Patents

Literature

55results about How to "Stable cycle life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inorganic/organic composite porous isolating membrane, preparation method and lithium-ion battery thereof

InactiveCN107895765AHigh mechanical strengthImprove reliabilityCell component detailsSecondary cells servicing/maintenancePolymer adhesiveSlurry

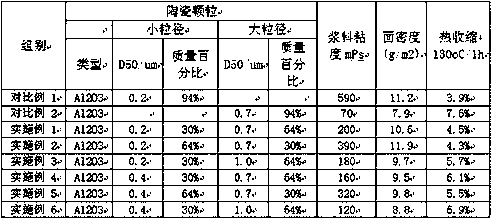

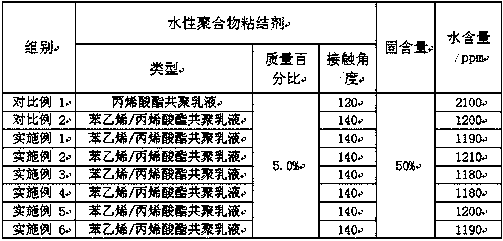

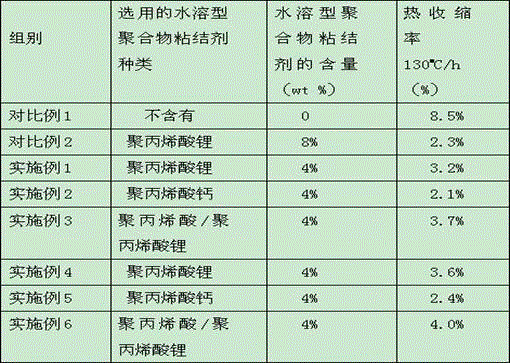

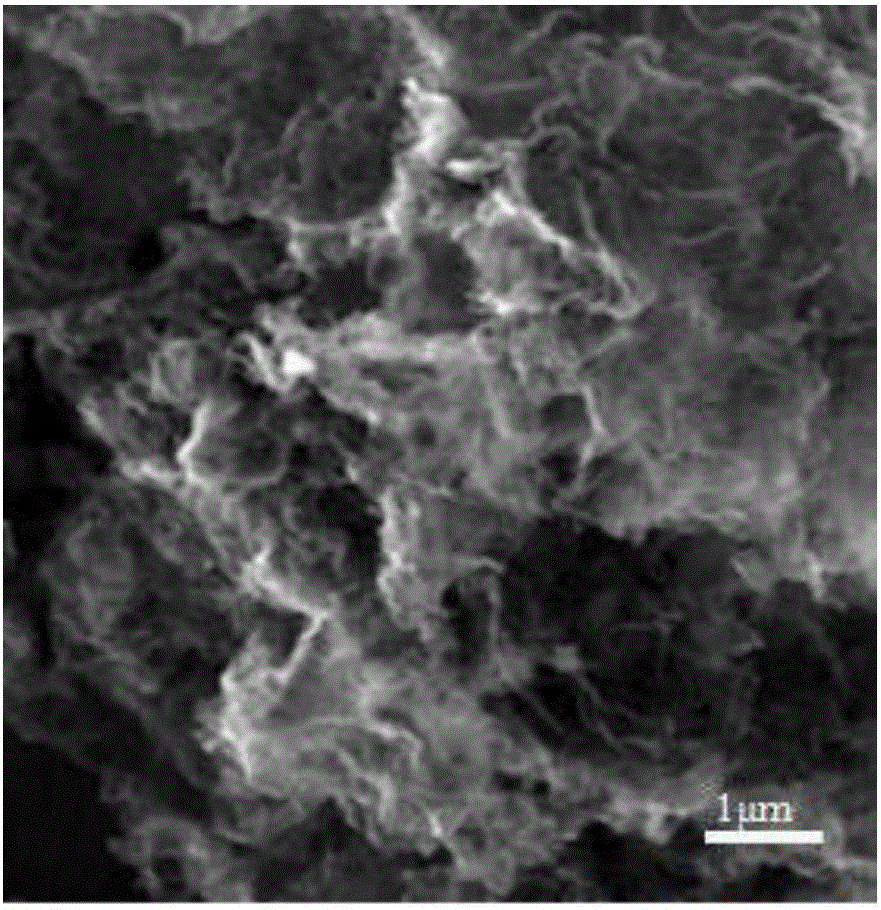

The invention discloses an inorganic / organic composite functional porous isolating membrane. The isolating membrane comprises porous base material and at least one inorganic functional coating adhering to the surface of the porous base material, and aqueous slurry prepared for the inorganic functional coatings is prepared from inorganic ceramic particles, water-soluble polymer thickener and aqueous polymer adhesive; the inorganic ceramic particles comprise the same substance in two types of particle sizes, wherein the average particle size (D50) of the smaller inorganic ceramic particles is 0.2-0.5 micrometer, and the average particle size (D50) of the larger inorganic ceramic particles is 0.6-1.0 micrometer; the aqueous polymer adhesive is a hydrophobic high-molecular polymer with the water drop contact angle of the dry adhesive of the aqueous polymer adhesive 110-140 degrees; the solid content of the aqueous slurry is 40-60%. According to the inorganic / organic composite functional porous isolating membrane, the high-temperature thermal stability of the isolating membrane can be effectively improved by means of the inorganic functional coatings, and the water content of the inorganic coatings is effectively reduced, so that the safe performance of a battery and the stability of long-term circulation are improved.

Owner:深圳市旭然电子有限公司

Inorganic/organic compound functional porous isolating membrane and preparation method as well as lithium ion battery adopting inorganic/organic compound functional porous isolating membrane

ActiveCN105789523AGood dispersionImproved high temperature thermal stabilitySecondary cellsCell component detailsPorous substrateOrganic compound

The invention provides an inorganic / organic compound functional porous isolating membrane. The inorganic / organic compound functional porous isolating membrane comprises a porous substrate and an inorganic functional coating which is adhered to at least one surface of the porous substrate, wherein the inorganic functional coating is prepared from inorganic ceramic particles, a water-soluble macromolecular thickening agent, a water emulsion type polymer binding agent and a water soluble type polymer binding agent; the water emulsion type polymer binding agent is a macromolecular polymer with the surface tensile force of 40dyne / cm to 50dyne / cm, and a water drip contact angle of water emulsion type polymer binding agent dry glue is 100 degrees to 130 degrees; the water emulsion type polymer binding agent is a polar macromolecular polymer with the glass transition temperature of 100 DEG C to 150 DEG C. Therefore, the inorganic / organic compound functional porous isolating membrane has the advantages that the heat stability of the isolating membrane can be effectively improved, and the moisture content of the inorganic coating can also be reduced, so that the safety performance of a battery and the stability of long-period cycle are improved.

Owner:深圳市旭然电子有限公司

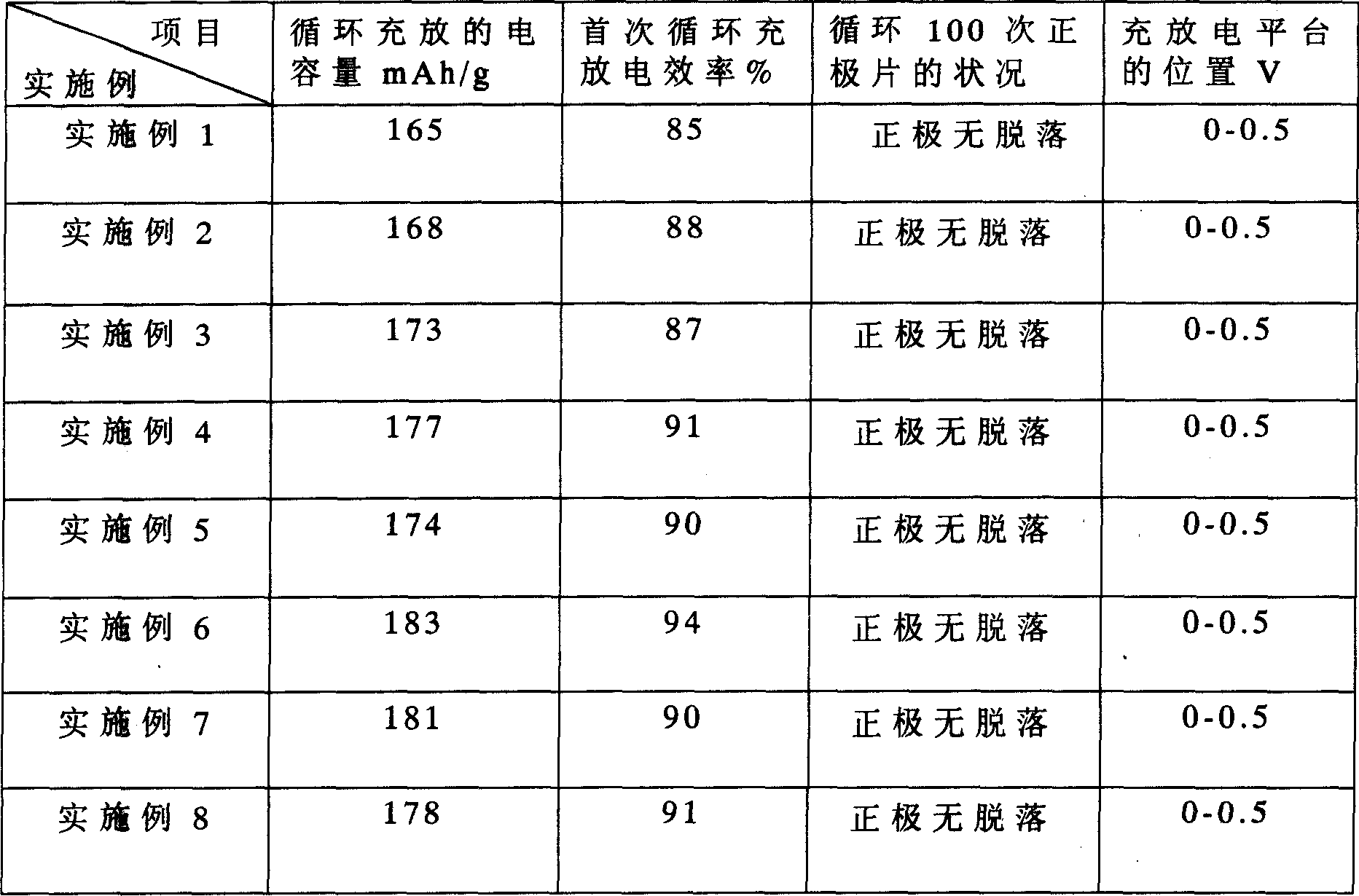

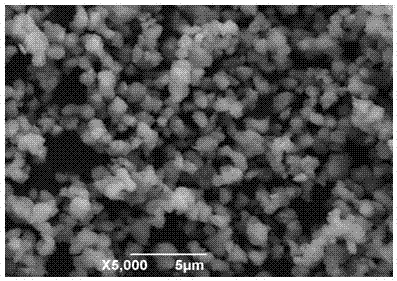

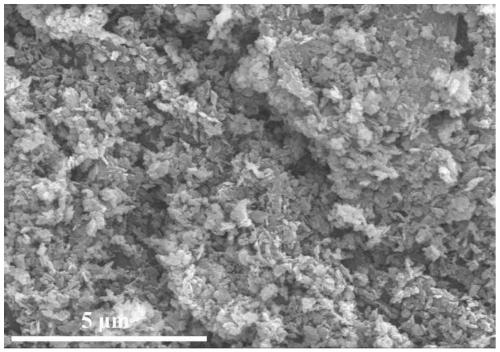

Sodium-ion battery carbon negative electrode material and preparation method thereof

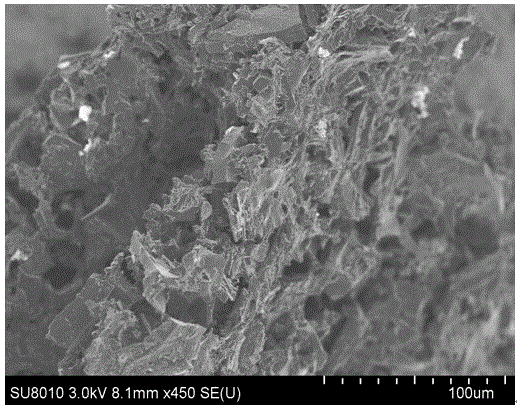

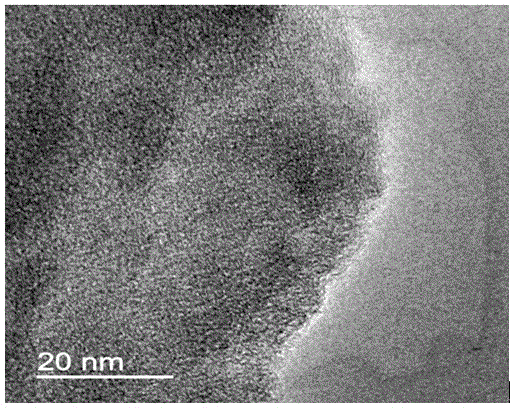

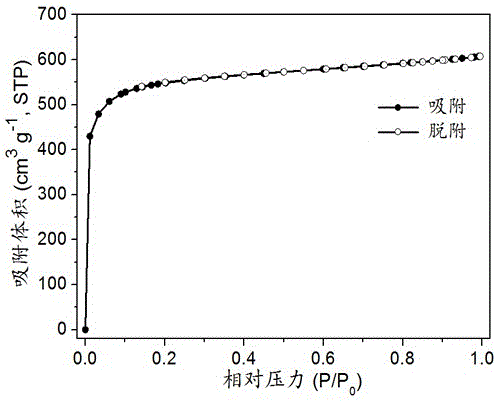

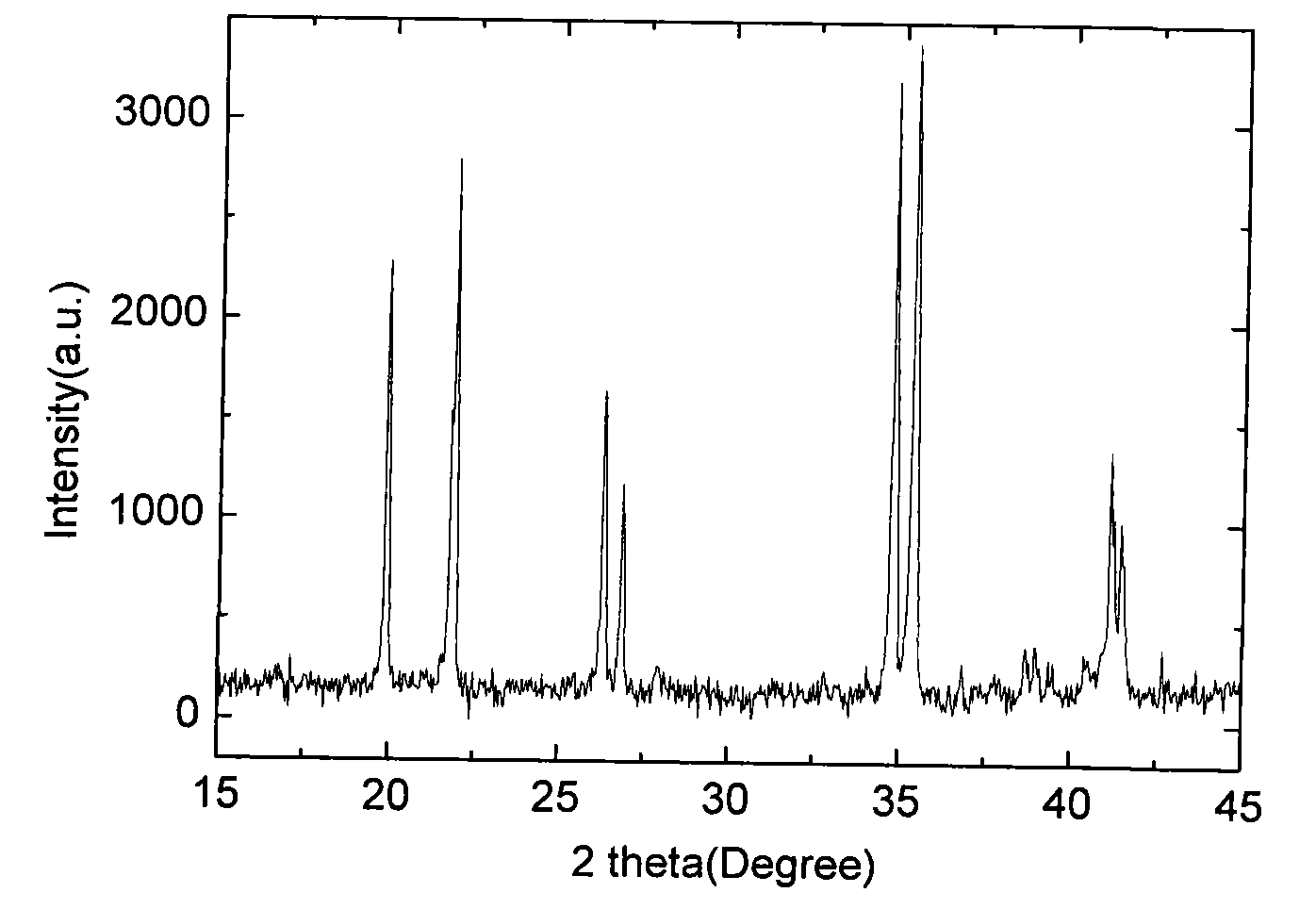

ActiveCN105870425AImprove conductivityShorten the transmission distanceCell electrodesSecondary cellsPorous grapheneCarbonization

The invention discloses a sodium-ion battery carbon negative electrode material. Raw materials of disordered low-graphitizing carbon materials coat or clad porous oxidized graphene or porous graphene through a hydrothermal method to obtain a carbon material precursor, the carbon material precursor is subjected to further carbonization and activation to form the sodium-ion battery carbon negative electrode material with porous graphene coated or cladded with the disordered low-graphitizing carbon materials, and the raw materials of the disordered low-graphitizing carbon materials are lignin. The invention further discloses a preparation method of the sodium-ion battery carbon negative electrode material. The obtained carbon material with the porous graphene cladded with the disordered low-graphitizing carbon has the advantages of being uniform in porosity distribution, appropriate in layer spacing, high in porosity, large in specific area, good in electrical conductivity and the like, and the composite material is used for a sodium-ion battery, and the good battery performance is shown.

Owner:CENT SOUTH UNIV

Preparation method for cicada slough based porous carbon material used for electrochemical capacitor

InactiveCN105152170AWide variety of sourcesSimple processHybrid capacitor electrodesHybrid/EDL manufactureCapacitancePorous carbon

The invention discloses a preparation method for cicada slough based porous carbon material capable of being used for an electrochemical capacitor. Cicada slough is adopted as a carbon source, an alkaline metal hydroxide is adopted as an activating agent, and the two steps of medium-temperature pre-carbonation and high-temperature activation are carried out, so that the cicada slough based porous carbon material for a high-performance supercapacitor is prepared; the prepared carbon material has the characteristics such as higher specific capacitance value, better cycle performance and higher multiplying power in a water system electrolyte, for example, in a 6.0 M KOH electrolyte, the weight specific capacitance value of the carbon material can reach 355 Fg<-1>, 288 Fg<-1> and 283 Fg<-1> respectively under the electric current density of 1 Ag<-1>, 10 Ag<-1> and 30 Ag<-1>, and after the carbon material is charged and discharged in a circulating manner for 3000 times under the condition of 10 Ag<-1>, the capacitance retention value of the carbon material is still 90% or above of the original value. According to the invention, biomass materials are fully utilized, the cost is low, the sources are wide, the preparation technology is simple, and the prepared porous carbon material has large specific surface area and excellent electrochemical capacitor performance, and has wide application prospect in the field of electrochemical energy storage.

Owner:SOUTHEAST UNIV

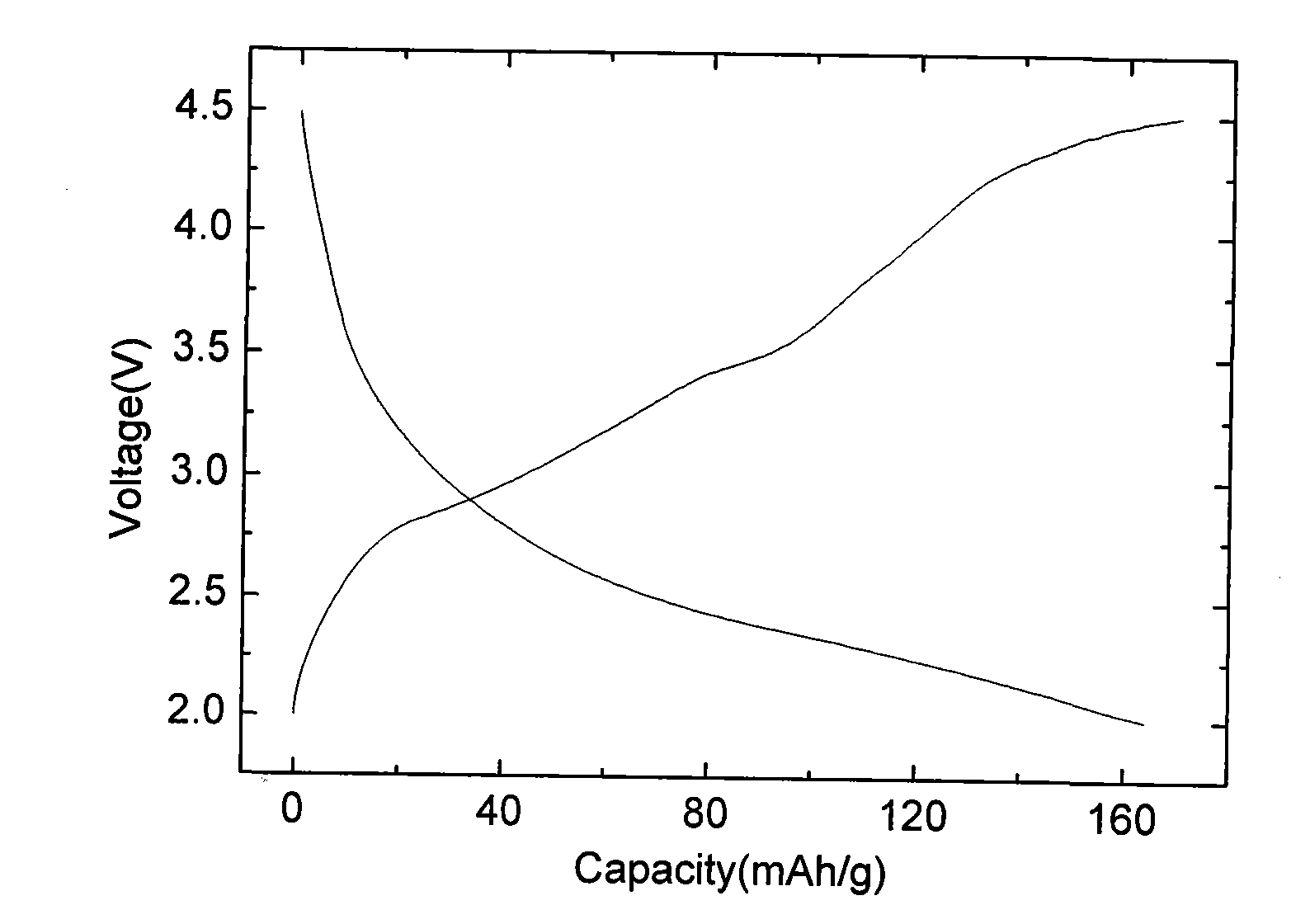

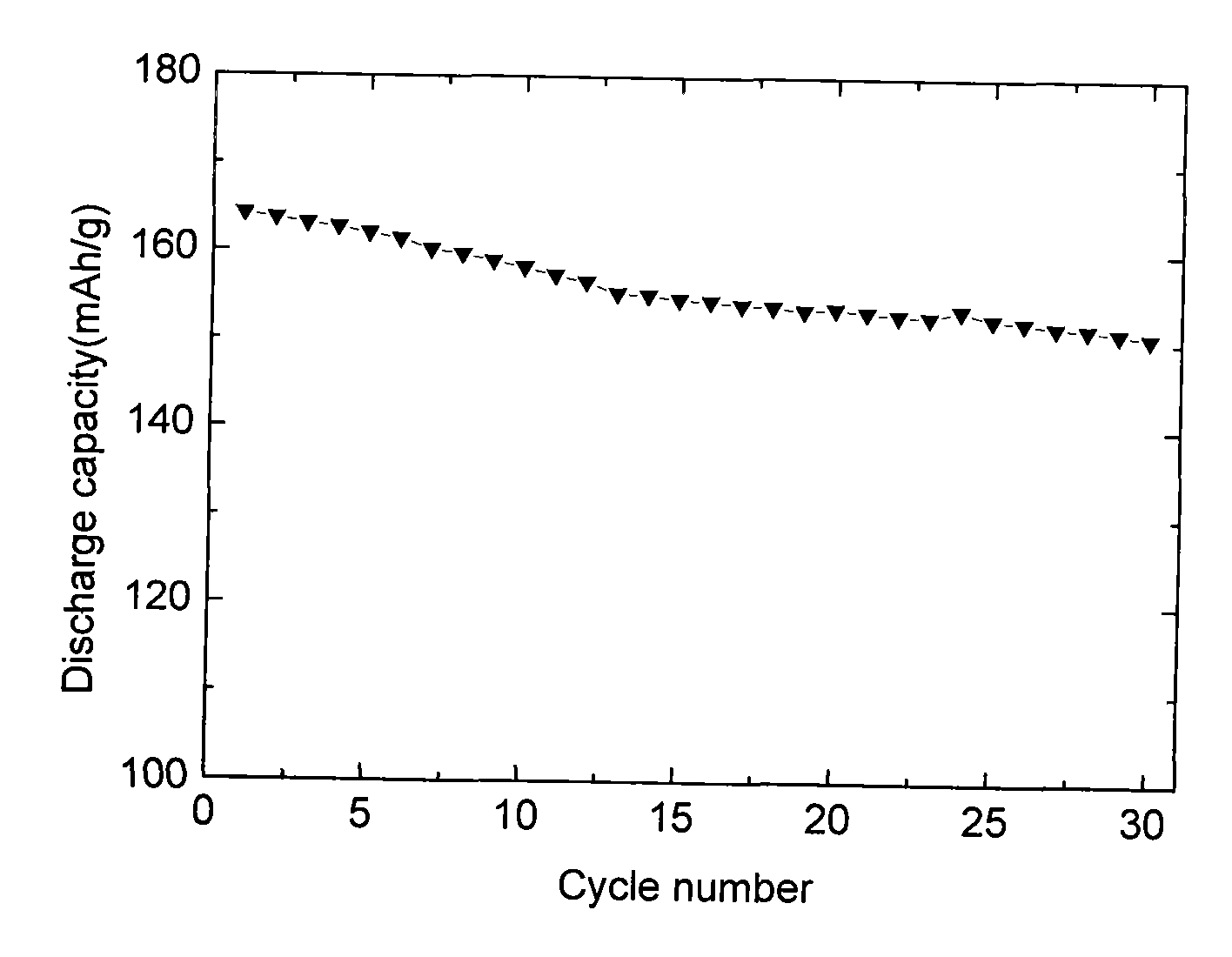

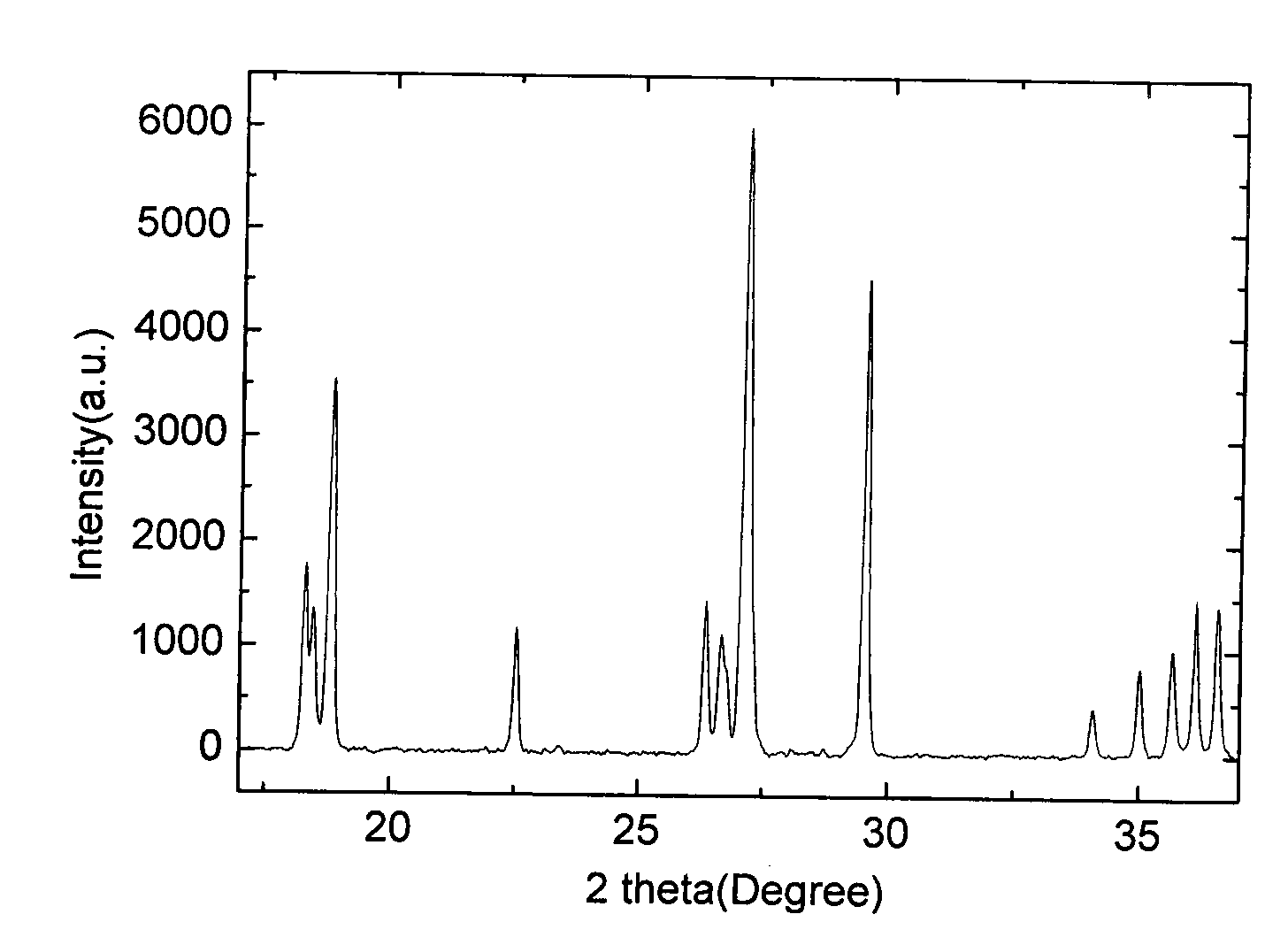

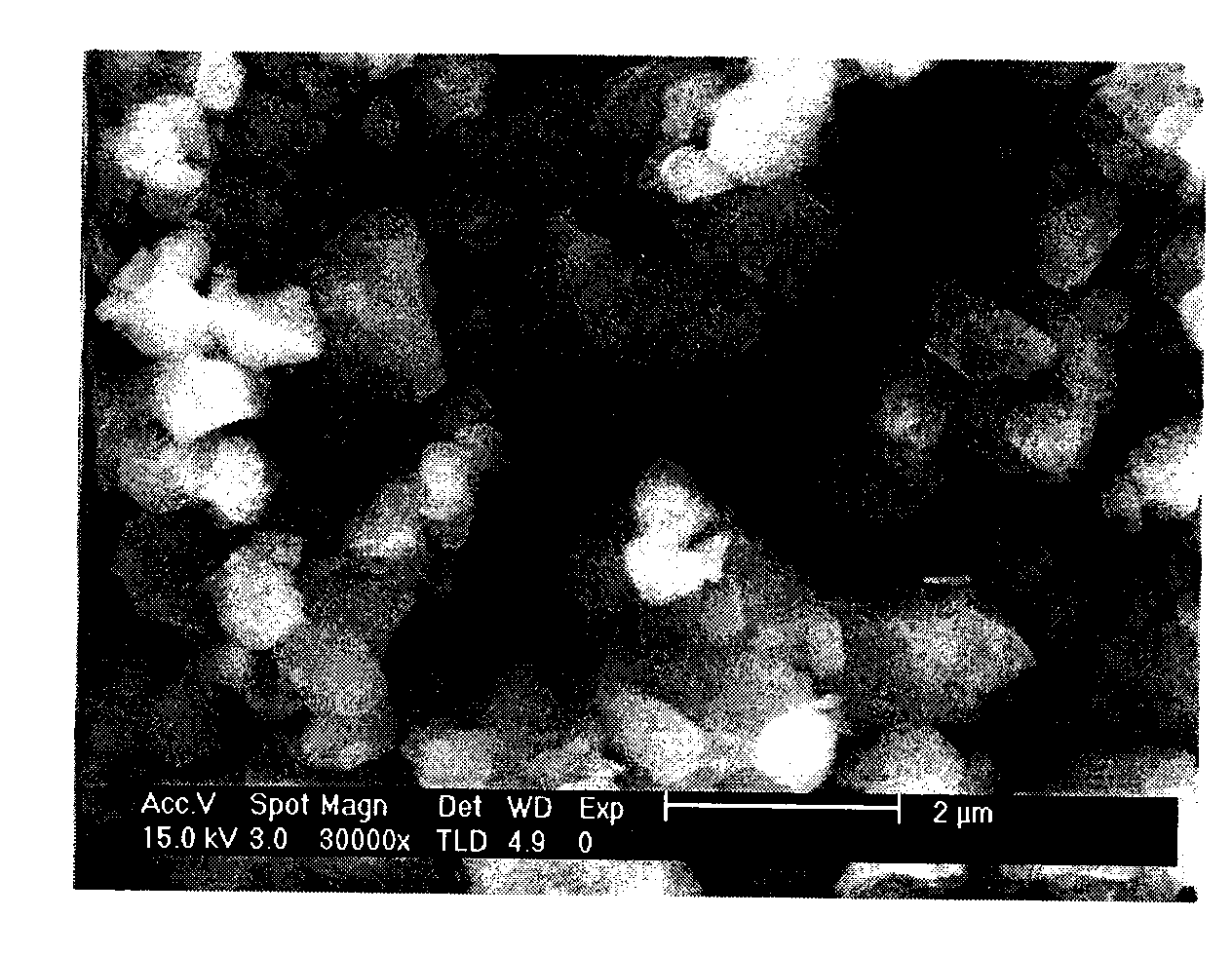

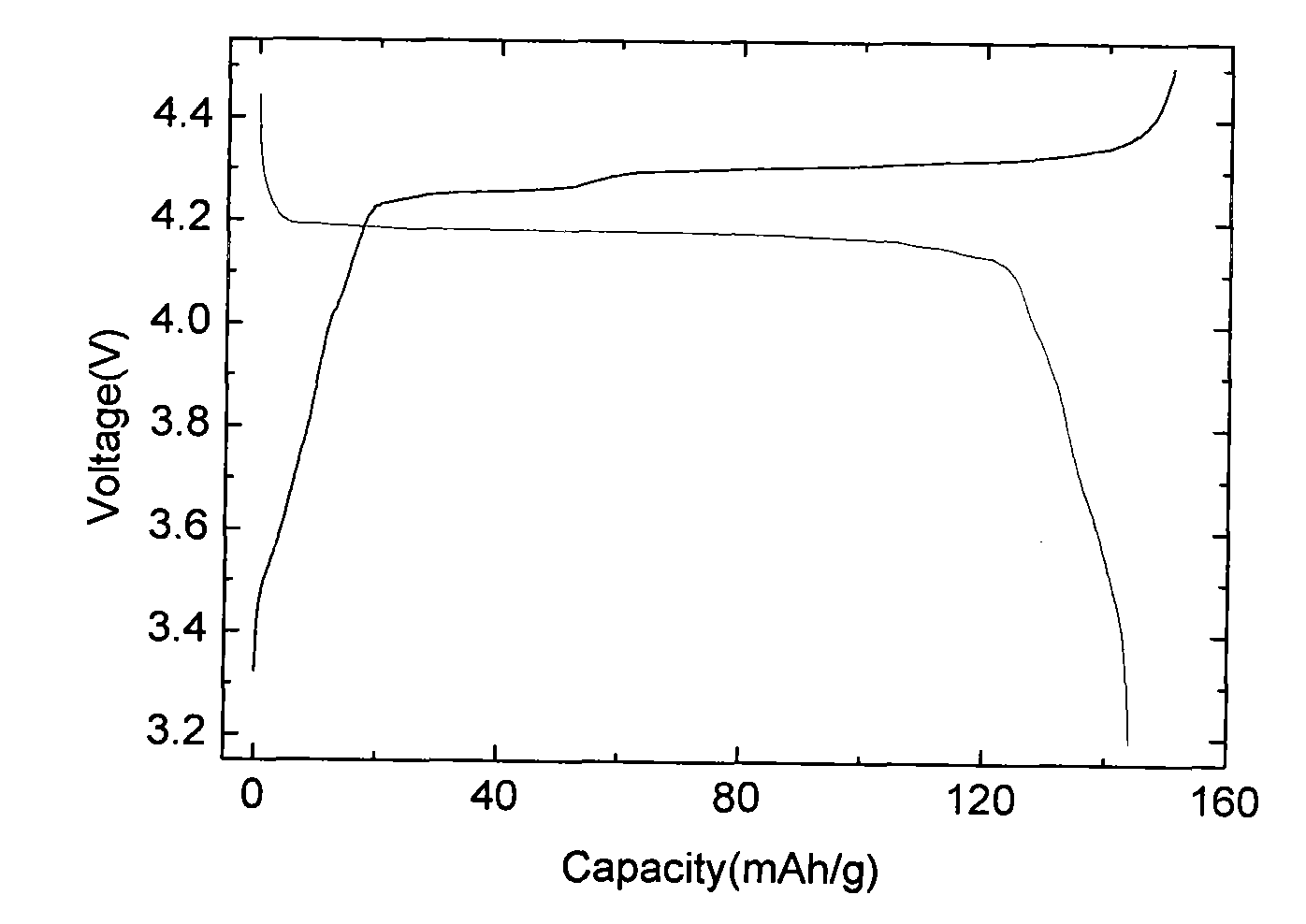

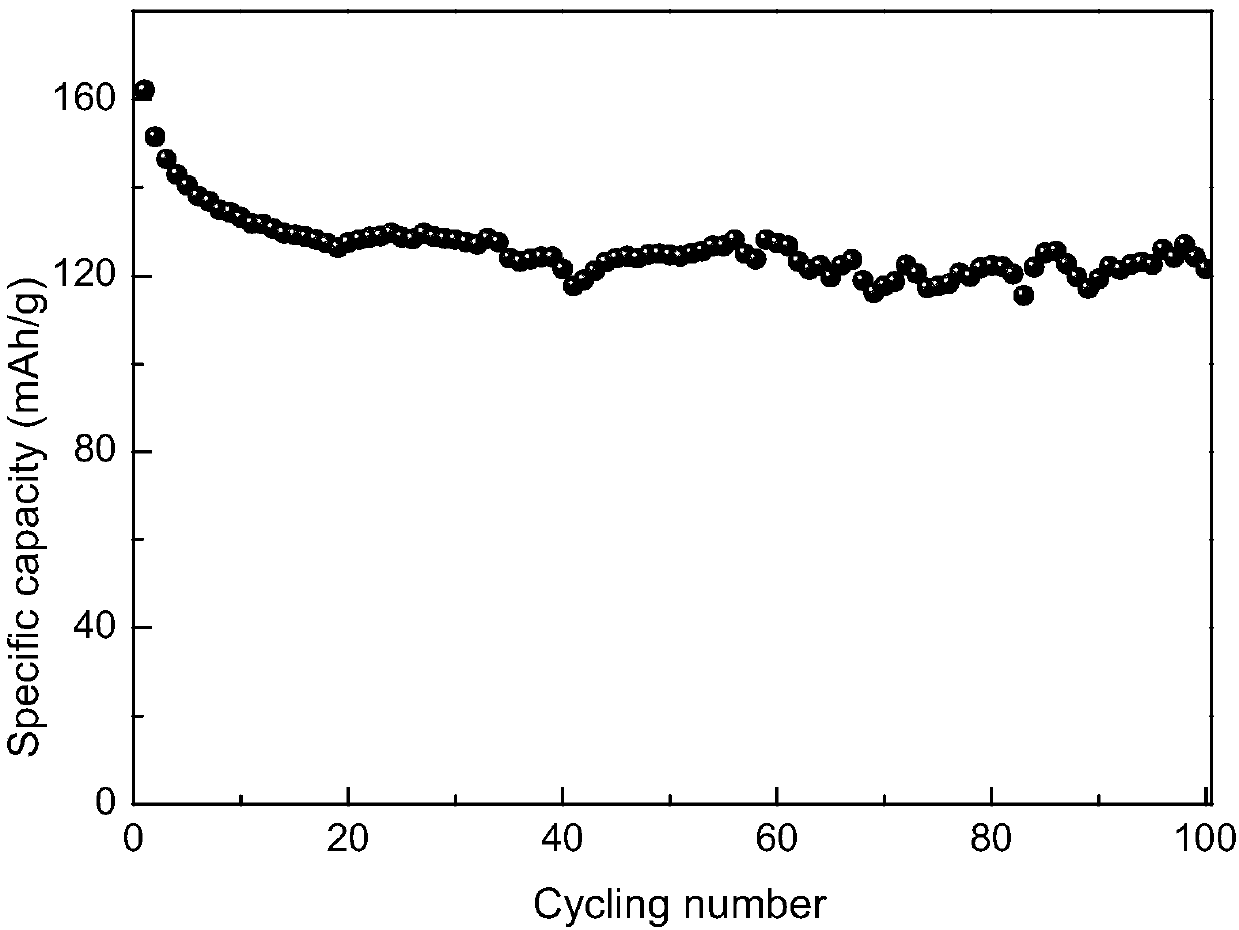

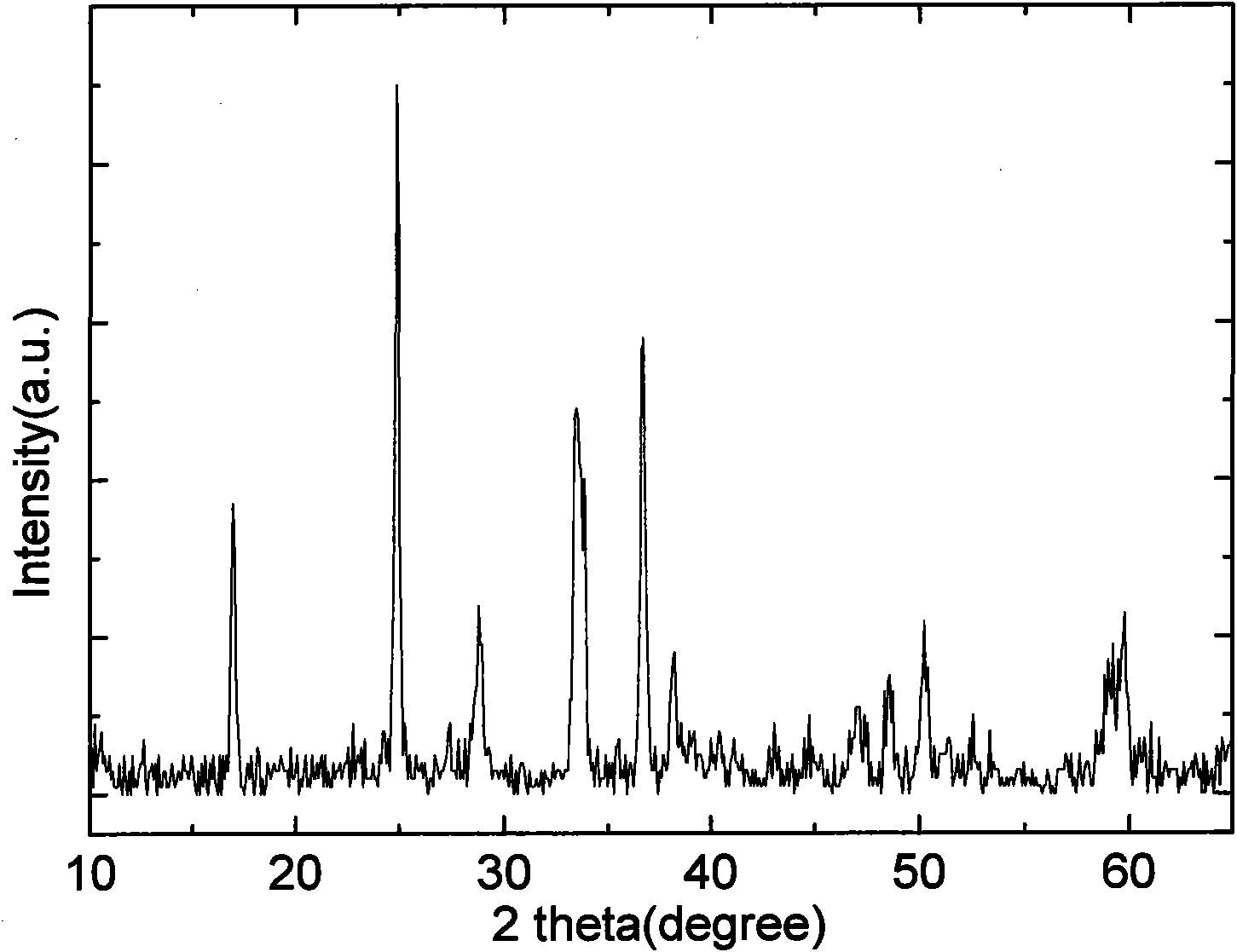

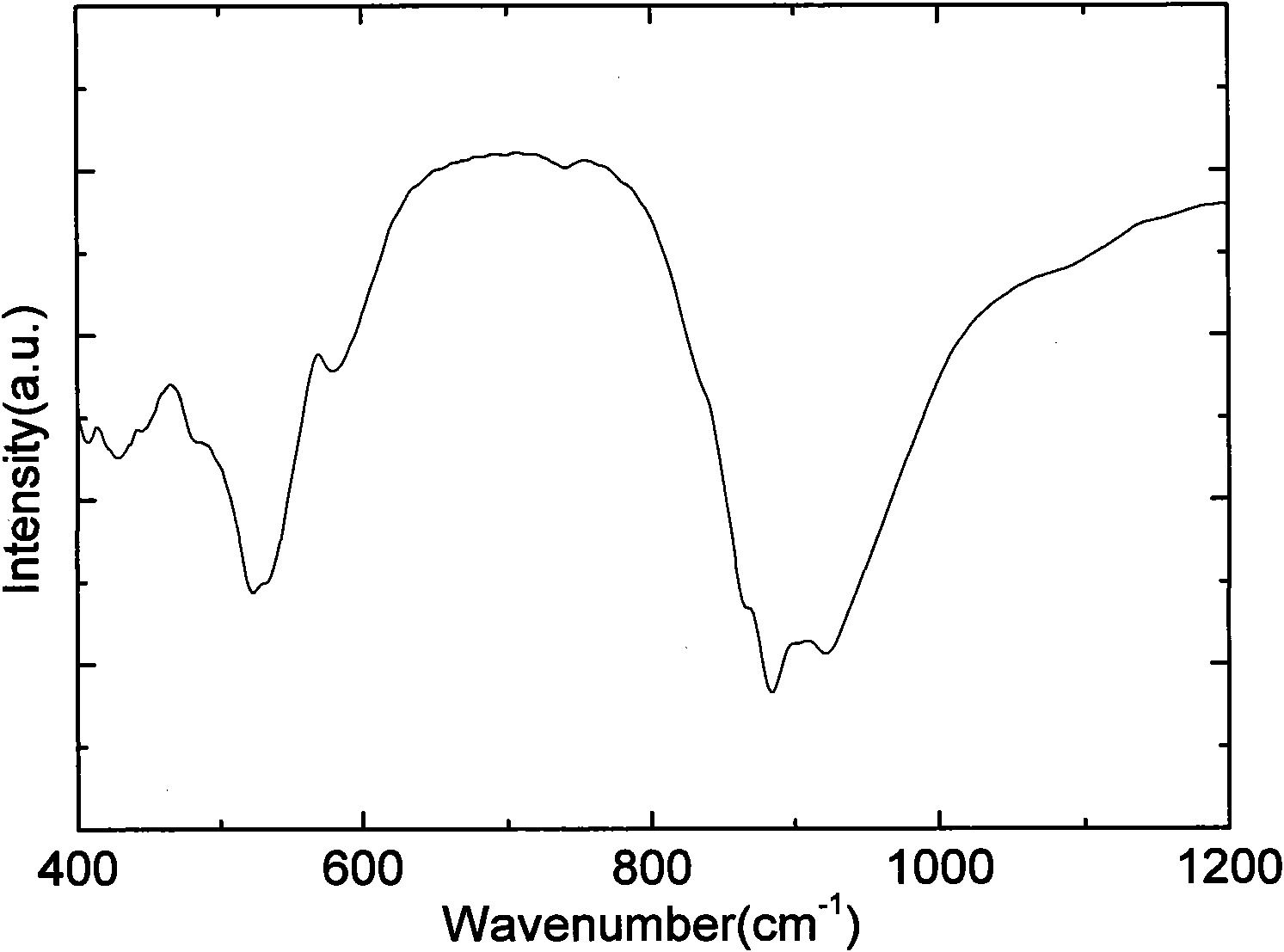

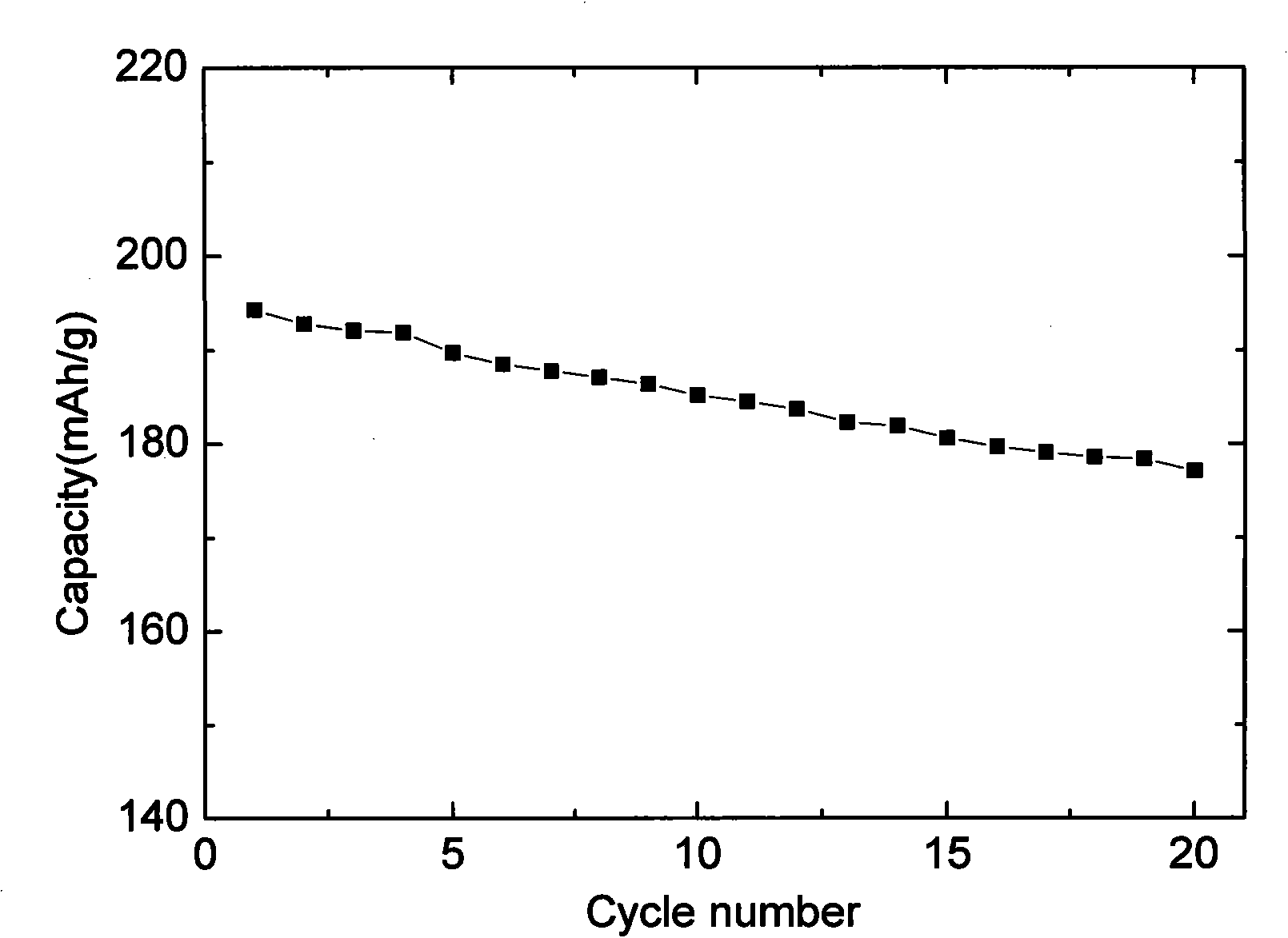

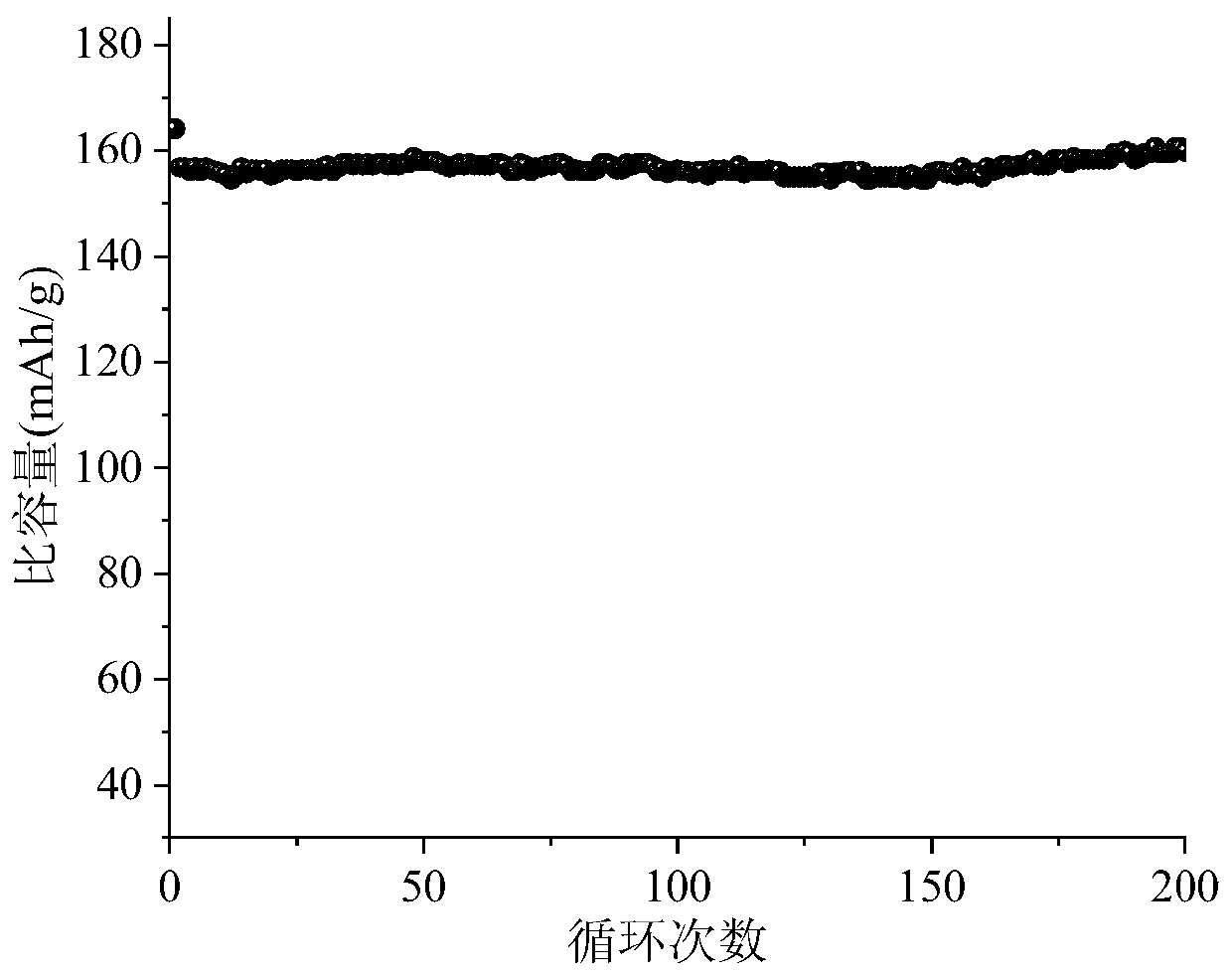

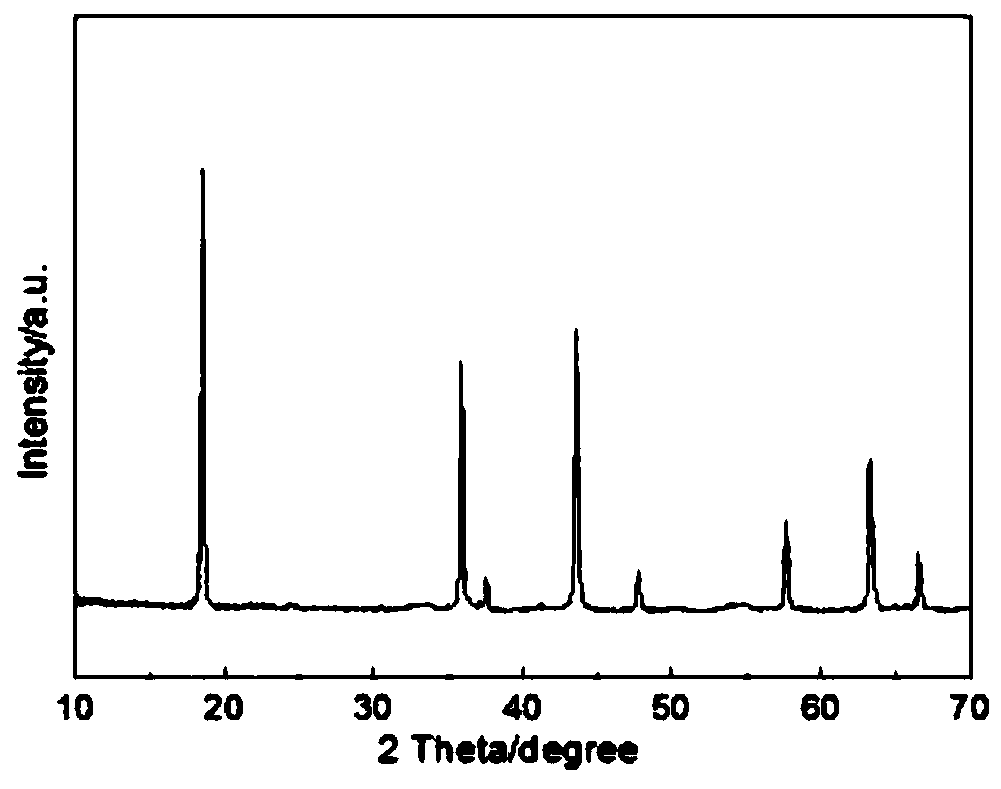

Method for preparing lithium iron borate serving as positive material of lithium ion battery by sol-gel technology

InactiveCN102079530ASimple manufacturing processHigh crystallinityBoratesSodium-ion batteryCrystallinity

The invention discloses a method for preparing lithium iron borate serving as a positive material of a lithium ion battery by a sol-gel technology. The method comprises the following steps of: dissolving a lithium source, an iron source, a borate source and a chelating agent in water according to a certain stoichiometric ratio; controlling the concentration of metal ions to be between 0.1 and 1mol / L; stirring at room temperature for 30 minutes to obtain sol; heating to 80 DEG C and keeping the temperature for 24 hours to form gel; drying the gel at the temperature of 120 DEG C and ball-milling for 2 hours; pressing into tablets under the pressure of 20MPa; sintering under the protection of argon at the temperature of between 600 and 900 DEG C for 10 hours; and naturally cooling to the room temperature to obtain the LiFeBO3. The method has the advantages of wide raw material source, simple operation process and high controllability and repeatability, the synthesis temperature of the material is effectively reduced, the preparation period of the material is shortened, and the production cost is saved. The particle size of the lithium iron borate synthesized by the method is between 60 and 600nm, and the particles have high dispersibility and crystallinity; and the lithium iron borate has higher reversible capacity and longer cycle life and can meet various requirements of the lithium ion battery during actual application.

Owner:NINGBO UNIV

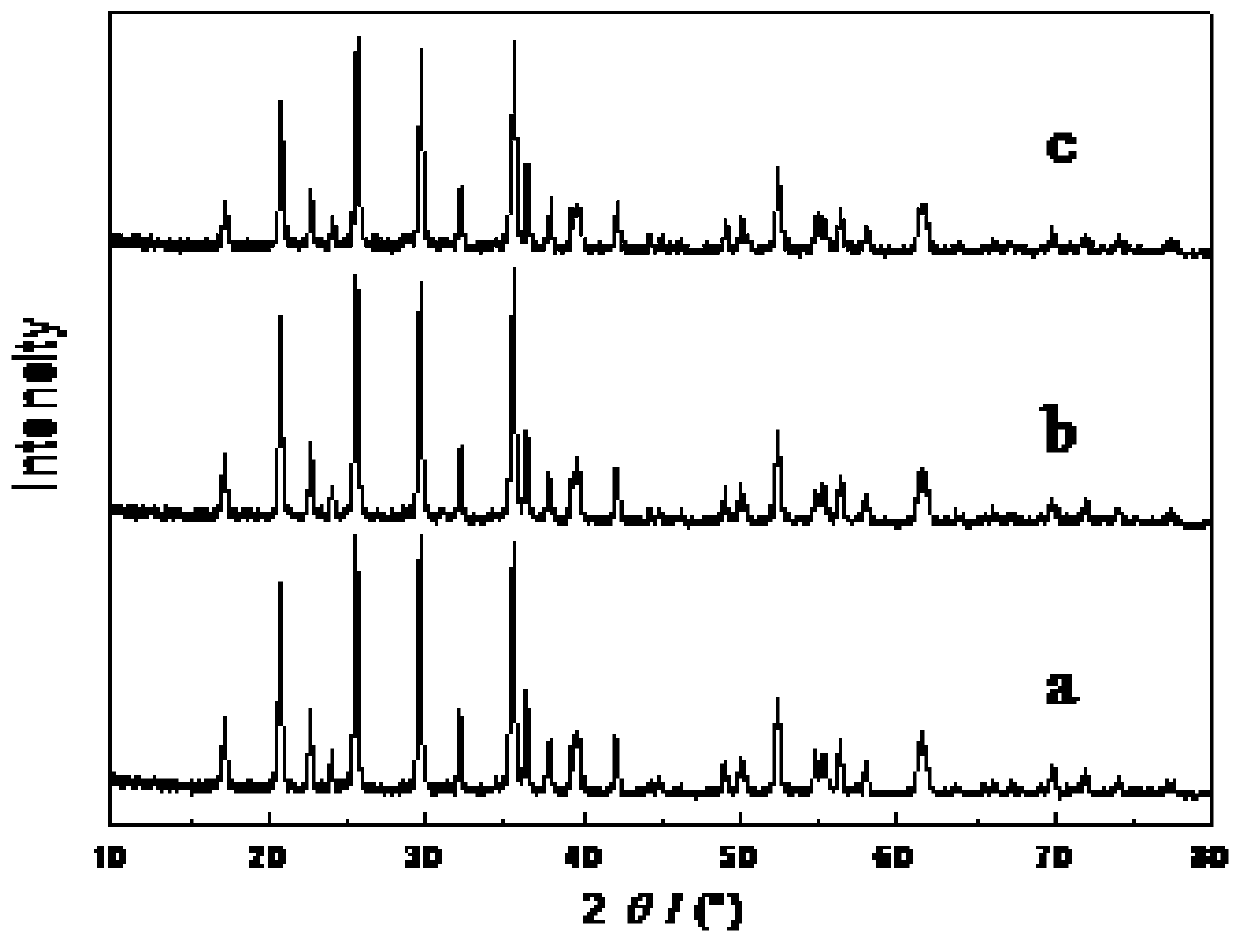

Method for preparing fluorizated lithium vanadium phosphate as lithium-ion battery anode material by using spray pyrolysis method

InactiveCN102079517ASimple manufacturing processGood dispersionCell electrodesPhosphorus compoundsHydrazine compoundCrystallinity

The invention discloses a method for preparing fluorizated lithium vanadium phosphate as a lithium-ion battery anode material by using a spray pyrolysis method. The preparation method comprises the following steps of: respectively adding a phosphate source, a vanadium source, a lithium source, a fluorine source, hydrazine hydrate and additives in a certain stoichiometric proportion to water, stirring for 30min to uniformly mix after adding each substance, and finally, forming a mixed solution with the metal ion concentration of 0.2-1.0mol / L; then, putting the mixed solution in a hydrogen airflow spray dryer, spraying and drying at 200-300 DEG C and collecting the product to obtain precursor powder; and tabletting the precursor powder at the pressure of 20MPa, then, sintering at 600-800 DEG C for 10h under hydrogen protection and naturally cooling to a room temperature to obtain LiVPO4F. The method has low raw material cost, simple operation process, strong controllability and high reproduction, effectively shortens the synthesis period of the material and saves the production cost. The fluorizated lithium vanadium phosphate synthesized by applying the method has the grain diameter of 60-500nm, good grain dispersibility, high crystallinity degree, higher reversible capacity and favorable cycle life, can meet various needs of the practical applications of the lithium-ion battery and can be directly used for the mass production of the lithium-ion battery anode material.

Owner:NINGBO UNIV

Composite lithium titanate preparation method

InactiveCN105406051AImprove conductivityIncrease the effective reaction areaCell electrodesLithiumOrganic solvent

The invention relates to a composite lithium titanate preparation method, which comprises: 1) uniformly mixing a lithium source compound, a titanium source compound and the compound of a doped modifier M according to a molar ratio of Li to Ti to M of (0.6-1):1:(0.06-0.3), dispersing in an organic solvent, carrying out ball milling for 6-12 h, sintering for 6-12 h at a temperature of 80-120 DEG C, and drying; 2) carrying out a heat treatment on the dried product obtained in the step 1) for 8-20 h at a temperature of 400-600 DEG C, and naturally cooling; and 3) carrying out mixing ball milling on the treated material obtained in the step 2) and a cladding material for 6-12 h according to a weight ratio of 100:(5-20), sintering for 8-20 h at a temperature of 700-950 DEG C under the protection of nitrogen, cooling, and screening with a 300 mesh sieve. According to the present invention, the preparation method has characteristics of rapid reaction, high product purity, low cost, and easy large-scale industrial production achieving.

Owner:HENAN KELONG NEW ENERGY CO LTD

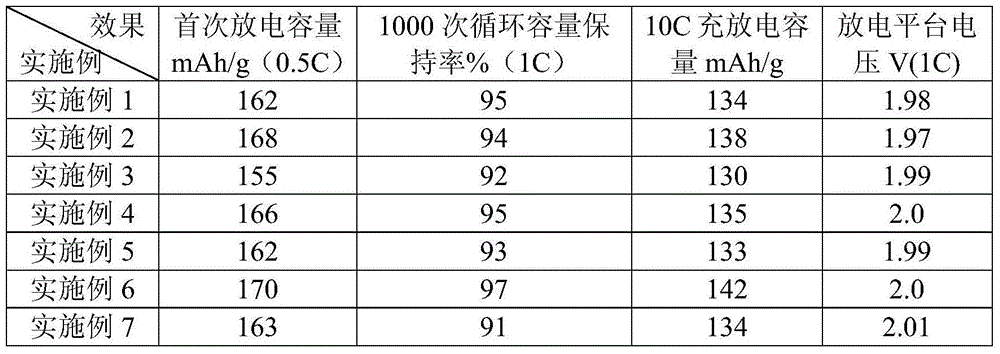

Preparation method of high capacity lithium ion battery lithium cobalt manganese nickel oxide positive electrode material

InactiveCN1514502AHigh reversible specific capacityPromote circulationElectrode thermal treatmentActive material electrodesManganeseLithium-ion battery

The method consists of procedures of solid phase synthesis and burning in high temperature including following steps. (1) According to lithium: cobalt, manganese, nickel=1-1.1 : 1 (atomic ratio), and cobalt : manganese : nickel=1:1:1, polyacrylamide and neodymia are added into even mixed sources of cobalt, manganese, nickel. The above admixture is mixed round evenly till it becoming colloid. (2) Baking drys the said colloid for 30 hr. under 150 deg.C, and ball milling is carried out till powder is passed through sieve. (3) With being preburned for 10 hr. at 300-450 deg.C, the said powder is cooled to room temperature. (4) Product is obtained after fine ball milling the preburned powder, passing through sieve, burning and sifting the powder by 300 screen mesh again. Comparing with prior art, the invented method adds polyacrylamide and neodymia as well as preburning step so as to possess features of high specific capacity, good cycle performance and pollution-free.

Owner:XINXIANG ZHONGKE SCI&TECH

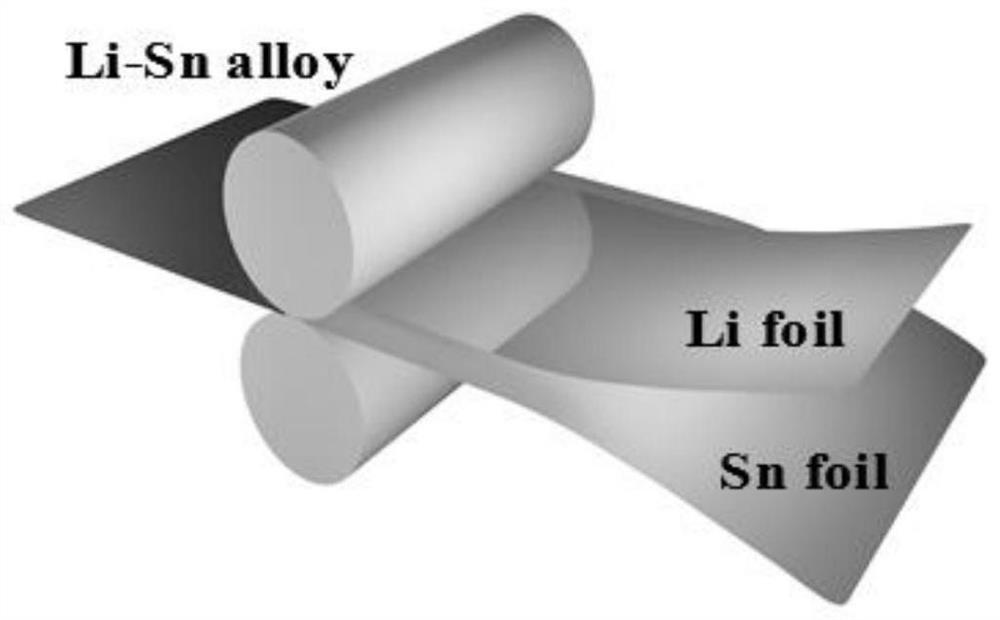

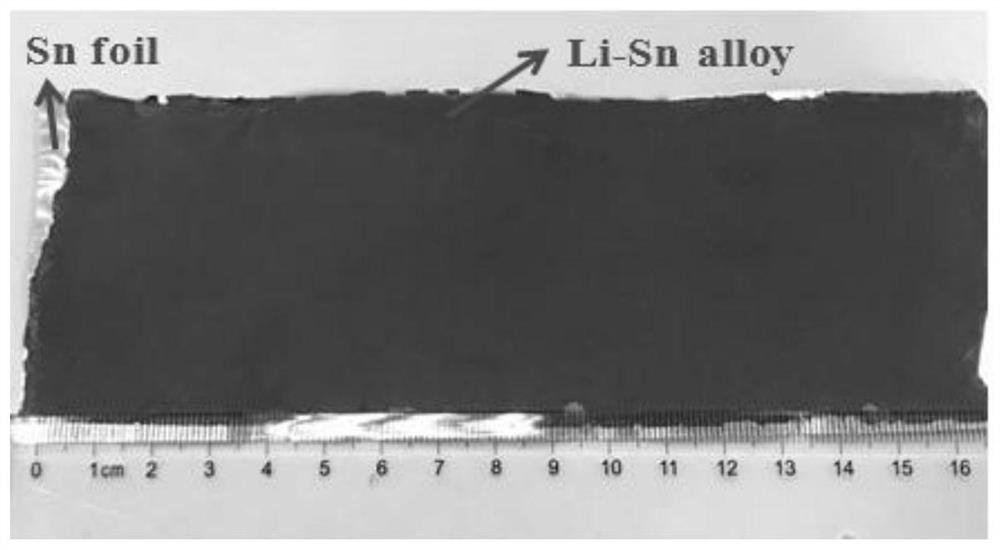

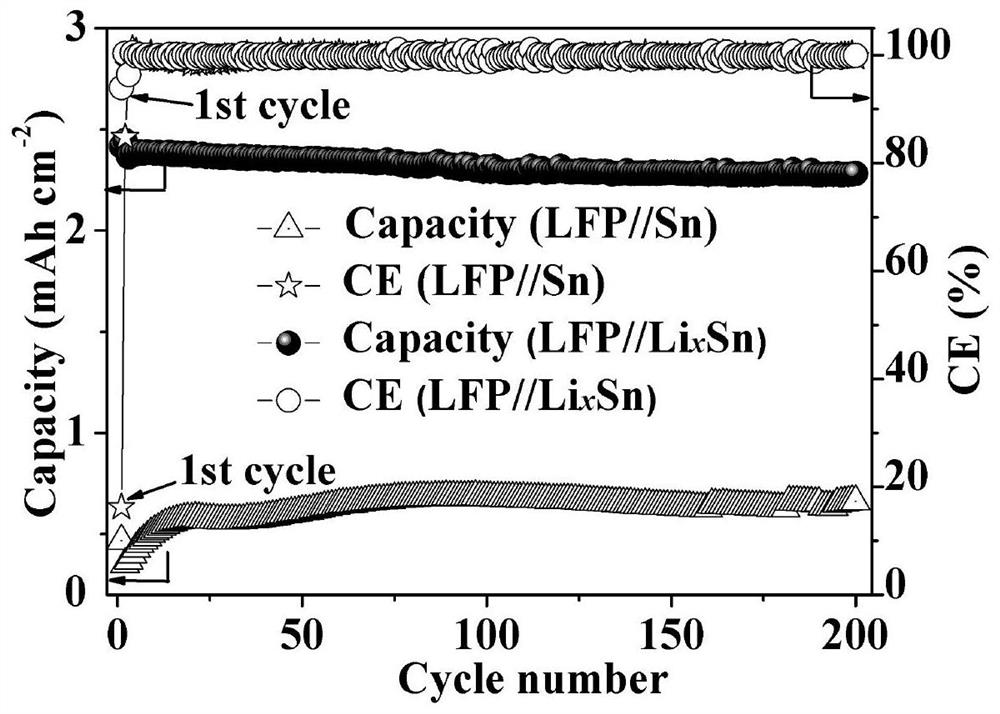

Pre-lithiated lithium ion secondary battery negative electrode material and mechanical pre-lithiation method thereof

ActiveCN111952545AImprove securityEasy to operateElectrode rolling/calenderingNon-aqueous electrolyte accumulator electrodesElectrical batteryMaterials science

The invention provides a pre-lithiated lithium ion secondary battery negative electrode material and a mechanical pre-lithiation method. The mechanical pre-lithiation method comprises the following steps: step 1, preparing a sheet-shaped battery negative electrode pole piece with a predetermined thickness; step 2, placing a lithium strip with a predetermined thickness and the sheet-shaped batterynegative electrode material in a dry environment, and flatly laminating the lithium strip and the sheet-shaped negative electrode material together to obtain a laminated material; and step 3, pressingthe bonding material obtained in the step 2 through pressure equipment to obtain the pre-lithiated secondary battery negative electrode material.

Owner:TONGJI UNIV

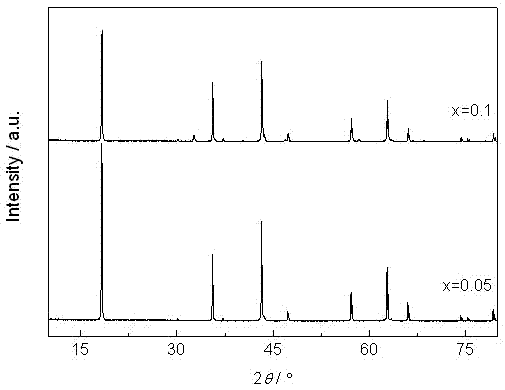

Preparation method of wide potential window negative electrode material of lithium ion battery

InactiveCN102368556ASimple manufacturing processImprove controllabilityCell electrodesElectrical batteryPhysical chemistry

The invention which provides a preparation method of a wide potential window negative electrode material of a lithium ion battery belongs to the technical field of lithium ion batteries. The preparation method of the invention comprises the following steps: 1, mixing a lanthanum source, TiO2 with different crystal forms, and a lithium source, and grinding for 6-12h in a ball mill to obtain a mixture; and 2, putting the mixture in a muffle furnace, reacting for 12-24h at 800-950DEG C, and naturally cooling to room temperature to obtain the wide potential window negative material Li4La5-xLaxO12of the lithium ion battery, wherein x is 0.05 or 0.1. The negative electrode material prepared in the invention has a wide potential window, a good reversible capacity, an excellent rate performance and a stable cycle life, so the material which has a high practical use value allows practical requirements of various applications of the lithium ion battery to be effectively satisfied. In addition, the method of the invention has the characteristics of simplified preparation technology, high controllable reappearance, low production cost and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

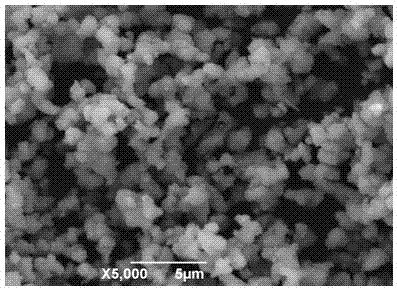

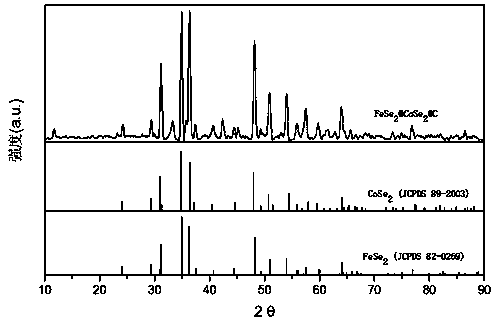

Preparation method of hexagonal-prism-shaped iron-cobalt double-metal selenide

ActiveCN110867571AImprove conductivityStable structureMaterial nanotechnologyCell electrodesCobalt metalIron salts

The invention belongs to the field of inorganic materials, and particularly relates to a preparation method of hexagonal-prism-shaped iron-cobalt double-metal selenide. The preparation method comprises the following steps: S1, mixing and dissolving iron salt and cobalt salt in isopropanol; S2, preparing a PVP isopropanol solution; S3, preparing a NaHCO3 aqueous solution; S4, mixing the solutions obtained in the step S1 and the step S2 according to a volume ratio of 1:(1-3), and carrying out ultrasonic treatment for 10-20 minutes; S5, adding the mixed solution obtained in the step S4 into the NaHCO3 aqueous solution to obtain an iron-cobalt metal precursor; and S6, mixing the iron-cobalt metal precursor obtained in the step S5 with selenium powders according to a mass ratio of 1: (1-3), andcarrying out calcining for 3-5 hours. The iron-cobalt bimetal selenium composite carbon material prepared by the preparation method provided by the invention has relatively stable cycle life and ratecapability; and the conductivity of the material can be enhanced by doping carbon, so that the specific capacity of a battery is improved.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Preparation method of lithium sodium titanate negative electrode material with multistage structure

ActiveCN107742718AStable structureCompact structureCell electrodesSecondary cellsDispersityHigh rate

The invention discloses a preparation method of a lithium sodium titanate negative electrode material with a multistage structure, and belongs to the technical field of lithium ion batteries. The method comprises the following specific steps: dissolving tetrabutyl titanate, lithium acetate and sodium nitrate in an alcohol solution, adding citric acid to serve as a chelating agent, then adding an amine compound, stirring to form gel, and performing vacuum drying; then mixing gamma-LiAlO2 with the dried gel, performing ball milling, performing preheating treatment in the air, then performing ball milling and calcining to obtain a Na2Li2Ti6O14@gamma-LiAlO2 material; putting the Na2Li2Ti6O14@gamma-LiAlO2 material into distilled water, performing ultrasonic treatment and adding sodium dodecyl benzene sulfonate; and pouring a dissolved pyrrole solution into the mixture, stirring, adding an initiator, centrifuging, washing and drying to obtain a target product. The synthesized negative electrode material has the advantages of uniform and consistent particles, high dispersity and high degree of crystallinity; with a stable multistage composite structure, the negative electrode material hasconsiderable wide-potential-window reversible capacity, high rate performance and stable cycle life.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Lithium manganese phosphate composite material as well as preparation method and application thereof

InactiveCN109742340AUniform particle sizeStable structureMaterial nanotechnologyCell electrodesPhosphateLithium hydroxide

The invention discloses a preparation method of a lithium manganese phosphate composite material; the preparation method comprises the following steps of dissolving manganese sulfate monohydrate and ferrous sulfate heptahydrate into deionized water, then adding ethylene glycol to stir to obtain a mixed solution; dropwise adding an ethylene glycol phosphate solution into a lithium hydroxide ethylene glycol solution for stirring, then dropwise adding the mixed solution, stirring, and carrying out hydrothermal reaction, and drying to obtain a LiMn0.5Fe0.5PO4 precursor; sequentially dissolving lithium hydroxide, tetrabutyl titanate and lanthanum nitrate into absolute ethyl alcohol for stirring, then adding deionized water, and then adding the LiMn0.5Fe0.5PO4 precursor for stirring, carrying out hydrothermal reaction and drying to obtain a Li0.3La0.56TiO3-LiMn0.5Fe0.5PO4 precursor; and enabling the Li0.3La0.56TiO3-LiMn0.5Fe0.5PO4 precursor to be mixed with glucose, and performing ball milling, calcining, cooling and sieving to obtain the lithium manganese phosphate composite material. The lithium manganese iron phosphate composite material is relatively small in particle size, uniform in particle size distribution, and high in degree of crystallinity, so that the electrochemical performance of the material is improved while the material preparation cost is lowered.

Owner:NANJING GUOXUAN BATTERY CO LTD

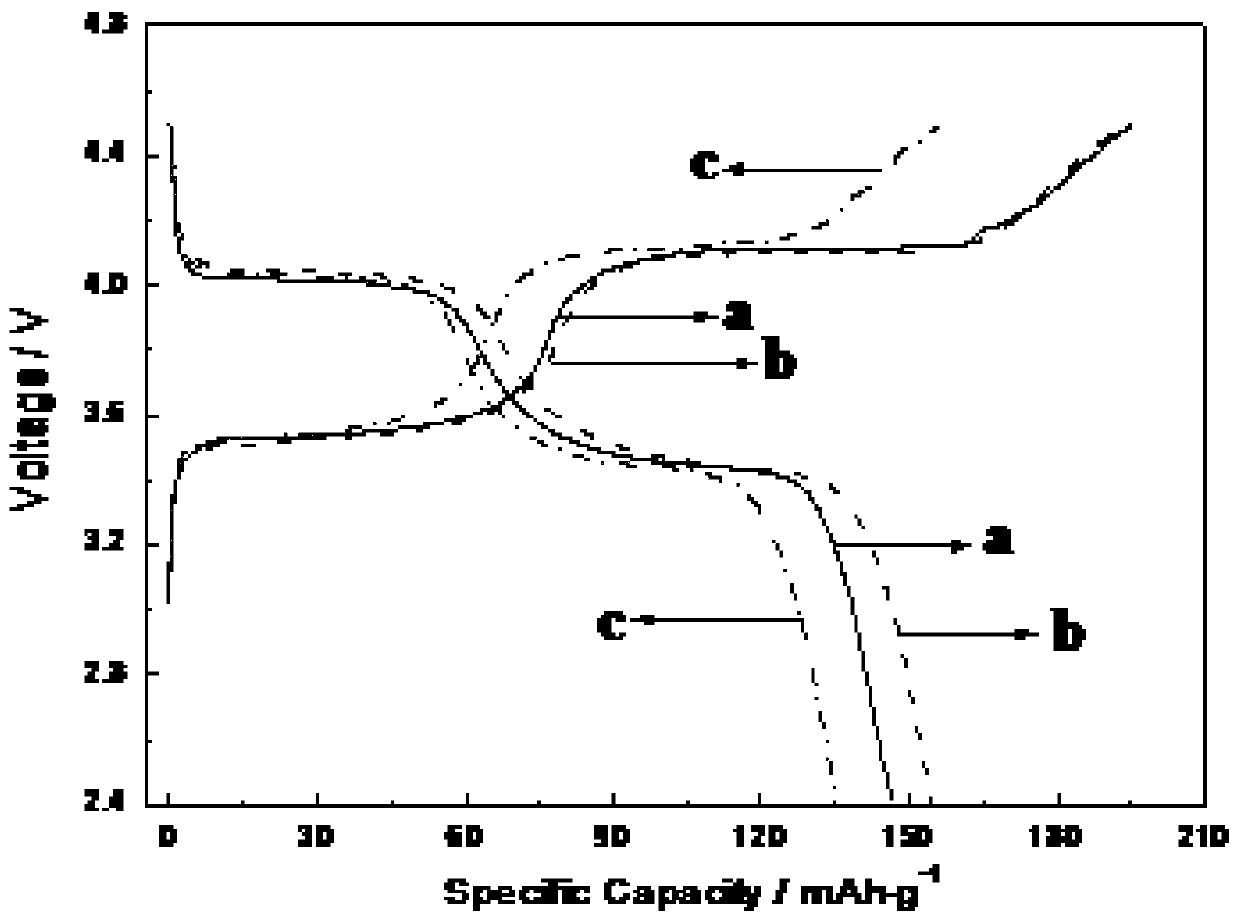

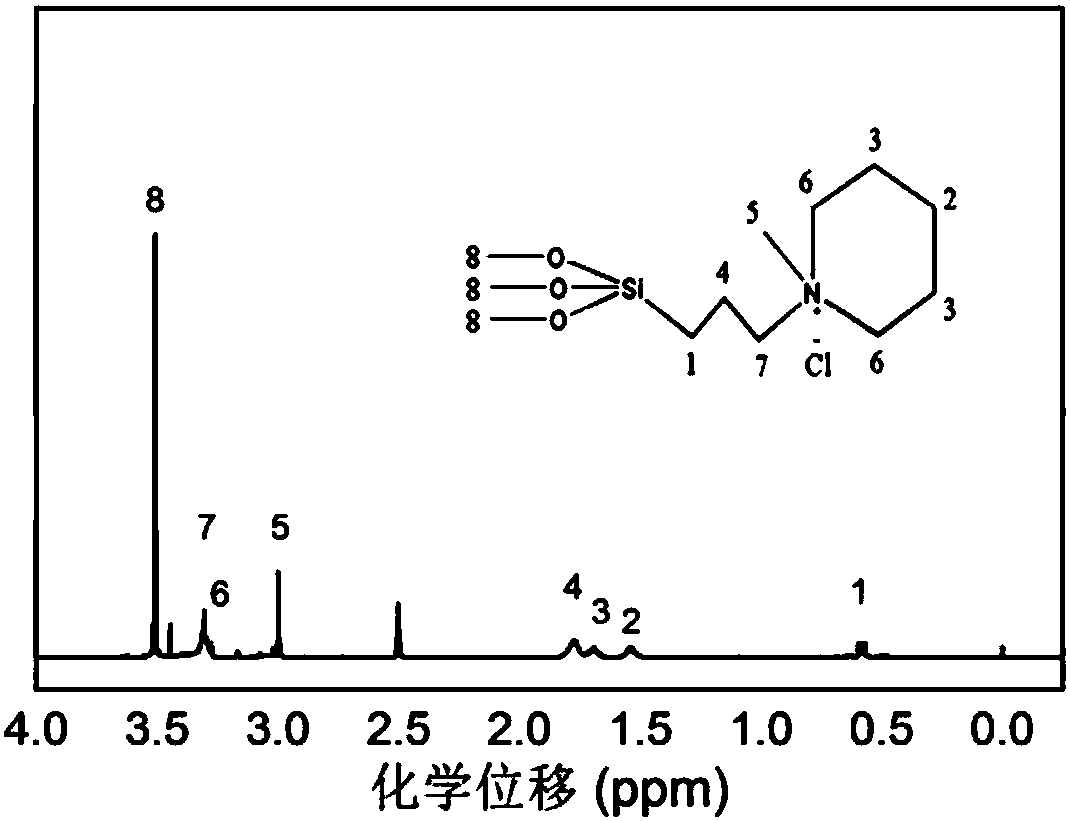

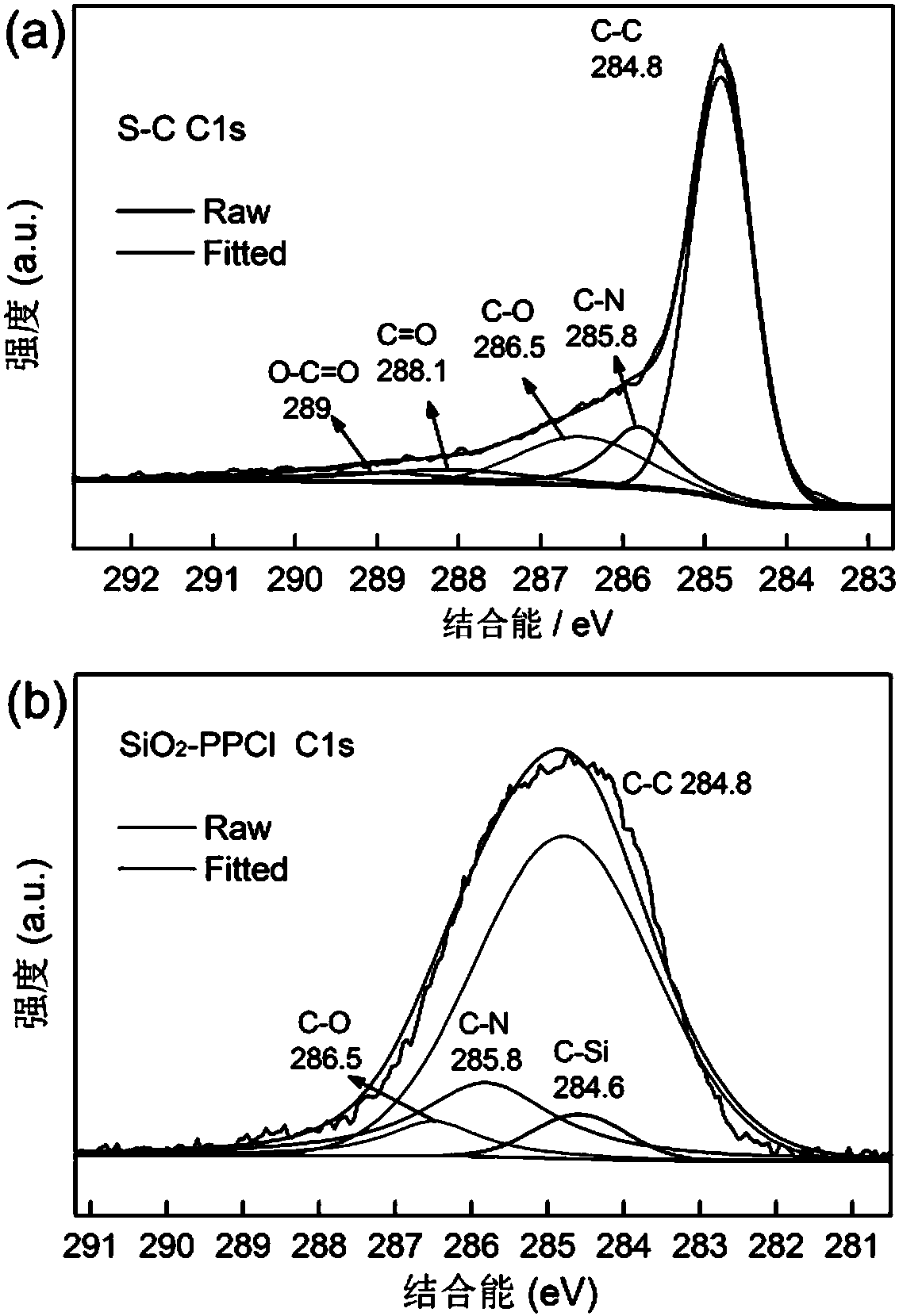

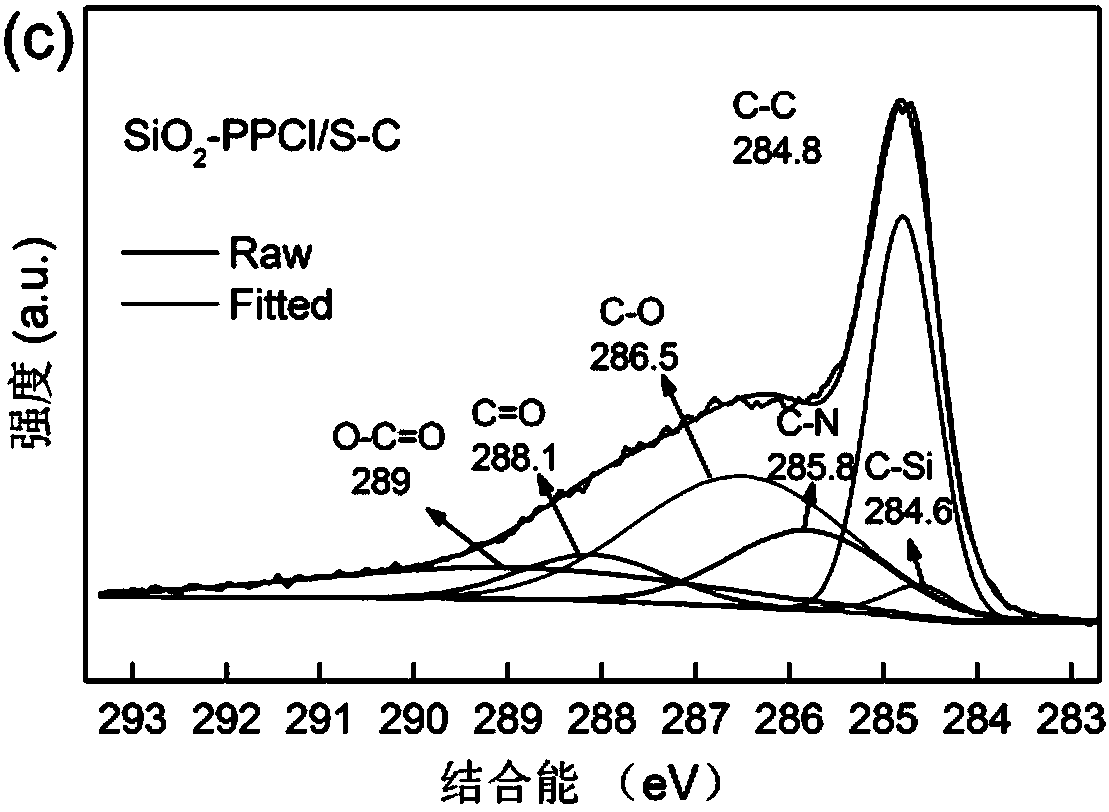

Functionalized ionic liquid/S-C composite material and preparation method and composite cathode material thereof

The invention relates to a functionalized ionic liquid / S-C composite material and a preparation method and a composite cathode material thereof, and belongs to the technical field of flow battery. Thefunctionalized ionic liquid comprises an ionic liquid and SiO2. The ionic liquid is 1-methyl-1-propyl(trimethoxy silane)piperidine onium chloride. In the invention, the ionic liquid (SiO2-PPCl) functionalized sulfur supernatant solution flow electrode is used as the cathode of a lithium-sulfur flow battery. During charge-discharge process, an active substance polysulfide can react with a functional group in SiO2-PPCl to form a bond so as to inhibit migration of polysulfide to lithium anode. During charge-discharge process, the ionic liquid is also helpful for helpful for reducing electrochemical polarization and promoting conversion between active substances.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of silicate positive electrode material for lithium ion battery

InactiveCN101920971AHigh purityGood reproducibilityCell electrodesSilicon compoundsDispersityAluminium-ion battery

The invention discloses a preparation method of a silicate positive electrode material for a lithium ion battery, which comprises the following steps of: dissolving manganous sulfate and ferrous sulfate into distilled water, after the manganous sulfate and the ferrous sulfate are completely dissolved, stirring while dripping 3-5mol / L of sodium hydroxide solution until the pH value is 11-13 so as to ensure that manganese ions and iron ions are completely precipitated; then filtering the precipitates and cleaning the precipitates with the distilled water; mixing the precipitates with silicon dioxide, lithium hydroxide and lithium nitrate; and carrying out one-step sintering on the mixed materials for 8-12h in the presence of inert gas shielding at 550-600DEG C to obtain Li2Mn1-xFexSiO4 powder as the silicate positive electrode material. The invention has the advantages that one-step sintering is only needed, is the method is simpler and more convenient compared with the traditional process with multiple sintering; meanwhile, because a high-temperature sintering process is avoided in the method, the positive electrode materials prepared are uniform with good dispersity, thereby ensuring that the prepared positive electrode material has favorable electrochemical property.

Owner:NINGBO UNIV

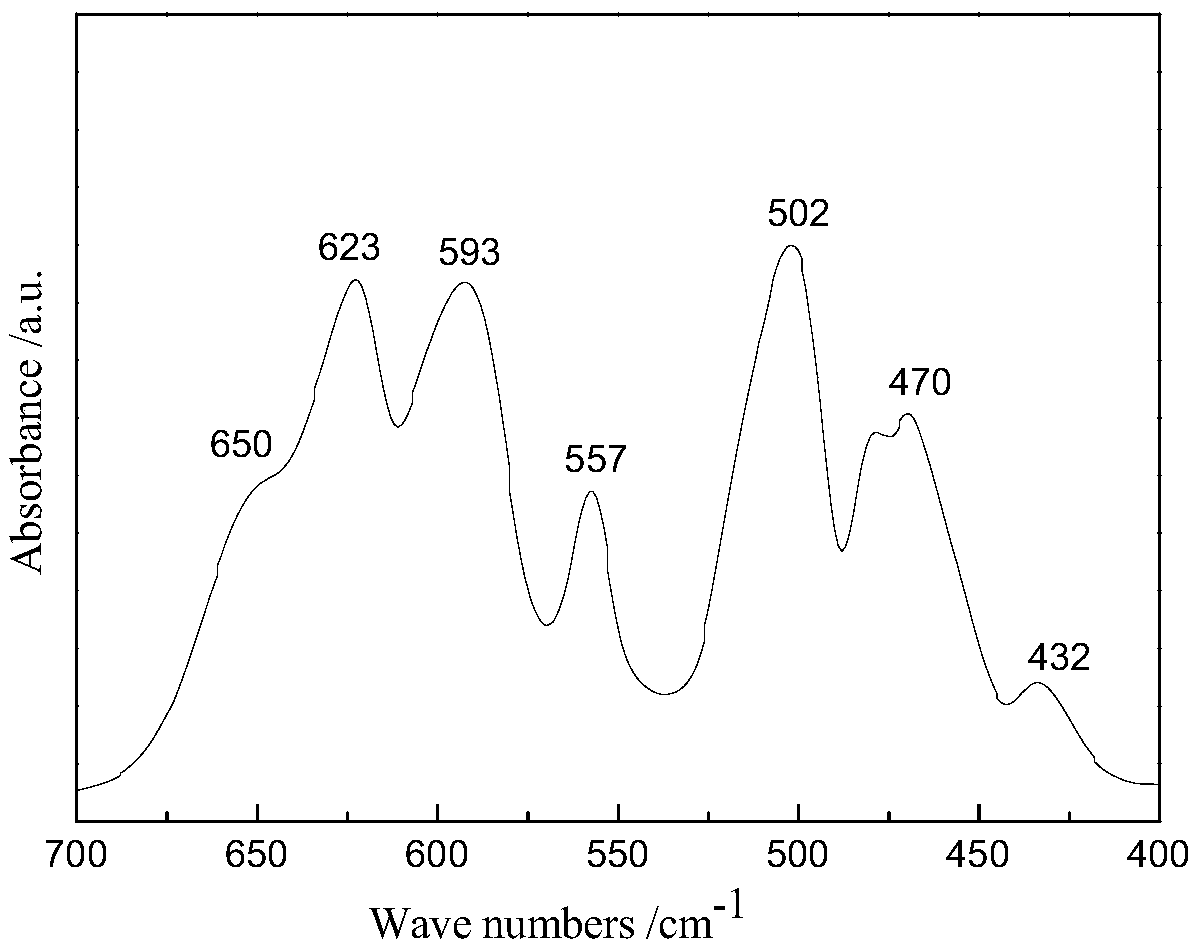

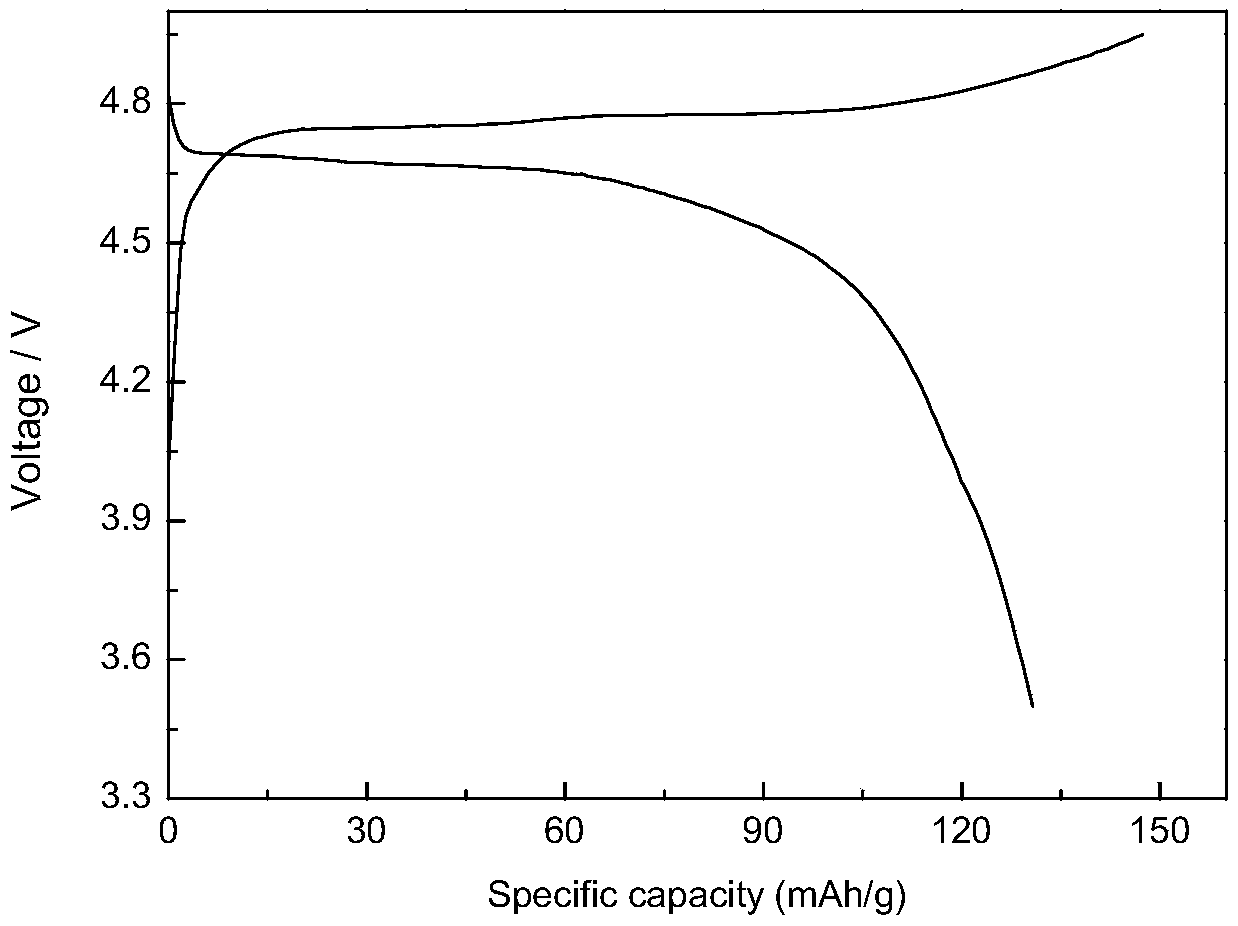

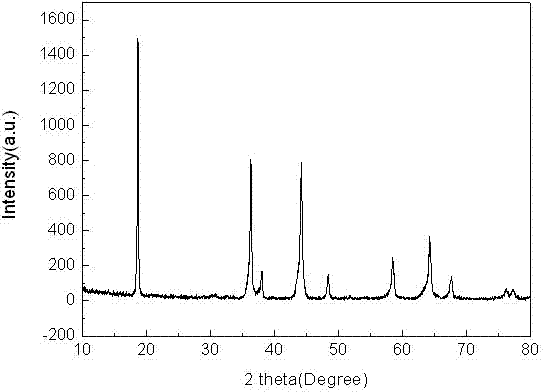

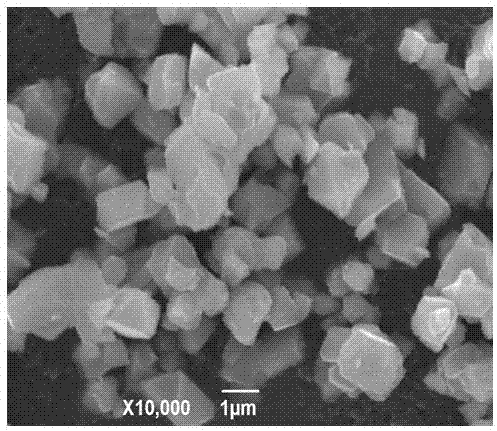

Preparation method of spherical porous lithium-ion battery high-voltage cathode material

InactiveCN105514412AImprove electrochemical performanceUniform particlesCell electrodesSecondary cellsHigh energyHigh pressure

The invention discloses a preparation method of a spherical porous lithium-ion battery high-voltage cathode material and belongs to the technical field of lithium-ion batteries. The chemical formula of the material is LiNi0.5Mn1.5O4-Li3xLa(2 / 3)-xTiO3, wherein 0.05<x<0.15, and the mass fraction of the Li3xLa(2 / 3)-xTiO3 is 5%. The material is prepared by adopting an organic solvent assisted coprecipitation method. The preparation method is wide in raw material source, simple and convenient to operate, good in controllability and high in reproducibility, and the long-time high-energy-consumption high-temperature sintering process is avoided. The prepared material has the porous spherical characteristics, is small in granule, uniform in particle size distribution, high in crystallinity and better in rate performance, is of a P4332 structure and can be used as the high-performance lithium-ion battery high-voltage cathode material.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Preparation method of lithium ion battery anode material with high multiplying power

InactiveCN102364731ASimple manufacturing processImprove controllabilityCell electrodesNiobiumRoom temperature

The invention provides a preparation method of a lithium ion battery anode material with high multiplying power, belonging to the technical field of lithium ion batteries. The preparation method comprises the following steps of: mixing a lithium source, a manganese source, a nickel source and a niobium source according to a certain stoichiometric ratio, grinding for 5-10h in a ball mill to obtain a mixture, putting the mixture into a muffle furnace, heating to 850-950 DEG C at a temperature rise speed of 5-10DEG C / min, reacting for 15-24h at 850-950 DEG C, and then naturally cooling to room temperature to obtain an LiMn1.425Ni0.525Nb0.05O4 anode material. The anode prepared by the preparation method disclosed by the invention has considerable reversible volume, excellent multiplying power and stably cycle life, thereby having higher actual usage value and being capable of effectively meeting actual requirements of various applications of lithium ion batteries. In addition, the preparation method disclosed by the invention has the characteristics of simplified preparation process, high controllable repeatability, low production cost and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Preparation method of titanate composite negative electrode material for lithium ion battery

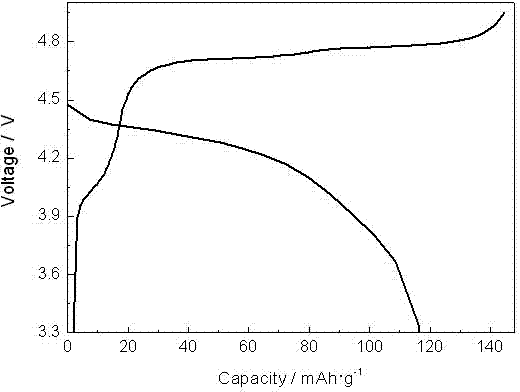

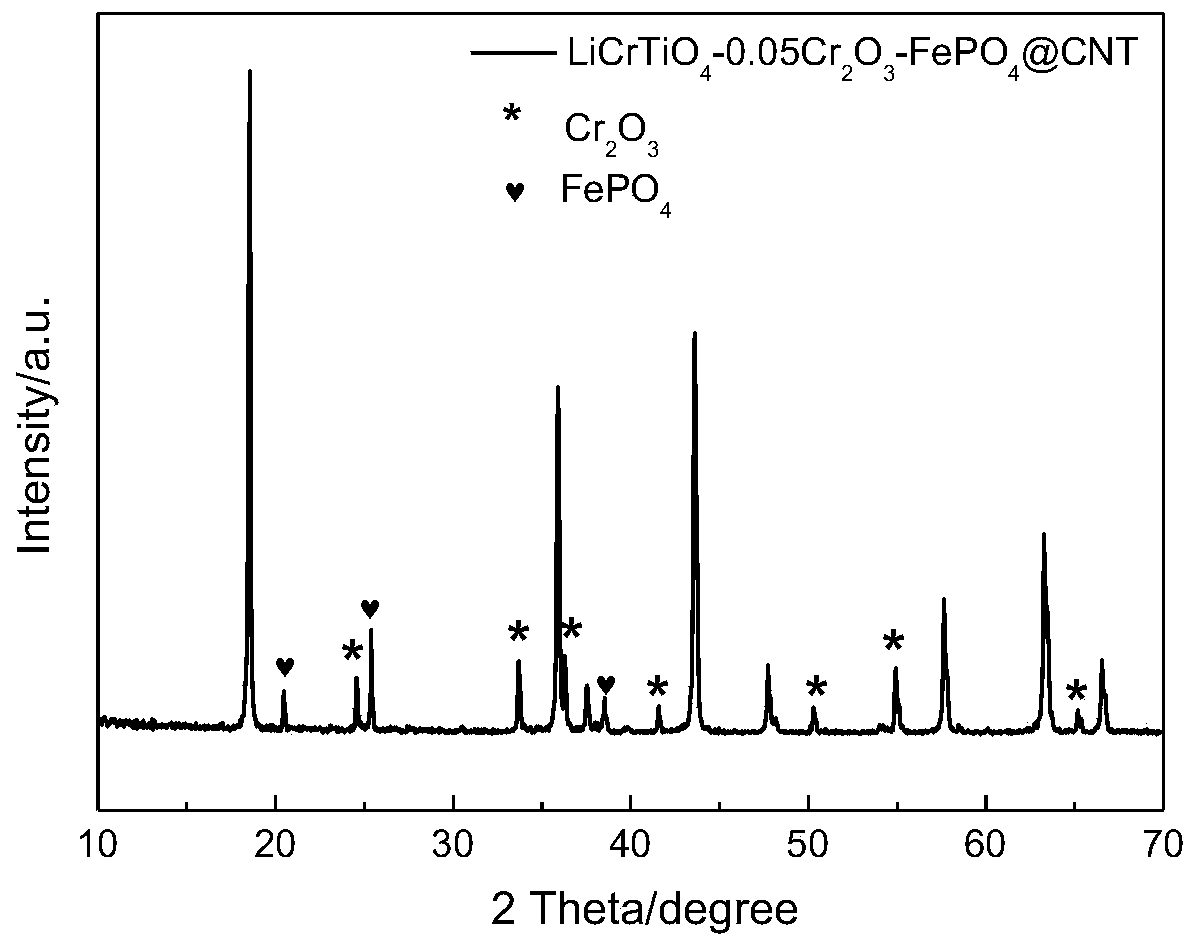

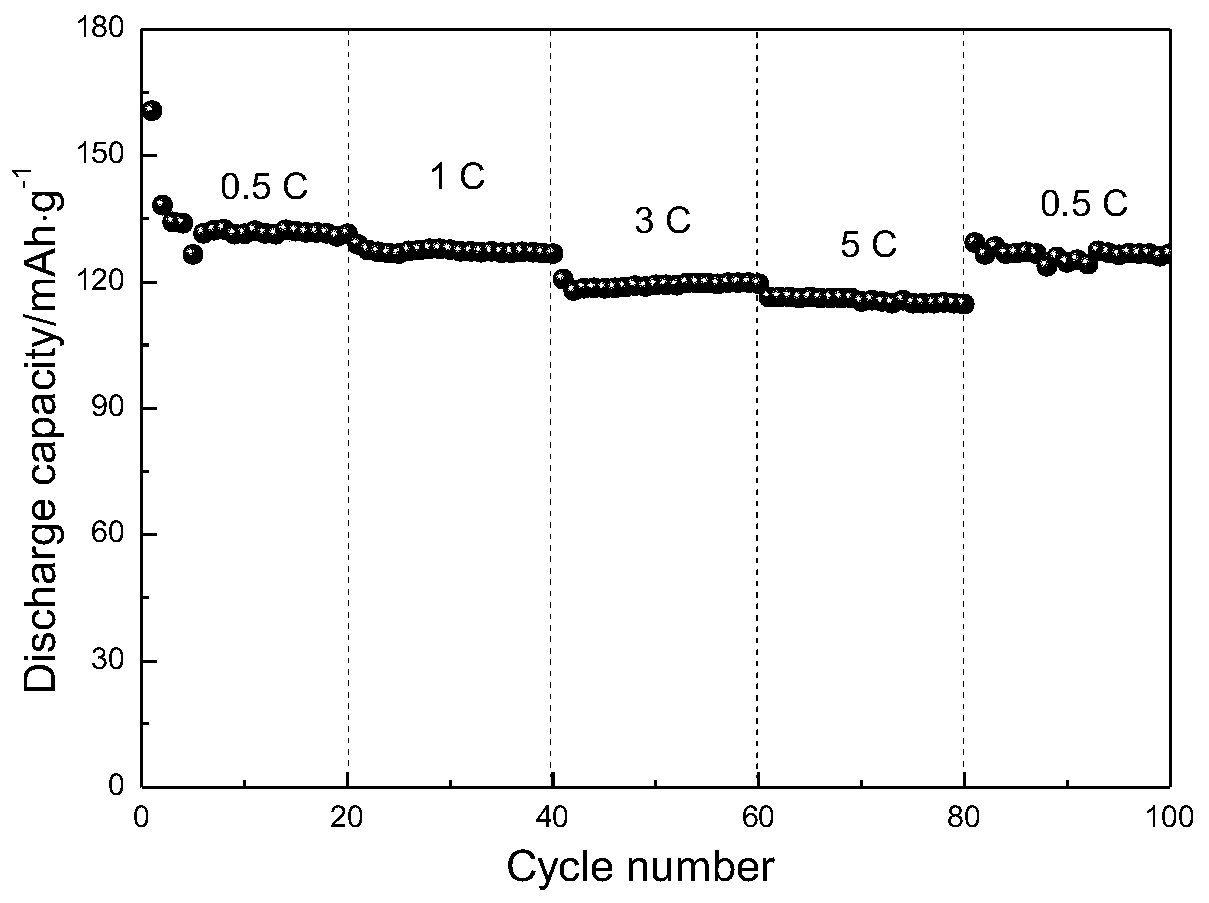

ActiveCN110176584AUniform particlesGood dispersionSecondary cellsNegative electrodesWater bathsCrystallinity

The invention discloses a preparation method of a titanate composite negative electrode material for a lithium ion battery. The preparation method comprises the following steps of dissolving a titanium source and a chromium source in an ethanol aqueous solution, adding citric acid under a stirring condition, adding the ethanol aqueous solution comprising a lithium source, performing water bath heating to form a gel state, performing drying and grinding, placing the product in a muffle furnace for pre-burning, and cooling to a room temperature to obtain a LiCrTiO<4-a<Cr2O3 precursor; dissolvingthe LiCrTiO<4-a<Cr2O3 precursor and FePO4 in absolute ethyl alcohol, performing uniform stirring and drying, cooling to the room temperature, placing the product in a ball-milling machine for ball-milling, performing sieving, placing the product in the muffle furnace for calcination, and cooling to the room temperature to obtain a LiCrTiO<4-a>Cr2O3-FePO4 electrode material; and dispersing the electrode material in an acetone solution, adding CNT, performing stirring, allowing a liquid to be completely volatilized to obtain the titanate composite negative electrode material for the lithium ionbattery. The preparation method has the advantages of wide raw materials, good controllability and high reproducibility and is simple and convenient to operate, the obtained material is relatively small in particle, uniform in grain size distribution and high in crystallinity, so that the material preparation cost is reduced, and the electrochemical performance of the material is improved.

Owner:NANJING GUOXUAN BATTERY CO LTD

Grinding preparation method and application of polyoxometallate-metal organic framework material

ActiveCN110444410AHigh specific capacitanceStable cycle lifeHybrid capacitor electrodesHybrid/EDL manufacturePolymer scienceMetal-organic framework

Owner:HARBIN NORMAL UNIVERSITY

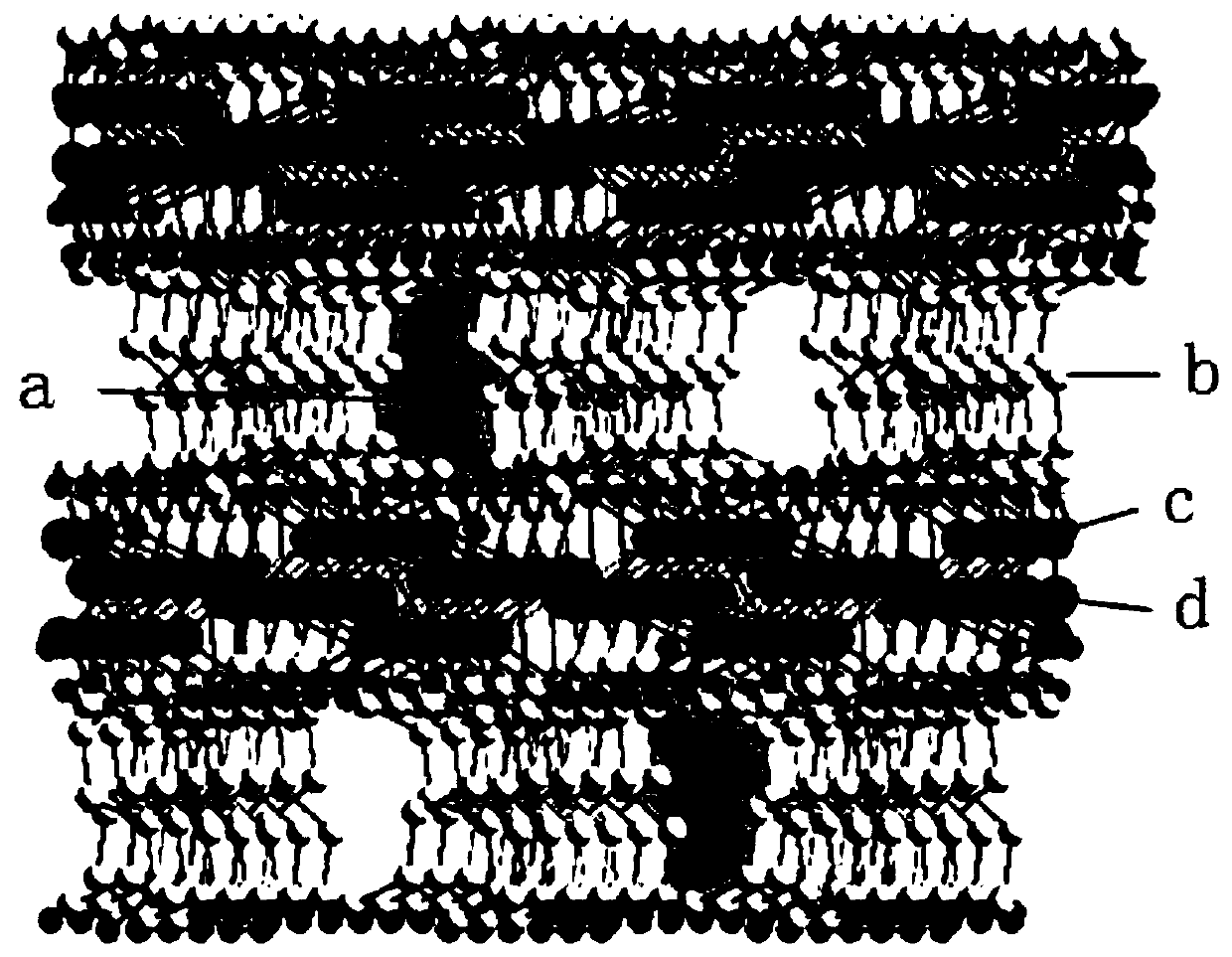

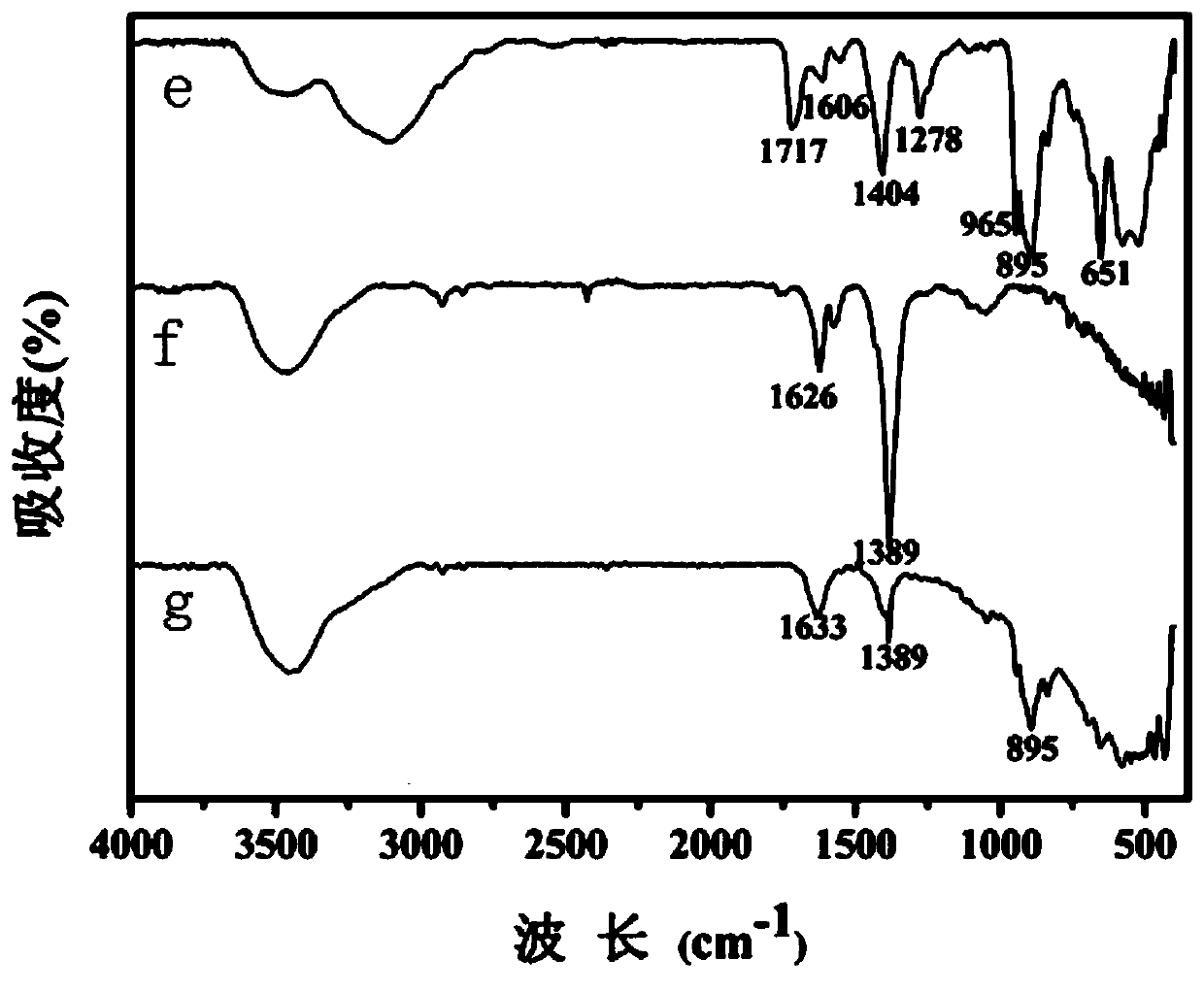

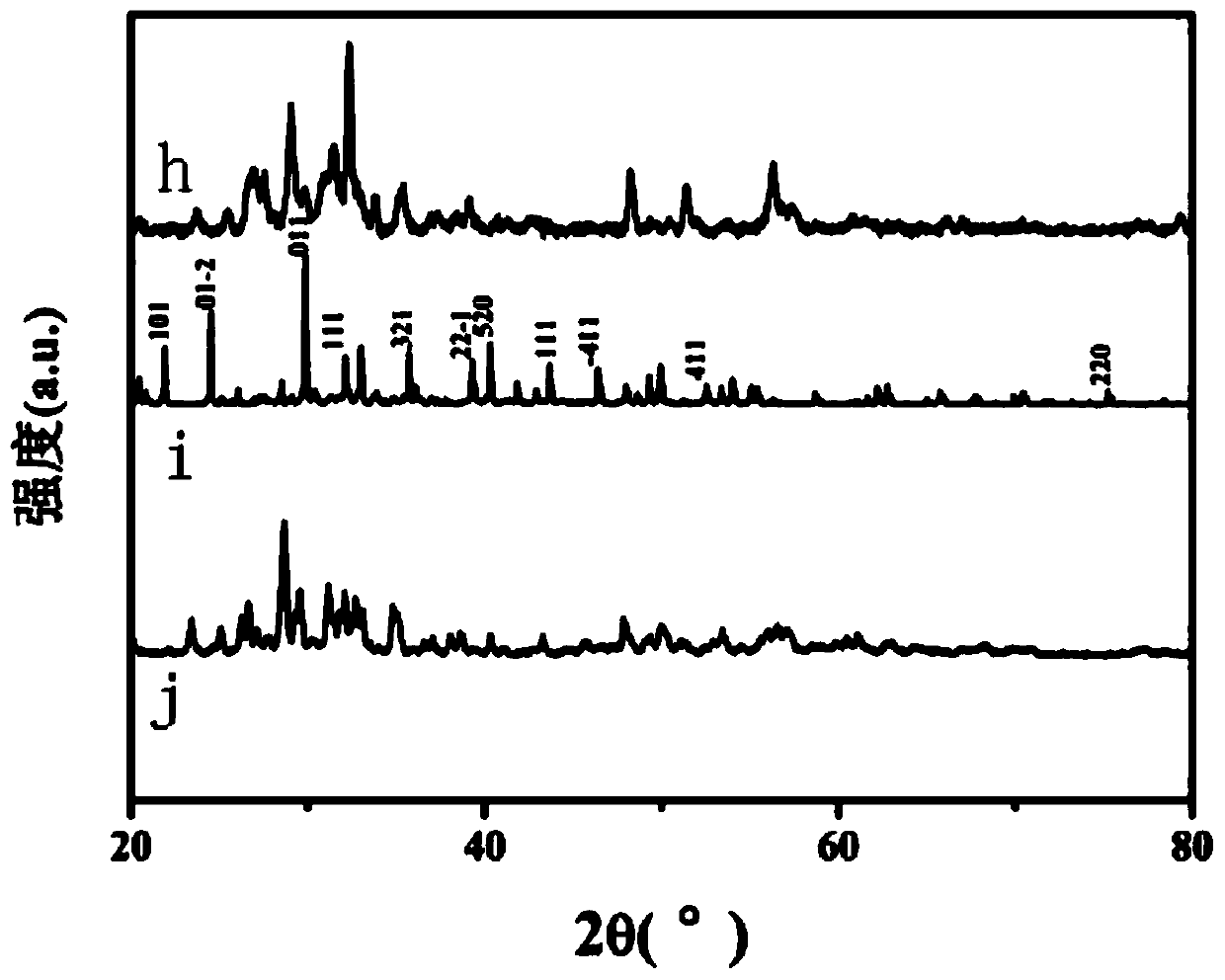

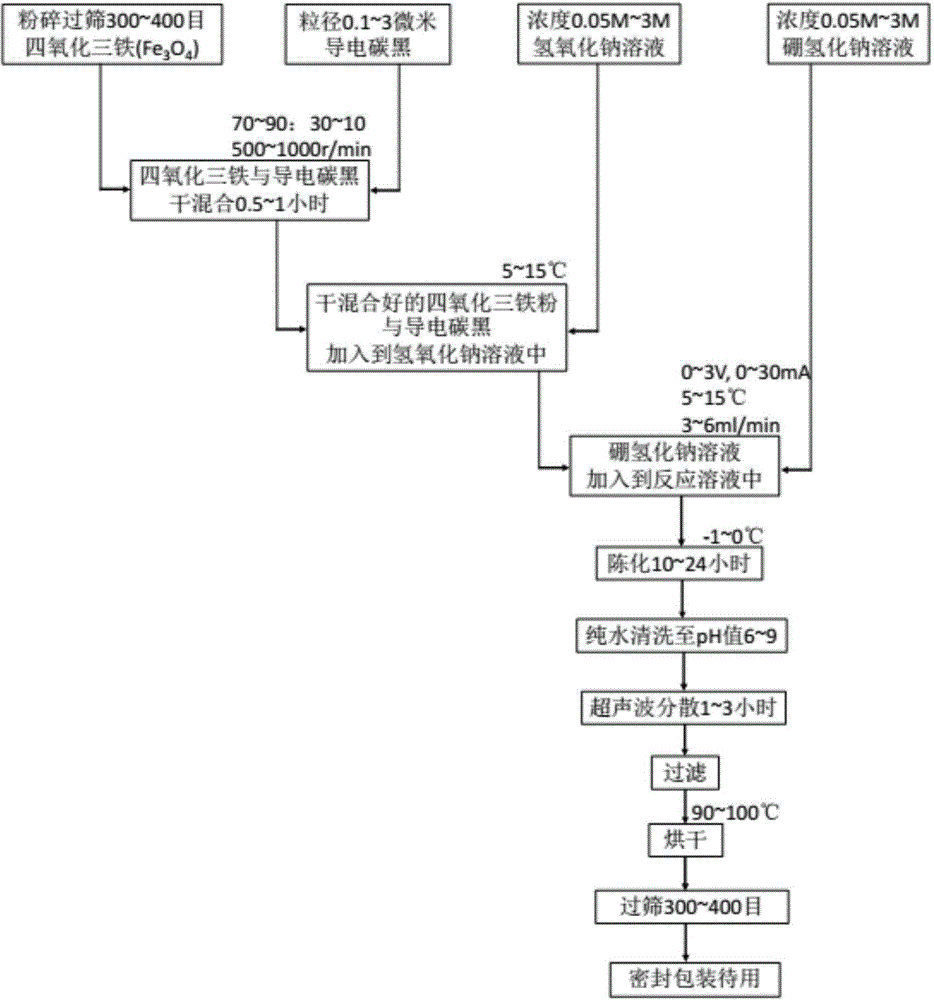

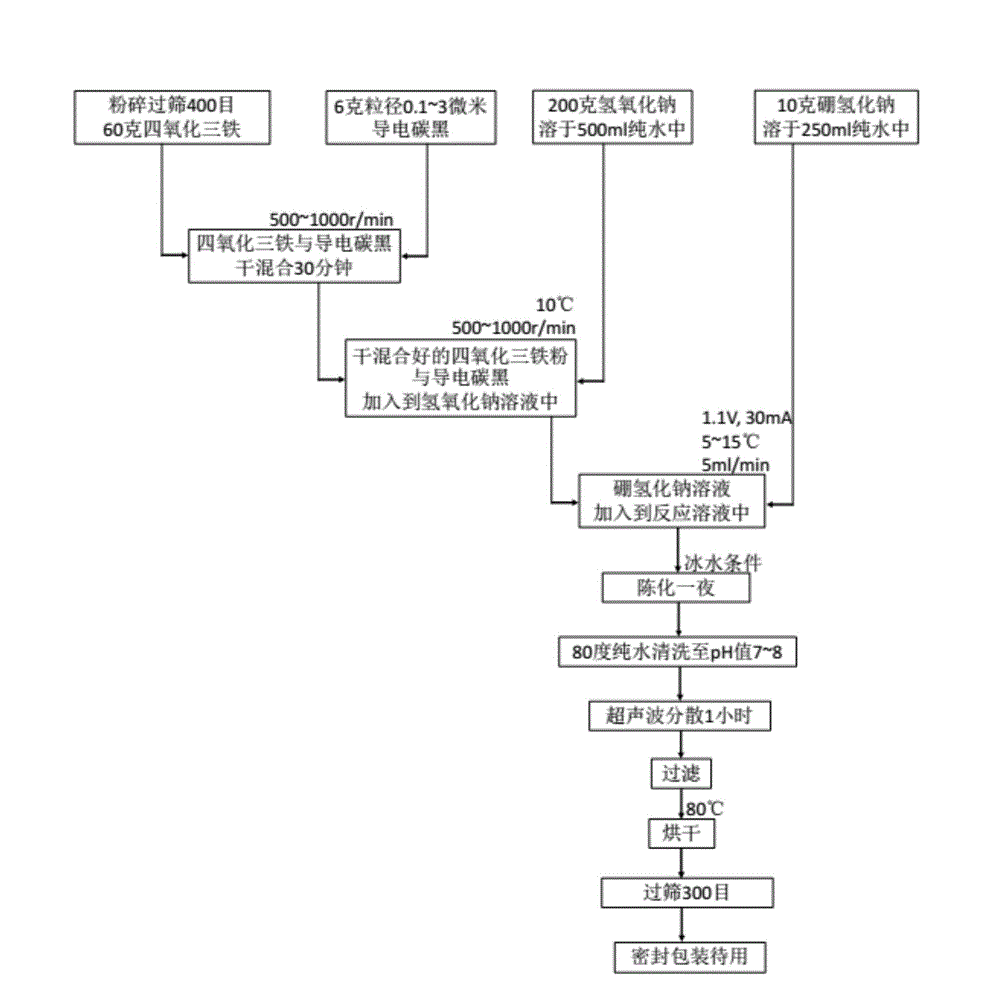

Preparation method for carbon-coated nano ferroferric oxide for battery

InactiveCN104953113ASolution to short lifeImprove electrical performancePositive electrodesBatteriesDry mixingCharge discharge

The invention provides a preparation method for carbon-coated nano ferroferric oxide for a battery. The method comprises the following steps: performing dry mixing on ferroferric oxide and conductive carbon black with high purity; adding the ferroferric oxide and conductive carbon black which are subjected to dry mixing into a prepared sodium hydroxide solution; adding a prepared sodium borohydride solution into a reaction solution; aging; cleaning with pure water; dispersing by using ultrasonic waves; filtering; stoving; sieving; and sealing and packaging. An iron nickel battery produced from the carbon-coated nano ferroferric oxide for a battery electrode is high in gram volume, high in charging-discharging efficiency, low in self discharging rate, simple in process, high in strength and long in service life, and can be sealed.

Owner:LONGZHOU WANHE TRADING CO LTD

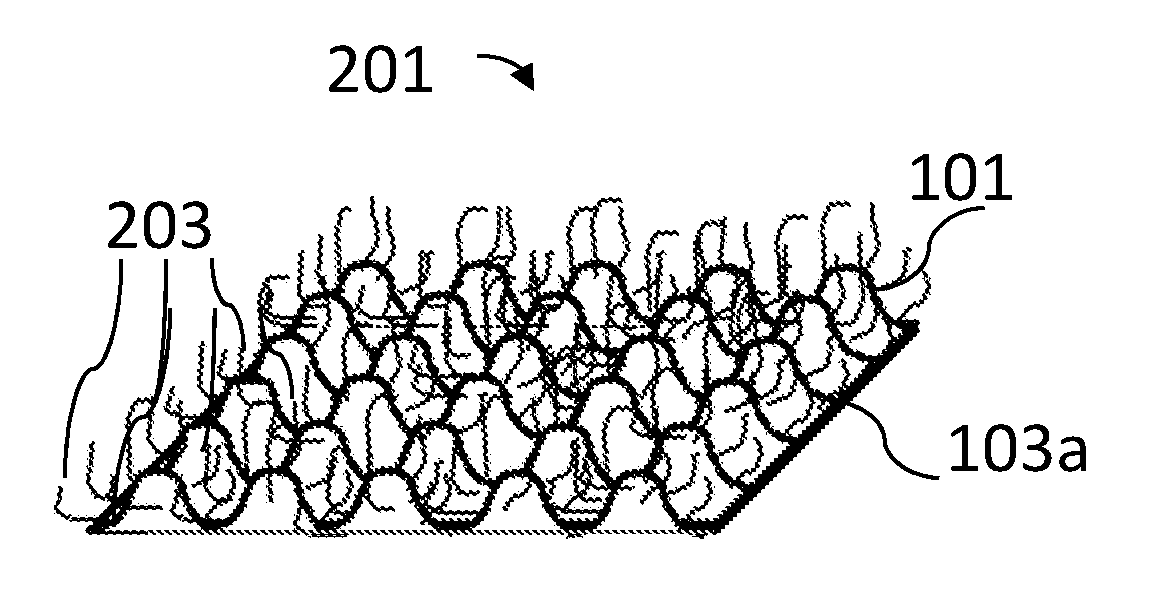

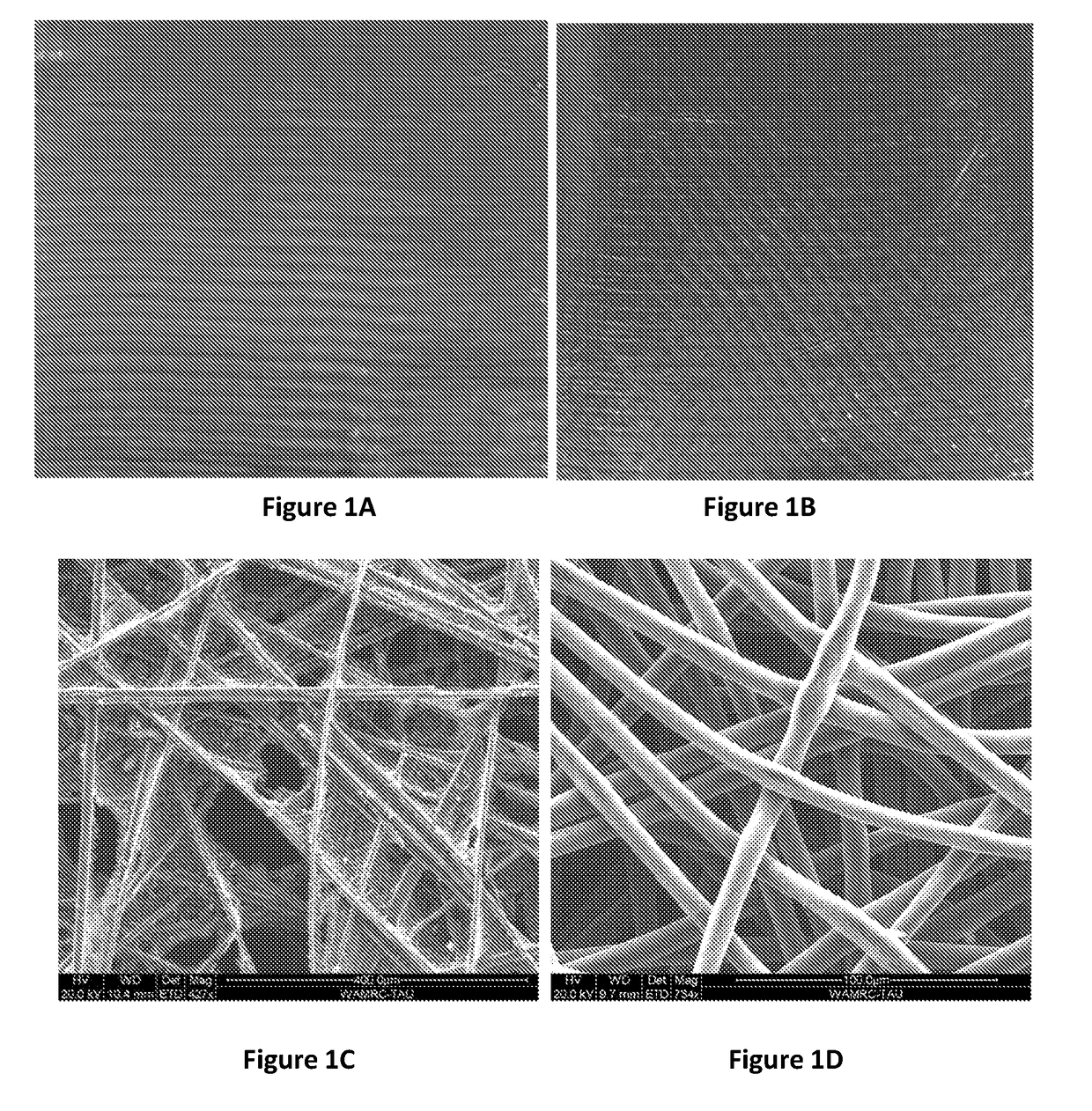

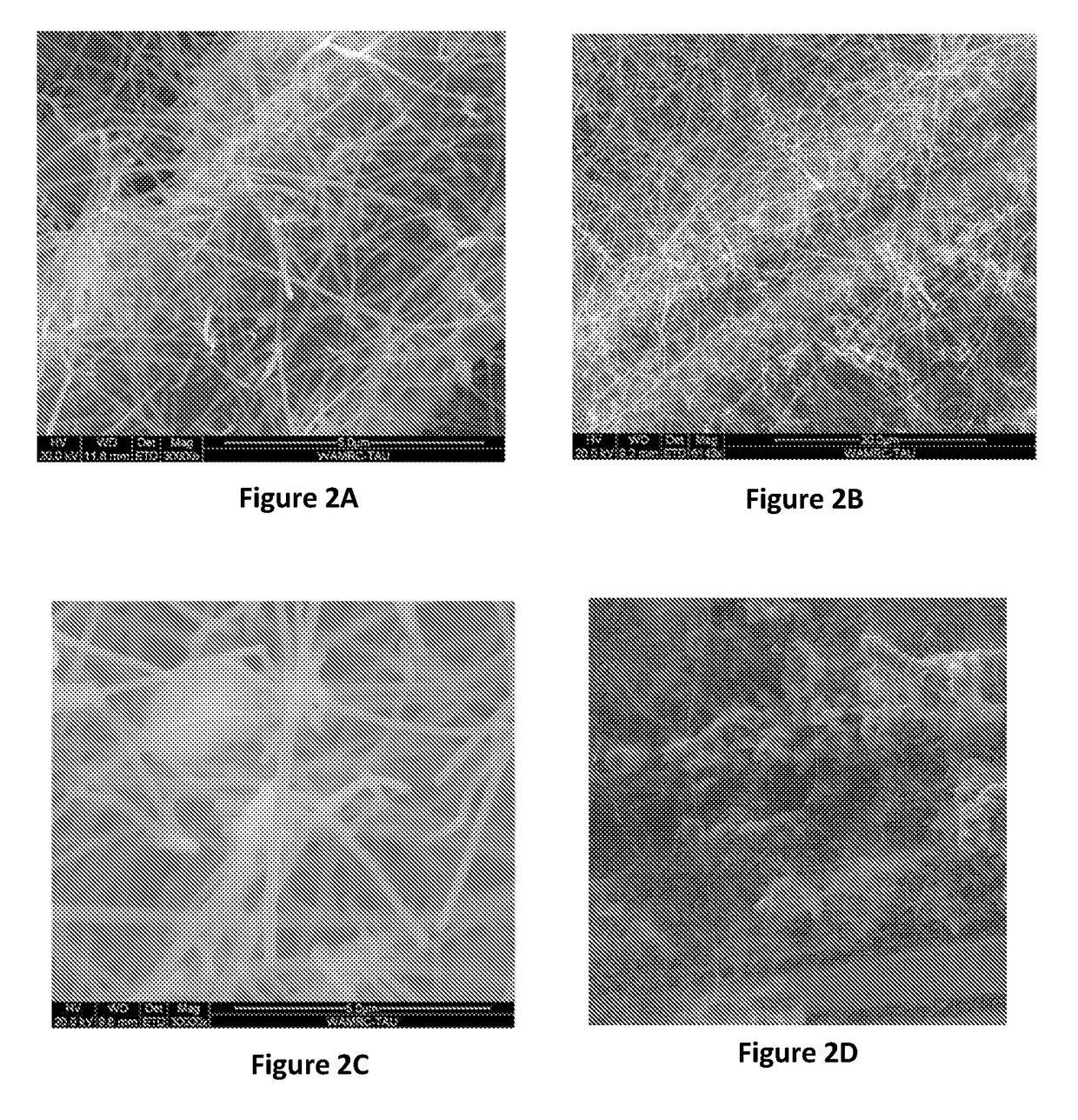

HIGH-CAPACITY SILICON NANOWlRE BASED ANODE FOR LITHIUM-ION BATTERIES

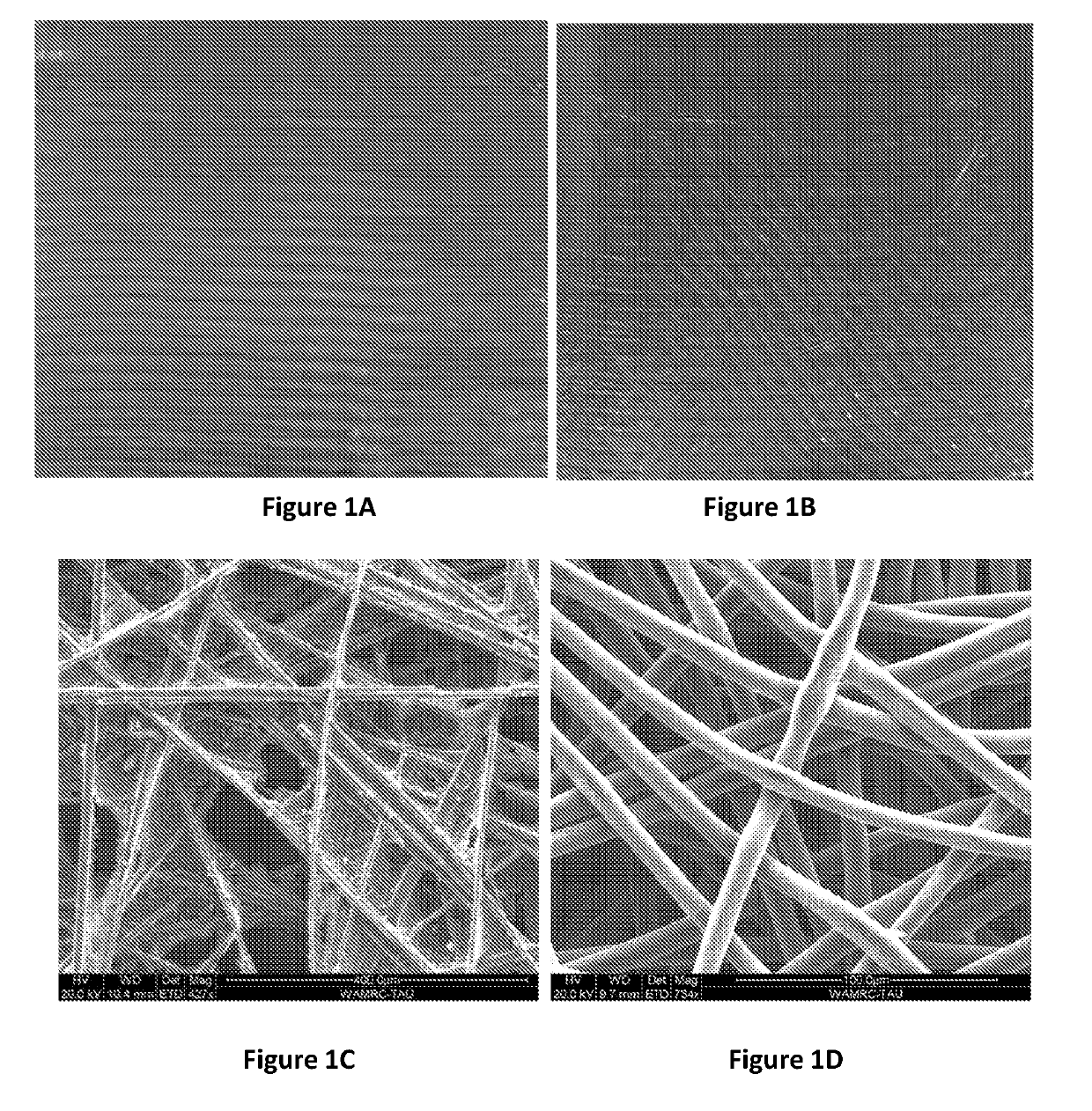

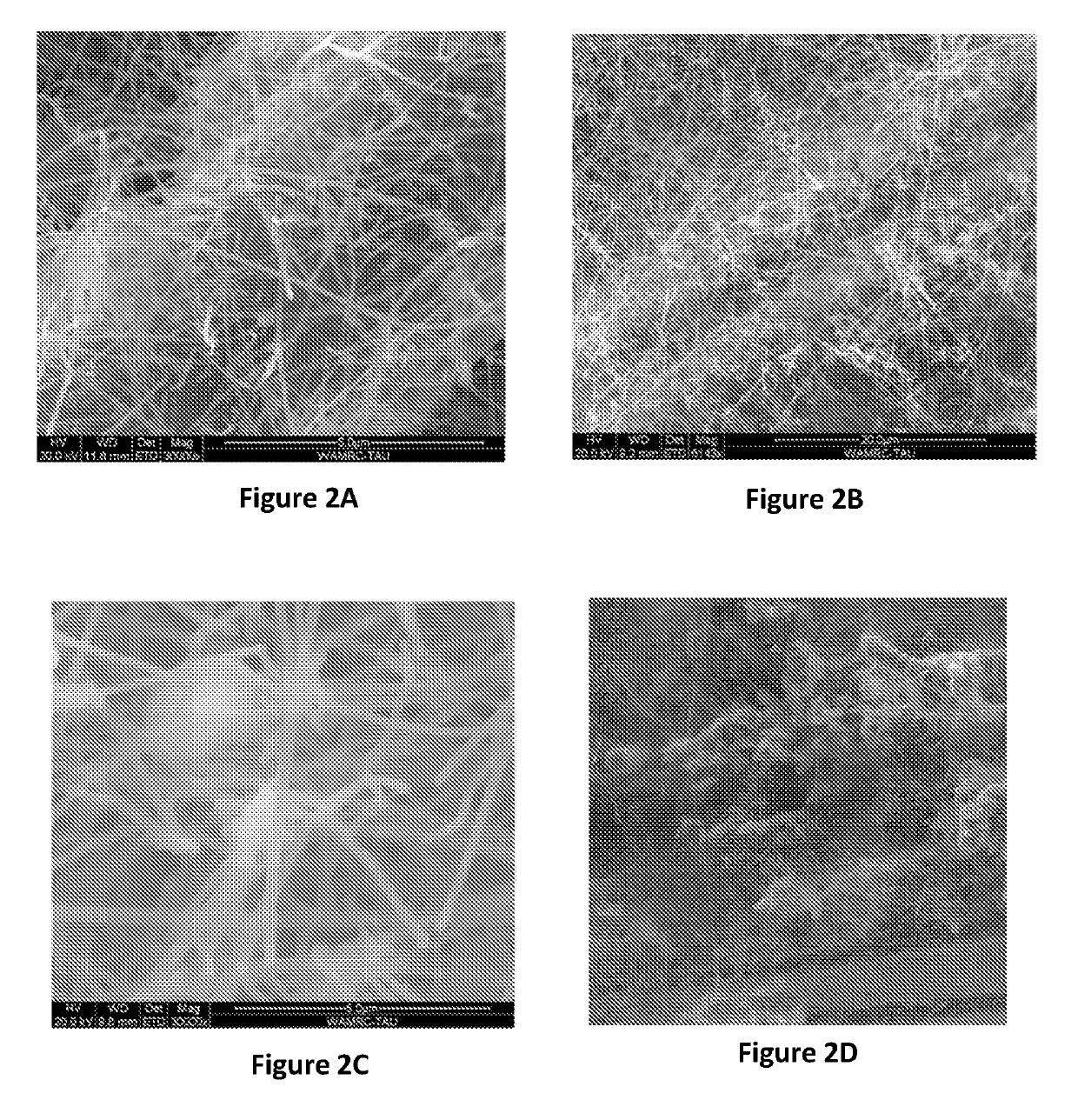

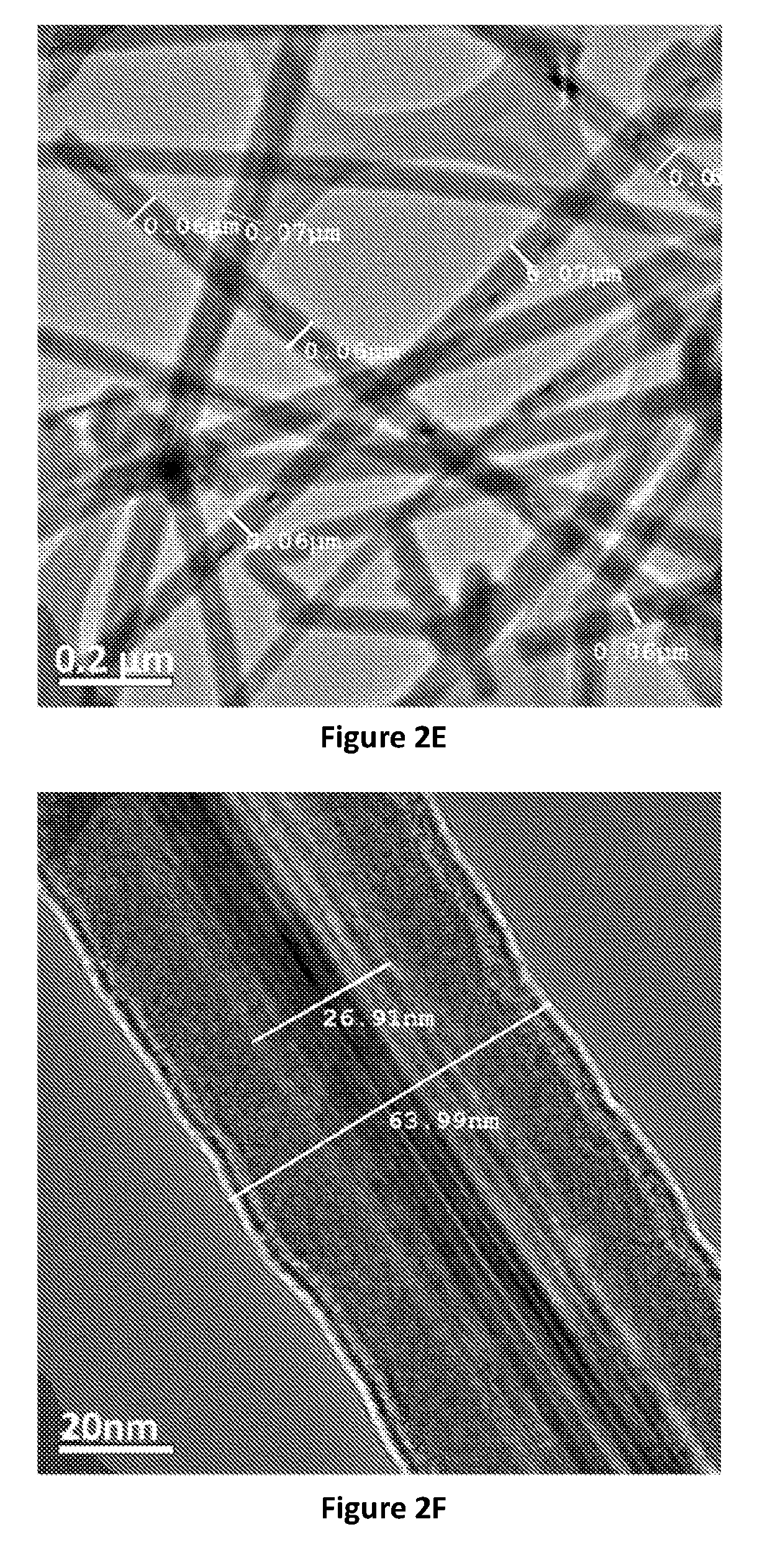

InactiveUS20170309903A1Stable cycle lifeHigh mechanical strengthMaterial nanotechnologyElectrode carriers/collectorsSilicon nanowiresLithium-ion battery

The present invention provides anodes comprising an electrically conductive substrate, comprising at least one non-uniform surface; and a random network of silicon nanowires (Si NWs) chemically grown on said at least one non-uniform surface of the substrate, wherein the Si NWs have at least about 30% amorphous morphology, and methods of manufacturing of the anodes. Further provided are lithium ion batteries comprising said anodes.

Owner:RAMOT AT TEL AVIV UNIV LTD

Preparation method of lithium titanate negative electrode material of lithium ion battery

ActiveCN111403721AStable structureCompact structureCell electrodesSecondary cells servicing/maintenancePhysical chemistryMixed gas

The invention provides a preparation method of a lithium titanate negative electrode material of a lithium ion battery. The invention belongs to the technical field of lithium-ion batteries. The method comprises the following steps: preparing porous Li4Ti5O12 nanosheets by utilizing LiOH.H2O, Ti (OC4H9) 4 and the like; then preparing nitrogen-doped carbon nanosheets by utilizing medium-temperaturecoal pitch and the like; then, grinding and transferring the porous Li4Ti5O12 nanosheets, the nitrogen-doped carbon nanosheets and a sulfur-containing substance into a tubular furnace; and carrying out continuous heat treatment in a mixed gas at 500-600 DEG C for 3 hours, and naturally cooling to room temperature to obtain a coal pitch-based sulfur and nitrogen-doped carbon nanosheet modified sulfur-doped lithium titanate negative electrode material with a hierarchical structure. The negative electrode material prepared by the invention is in a nanosheet shape, is stable and compact in structure, maintains the stability and high conductivity of an electrode structure, and has excellent high-rate performance and cycling stability.

Owner:JIANGSU AOXIN TECH DEV

Method for preparing chromium-titanium-based lithium ion battery composite material

ActiveCN110137450ASmall particle sizeEvenly distributedCell electrodesSecondary cellsLithium-ion batteryLithium electrode

The invention discloses a method for preparing a chromium-titanium-based lithium ion battery composite material, comprising the following steps of: S1, dissolving a titanium source and a chromium source in an aqueous solution of absolute ethanol, adding an aqueous solution of ethanol containing a lithium source, stirring the mixed solution, and then adding an aqueous solution containing nickel nitrate and sodium molybdate, stirring the mixed solution to react at 140 to 180 degrees centigrade for 24 to 26 hours, and cooling and filtering a reaction product to obtain a precursor; S2, drying, calcining, cooling, ball milling, sieving, sintering and cooling the precursor to obtain a LiCrTiO4-aNiMoO4 material; S3, dissolving the LiCrTiO4-aNiMoO4 material in deionized water, dispersing ultrasonically the material, adding a surfactant, stirring the mixture, then adding pyrrole monomer, hydrochloric acid and an ammonium persulfate aqueous solution, stirring, filtering and drying the mixture toobtain the chrome-titanium-based lithium ion battery composite material.

Owner:NANJING GUOXUAN BATTERY CO LTD

A kind of preparation method of chromium-titanium-based lithium-ion battery multi-level structure negative electrode material

ActiveCN107732207BStable structureCompact structureCell electrodesSecondary cellsPhysical chemistryCarbon nanotube

The invention discloses a preparation method of a negative electrode material of the multistage structure of a chromium-titanium-based lithium-ion battery, and belongs to the technical field of lithium-ion batteries. The method includes the steps that a titanium source, a lithium source and a chromium source are dissolved in an alcohol solution, organic acid is added and serves as a chelating agent, stirring is conducted until gel is formed, and vacuum drying is conducted; alpha-LiALO2 prepared in advance is mixed with a precursor, pre-high-temperature treatment is conducted in the air, then ball-milling is conducted, and calcination is conducted at 800 DEG C to obtain Li5Cr7Ti6O25-LiAlO2; after mixing and ball-milling are conducted on the Li5Cr7Ti6O25-LiAlO2 and a nitrified carbon nano tube, the mixture is treated in an inert atmosphere, and an obtained product is the Li5Cr7Ti6O25@alpha-LiAlO2@CNT. The negative electrode material compounded through the method has even and uniform particles, the diversity is high, the crystallinity degree is high, and the negative electrode material has the stable multistage composite structure, so that the negative electrode material has considerable reversible capacity of wide potential windows, high rate performance, stable cycle life and a very high actual use value.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A kind of preparation method of multi-level structure titanate negative electrode material for lithium ion battery

ActiveCN107749471BStable structureCompact structureMaterial nanotechnologyCell electrodesLithium-ion batteryMuffle furnace

The invention discloses a preparation method of a multilevel structure titanate negative electrode material for a lithium ion battery, and belongs to the technical field of lithium ion batteries. Themethod concretely comprises the following steps: dispersing a sodium source and a titanium source in a glycol and anhydrous ethanol mixed solution to form a solution A; dissolving a barium source in an aqueous solution of anhydrous ethanol to form a solution B; mixing and stirring the solution A and the solution B, heating the obtained solution until evaporative drying is achieved, placing the obtained precursor in a muffle furnace, and carrying out pre-calcining, ball milling and calcining to obtain a BaNa2Ti6O14 material; dispersing the material in an acetone solution, adding carbon nano-tubes, and stirring and heating the obtained solution until the solution is completely volatilized in order to obtain BaNa2Ti6O14-CNT; and carrying out mixing and ball-milling on the BaNa2Ti6O14-CNT andcarbon fibers, and sintering the obtained mixture in nitrogen to obtain the target product. The titanate negative electrode material obtained in the invention has a stable multilevel composite structure, so the titanate negative electrode material has the advantages of considerable wide potential window reversible capacity, excellent rate performances and stable cycle life.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

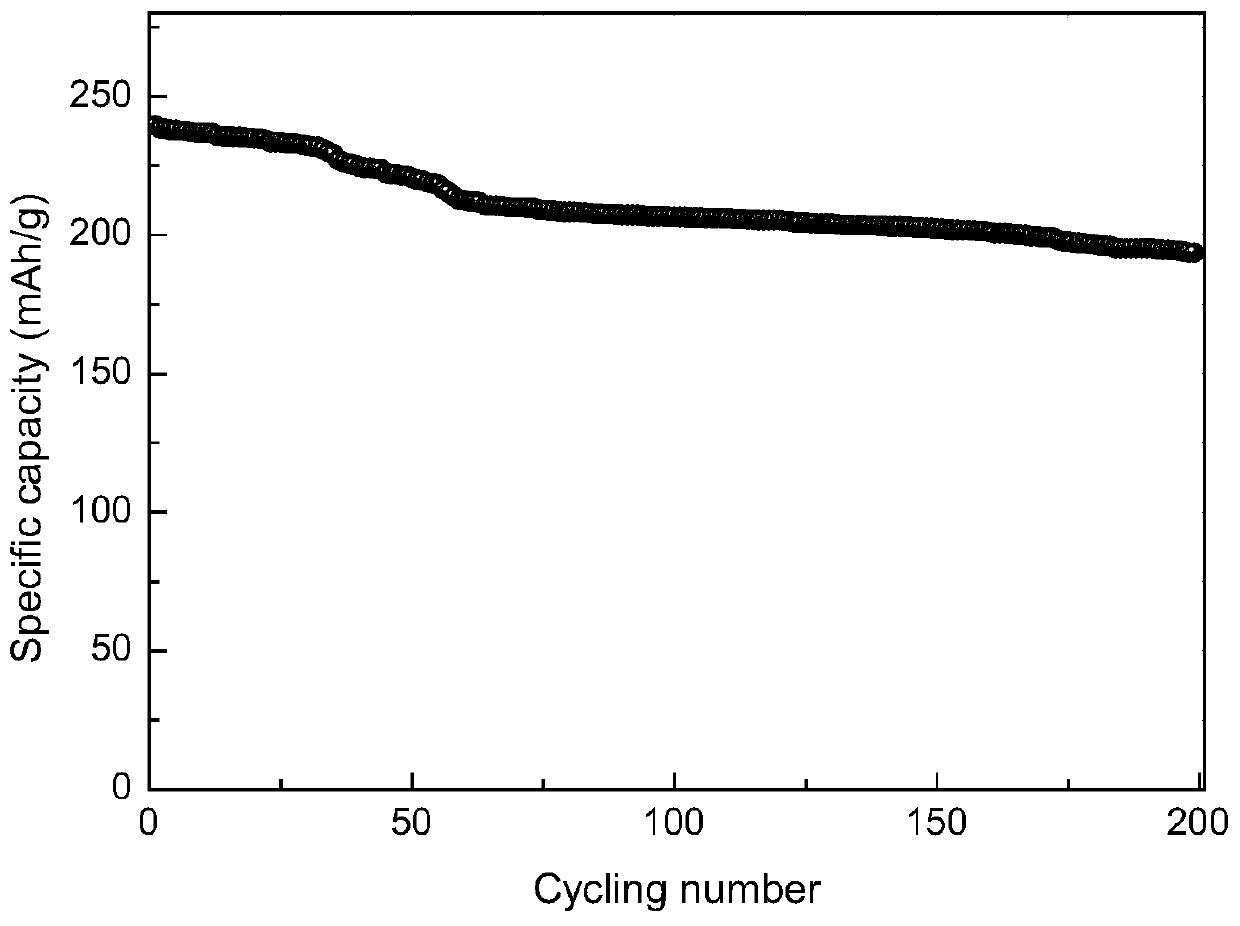

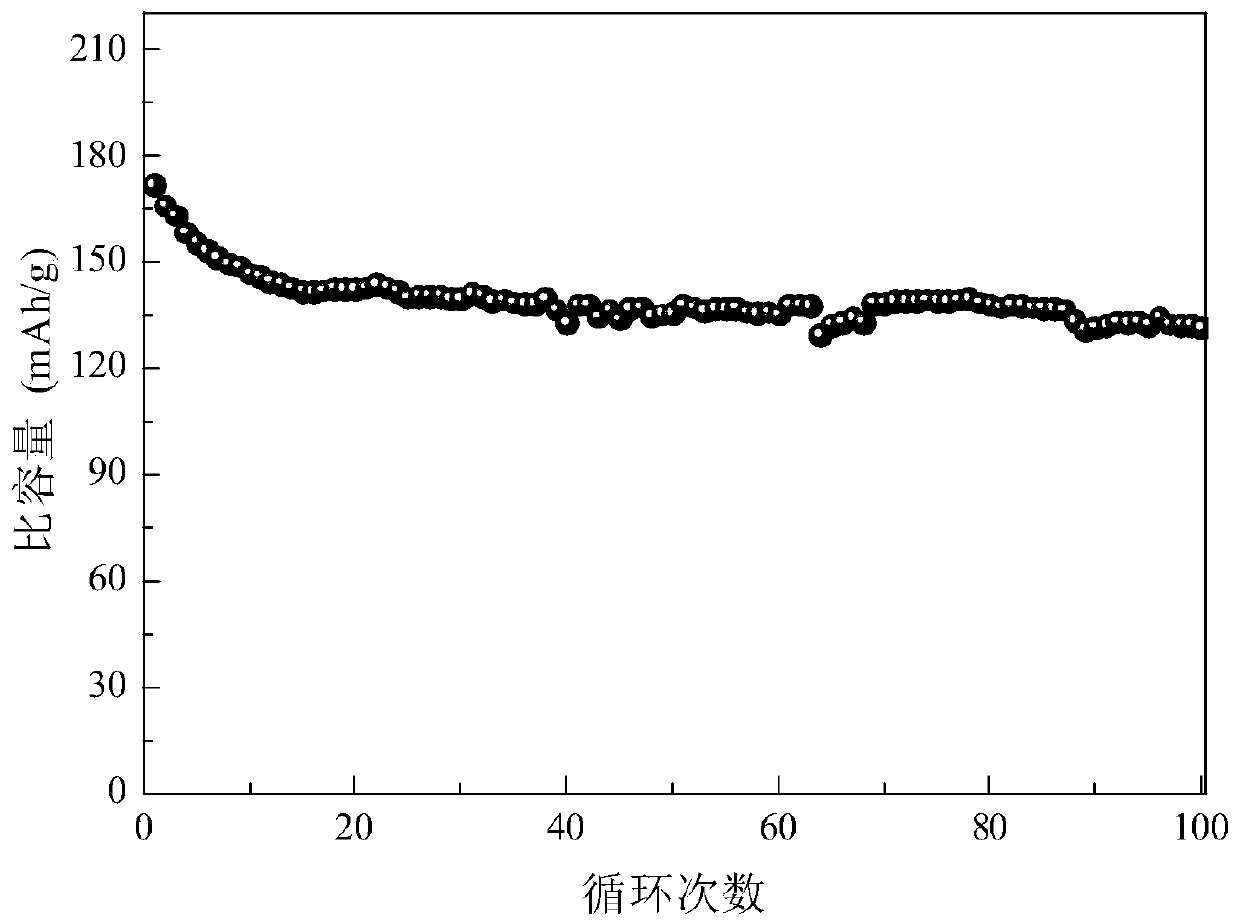

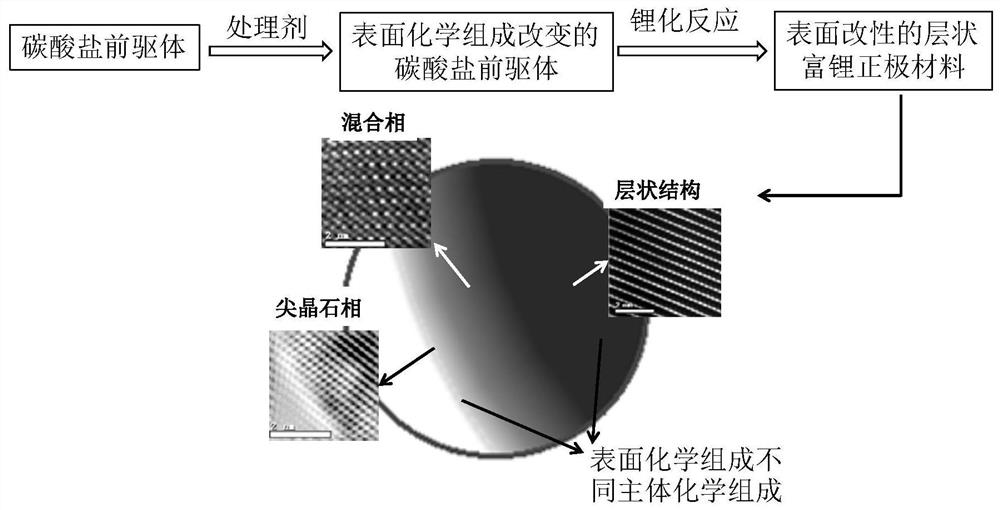

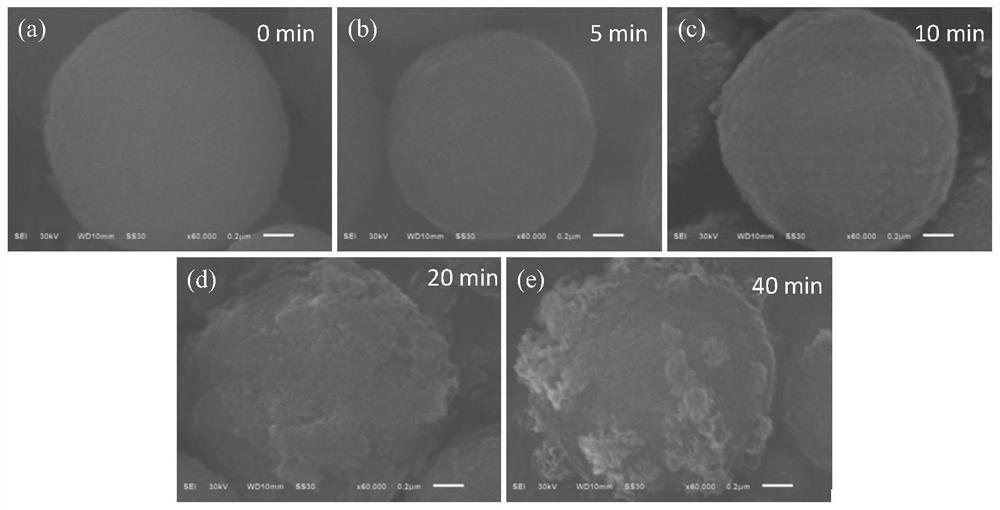

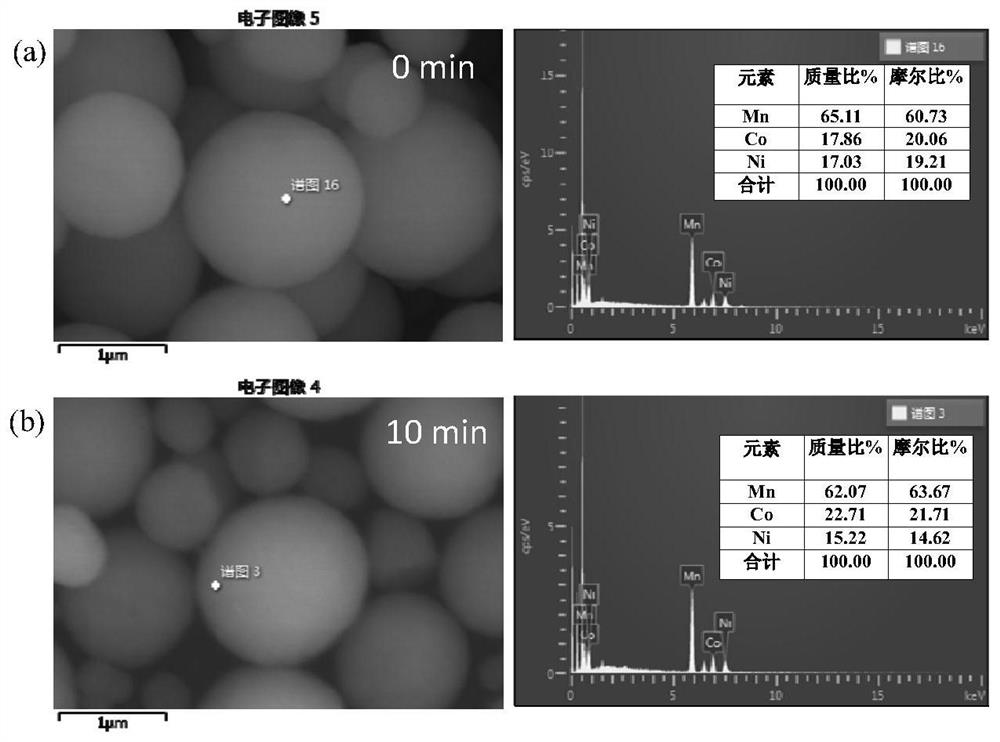

A method for simultaneous regulation of surface structure and chemical composition of layered lithium-rich cathode materials

ActiveCN108767254BStable cycle lifeWeak voltage decayCell electrodesSecondary cellsChemical compositionSynchronous control

Owner:XIANGTAN UNIV

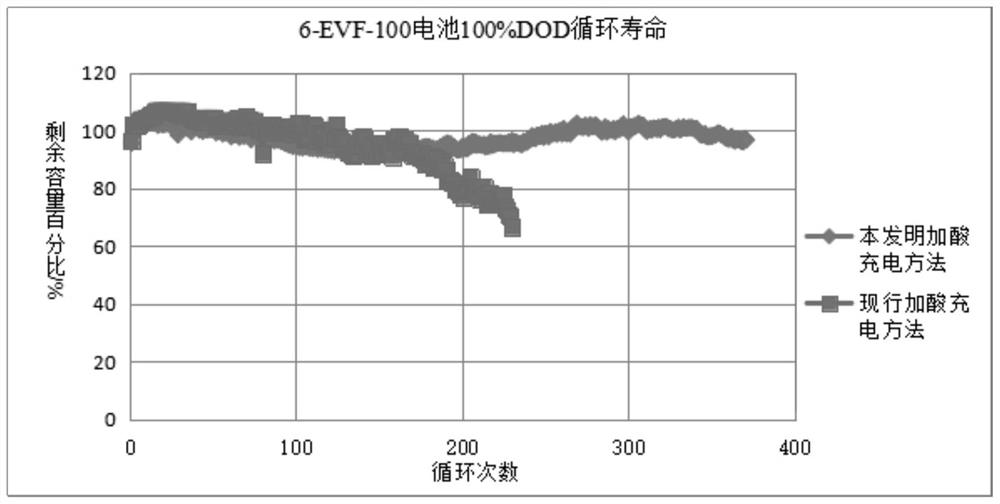

Acid-adding charging method for prolonging cycle life of power valve-regulated lead-acid storage battery

InactiveCN113285183AImprove cycle lifeStable cycle lifeFinal product manufactureSecondary cells charging/dischargingElectrolytic agentElectrical battery

The invention discloses an acid-adding charging method for prolonging the cycle life of a power valve-regulated lead-acid storage battery. The method comprises the following steps: 1, putting the valve-regulated lead-acid storage battery provided with a green plate into a vacuum acid-adding machine, and adding a low-acid-density electrolyte of which the acid amount is 50-67% of the acid amount required by the battery into the battery through the vacuum acid adding machine, and then vacuumizing to make the vacuum degree reach -0.085 MPa; 2, electrically connecting the two ends of the unformed plate of the battery with a power supply, charging for 10-20 hours, and then pausing charging; and 3, adding the high-acid-density electrolyte with the residual acid amount required by the battery into the battery on line through the vacuum acid adding machine. The technical problem that the service life of the battery produced by the battery formation process is short is solved, and the cycle life of the power valve-regulated lead-acid storage battery is prolonged.

Owner:ANHUI CHAOWEI POWER

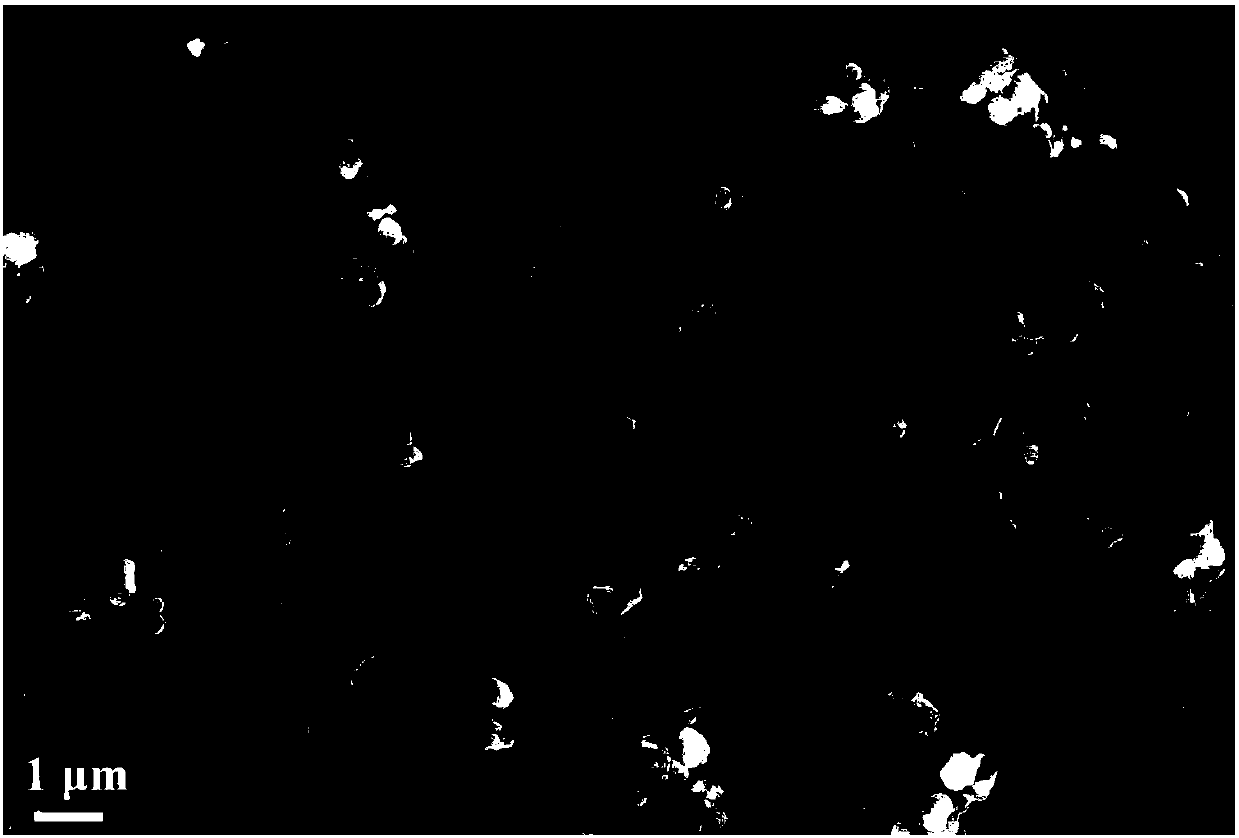

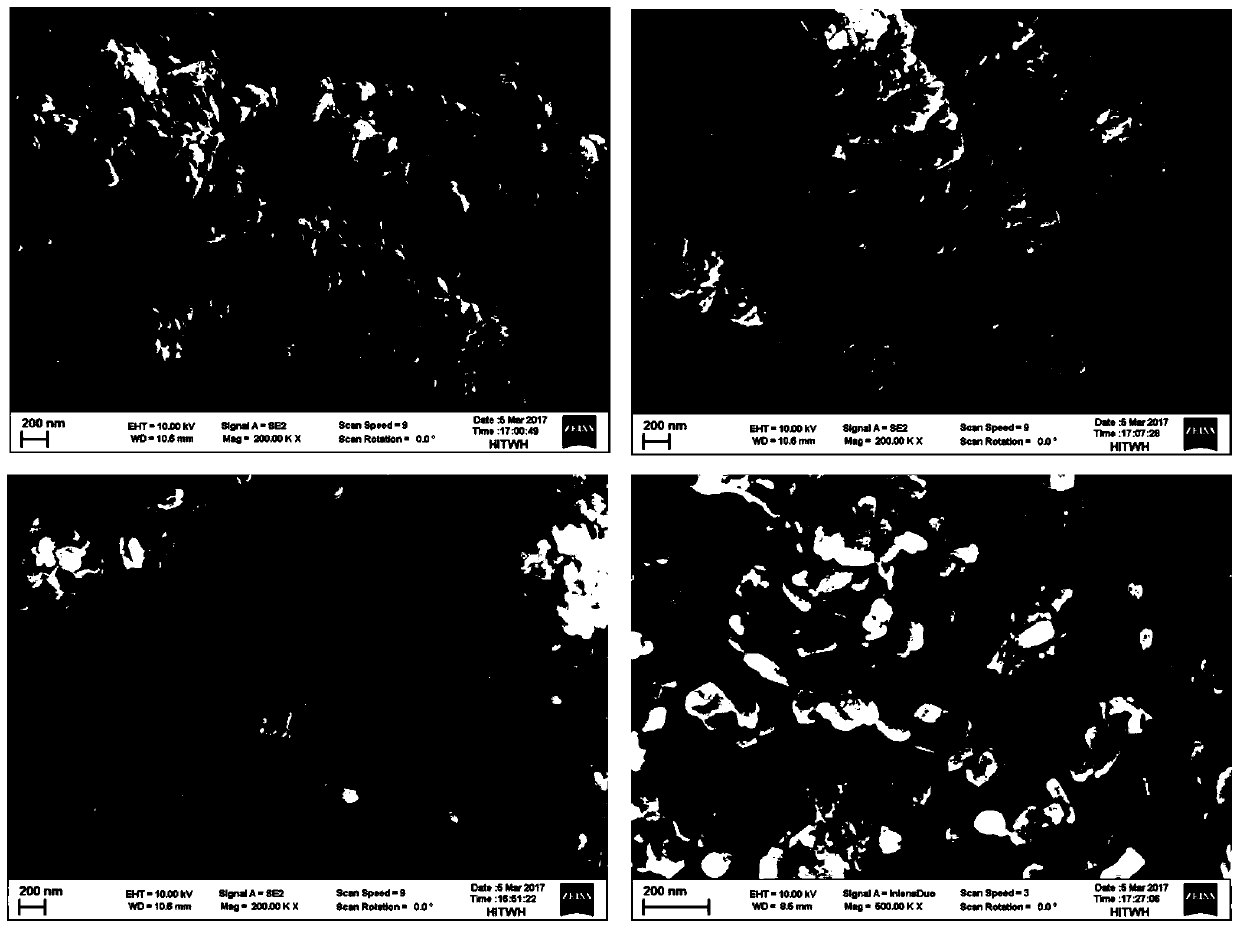

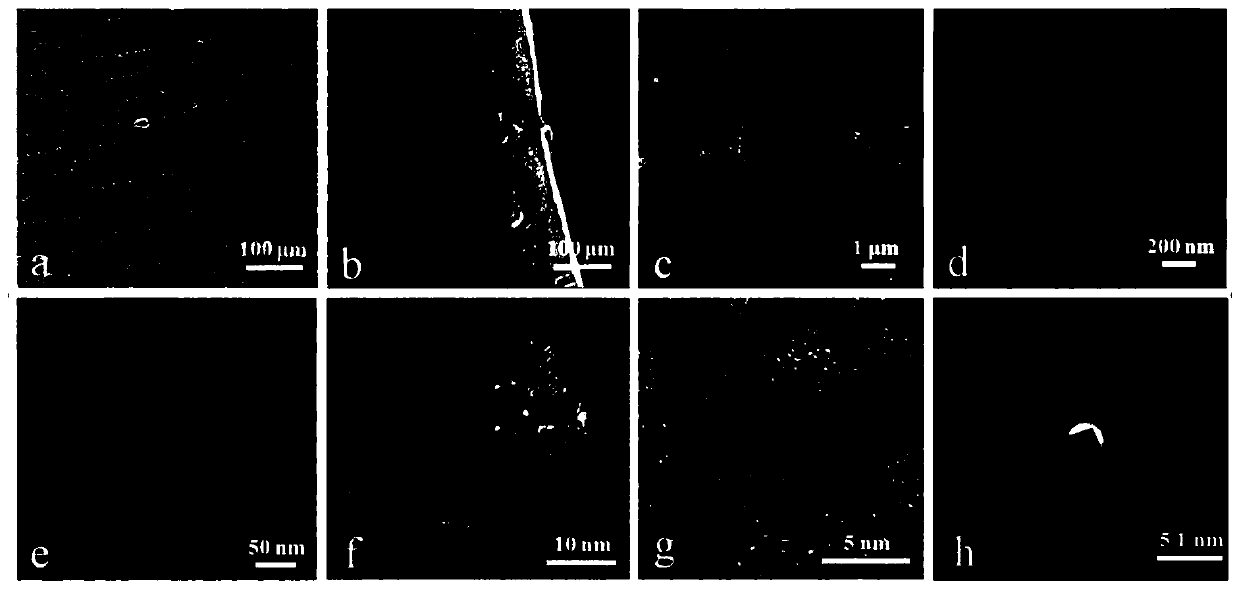

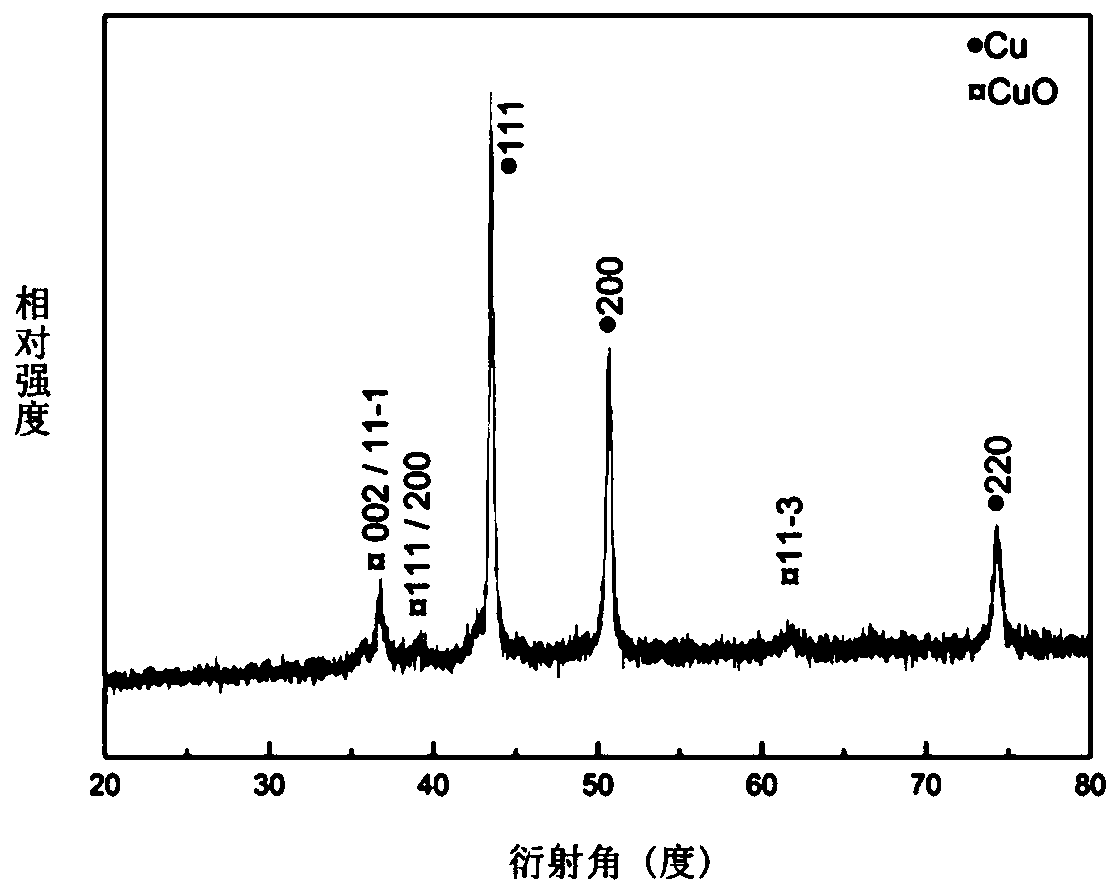

A laser ablation and oxidation in-situ preparation method of an integrated negative electrode of a lithium-ion battery

ActiveCN107221637BStable and long cycle lifeStable cycle lifeElectrode thermal treatmentSecondary cellsMetal foilSodium-ion battery

Disclosed is a laser ablation oxidization in-situ preparation method for an integrated negative electrode of a lithium ion battery. A metal foil sheet is subjected to ultrasonic cleaning by ethyl alcohol or acetone and deionized water separately; in the atmosphere of air at the room temperature, the metal foil sheet is scanned and irradiated by nanosecond pulse laser, wherein the laser is perpendicular to the metal foil sheet to obtain a metal oxide-metal integrated negative electrode; next, the metal oxide-metal integrated negative electrode is placed into a vacuum drying oven to be dried; and finally, the dried metal oxide-metal integrated negative electrode is immersed in a mixed solution of tetrabutyl titanate and absolute ethyl alcohol, and next the negative electrode is subjected to natural hydrolysis in the air and dried in the drying oven to obtain the modified metal oxide-metal integrated negative electrode. When the modified metal oxide-metal integrated negative electrode is used as the negative electrode material of the lithium ion battery, excellent charging-discharging high cycling stability and excellent electrochemical performance are shown; and in addition, the laser ablation oxidization in-situ preparation method has the advantages of simplicity, high efficiency and low cost.

Owner:TSINGHUA UNIV

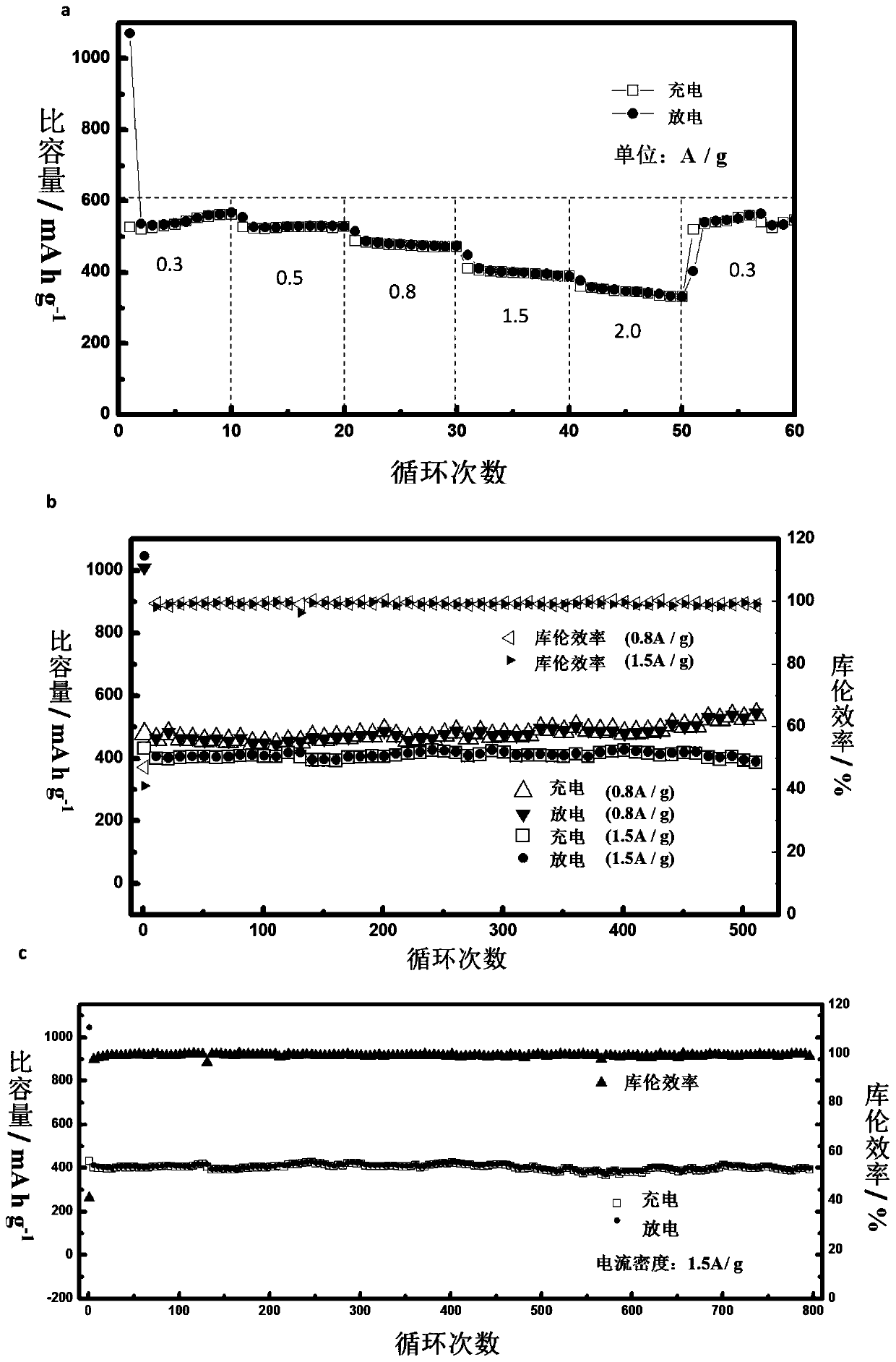

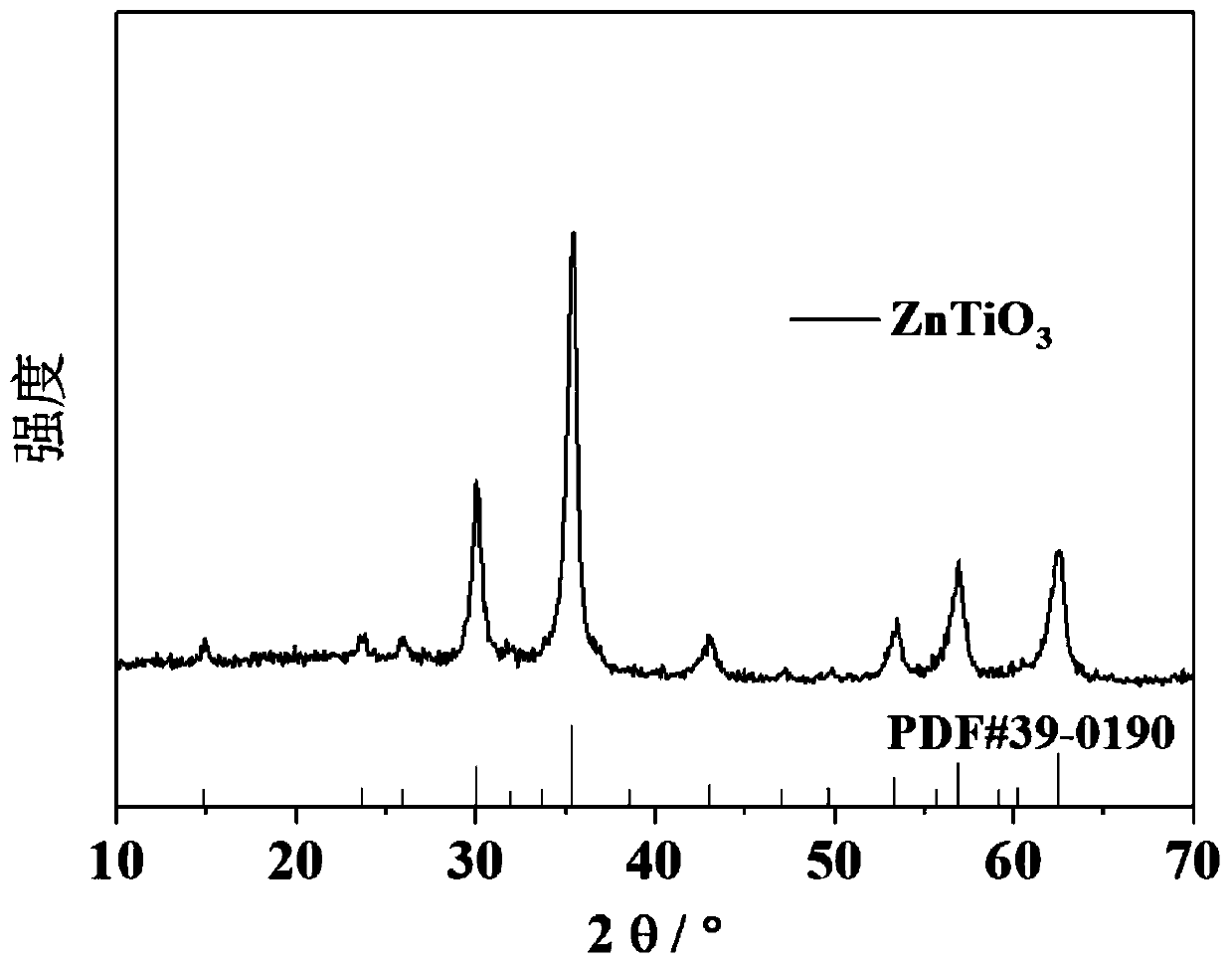

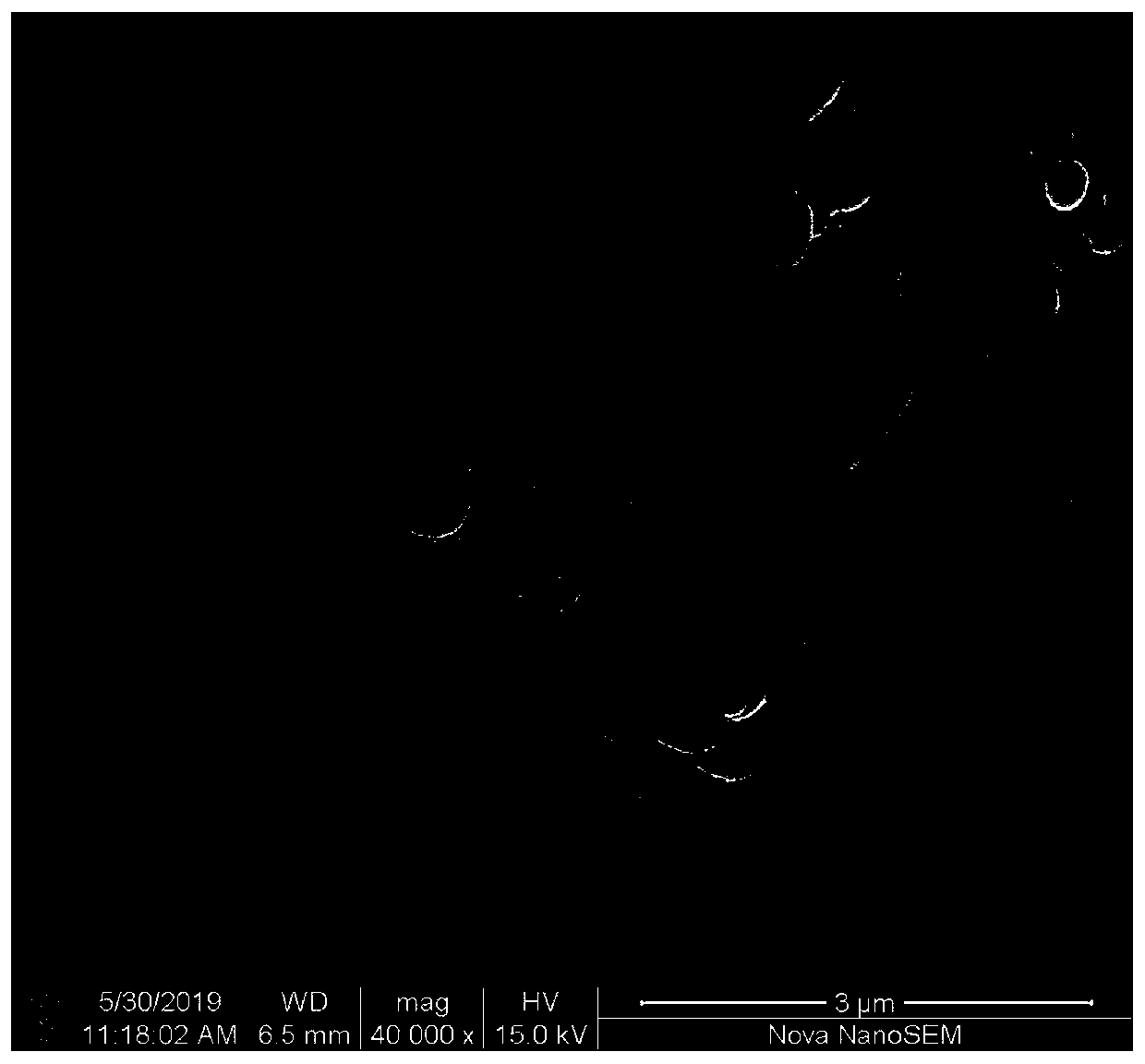

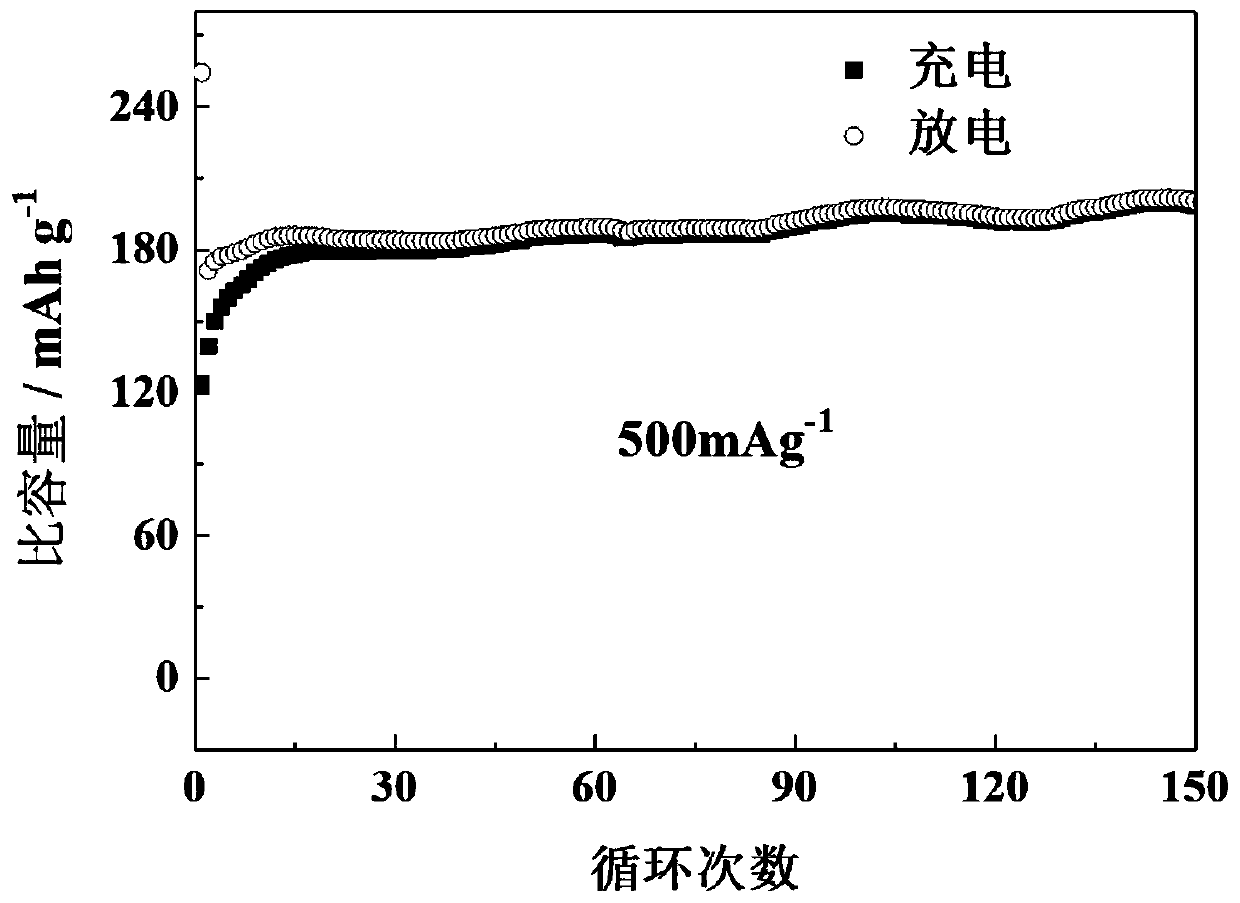

Preparation method of zinc-based negative electrode material, prepared negative electrode material, negative-electrode plate and lithium battery

ActiveCN110577237AImprove controllabilityGood reproducibilityCell electrodesSecondary cellsOrganic solventHigh energy

The invention provides a preparation method of a zinc-based negative electrode material, the prepared negative electrode material, a negative-electrode plate and a lithium battery. The preparation method comprises the following steps: respectively dissolving a zinc source and a titanium source in an organic solvent; and carrying out mixing, heating, ball milling and sintering to realize uniform mixing of the zinc source and a titanium source. According to the invention, long-time high-energy-consumption high-temperature sintering process is avoided; the problems of easy agglomeration of powder, large granularity and difficulty in acquiring high-purity micropowder in the prior art are overcome; the preparation method has the advantages of simple operation and high reproducibility; and the negative electrode material prepared by using the preparation method has excellent rate capability and stable cycle life, is high in practical use value, and can effectively meet the practical requirements of various application occasions of the lithium ion battery.

Owner:东北大学秦皇岛分校

High-capacity silicon nanowire based anode for lithium-ion batteries

InactiveUS10403889B2Stable cycle lifeHigh mechanical strengthMaterial nanotechnologyElectrode carriers/collectorsSilicon nanowiresLithium-ion battery

The present invention provides anodes comprising an electrically conductive substrate, comprising at least one non-uniform surface; and a random network of silicon nanowires (Si NWs) chemically grown on said at least one non-uniform surface of the substrate, wherein the Si NWs have at least about 30% amorphous morphology, and methods of manufacturing of the anodes. Further provided are lithium ion batteries comprising said anodes.

Owner:RAMOT AT TEL AVIV UNIV LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com