Preparation method for cicada slough based porous carbon material used for electrochemical capacitor

A porous carbon material, electrochemical technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problem of low specific capacitance of ordinary activated carbon, to achieve the promotion of specific capacitance and energy density, high specific capacitance Value, the effect of increasing the specific capacitance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

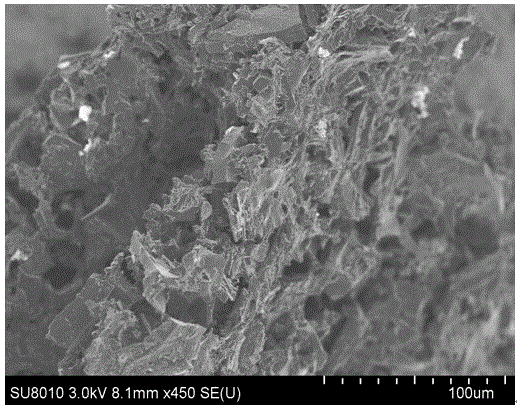

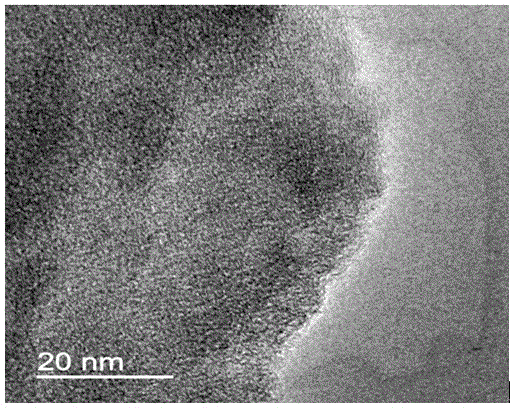

Embodiment 1

[0025] Cicada slough was purchased from Nanjing Jinling Pharmacy Co., Ltd., and the obtained cicada slough was dried at 60°C and crushed until the size of the powder was larger than 10 mesh. First, the sediment in the crushed powder was cleaned with tap water, soaked in ethanol for 2 minutes, filtered and dried at 60°C. Dry in a dry oven; the dried cicadas are sloughed into powder, and nitrogen is used as a protective gas in a tube furnace at 10°C min -1 The heating rate was raised to 400°C and kept for 5 hours, and carbonaceous was obtained after natural cooling; the obtained carbonaceous and sodium hydroxide were uniformly mixed at a mass ratio of 1:1, and nitrogen was used as a protective gas. 10℃min -1 In order to raise the temperature to 900°C for further activation treatment and keep it for 2 hours, the activated product is obtained after natural cooling; the obtained activated product is neutralized with phosphoric acid, then cleaned with deionization to neutrality, and...

Embodiment 2

[0028] Cicada slough was purchased from Nanjing Jinling Pharmacy Co., Ltd., and the obtained cicada slough was dried at 65°C and crushed until the size of the powder was larger than 10 mesh. First, the sediment in the crushed powder was cleaned with tap water, soaked in ethanol for 5 minutes, filtered and dried at 65°C. Dried in a dry oven; the dried cicadas were sloughed into powder, and heated in a tube furnace at 4°C min with nitrogen as a protective gas. -1 The heating rate was increased to 500°C and kept for 1h, and the carbonaceous was obtained after natural cooling; the obtained carbonaceous and potassium hydroxide were uniformly mixed at a mass ratio of 1:3, and heated at 4°C min in a nitrogen atmosphere. -1 In order to increase the heating rate to 650°C, further activate the carbonaceous material and keep it for 1 hour, and obtain the activated product after natural cooling; neutralize the obtained activated product with hydrochloric acid, then wash it to neutral with ...

Embodiment 3

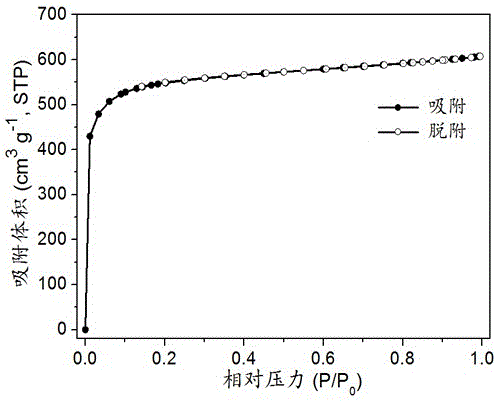

[0031] The preparation method of the cicada base porous carbon material is the same as that of Example 2.

[0032] Take 3 mg of the prepared porous carbon, mix them uniformly according to the mass ratio of active material: acetylene black: polytetrafluoroethylene = 80:15:5, and press the mixed slurry onto the foamed nickel current collector at a pressure of 15 MPa to form a Two identical supercapacitor single electrodes were used to perform electrochemical tests on two symmetrical working electrodes with 6.0MKOH as the electrolyte. Electrochemical tests show that at 0.5, 5, 10Ag -1 The specific capacitance under the current density is 335, 224, 202Fg -1 (attached Figure 4 B), still showing good rate performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com