Sodium-ion battery carbon negative electrode material and preparation method thereof

A carbon anode material, a technology for sodium-ion batteries, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as effective insertion and de-insertion of unfavorable sodium ions, difficulty in meeting high-efficiency sodium-ion batteries, and lack of reactive sites. , to achieve the effect of more reactive sites, shortened transmission distance, and abundant pore channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

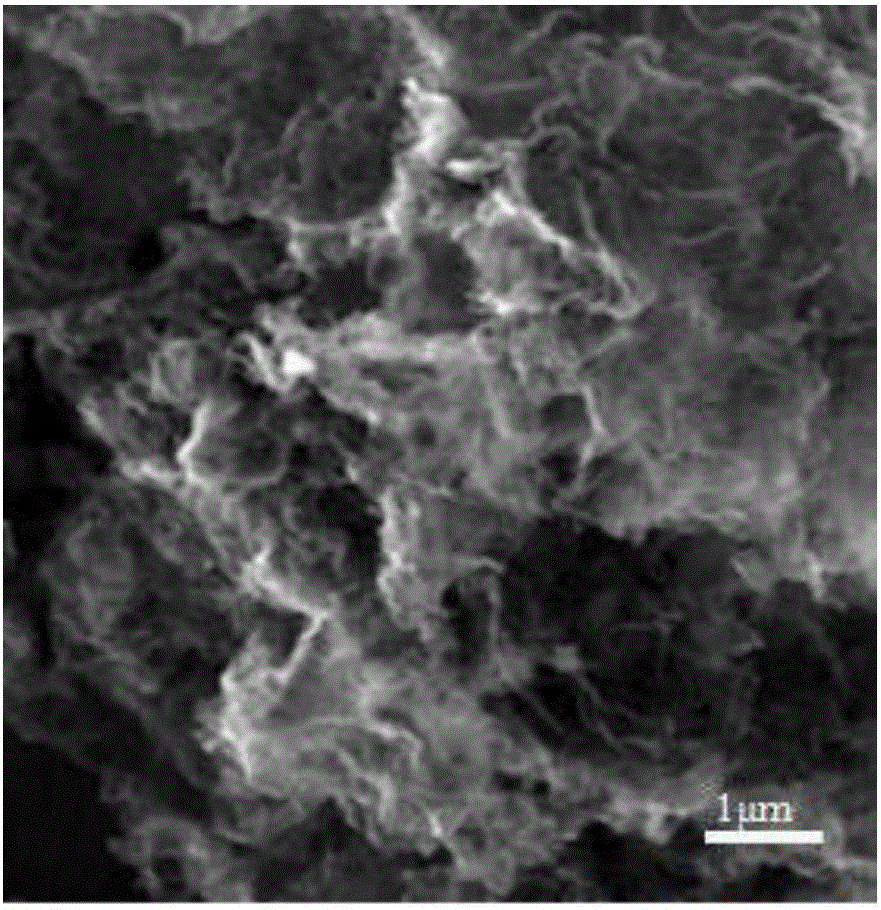

Embodiment 1

[0058] Add 2g of lignin to 20ml of 0.1mol / L sodium hydroxide solution, stir at room temperature for 1h to form a uniform suspension; use the modified Hummer method to prepare graphene oxide; measure 50ml of 5g / L graphene oxide dispersion, Graphene oxide was obtained by freeze-drying at -50°C for 20 hours, and the obtained graphene oxide was added into 50 ml of deionized water, and dispersed by ultrasonication at room temperature for 1 hour to obtain a uniform graphene oxide dispersion. Mix and stir the above two dispersions for 1 h, add 10 ml of silica template emulsion (the particle size of the template emulsion is 140 nm, and the volume concentration of the template emulsion is 40%), and place the mixed solution in a hydrothermal reaction kettle for hydrothermal reaction for 150 ℃ 20h, cooled to room temperature, filtered to obtain black particles. Add the obtained black granules to 20ml of 10% hydrofluoric acid, stir for 5h, filter, then wash 3 times with deionized water, t...

Embodiment 2

[0061] Add 3g of lignin to 20ml of 0.5mol / L sodium hydroxide solution, stir at room temperature for 1h to form a uniform suspension; use the modified Hummer method to prepare graphene oxide; measure 100ml of 5g / L graphene oxide dispersion, Graphene oxide was obtained by freeze-drying at -50°C for 40 hours, and the obtained graphene oxide was added to 100 ml of deionized water, and dispersed by ultrasonication at room temperature for 2 hours to obtain a uniform graphene oxide dispersion. Mix and stir the above two dispersions for 2 hours, add 20ml of magnesium carbonate template emulsion (template emulsion particle size is 50nm, template emulsion volume concentration is 20%), put the mixed solution in a hydrothermal reaction kettle for hydrothermal reaction at 160°C 15h, cooled to room temperature, and filtered to obtain black particles. Add the obtained black particles to 60ml of 10% hydrofluoric acid, stir for 5h, filter, then wash with deionized water for 3 times, then wash ...

Embodiment 3

[0064] Add 2g lignin to 20ml 1mol / L sodium hydroxide solution, stir at room temperature for 2h to form a uniform suspension; use the improved Hummer method to prepare graphene oxide; measure 100ml 5g / L graphene oxide dispersion, Freeze-dry at -50°C for 40 hours to obtain graphene oxide, add the obtained graphene oxide into 20 ml of deionized water, and disperse by ultrasonication at room temperature for 0.5 hours to obtain a uniform graphene oxide dispersion. Mix and stir the above two dispersions for 1 hour, add 15ml of calcium carbonate template emulsion (template emulsion particle size is 100nm, template emulsion volume concentration is 30%), put the mixed solution in a hydrothermal reaction kettle for hydrothermal reaction at 200°C 20h, cooled to room temperature, filtered to obtain black particles. Add the obtained black particles to 50ml of 10% hydrofluoric acid, stir for 5h, filter, then wash with deionized water for 3 times, then wash with absolute ethanol for 2 times,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Volume concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com