A kind of network graphene nanomaterial and its preparation method and application

A nanomaterial and graphene technology, which is applied in the field of network graphene nanomaterials and their preparation, can solve problems such as difficulty in realizing industrialized production and complicated processes, and achieve the effects of stable product quality, simple process flow and abundant raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

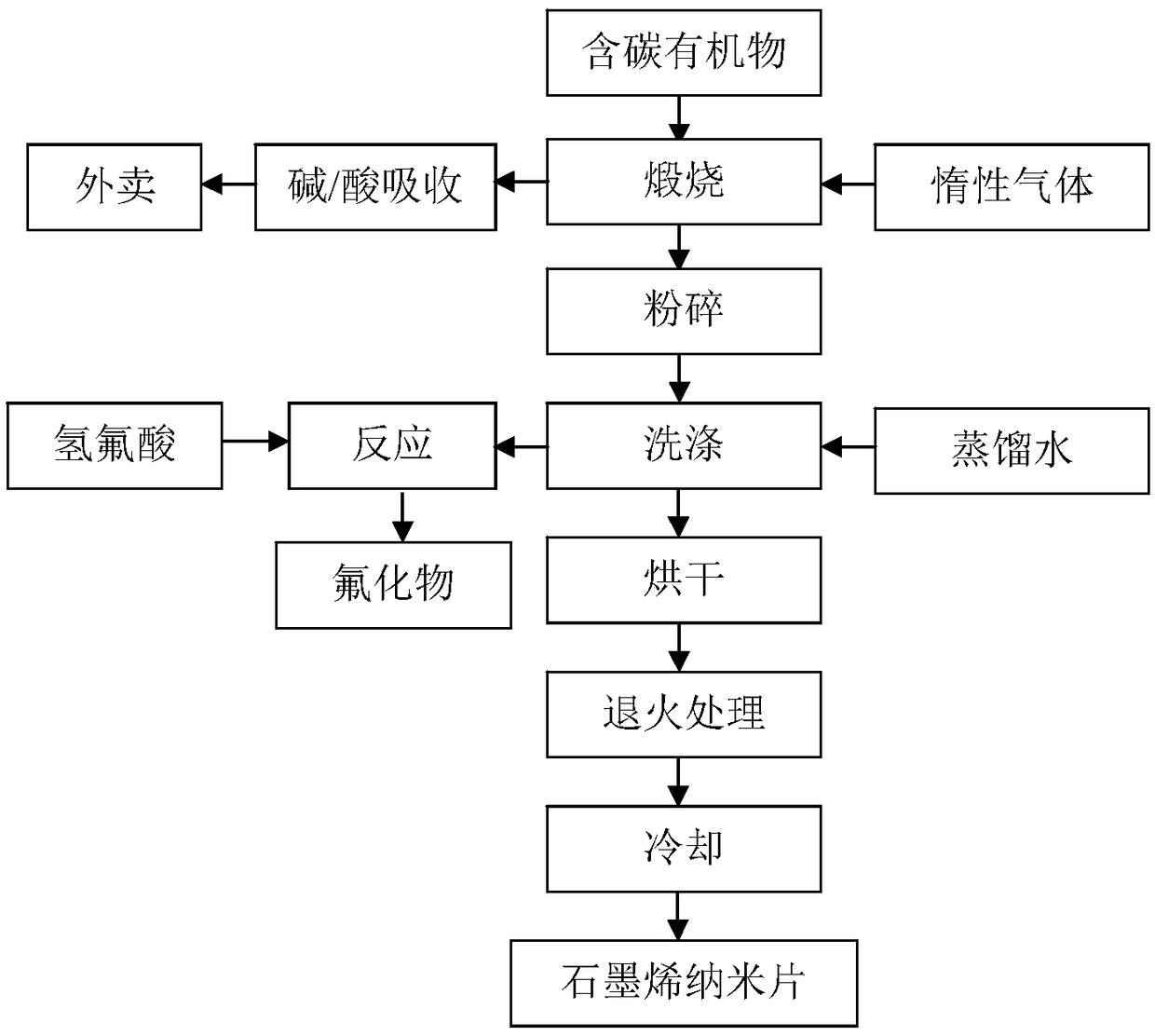

[0036] The networked graphene nanomaterial of the present embodiment, technological process such as figure 1 Shown, adopt the following method to prepare:

[0037] 1) Weigh 1 kg of sodium gluconate, add it to a porcelain boat and place it in an argon atmosphere furnace, raise the temperature to 500 °C at a rate of 10 °C / min, keep it warm for 4 hours, and after cooling down to room temperature, a black lump is obtained and crushed, that is Calcined product;

[0038] 2) adding 6kg of distilled water at a temperature of 30°C to the calcined product for suction filtration and washing, repeated 8 times, and drying the washed filter residue at 60°C for 12 hours to obtain network-shaped amorphous carbon nanosheets;

[0039] 3) Under an argon atmosphere, heat up the network-like amorphous carbon nanosheets at a rate of 20°C / min to 600°C for annealing treatment, keep the temperature at 600°C for 6 hours, and obtain 50 g of network-like graphene nanosheets after cooling down to room te...

Embodiment 2

[0042] The networked graphene nanomaterial of the present embodiment, technological process such as figure 1 Shown, adopt the following method to prepare:

[0043] 1) Weigh 1 kg of calcium stearate into a porcelain boat and place it in a nitrogen atmosphere furnace, raise the temperature to 1000 °C at a rate of 8 °C / min, keep it warm for 2 hours, and after cooling down to room temperature, a black lump is obtained and crushed, that is Calcined product;

[0044] 2) adding 2kg of distilled water at a temperature of 60°C to the calcined product for suction filtration and washing, repeated twice, and drying the washed filter residue at 60°C for 20 hours to obtain network-shaped amorphous carbon nanosheets;

[0045] 3) Under an argon atmosphere, heat the network-shaped amorphous carbon nanosheets at a rate of 15°C / min to 1600°C for annealing treatment, keep it at 1600°C for 1 hour, and obtain 30g of network-shaped graphene nanosheets after cooling down to room temperature. piece....

Embodiment 3

[0048] The networked graphene nanomaterial of the present embodiment, technological process such as figure 1 Shown, adopt the following method to prepare:

[0049] 1) Weigh 1kg of lithium citrate into a porcelain boat and place it in an air atmosphere furnace, heat up to 700°C at a rate of 3°C / min, keep it warm for 1h, and after cooling down to room temperature, black lumps are obtained and crushed, which is calcination thing;

[0050] 2) adding 3 kg of distilled water at a temperature of 70° C. to the calcined product for suction filtration and washing, repeated 5 times, and drying the washed filter residue at 60° C. for 20 hours to obtain network-shaped amorphous carbon nanosheets;

[0051] 3) Under an argon atmosphere, heat up the network-like amorphous carbon nanosheets at a rate of 5°C / min to 900°C for annealing treatment, keep the temperature at 900°C for 1 hour, and obtain 40 g of network-like graphene nanosheets after cooling down to room temperature. piece.

[0052] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com