Preparation method of titanate composite negative electrode material for lithium ion battery

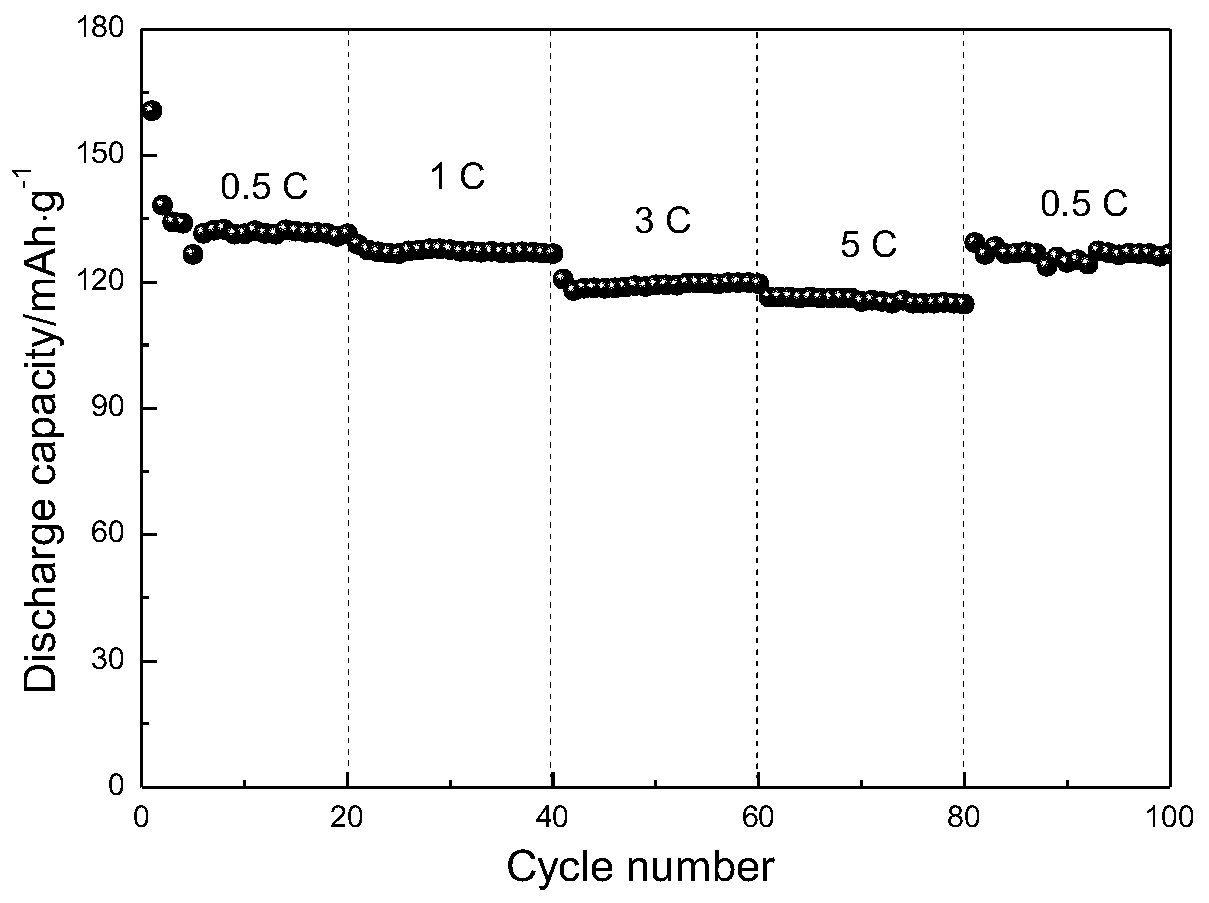

A technology of lithium ion battery and negative electrode material, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of low conductivity, capacity decay, poor rate performance, etc., achieve high crystallinity, improve energy density and power Effect of density and stable cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of a titanate composite negative electrode material for a lithium ion battery, comprising the steps of:

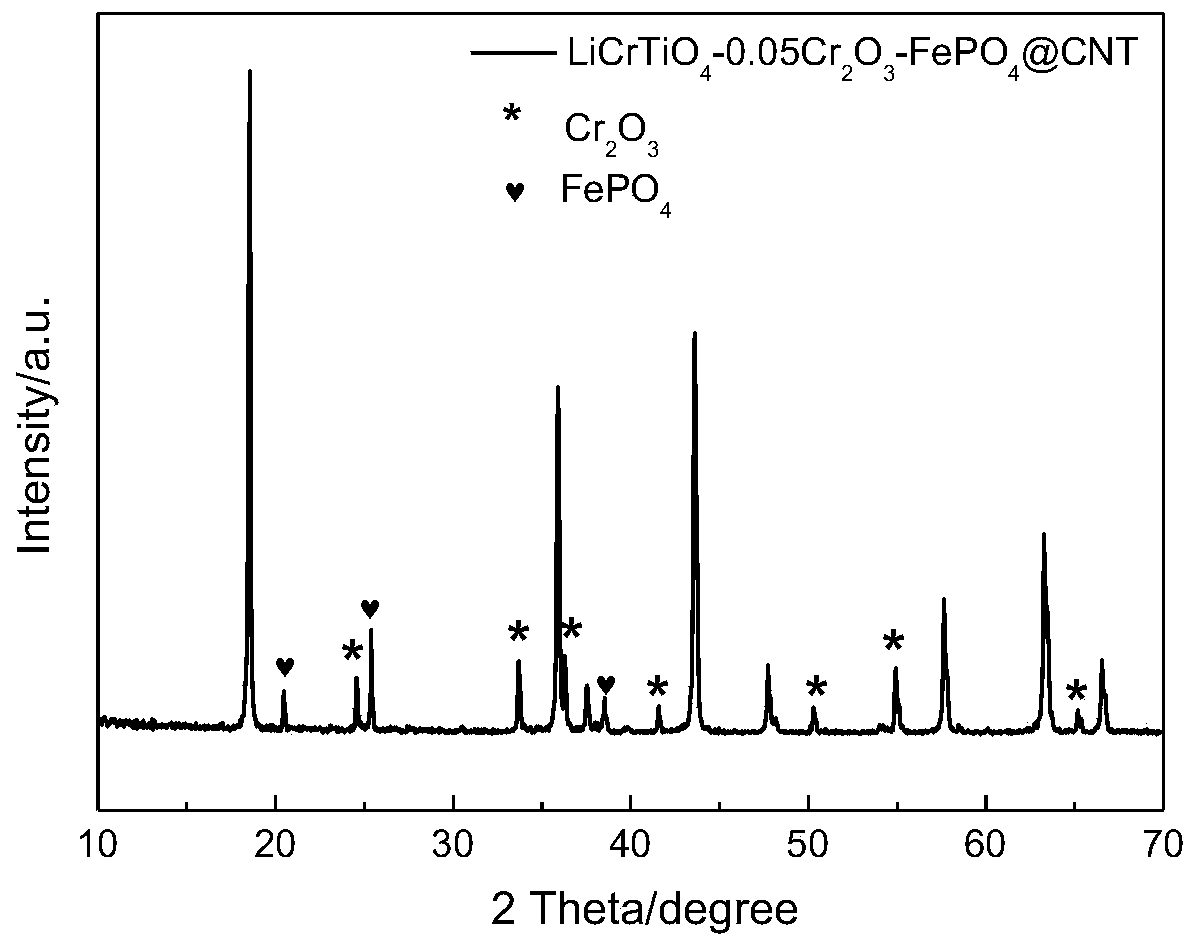

[0032] S1, 12mmol tetrabutyl titanate (C 16 h 36 o 4 Ti), 13.2mmol chromium nitrate (Cr(NO 3 ) 3 9H 2 O) be dissolved in ethanol aqueous solution, add under the condition of stirring and contain 36mmol citric acid (C 6 h 8 o 7 ·H 2 O) aqueous solution, 15mmol lithium nitrate (LiNO 3 ) in a water bath at a temperature of 70°C until it becomes gelatinous, put it into an oven at 80°C for drying, put it in a muffle furnace after grinding, pre-sinter at a temperature of 600°C for 6 hours, and cool to room temperature to obtain LiCrTiO 4 -0.05Cr 2 o 3 Precursor;

[0033] S2, the LiCrTiO obtained by 1000mg 4 -0.05Cr 2 o 3 Precursor, 40mgFePO 4 Dissolve in absolute ethanol, stir evenly, evaporate to dryness at a temperature of 60°C, send it to an oven at 80°C for drying, cool to room temperature, put it in a ball mill for ball milling fo...

Embodiment 2

[0041] A preparation method of a titanate composite negative electrode material for a lithium ion battery, comprising the steps of:

[0042] S1, 12mmol tetrabutyl titanate (C 16 h 36 o 4 Ti), 12.72mmol chromium nitrate (Cr(NO 3 ) 3 9H 2 O) be dissolved in ethanol aqueous solution, add under the condition of stirring and contain 36mmol citric acid (C 6 h 8 o 7 ·H 2 O) aqueous solution, 15mmol lithium nitrate (LiNO 3 ) in a water bath with a temperature of 70°C until it becomes gelatinous, then put it into an oven at 80°C for drying, put it in a muffle furnace after grinding, pre-fire at a temperature of 600°C for 6 hours, and cool to room temperature to obtain LiCrTiO 4 -0.03Cr 2 o 3 Precursor;

[0043] S2, the LiCrTiO obtained by 1000mg 4 -0.03Cr 2 o 3 Precursor, 40mgFePO 4 Dissolve in absolute ethanol, stir evenly, evaporate to dryness at a temperature of 60°C, send it to an oven at 80°C for drying, cool to room temperature, put it in a ball mill for ball mill...

Embodiment 3

[0047] A preparation method of a titanate composite negative electrode material for a lithium ion battery, comprising the steps of:

[0048] S1, 12mmol tetrabutyl titanate (C 16 h 36 o 4 Ti), 13.92mmol chromium nitrate (Cr(NO 3 ) 3 9H 2 O) be dissolved in ethanol aqueous solution, add under the condition of stirring and contain 36mmol citric acid (C 6 h 8 o 7 ·H 2 O) aqueous solution, 15mmol lithium nitrate (LiNO 3 ) in a water bath at a temperature of 70°C until it becomes gelatinous, put it into an oven at 80°C for drying, put it in a muffle furnace after grinding, pre-sinter at a temperature of 600°C for 6 hours, and cool to room temperature to obtain LiCrTiO 4 -0.08Cr 2 o 3 Precursor;

[0049] S2, the LiCrTiO obtained by 1000mg 4 -0.08Cr 2 o 3 Precursor, 40mgFePO 4 Dissolve in absolute ethanol, stir evenly, evaporate to dryness at a temperature of 60°C, dry in an oven at 80°C, cool to room temperature, place in a ball mill for ball milling for 4 hours, siev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com