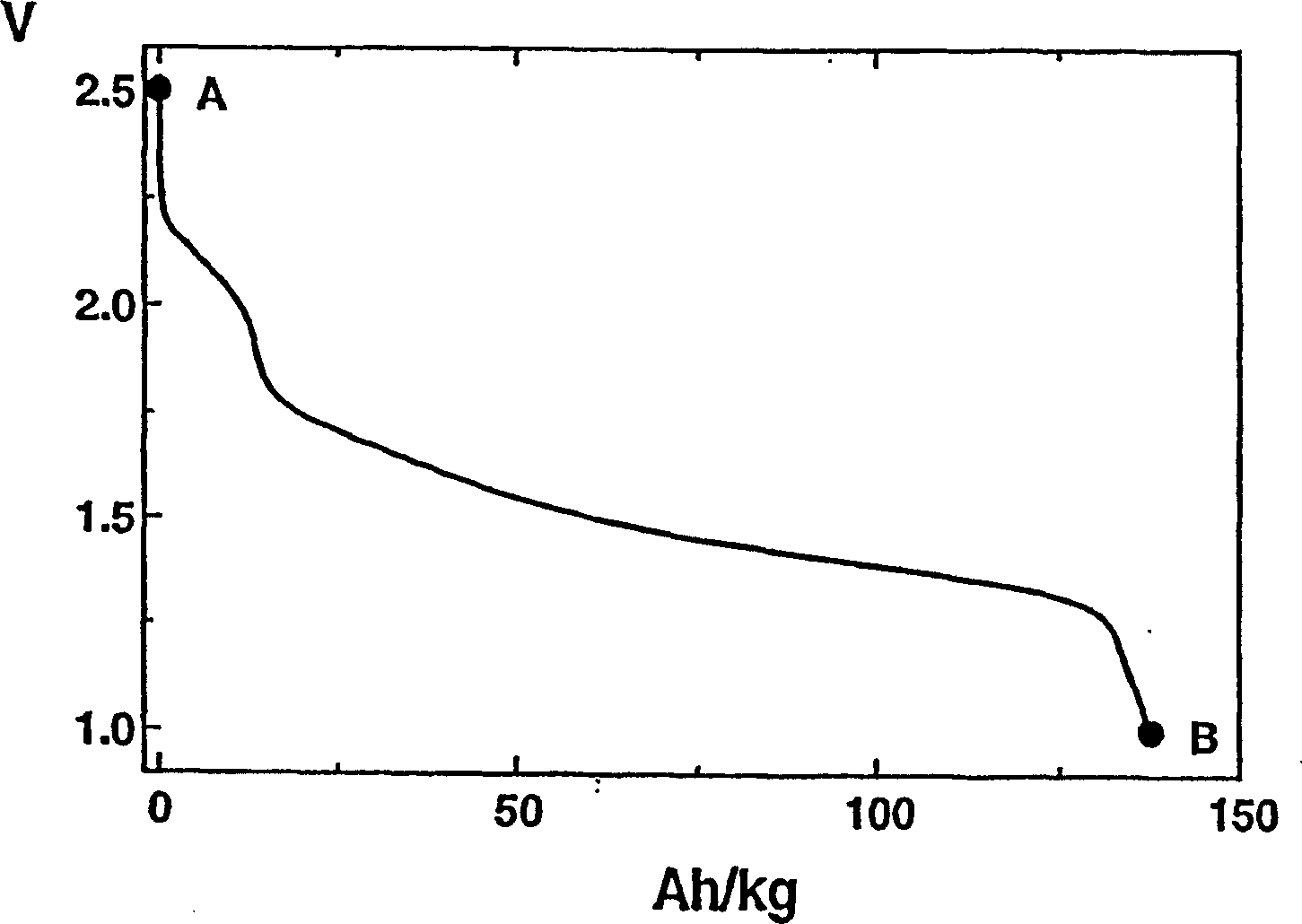

[0021] Orthorhosite Li used as a negative electrode in lithium-ion batteries 2 Ti 3 o 7 The electrochemical properties are based on a single-phase intercalation mechanism of lithium ions without modification of the host compound. Such a mechanism requires good stability of the host network, vacancies for intercalation of lithium, and the presence of electrochemically active cations, in this case Ti 4+ . Li 2 Ti 3 o 7 The structure can be obtained from shared octahedra with channels in TiO 6 The edge and surface description of is partially occupied by lithium atoms (2 Li atoms for 7 O atoms) of the host element. These channels are easily filled by electrochemically intercalated lithium ions. The crystalline sites of titanium are not fully occupied, and the vacancies (0.5 vacancies for 7 O atoms) can be occupied by lithium of the host material. This description can be summarized as Li 2 Ti 3 o 7 The expansion of is:

[0022] (Li 2-x Vα 1.5+x ) channel (Ti 3 Li ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com