O3 type sodium ion battery cathode material and preparation method thereof

A technology for sodium ion batteries and cathode materials, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of low reversible capacity and cycle performance, and achieve great application value, good cycle stability, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

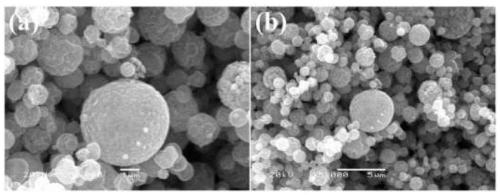

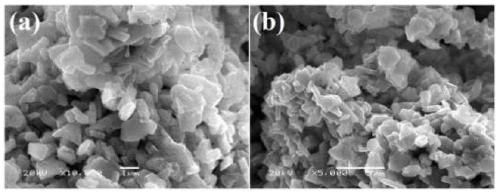

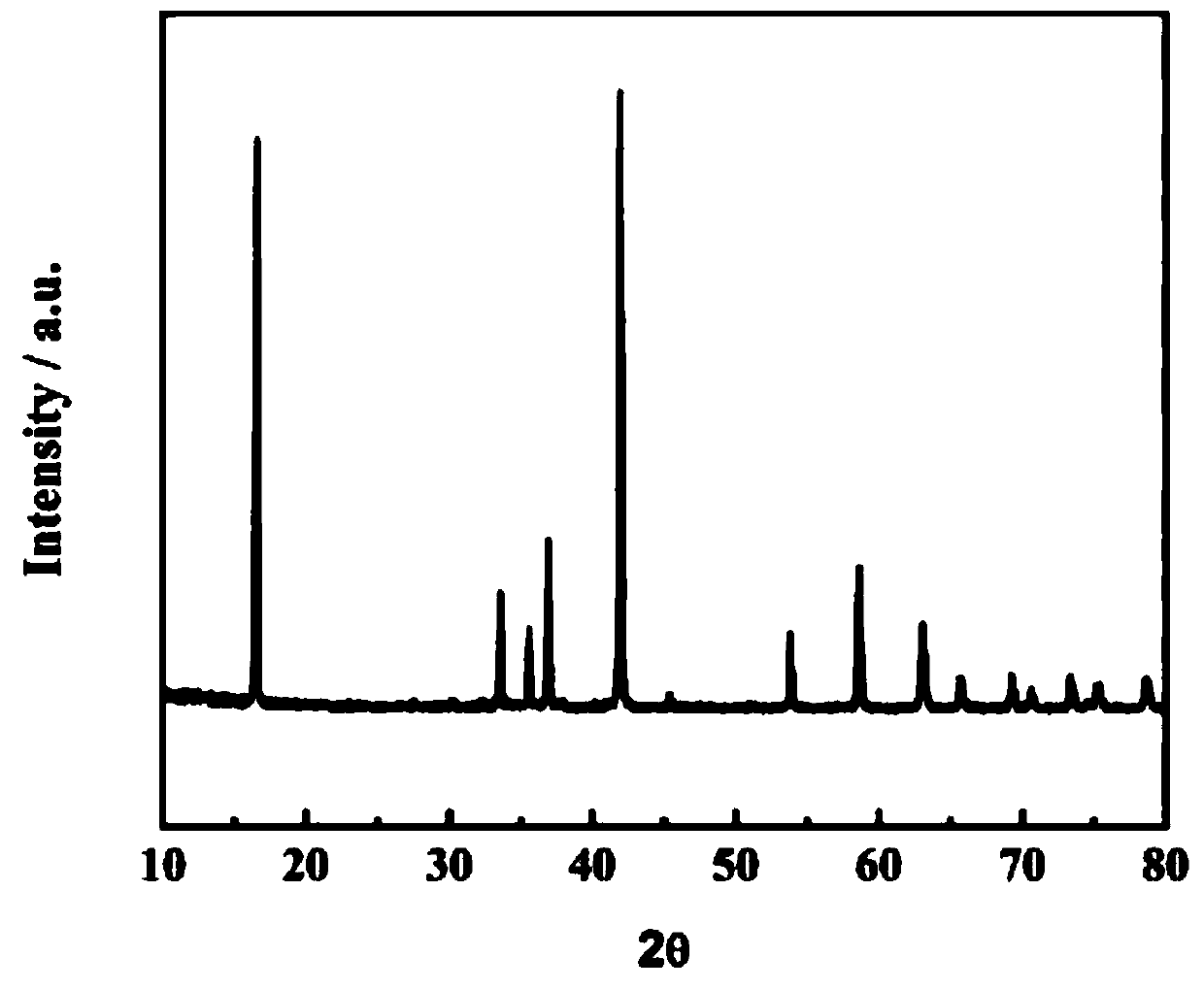

[0031] Prepare NiCl with a total metal ion concentration of 0.5mol / L 2 ·6H 2 O, MnCl 2 4H 2 O, FeCl 3 ·6H 2 O and AlCl 3 ·6H 2 O mixed solution is used as the spray pyrolysis precursor solution, wherein the ratio of the amount of each metal element is Ni:Mn:Fe:Al=(1 / 3:1 / 3:1 / 3) 0.95 : 0.05. The resulting solution was ultrasonically atomized and pyrolyzed at a temperature of 800 °C with a carrier gas (O 2 ) flow rate is 5L / min, collect the metal oxide powder material after pyrolysis, the SEM spectrum of this material is as follows figure 1 shown. Depend on figure 1 It can be seen that the obtained (Ni 1 / 3 mn 1 / 3 Fe 1 / 3 ) 0.95 al 0.05 o 2 It is a micron-sized spherical particle with a particle diameter of 1-4 μm and uniform distribution. Weigh the oxide precursor (Ni 1 / 3 mn 1 / 3 Fe 1 / 3 ) 0.95 al 0.05 o 2 Mix and grind with anhydrous sodium carbonate according to the total metal molar to sodium molar ratio of 1:1.05 (Na excess coefficient is 5%), use a mold t...

Embodiment 2

[0035] Prepare Ni(NO 3 ) 2 ·6H 2 O, Mn(NO 3 ) 2 ·H 2 O, Fe(NO 3 ) 3 9H 2 O and Al(NO 3 ) 3 9H 2 O mixed solution is used as spray pyrolysis precursor solution, wherein the ratio of the amount of each metal element substance is Ni:Mn:Fe:Al=(2 / 5:1 / 2:1 / 10) 0.8 : 0.2. The resulting solution was ultrasonically atomized and pyrolyzed at a temperature of 800 °C with a carrier gas (O 2 ) with a flow rate of 5 L / min to collect the pyrolyzed metal oxide powder material. Weigh the oxide precursor (Ni 1 / 10 mn 1 / 2 Fe 2 / 5 ) 0.8 al 0.2 o 2 Mix and grind with anhydrous sodium carbonate according to the total metal molar to sodium molar ratio of 1:1.05 (Na excess coefficient is 5%), use a mold to press the powder into a disc with a diameter of 12mm under a pressure of 20MPa, and place it on a corundum burner in a boat, placed in a tube furnace at O 2 Under the atmosphere, calcining at 850°C for 20h at a heating rate of 5°C / min, and cooling to room temperature with the furna...

Embodiment 3

[0038] Prepare NiSO with a total metal ion concentration of 0.5mol / L 4 ·6H 2 O, MnSO 4 4H 2 O, Fe 2 (SO 4 ) 3 9H 2 O and Al 2 (SO 4 ) 3 18H 2 O mixed solution is used as spray pyrolysis precursor solution, wherein the ratio of the amount of each metal element substance is Ni:Mn:Fe:Al=(3 / 5:1 / 5:1 / 5) 0.75 : 0.25. The resulting solution was ultrasonically atomized and pyrolyzed at a temperature of 800 °C with a carrier gas (O 2 ) with a flow rate of 5 L / min, and use a powder collector to collect the pyrolyzed metal oxide powder material. Weigh the oxide precursor (Ni 4 / 5 mn 1 / 10 Fe 1 / 10 ) 0.55 al 0.45 o 2 Mix and grind with anhydrous sodium carbonate according to the total metal molar to sodium molar ratio of 1:1.05 (Na excess coefficient is 5%), use a mold to press the powder into a disc with a diameter of 12mm under a pressure of 20MPa, and place it on a corundum burner in a boat, placed in a tube furnace at O 2 Under the atmosphere, calcining at 1000 °C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com