Preparation method of high capacity lithium ion battery lithium cobalt manganese nickel oxide positive electrode material

A technology for lithium-ion batteries and positive electrode materials, applied in lithium oxide;/hydroxide, nickel compound, electrode manufacturing, etc., can solve the problems of high process cost, complicated equipment, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

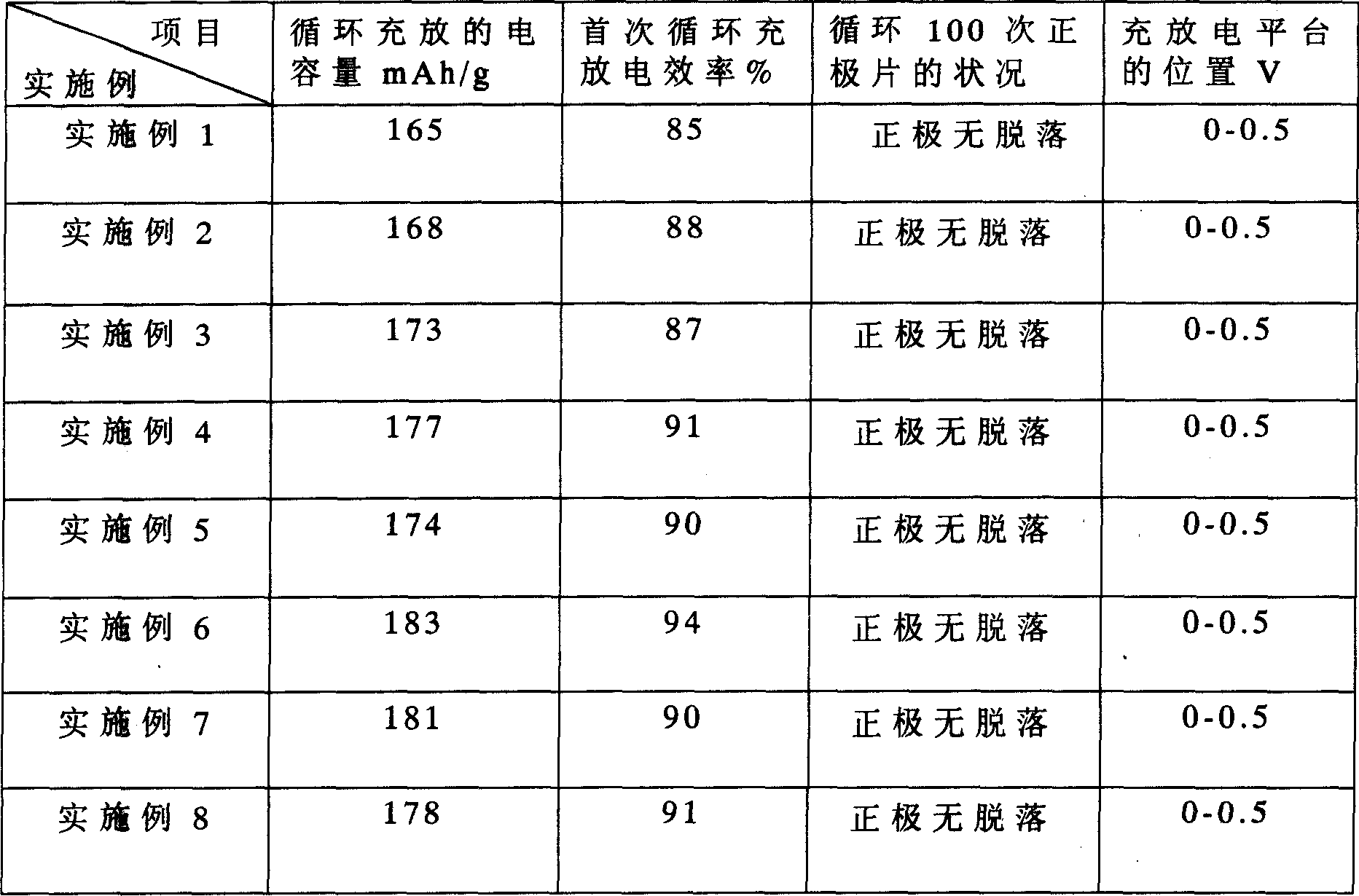

Examples

Embodiment 1

[0005] Operation (1) The atomic ratio of lithium and cobalt, manganese, nickel is 1 and the atomic ratio of cobalt: manganese: nickel is a lithium source, a cobalt source, a manganese source, and a nickel source. 6% of the weight ratio is added to polyacrylamide, and 5% of the atomic ratio of cobalt, manganese and nickel is added to neodymium oxide, and the mixture is evenly stirred to form a gel.

[0006] Step (2) Dry the jelly obtained in the above step (1) in a drying oven at 150° C. for 30 hours, then weigh a certain amount of dried material and ball mill it for 5 hours, and pass through a 300-mesh vibrating sieve.

[0007] Step (3) The powder material obtained in the above step (2) was pre-fired at 300° C. for 10 hours and cooled naturally.

[0008] Step (4) The powder pre-calcined in the above step (3) is then ground, finely ground, sieved, then burned at 700°C for 3 hours, and passed through a 300-mesh sieve.

Embodiment 2

[0010] Operation (1) The atomic ratio of lithium and cobalt, manganese, nickel is 1.02 and the atomic ratio of cobalt: manganese: nickel is the mixing of lithium source and cobalt source, manganese source, nickel source, and mixes according to this 6% of the weight ratio is added to polyacrylamide, and 5% of the atomic ratio of cobalt, manganese and nickel is added to neodymium oxide, and the mixture is evenly stirred to form a gel.

[0011] Step (2) Dry the jelly obtained in the above step (1) in a drying oven at 150° C. for 30 hours, then weigh a certain amount of dried material and ball mill it for 5 hours, and pass through a 300-mesh vibrating sieve.

[0012] Step (3) The powder material obtained in the above step (2) was pre-fired at 350° C. for 10 hours and cooled naturally.

[0013] Step (4) The powder pre-burned in the above step (3) is then ground, finely ground, sieved, then burned at 750°C for 3 hours, and passed through a 300-mesh sieve for use.

Embodiment 3

[0015] Operation (1) the atomic ratio of lithium and cobalt, manganese, nickel is 1.05 and the atomic ratio of cobalt: manganese: nickel is the mixing material of lithium source and cobalt source, manganese source, nickel source, mixes according to this 8% of the weight ratio is added to polyacrylamide, and 6% of the atomic ratio of cobalt, manganese and nickel is added to neodymium oxide, and the mixture is evenly stirred to form a gel.

[0016] Step (2) Dry the jelly obtained in the above step (1) in a drying oven at 150° C. for 30 hours, then weigh a certain amount of dried material and ball mill it for 5 hours, and pass through a 300-mesh vibrating sieve.

[0017] Step (3) The powder material obtained in the above step (2) was pre-fired at 400° C. for 10 hours and cooled naturally.

[0018] Step (4) The powder material pre-calcined in the above step (3) is ball milled, pulverized, sieved, burned at 650°C for 3 hours, and passed through a 300-mesh sieve for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com