High-capacity potassium ion battery negative electrode material and preparation method and application thereof

A battery anode, potassium ion technology, applied in battery electrodes, nanotechnology for materials and surface science, negative electrodes, etc., can solve the problems of unfavorable capacity, poor electrical conductivity, high energy consumption, etc., and achieve excellent cycle performance, Excellent rate performance, solving the effect of low capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

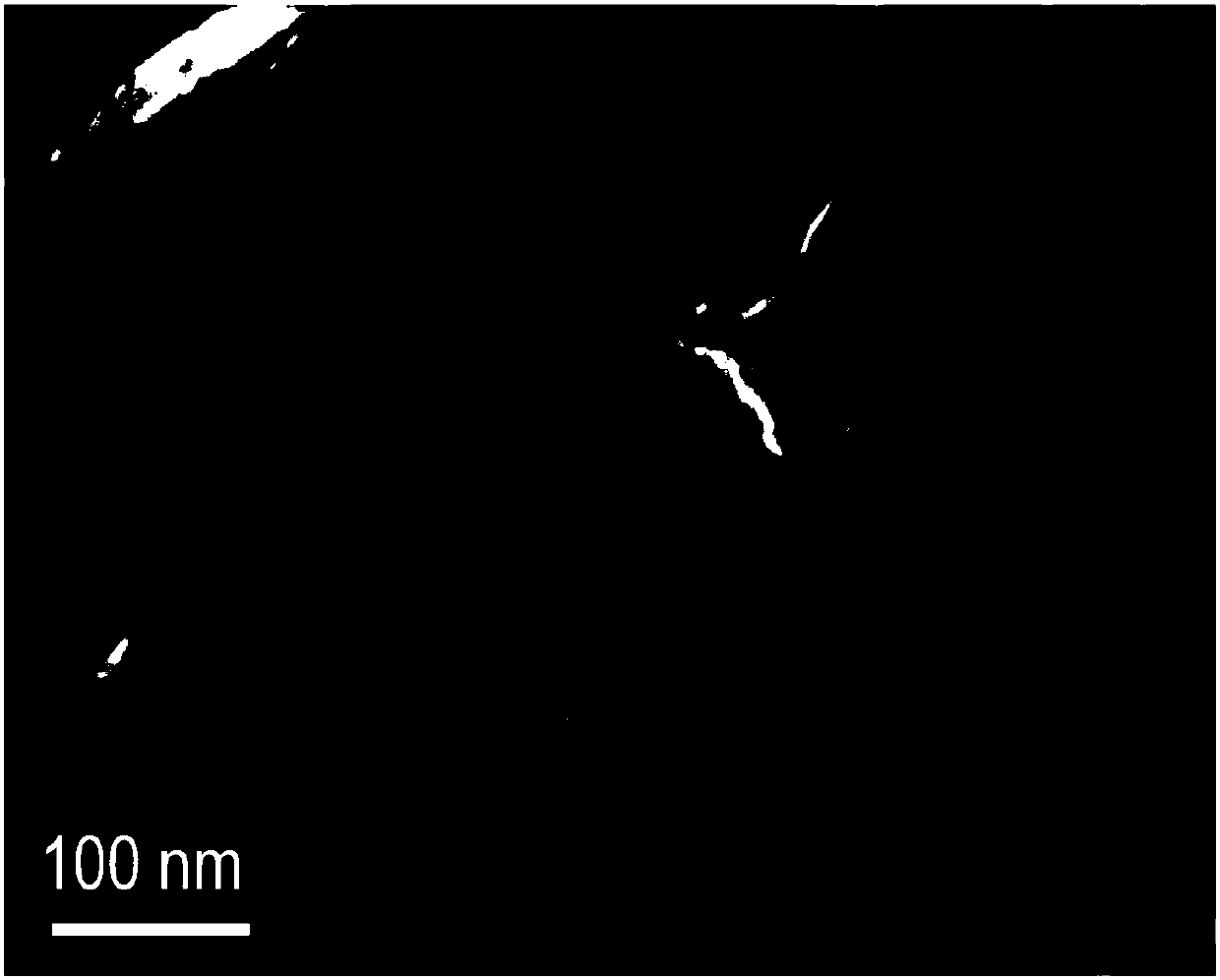

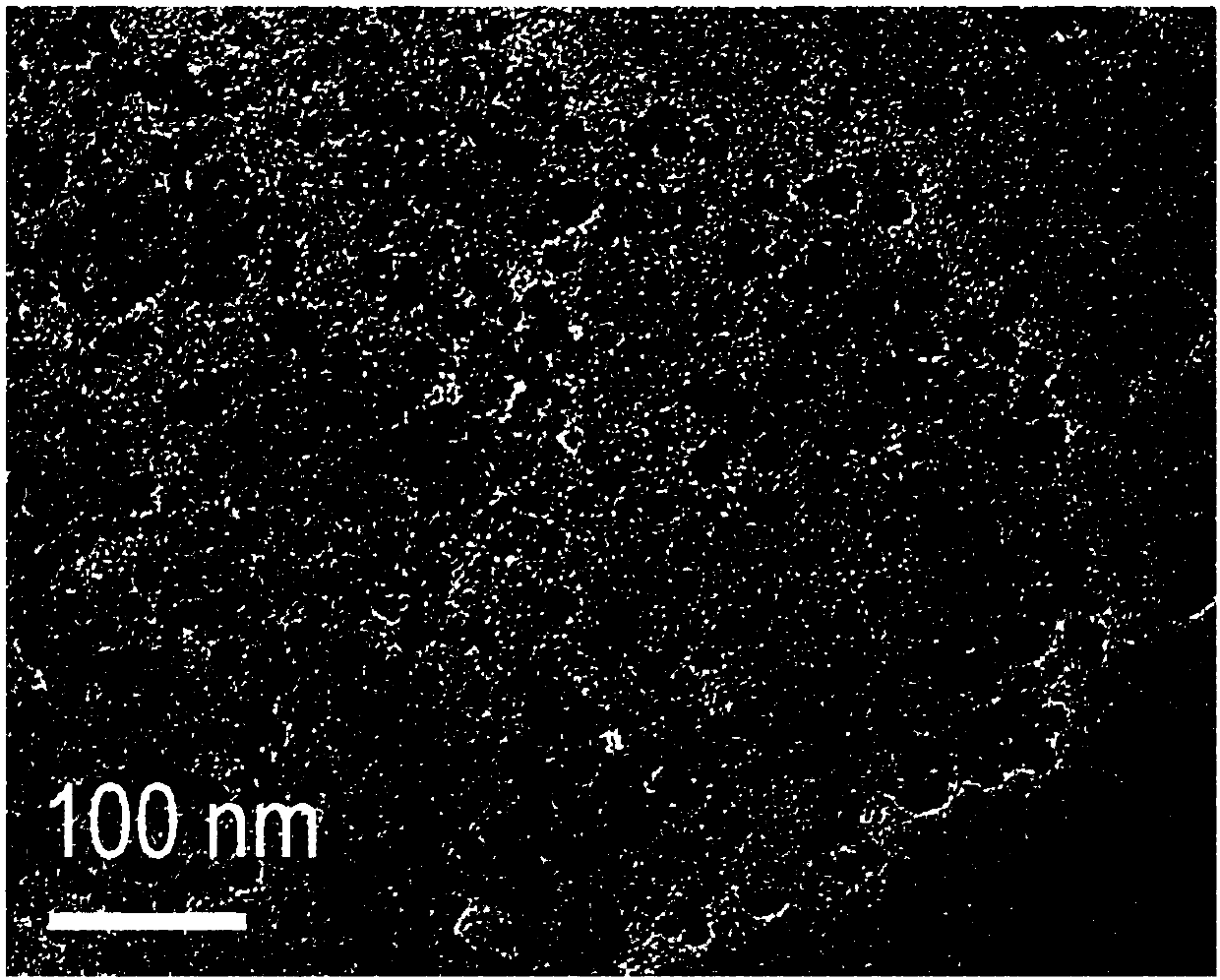

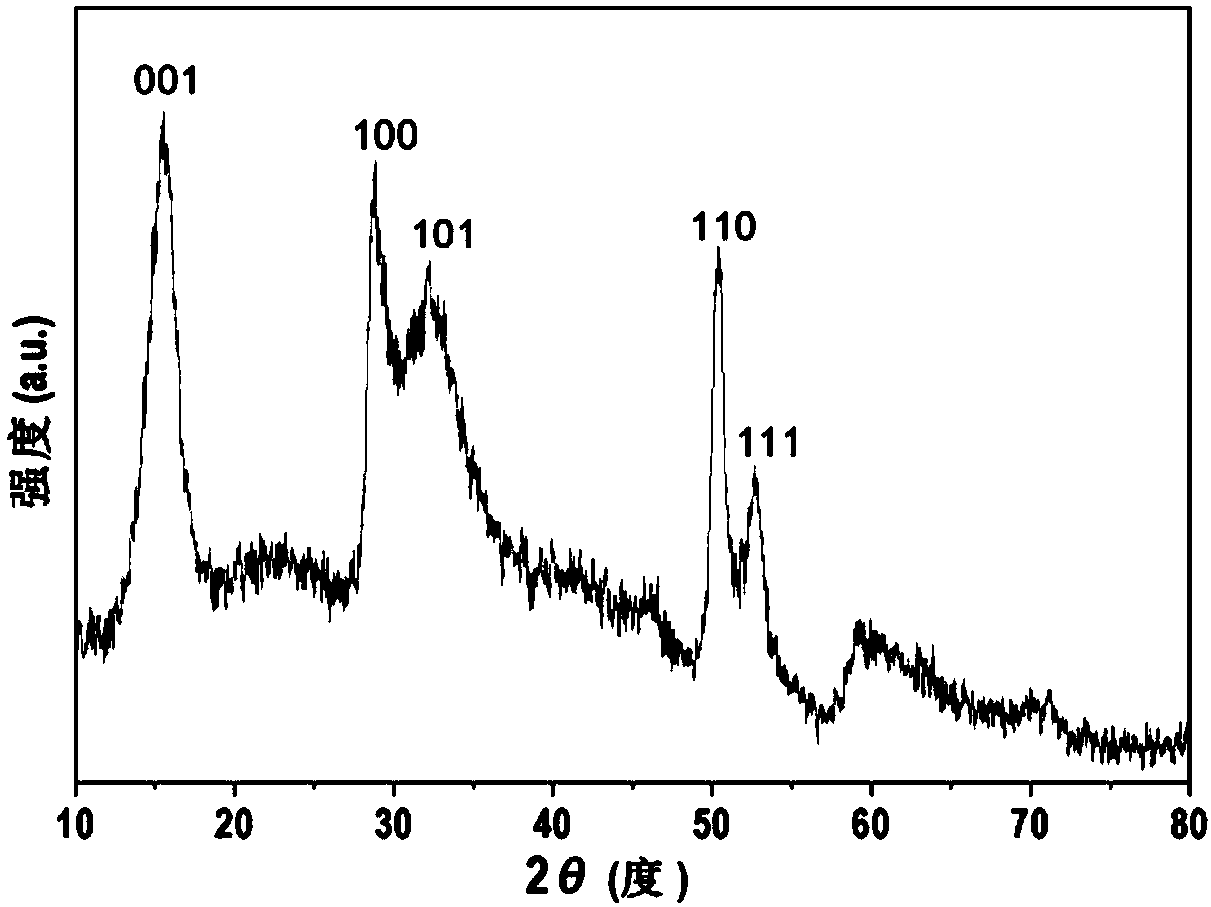

[0043] Example 1 Nano SnS 2 / Preparation of graphene composites

[0044] This embodiment provides a nano SnS 2 The preparation of / graphene composite material comprises the steps:

[0045] a, tin tetrachloride pentahydrate (SnCl 4 ·5H 2 0) Dissolve 1.4g (4mmol) source in 80ml, 1.5mg / mL graphene aqueous solution, stir magnetically or sonicate for 30min until it is completely dissolved to form a homogeneous solution.

[0046] b. Then, add 0.6 g (~8 mmol) of thioacetamide to the above solution, stir magnetically or sonicate for a period of time until the thioacetamide is completely dissolved to form a uniform solution.

[0047] c. Add 0.1 g of ethylenediamine to the above solution, and stir magnetically or sonicate for 30 minutes until it is completely dissolved to form a uniform solution.

[0048] d. Transfer the solution obtained in c to a 50ml hydrothermal reaction kettle, and conduct a hydrothermal reaction at 100°C for 6h.

[0049] e. After hydrothermal treatment, cool...

Embodiment 2

[0054] Example 2 Potassium ion battery negative electrode sheet preparation and battery assembly

[0055] This embodiment provides a method for preparing a negative pole piece of a potassium ion battery and assembling the battery, including:

[0056] a, the resulting SnS 2 / Graphene composite material, conductive agent Super P, and binder sodium alginate are mixed according to the mass ratio of 85:5:10, and a few drops of deionized water are added, and after mechanical stirring to form a uniform slurry, it is coated Spread it on the copper foil, and then dry it at 80°C for 10h under vacuum condition to get the dried electrode sheet.

[0057] b. Cut the dried electrode sheet into a circular electrode sheet with a diameter of 10 nm.

[0058] c. Use the circular electrode sheet prepared above as the negative electrode, the glass fiber diaphragm as the diaphragm, and pack the metal potassium sheet into a button battery. The model of the button battery is CR2032, and the concentr...

Embodiment 3

[0062] Example 3 Nano SnS 2 / Preparation of graphene composites

[0063] Proceed as follows:

[0064] a, tin tetrachloride pentahydrate (SnCl 4 ·5H 2 0) Dissolve 0.7g (~2mmol) source in 80ml, 1.5mg / L graphene aqueous solution, stir magnetically or sonicate for 30min until it is completely dissolved to form a homogeneous solution.

[0065] b. Then, add 0.32 g (~2 mmol) of sodium thiosulfate to the above solution, stir magnetically or ultrasonically for a period of time until the sodium thiosulfate is completely dissolved and a uniform solution is formed.

[0066] c. Add 0.1 g of ethylenediamine to the above solution, and stir magnetically or sonicate for 30 minutes until it is completely dissolved to form a uniform solution.

[0067] d. Transfer the solution obtained in c to a 50 ml hydrothermal reaction kettle, and conduct a hydrothermal reaction at 95° C. for 6 h.

[0068] e. After hydrothermal treatment, cool to normal temperature, centrifuge, wash, and dry, and treat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com