Preparation method of silicon-carbon negative electrode material of lithium ion battery

A lithium-ion battery, silicon carbon technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of side reactions between nano-silicon particles and electrolyte, battery discharge capacity and cycle capacity reduction, etc., to avoid side reactions, Effect of improving cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

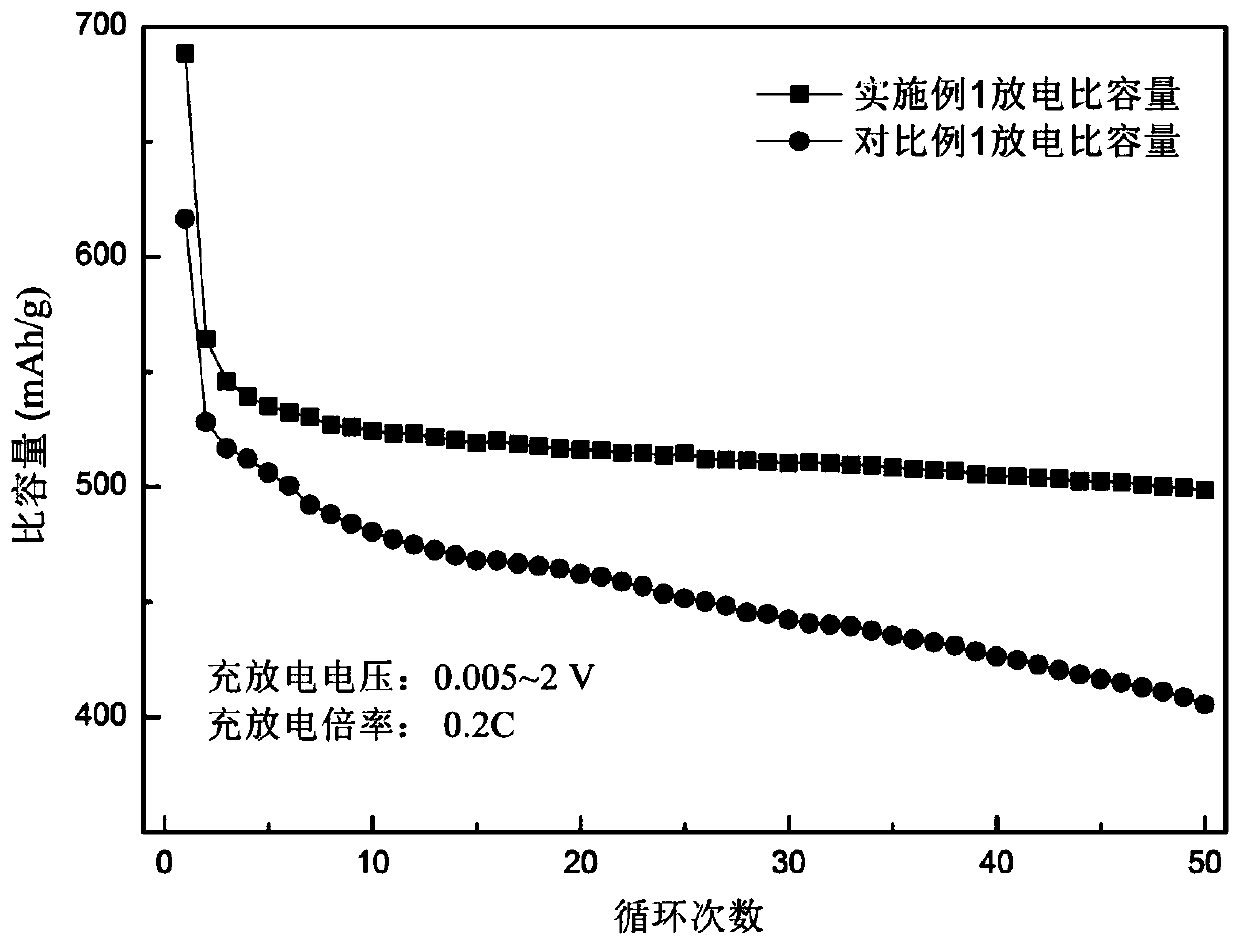

Embodiment 1

[0030] A method for preparing a silicon-carbon negative electrode material for a lithium-ion battery, the specific preparation steps are as follows:

[0031] In the first step, 1g of nano-Si powder with an average particle size of 100nm, 0.1g of polyethylene glycol p-isooctylphenyl ether, and 0.5g of glucose were added to 50g of absolute ethanol, and after ultrasonic stirring for 45min, a uniformly dispersed Nano-Si suspension; 2g graphene and 1g Ketjen black were added to 50g absolute ethanol, and a uniformly dispersed graphene / Ketjen black mixture was formed after acoustic stirring for 45min;

[0032] In the second step, the graphene / Ketjen Black mixed solution is slowly and uniformly added to the mixed solution containing nano-silicon powder, and after being ultrasonically stirred for 30 minutes, a uniformly dispersed silicon and graphene / Ketjen Black composite material precursor is mixed solution;

[0033] In the third step, the precursor solution obtained in the second s...

Embodiment 2

[0036] In the first step, 1g of nano-Si powder with an average particle size of 150nm, 0.05g of cetyltrimethylammonium bromide, and 0.33g of sucrose were added to 50g of absolute ethanol, and a uniformly dispersed nano-Si suspension was formed after ultrasonic stirring for 40min. Liquid; 1.5g graphene and 0.5g Ketjen black are joined in 50g dehydrated alcohol, form the graphene / ketjen black mixed solution of uniform dispersion after acoustic stirring 40min;

[0037] In the second step, the graphene / Ketjen Black mixed solution is slowly and uniformly added to the mixed solution containing nano-silicon powder, and after being ultrasonically stirred for 45 minutes, a uniformly dispersed silicon and graphene / Ketjen Black composite material precursor is mixed solution;

[0038] In the third step, the precursor solution obtained in the second step is fully dried with dry powder making equipment, and then the obtained powder particles are placed in a tube furnace with an argon atmosp...

Embodiment 3

[0041]In the first step, 1g of nano-Si powder with an average particle diameter of 200nm, 0.08g of sodium tripolyphosphate, and 0.25g of citric acid are added to 50g of absolute ethanol, and a uniformly dispersed nano-Si suspension is formed after ultrasonic stirring for 35min; Add 1.25g of graphene and 1.25g of Ketjen black into 50g of absolute ethanol, and form a uniformly dispersed graphene / Ketjen black mixture after acoustic stirring for 35 minutes;

[0042] In the second step, the graphene / Ketjen Black mixed solution is slowly and uniformly added to the mixed solution containing nano-silicon powder, and after being ultrasonically stirred for 50 minutes, a uniformly dispersed silicon and graphene / Ketjen Black composite material precursor is mixed solution;

[0043] The third step is to fully dry the precursor solution obtained in the second step with dry powder making equipment, and then place the obtained powder particles in a tube furnace with a nitrogen gas flow rate of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com