Preparation method of lamellar lithium manganese battery

A technology of layered lithium manganate and a production method, which is applied in the manufacture of electrolyte batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problem of low energy density of lithium iron phosphate, poor high temperature performance of spinel lithium manganate, ternary The problem of poor material safety performance, etc., achieves the effect of low cost, excellent high temperature performance and high energy density

Active Publication Date: 2011-02-02

BTR NEW MATERIAL GRP CO LTD

View PDF4 Cites 49 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The above-mentioned materials are not widely used in lithium-ion batteries, especially in power batteries, due to the defects of varying degrees, such as the low ene

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

Login to View More

Abstract

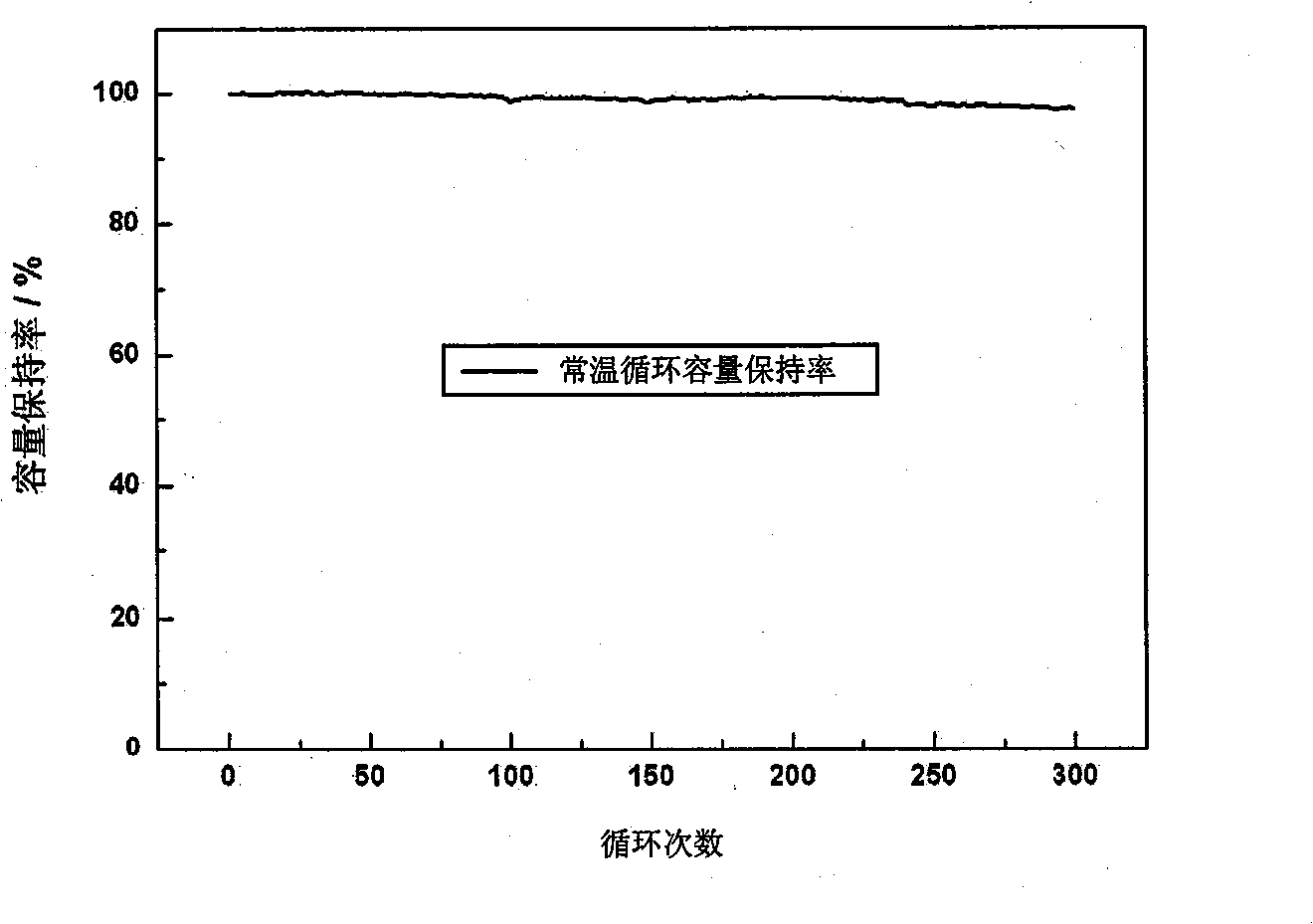

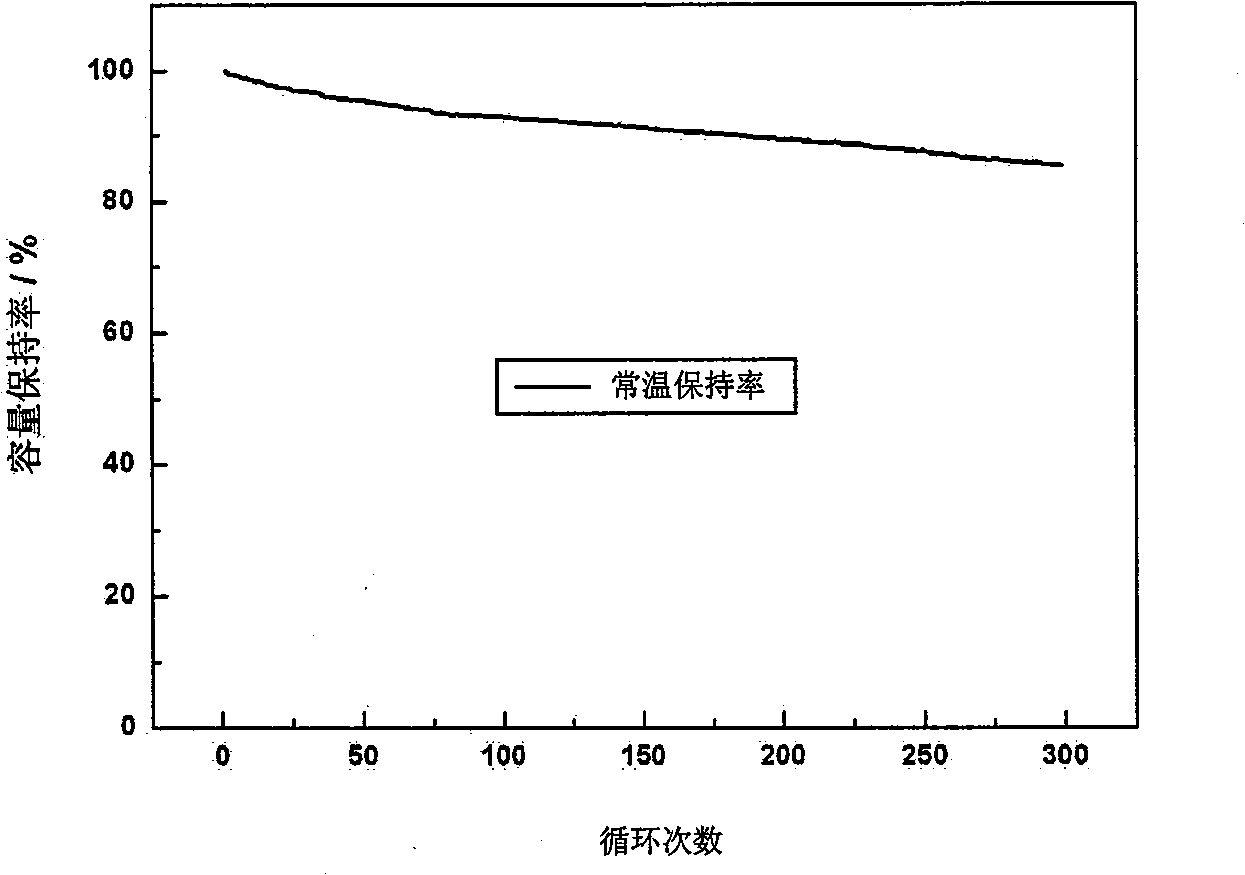

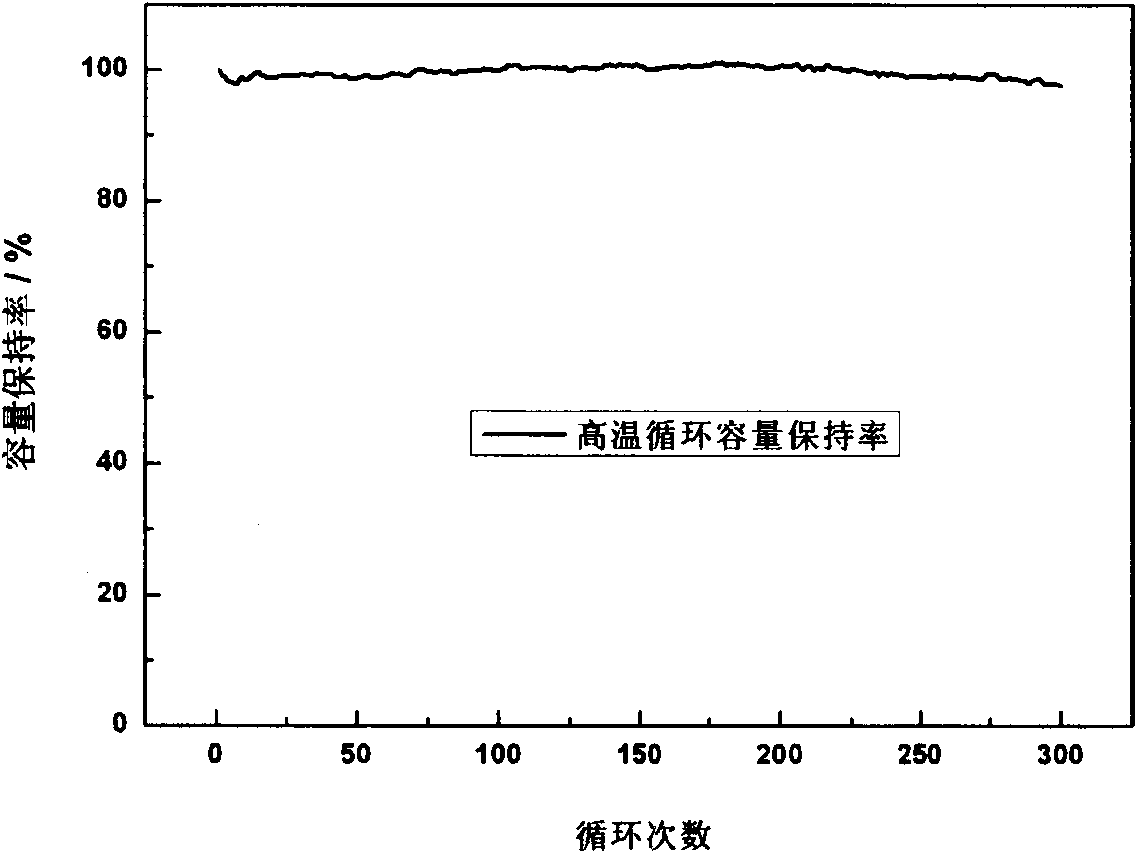

The invention discloses a preparation method of lamellar lithium manganese batteries, solving the technical problems of reducing the cost of lithium batteries, improving the high-temperature performance of the lithium batteries and simultaneously improving the energy density of the batteries. The preparation method of lamellar lithium manganese batteries comprises the following steps of preparing anode slurry, preparing cathode slurry, coating, baking, cutting and pressing to make a battery monomer. Compared with the prior art, the invention uses lamellar lithium manganese as anode active materials to make the battery monomer, and the lamellar lithium manganese is such a material that is rich in lithium and manganese, contains less nickel and no cobalt and has low cost; the lamellar lithium manganese batteries have visible reversible capacity at high voltage, is higher than 250 mAh/g when being charged to 4.8V, has the energy density higher than that of all the other anode materials, has excellent high-temperature performance and high energy density, and is suitable for various lithium ion batteries.

Description

technical field [0001] The invention relates to a manufacturing method of a lithium ion battery, in particular to a manufacturing method of a lithium ion battery using lithium manganate as a positive active material. Background technique [0002] According to statistics, in the components of lithium-ion batteries, the cost of cathode materials exceeds 30% of the total cost of the battery, which is the highest among all components of the battery. The reason for the highest cost of the positive electrode is that the current commercial lithium-ion batteries mainly use lithium cobalt oxide LiCoO 2 As a positive electrode active material, since the abundance of cobalt in the earth's crust is only 25ppm, its price in 2009 was about 25 US dollars / kg, which eventually led to a higher cost for the positive electrode. Since the abundance of iron, manganese and nickel in the earth's crust is much higher than that of cobalt, iron 50000ppm, manganese 950ppm, nickel 75ppm, the price is m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M10/058H01M4/1391

CPCY02E60/122Y02E60/10Y02P70/50

Inventor 程林梁奇黄友元

Owner BTR NEW MATERIAL GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com