Patents

Literature

43results about How to "Increase the binding point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microbiological fuel cell as well as preparation method and applications thereof

InactiveCN101645515AImprove power generation performanceAvoid troubleFinal product manufactureCell electrodesBrown iron oxideCarbon nanotube

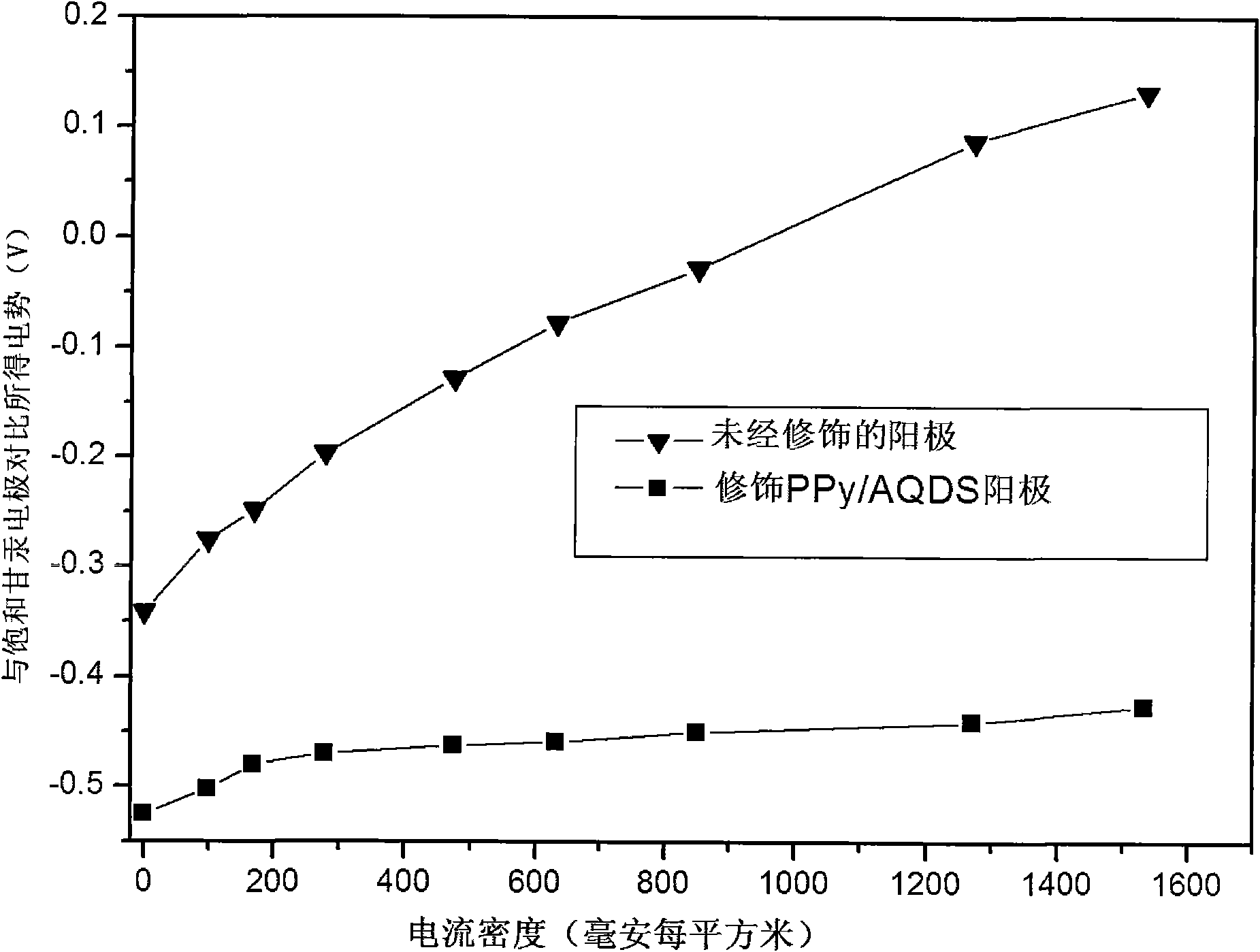

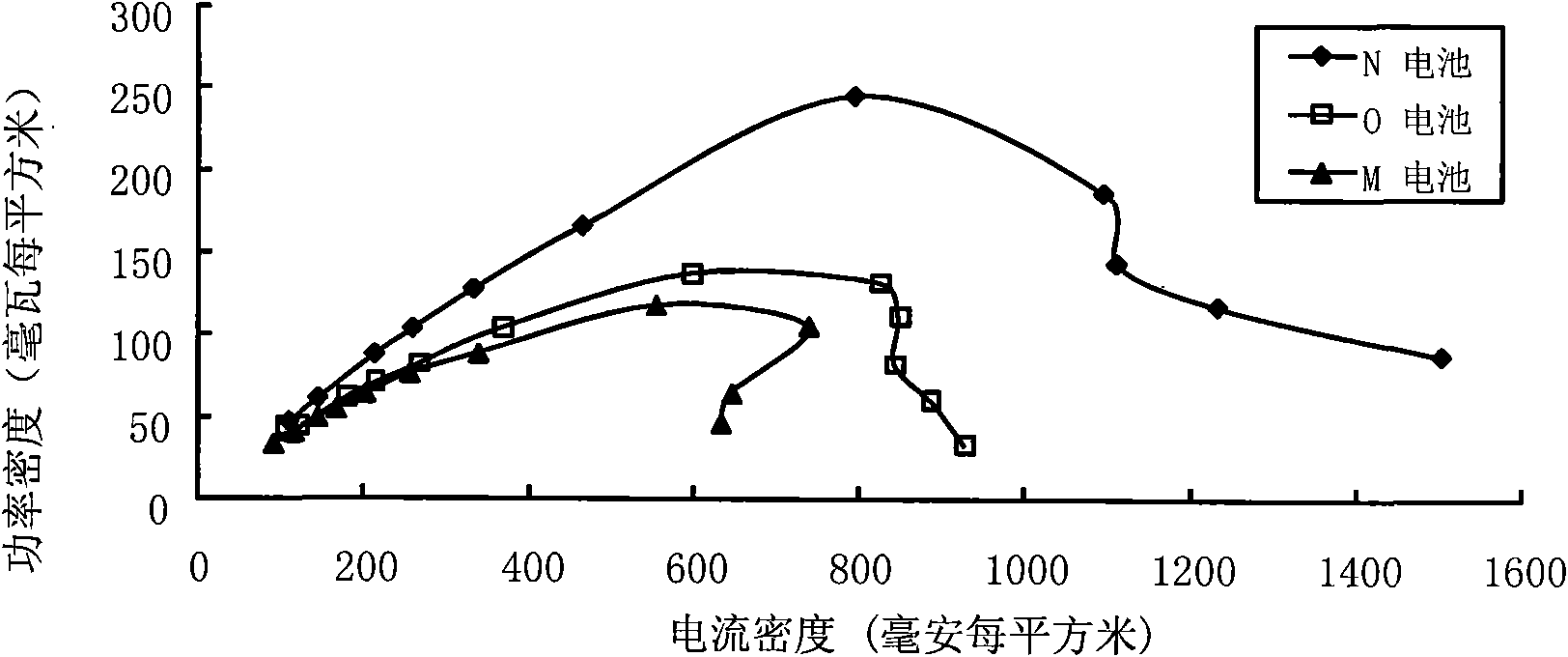

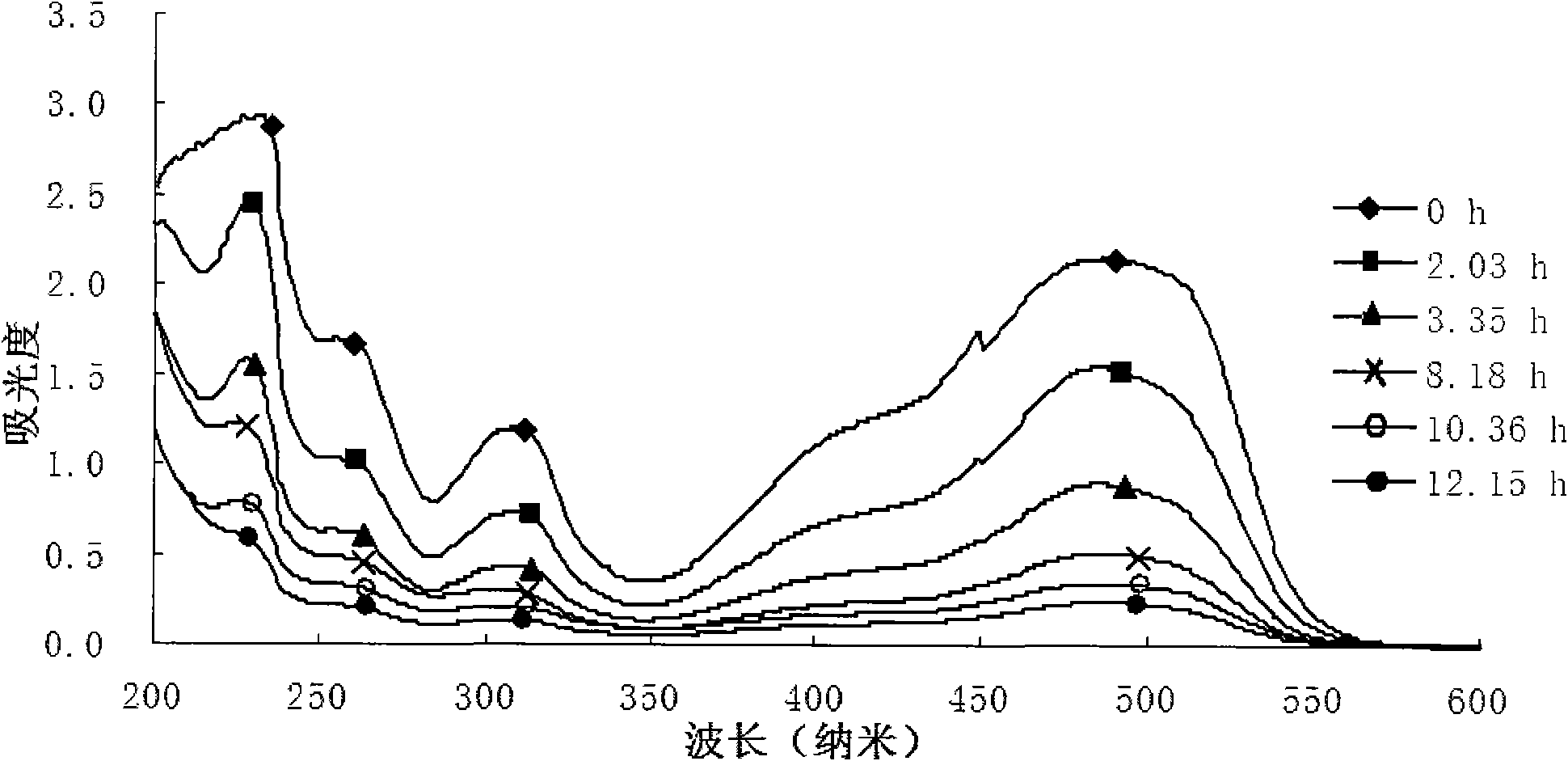

The invention relates to the field of microbiological fuel cells, in particular to a microbiological fuel cell as well as a preparation method and applications thereof. The anode is carbon felt, the surface of which is deposited with polypyrrole and anthraquinone-2,6-sodium disulfonate; and the cathode mainly comprises carbon nano tubes, polyfluortetraethylene and gamma-iron oxide basic. The invention combines the advantages of microbiological fuel cells and electro-Fenton, and utilizes electric energy produced under the action of microorganisms on organic substrates in the anolyte as the energy of the electro-Fenton reaction to further oxidize and degrade contaminants in water bodies. The method is environmental-friendly and has the effects of production capacity and water treatment so that a new method for degrading organic contaminants with microbiological fuel cells is provided.

Owner:SOUTH CHINA UNIV OF TECH

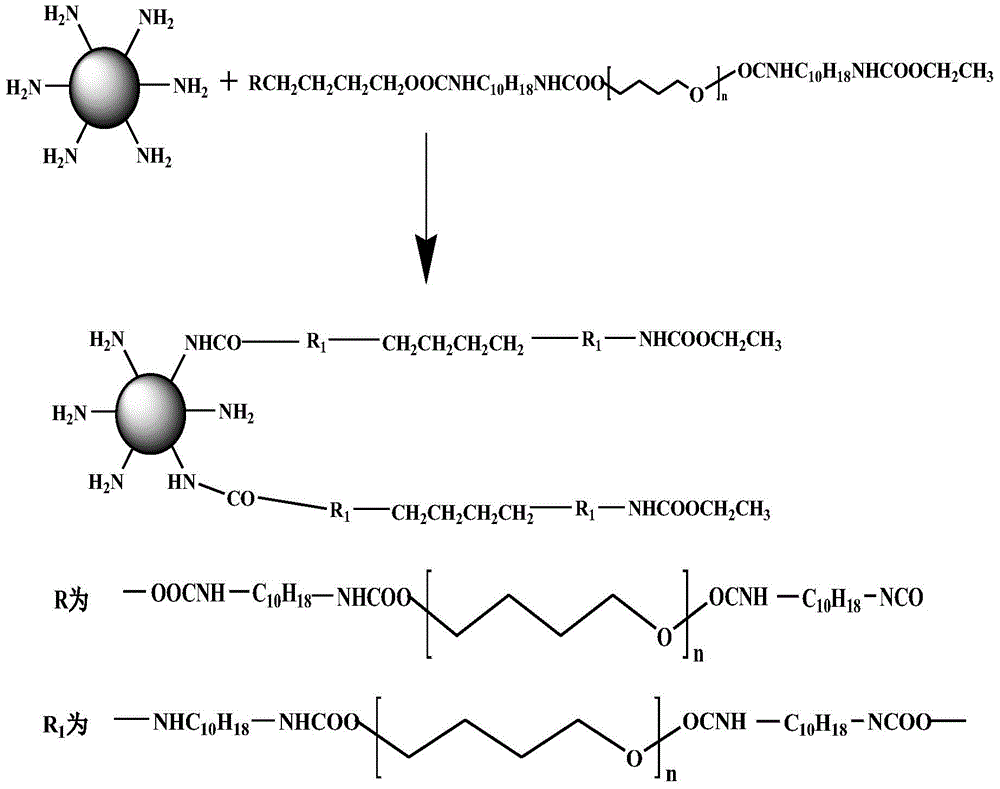

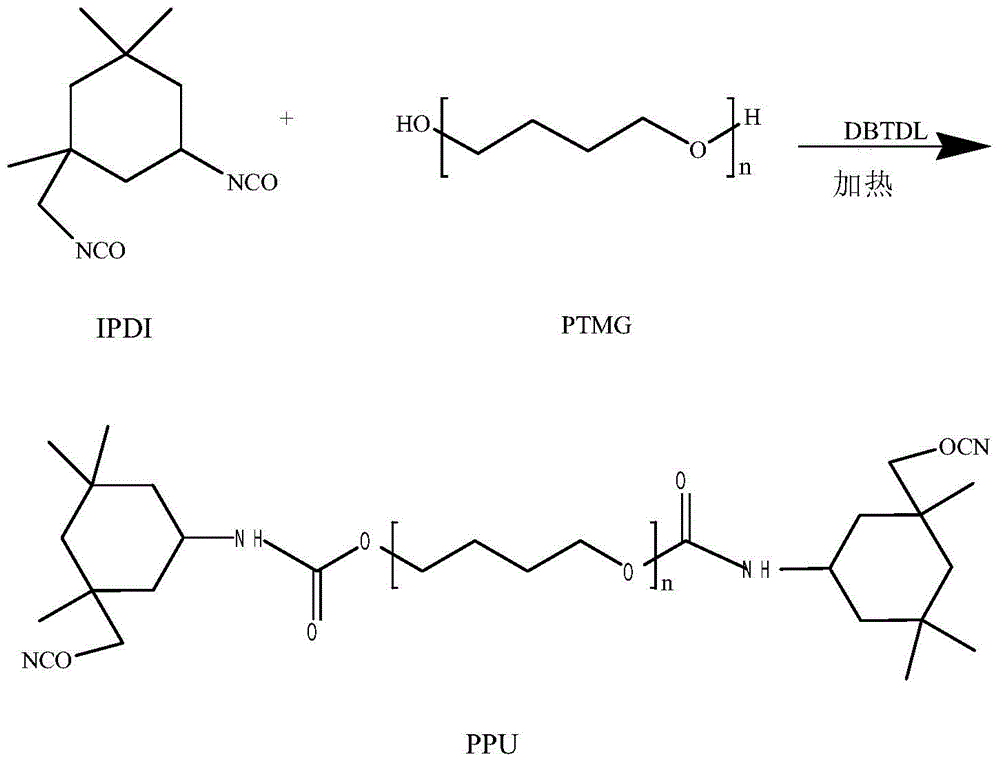

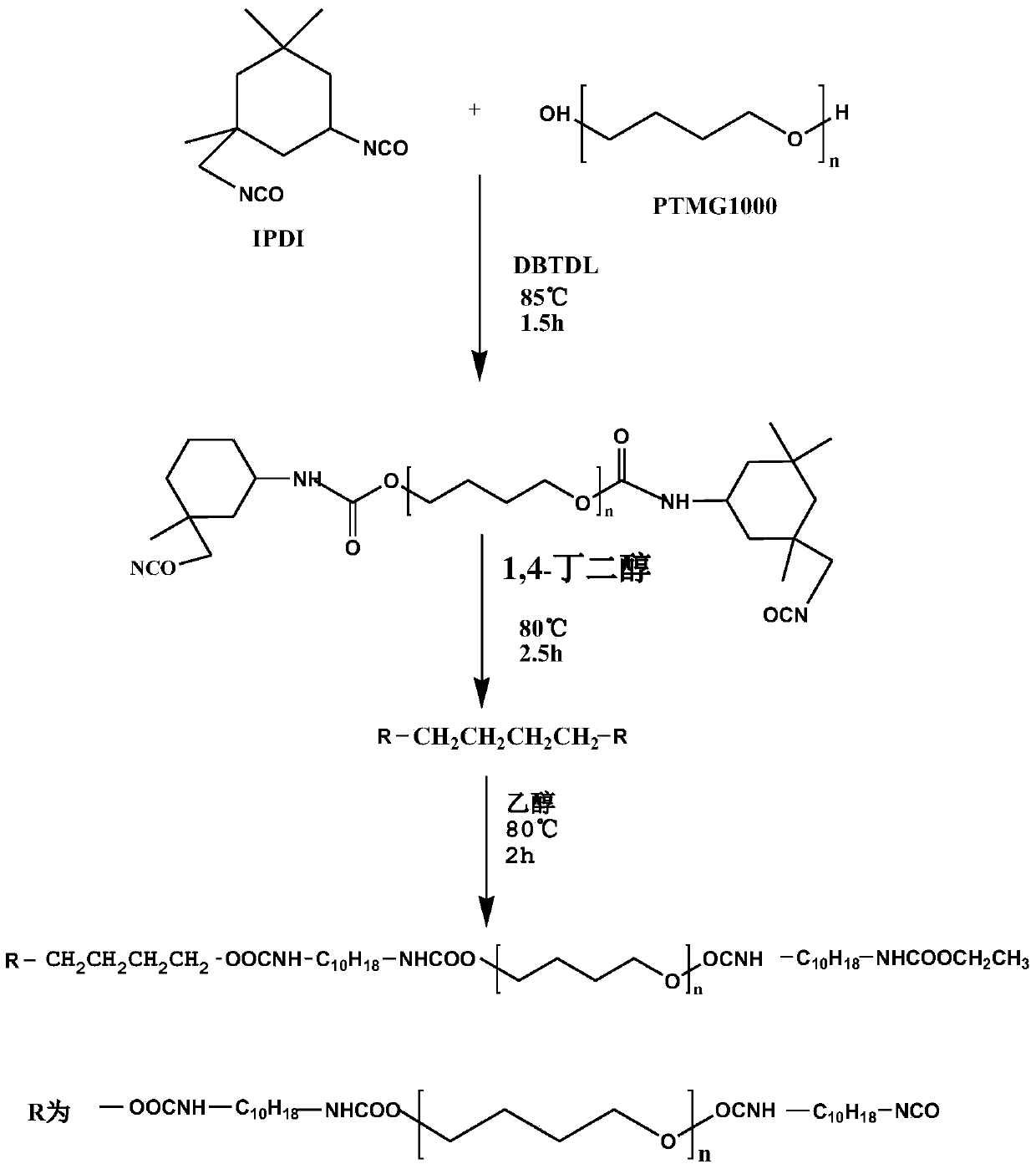

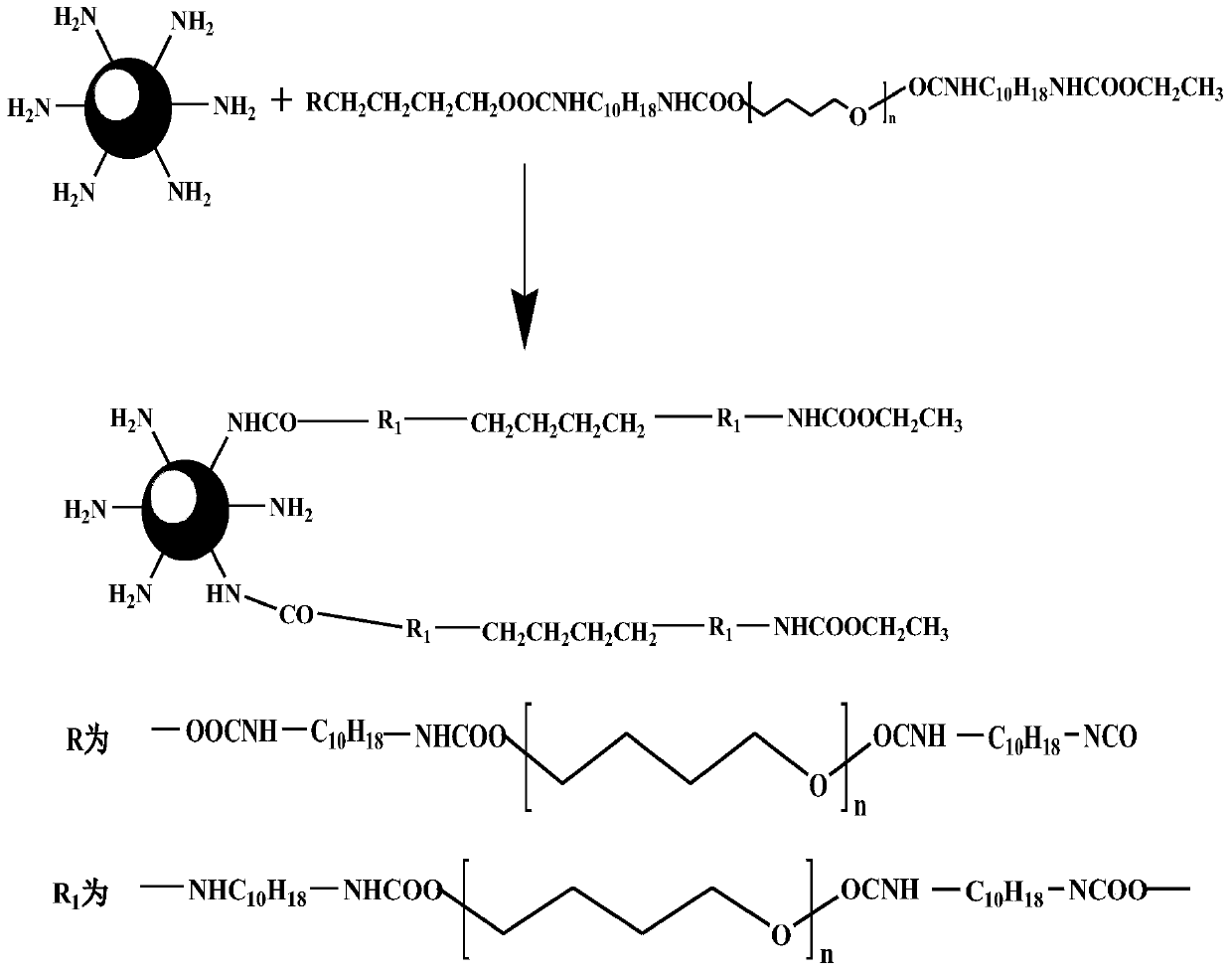

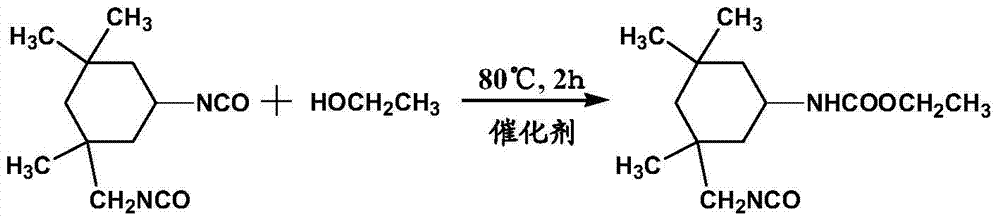

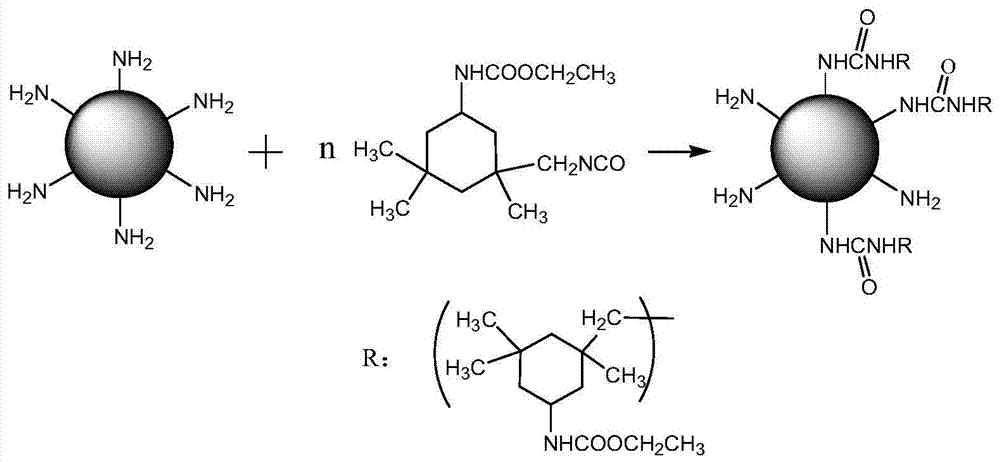

Hyperbranched polyurethane containing active amino groups and preparation method thereof

The invention discloses hyperbranched polyurethane containing active amino groups and a preparation method thereof. The preparation method comprises the steps that firstly, polyether polyol and diisocyanate are mixed and stirred to react; secondly, a catalyst is added, organic aprotic solvent serves as solvent, and a small-molecule chain extender is added for chain extension after the reaction is performed for a period of time; thirdly, an end-capping reagent is added for partial end capping, so that linear polyurethane pre-polymers are obtained; afterwards, amino-teminated hyperbranched polymers and the linear polyurethane pre-polymers are mixed and stirred to react, so that the hyperbranched polyurethane is obtained. Hyperbranched polyurethane resin obtained by synthesizing the hyperbranched polyurethane contains a lot of active amino groups and imino groups, so the sanitary property of a polyurethane film can be improved, and the dyeing property of the polyurethane film can also be improved.

Owner:SHAANXI UNIV OF SCI & TECH

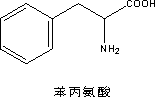

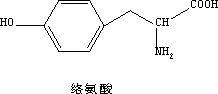

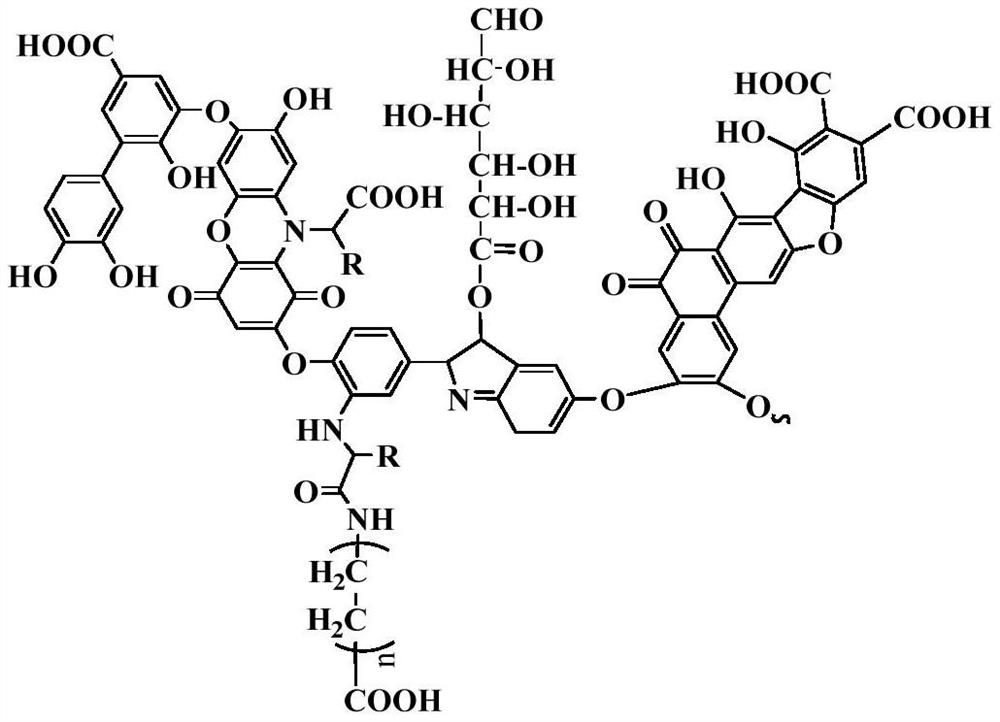

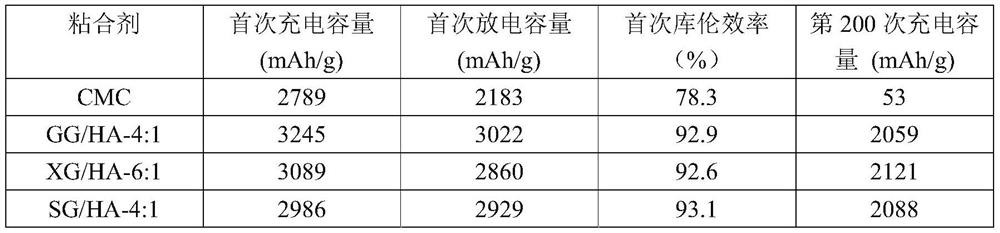

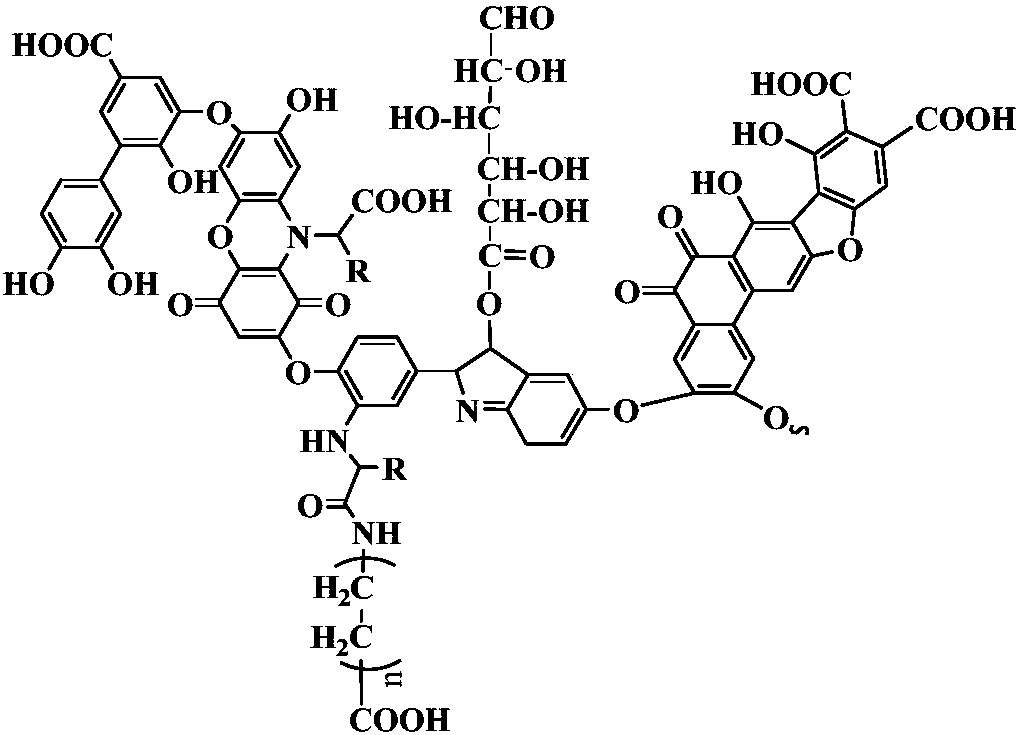

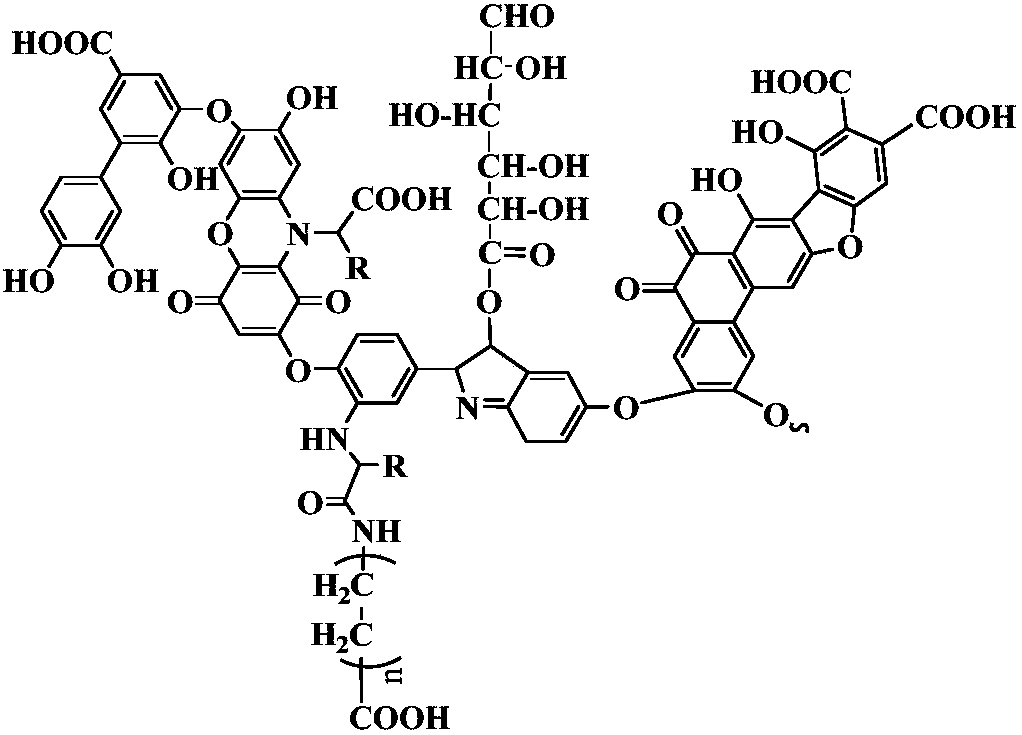

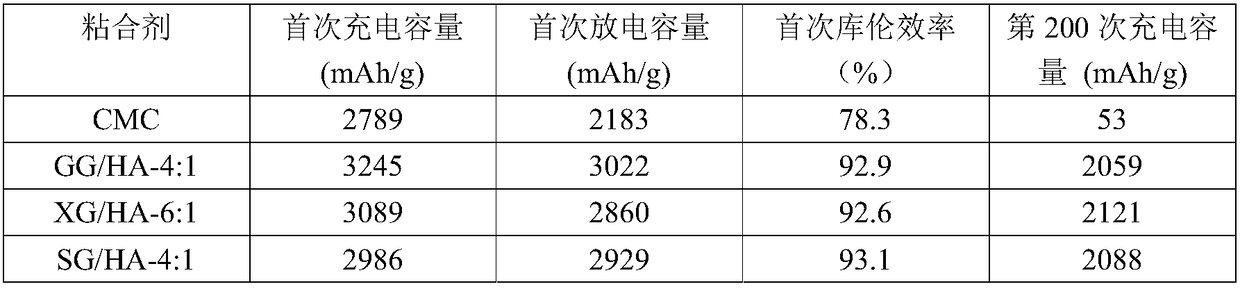

Adhesive for nano-silicon carbon anode material of lithium battery and preparation method of adhesive

InactiveCN108428895AHigh tensile strengthIncrease elasticityCell electrodesSecondary cellsSilicon electrodeCarboxylic group

The invention discloses an adhesive for a nano-silicon carbon anode material of a lithium battery. The high-molecular polymer adhesive is prepared from amino acid containing amino and polymers containing carboxyl or ester by condensation; amino in amino acid is subjected to a reaction with carboxyl in PAA (polyacrylic acid) or ester in polyacrylate and dehydrated to form an amido bond, then a high-molecular polymer with a three-dimensional network structure is formed, and synergistic effect of amino in amino acid and carboxyl is utilized sufficiently, so that the polymer has excellent mechanical property and machinability and high tensile strength and elastic restoring force. The adhesive can effectively limit change of electrode thickness in a lithium-intercalation process, an electrode also has better recovery capability in a lithium separation process, structural stability of the silicon electrode in the lithium separation / intercalation process is effectively kept, and the defect that volume of a silicon pole piece is extremely prone to expanding in a charge-discharge process is overcome.

Owner:中国东方电气集团有限公司

Diamond polishing film production method

InactiveCN104275651AExtended service lifeNot easy to fall offGrinding devicesLapping toolsMetallurgyMaterials science

The invention discloses a diamond polishing film production method and belongs to the technical fields of grinding materials and grinding tools. The diamond polishing film production method includes that diamond micro-powder is scattered to a binding agent and the surface of a basal film is coated, wherein the diamond micro-powder is washed before scattering till pH (potential of hydrogen) value of washing liquid reaches more than 6.0. The pH value of the surface of diamond is controlled to be near neutral or neutral through washing, binding strength of the diamond micro-powder and the binding agent can be greatly improved, the diamond micro-powder on the polishing film is less prone to falling off during use, and service life of the polishing film can be prolonged.

Owner:HENAN UNION ABRASIVES

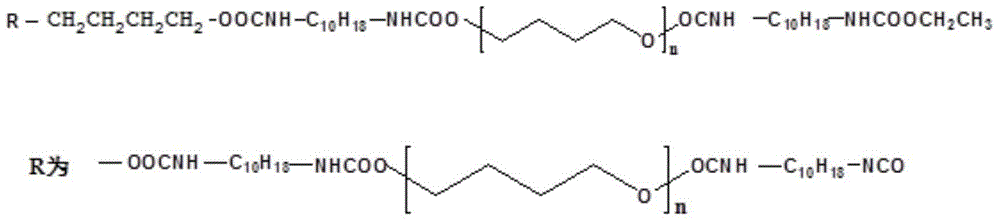

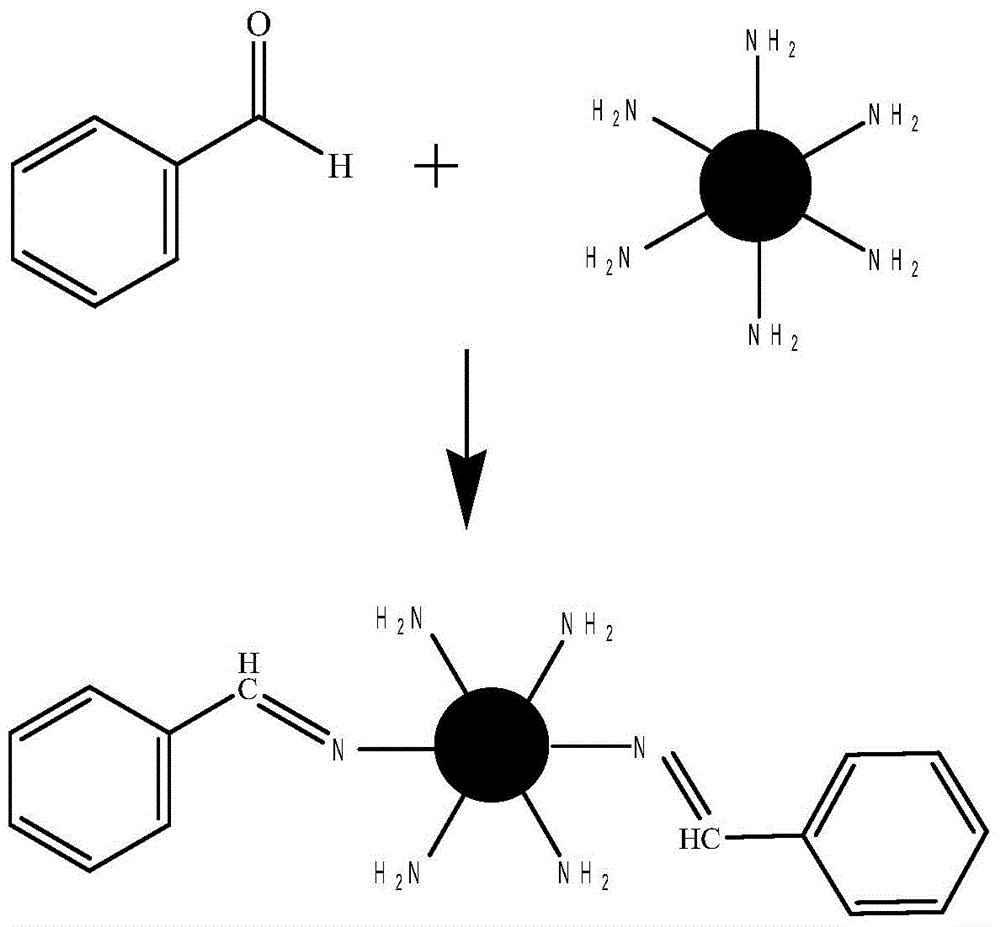

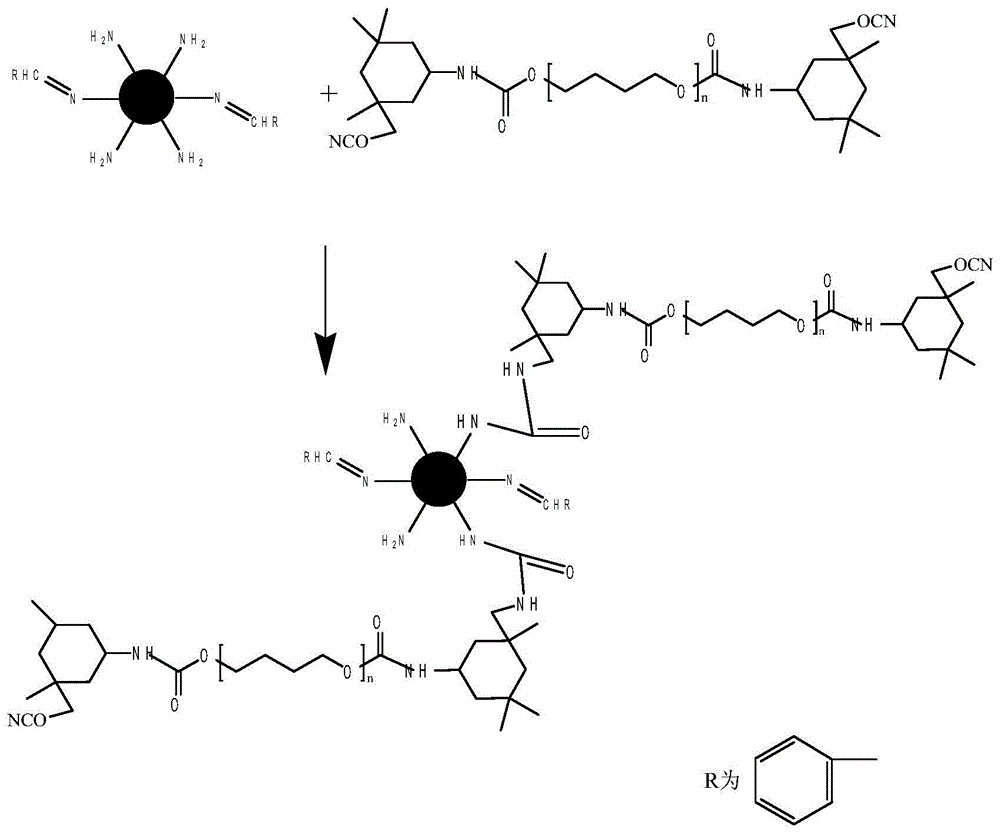

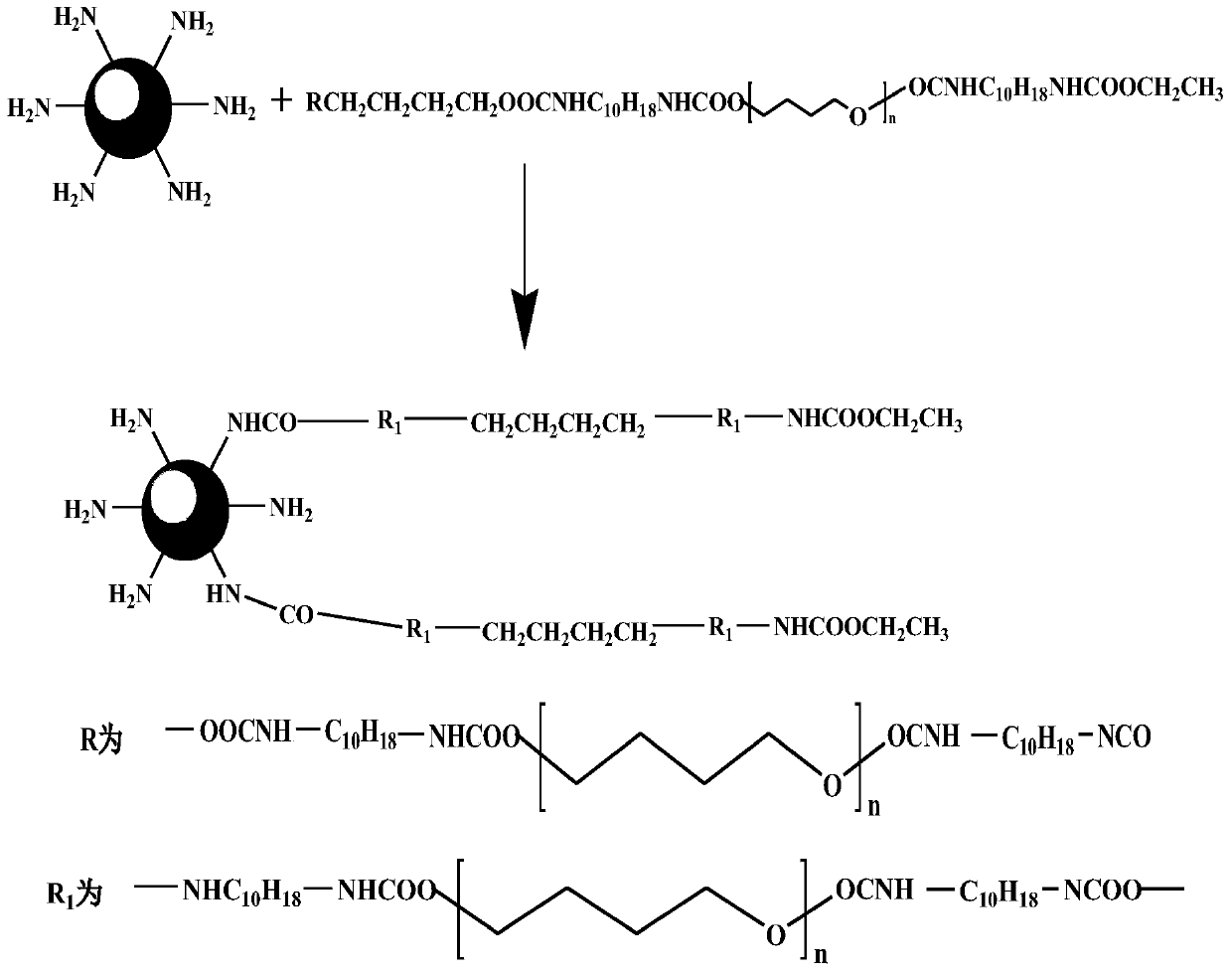

Preparation method of chromatophilous polyurethane applied to superfine fiber synthetic leather

The invention discloses a preparation method of chromatophilous polyurethane applied to superfine fiber synthetic leather. The preparation method comprises the following steps: firstly mixing polyether polyol with diisocyanate, stirring for reacting, adding a catalyst and taking an aprotic organic solvent as a solvent to prepare a polyurethane prepolymer; mixing an amino-terminated hyperbranched polymer with benzaldehyde, and stirring for reacting to prepare a hyperbranched polymer which is partially protected; subsequently mixing the hyperbranched polymer which is partially protected with the polyurethane prepolymer, and stirring for reacting to prepare hyperbranched polyurethane; finally mixing the hyperbranched polyurethane with a hydrochloric acid alcohol solution, stirring for reacting, washing by ethyl alcohol and acetone after the reaction is ended, drying in vacuum to prepare amino-containing hyperbranched polyurethane. Polyurethane resin synthesized by the amino-containing hyperbranched polyurethane contains active amino, so that the number of active hydrophilic groups is increased; the health performance is improved; the dye integration points are increased; anionic dye is integrated with the amino with positive charge, so that the dyeing effect is improved; the dyeing rate and the dyeing fastness are improved.

Owner:威海佐伦鞋材有限公司

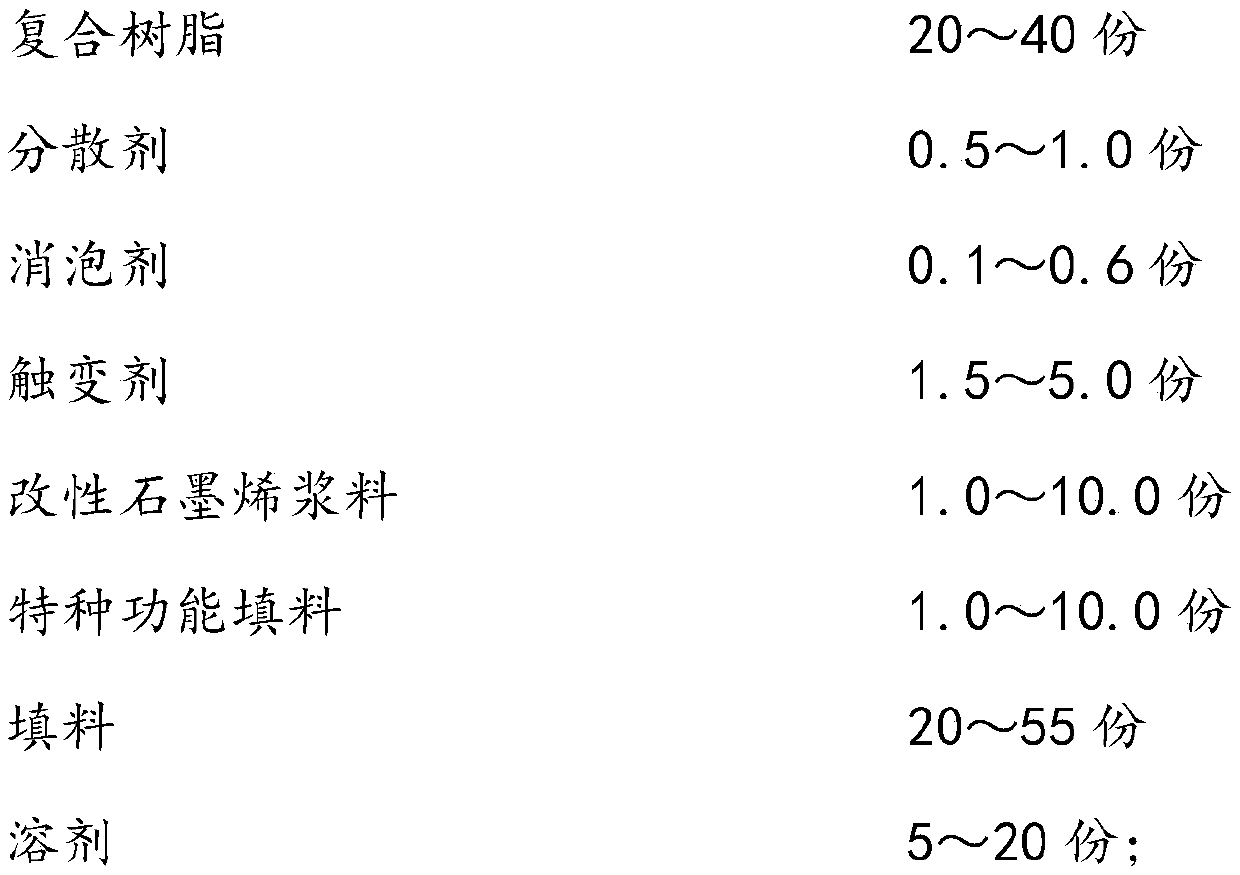

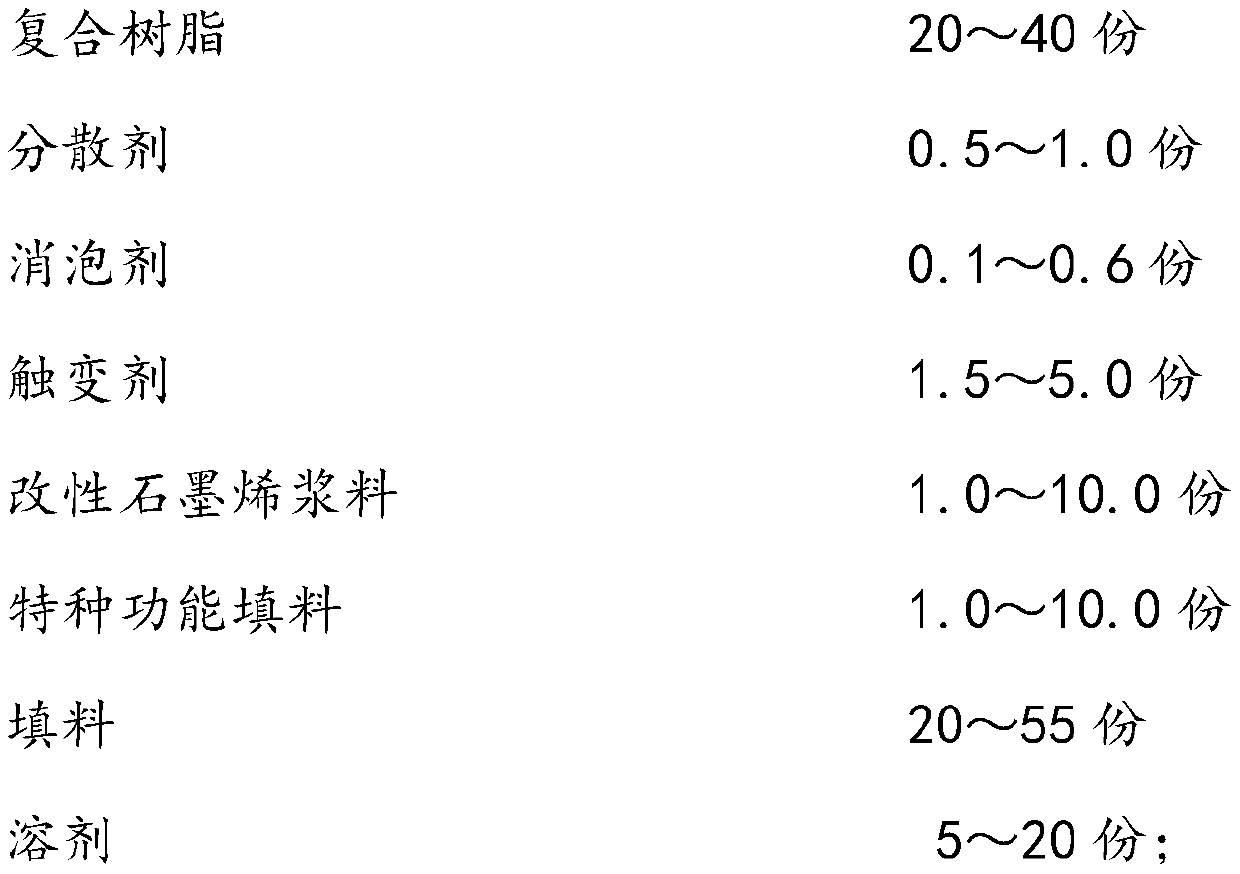

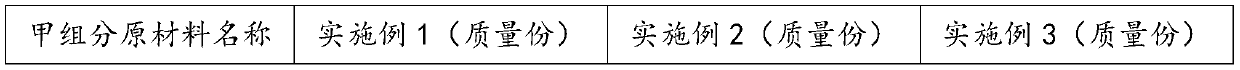

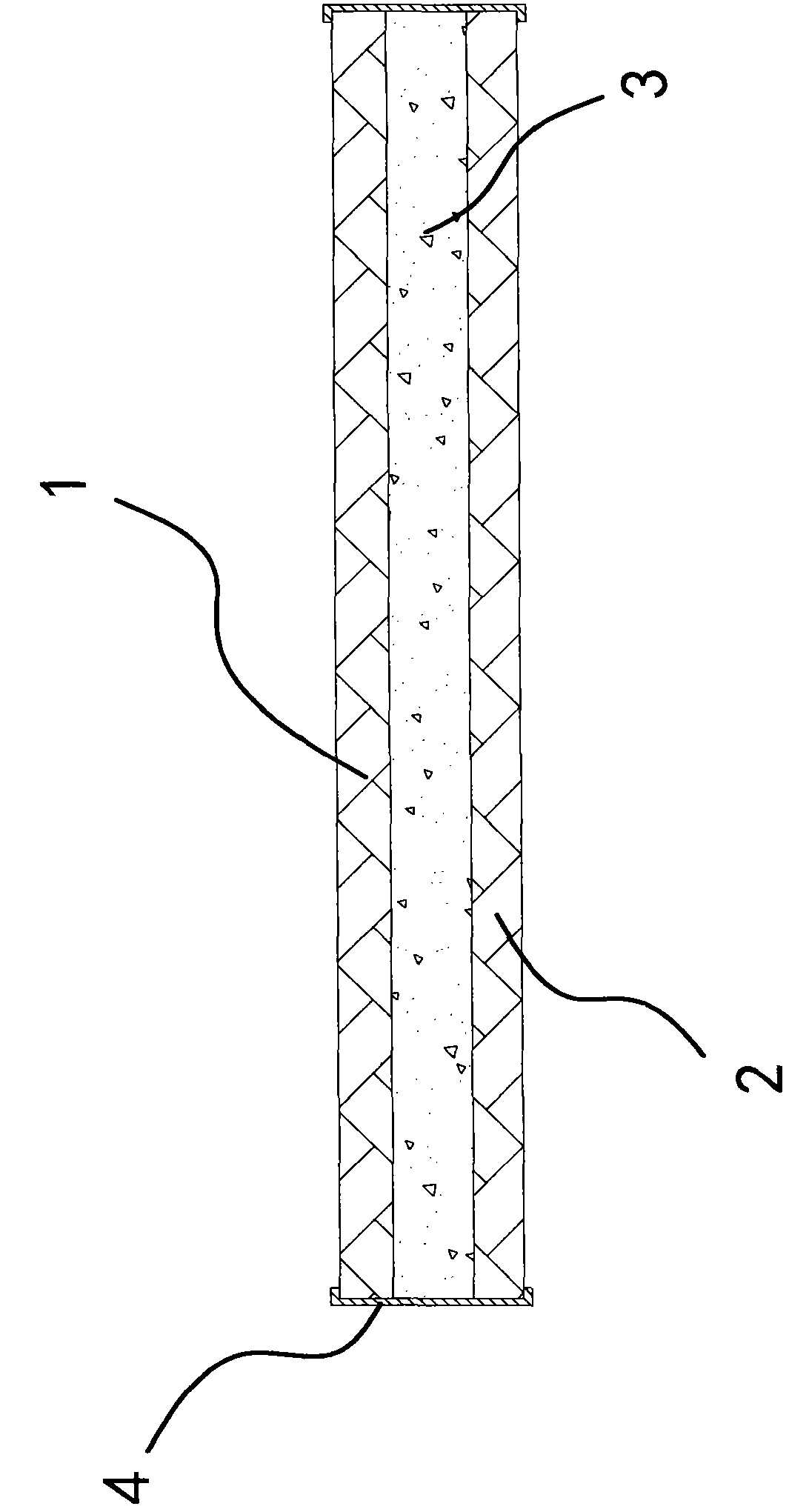

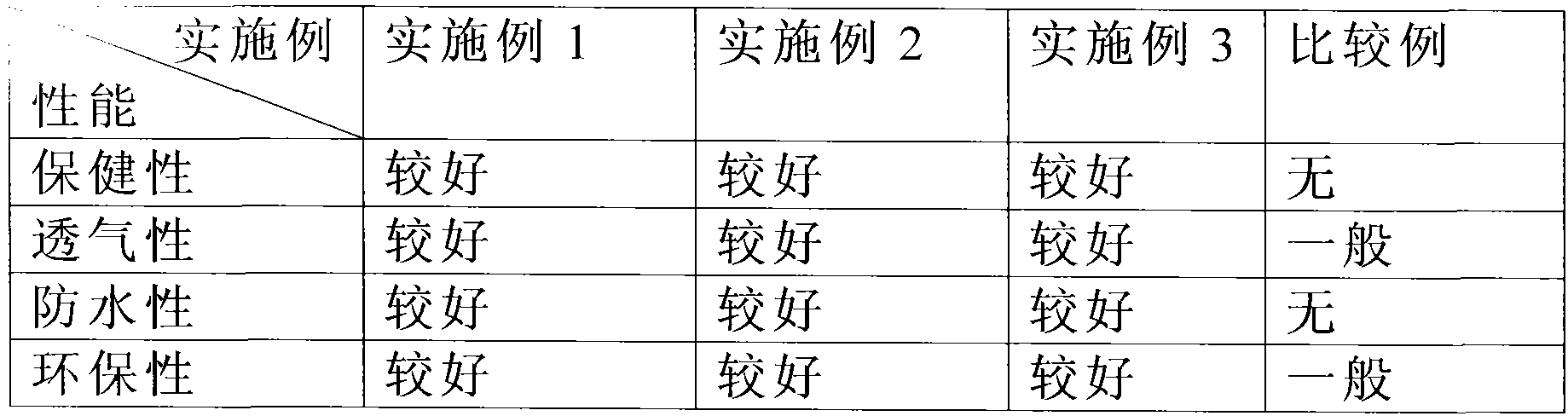

Thin-coating heavy-duty anticorrosive coating and preparation method thereof

InactiveCN110643267AImprove corrosion resistanceHigh glass transition temperatureAnti-corrosive paintsEpoxy resin coatingsFirming agentResin-Based Composite

The invention relates to the technical field of anticorrosive coatings, and in particular, relates to a thin-coating heavy-duty anticorrosive coating and a preparation method thereof. The thin-coatingheavy-duty anticorrosive coating comprises the following raw materials in parts by mass: composite resin, a dispersing agent, a defoaming agent, a thixotropic agent, glass flakes, modified graphene slurry, a special functional filler, a filler, a solvent and a composite curing agent. With adopting of the thin-coating type heavy-duty anticorrosive coating provided by the invention, the problems ofslow paint film drying time, long construction period, insufficient flexibility, coating layer failure such as easiness in cracking and peeling and like due to the high-film-thickness design of a conventional heavy-duty anticorrosive coating are solved, the coating is applied to long-acting heavy-duty corrosion prevention of steel structures and concrete engineering in a marine environment, improves the paint film defect of high-film-thickness design of the conventional heavy-duty anticorrosive coating, greatly reduces the construction cost and the construction progress, reduces the use amount of the coating and reduces the emission of volatile organic compounds. The production process is simple, the processing cost is low, and large-scale commercial production is easy.

Owner:XIAMEN SUNRUI SHIP COATING

Health care mat for infants and manufacturing method thereof

InactiveCN103405088APowerful insecticidePromote circulationNervous disorderImmunological disordersTraditional medicineSemen

The invention provides a health care mat for infants and belongs to the technical field of textile processing. The health care mat for infants is of a three-layer double-side structure, a front side layer and a back side layer are both a simulation rattan mat body, and a middle health care layer is formed by evenly mixing and flattening 100 parts of Chinese herbal medicine and 5-40 parts of natural rubber cement by weight. The Chinese herbal medicine of the health care layer includes the following raw materials by weight: 1 part to 10 parts of bamboo charcoal, 1 part to 10 parts of jasmine flower, 20-35 parts of negundo chastetree fruit, 10-30 parts of semen cassiae, 10-30 parts of lavender and 10-20 parts of mint. The manufacturing method includes manufacturing the simulation rattan mat bodies, taking the Chinese herbal medicine according to the prescription, drying and breaking the Chinese herbal medicine, mixing the dried and broken Chinese herbal medicine with the natural rubber cement to obtain the health care layer, evenly coating the natural rubber cement on the bottom face of one simulation rattan mat body, laying the health care layer, then laying the other simulation rattan mat body and conducting clipping and edge wrapping to obtain a finished product of the health care mat for the infants. The health care mat is good in health care effect and low in cost.

Owner:NINGBO YINZHOU LIMING ARTS & CRAFTS

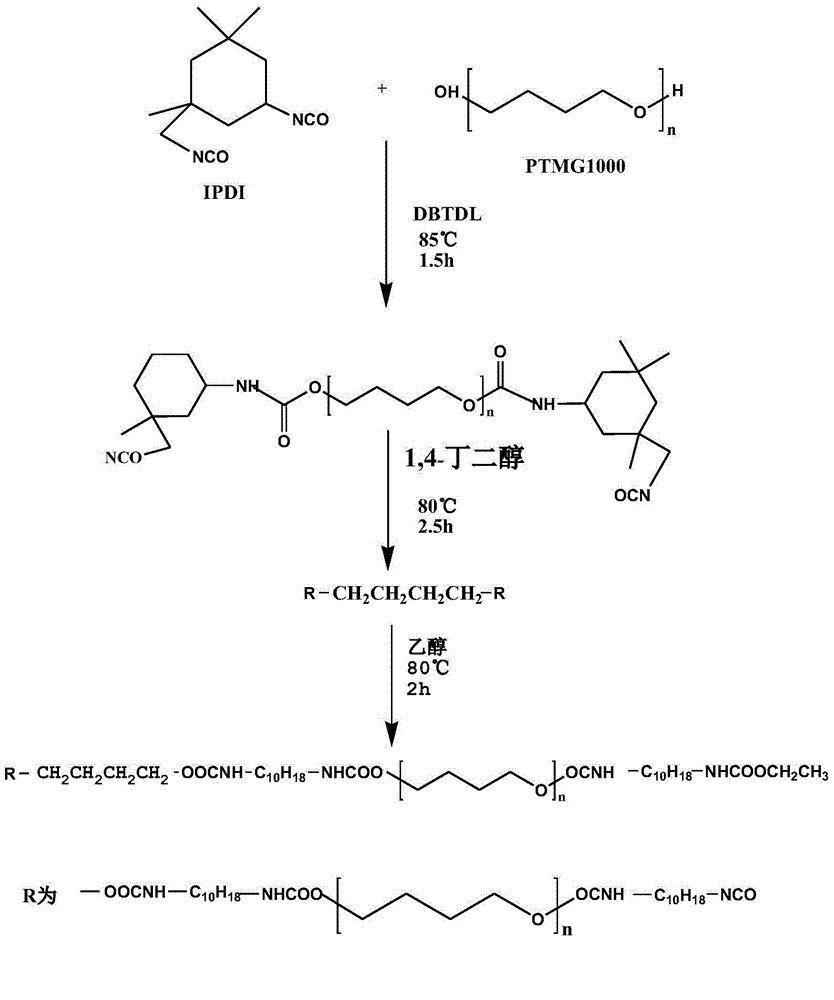

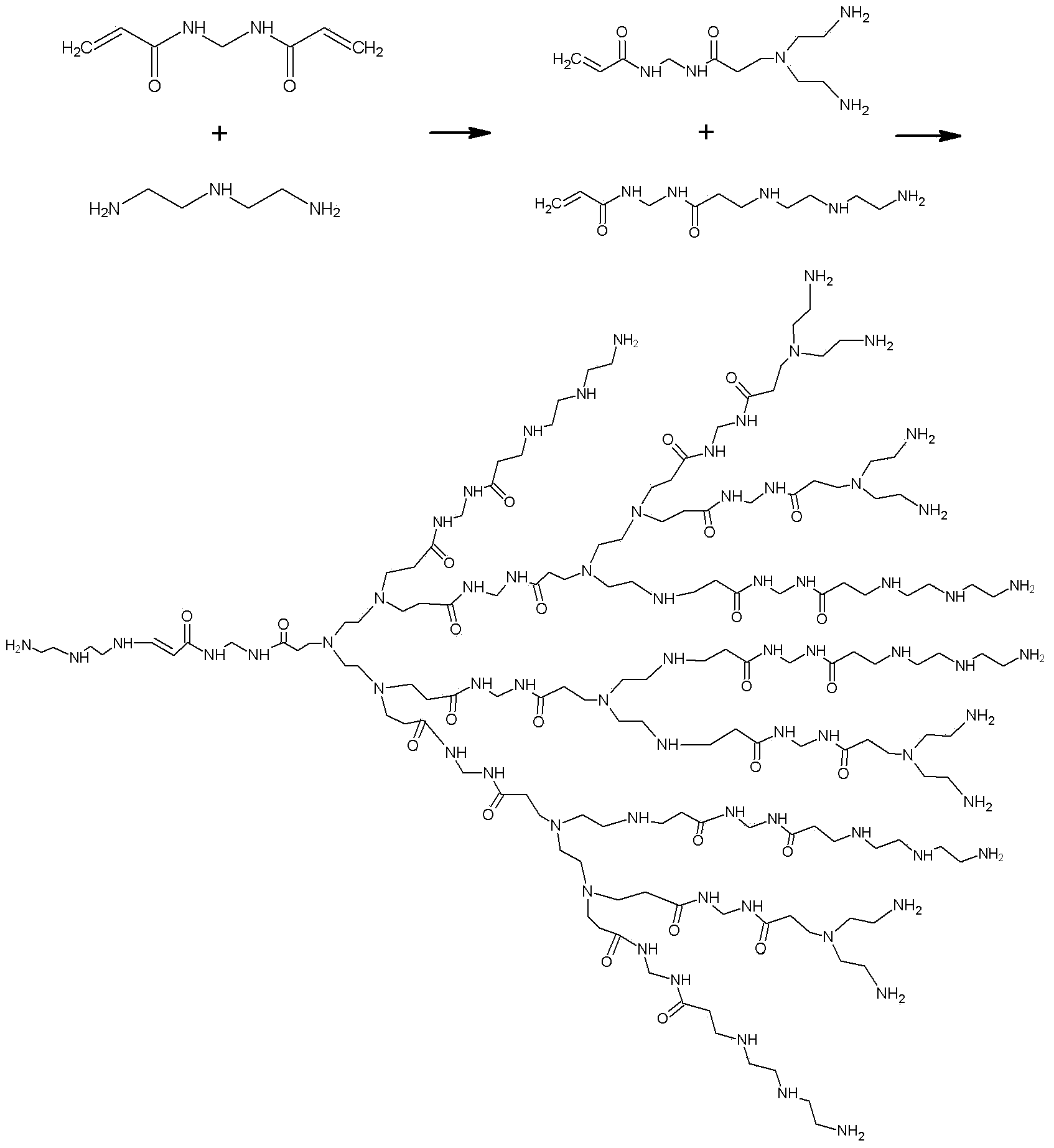

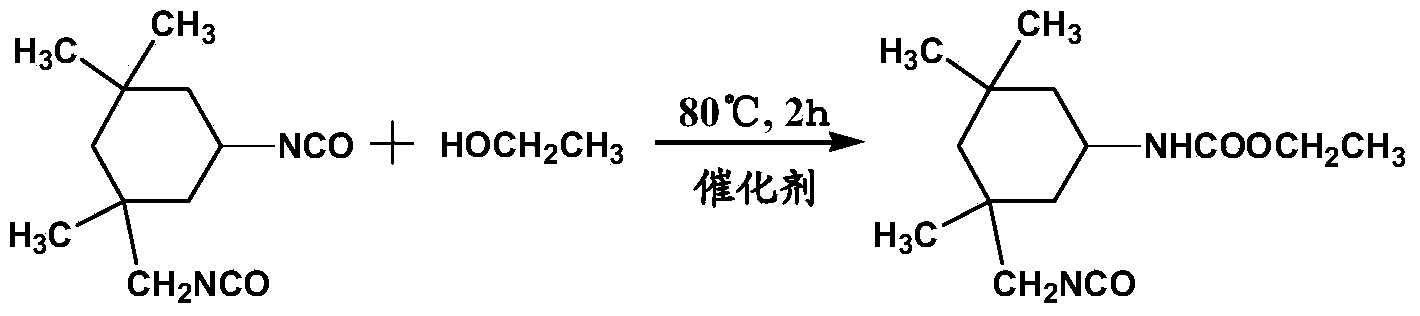

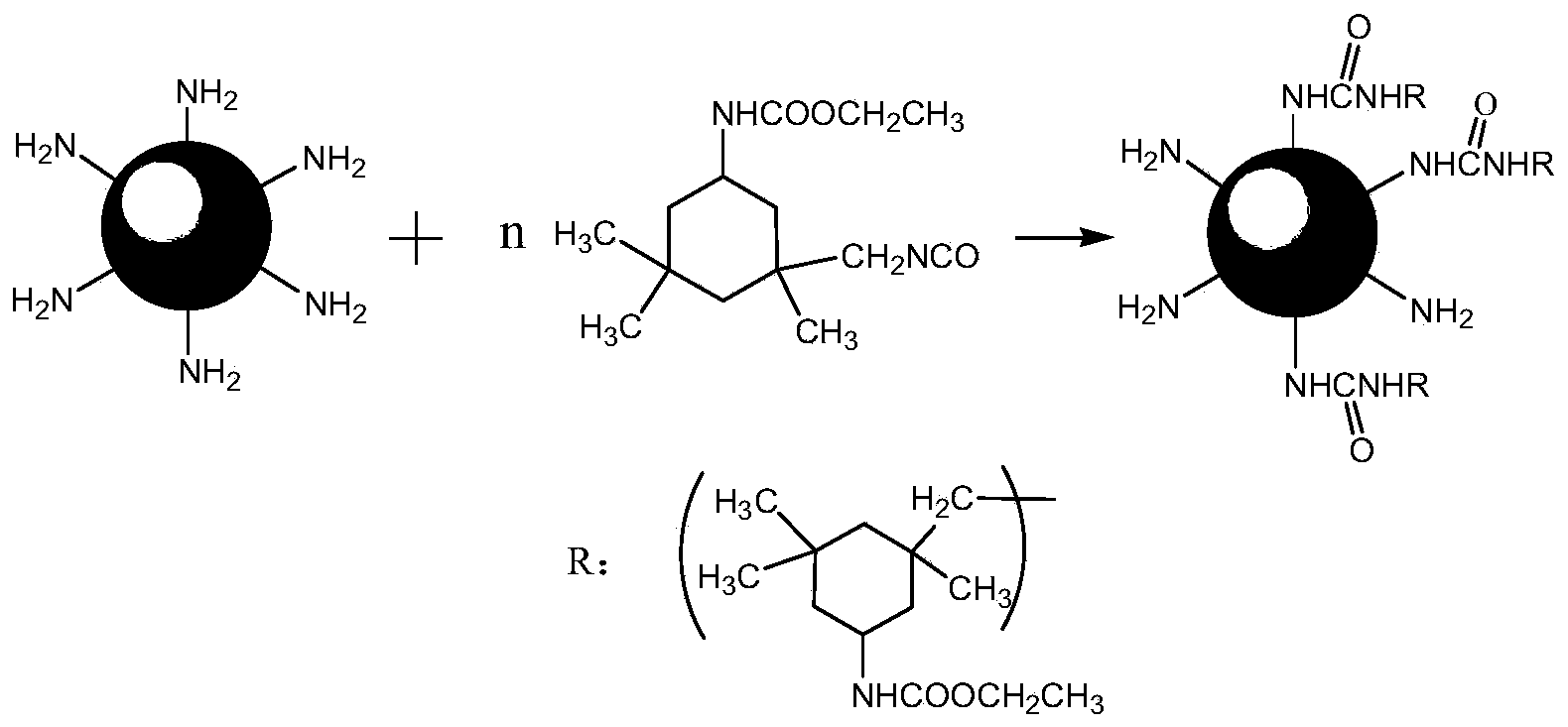

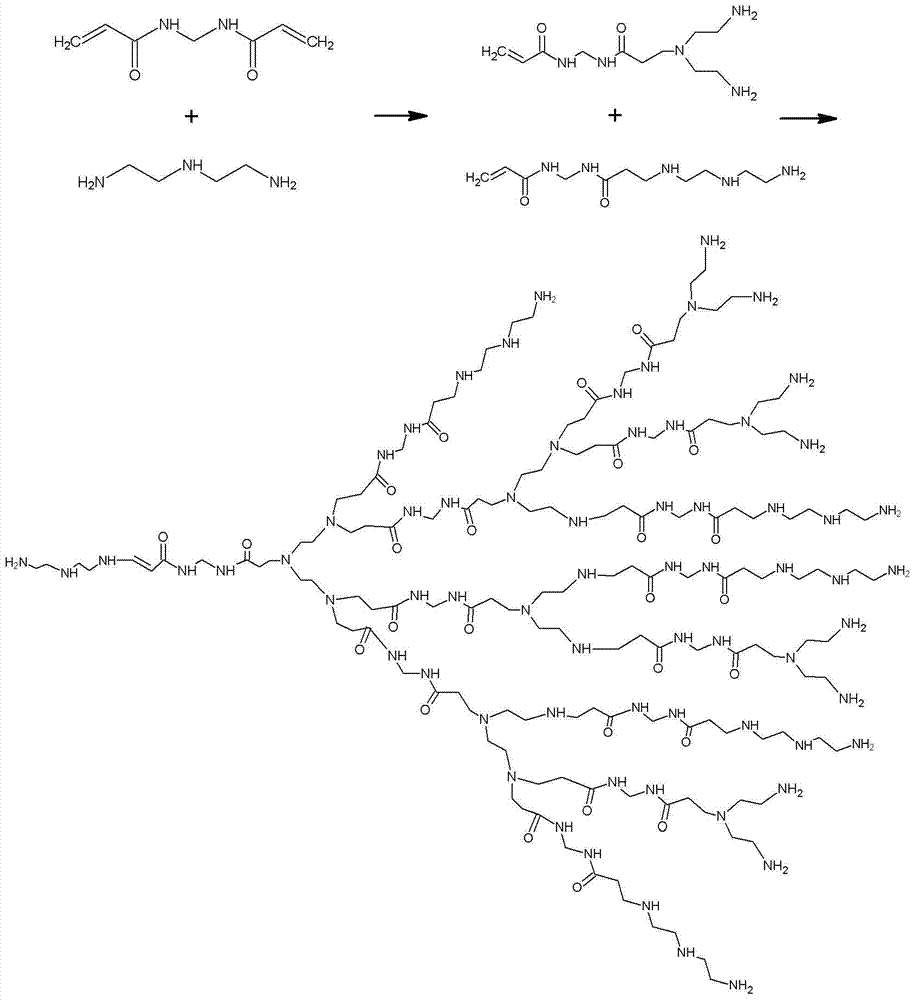

Preparation method for dyeable polyurethane film

The invention discloses a preparation method for a dyeable polyurethane film. The preparation method comprises the following steps: firstly, adding N, N-methylene bisacrylamide and diethylenetriamine into N, N-dimethylformamide to prepare an amino-terminated hyperbranched polymer; terminating the obtained product by using ethanol terminated isophorone diisocyanate; then, adding the terminated product into an N, N-dimethylformamide solution of polyurethane to prepare a casting film solution; pouring the casting film solution on a substrate; dipping in a coagulating bath to form a film by a wet process; and drying to obtain the dyeable polyurethane film. According to the film prepared by the method, as an active group -NH2 is introduced into a component of the film, bonding points of the dye are increased. Moreover, in an acidic solution, the film has positive charges, so that an anionic dye is gradually bonded with amino (P-NH3+) with positive charges in the film by virtue of ionic bonds to play a dyeing effect, thereby improving the dyeing rate and the color fastness. Meanwhile, the method is simple, convenient and feasible to operate, low in requirements on equipment and easy for industrial popularization.

Owner:汕头市亮彩新材料科技有限公司

A kind of hyperbranched polyurethane containing active amino group and preparation method thereof

The invention discloses hyperbranched polyurethane containing active amino groups and a preparation method thereof. The preparation method comprises the steps that firstly, polyether polyol and diisocyanate are mixed and stirred to react; secondly, a catalyst is added, organic aprotic solvent serves as solvent, and a small-molecule chain extender is added for chain extension after the reaction is performed for a period of time; thirdly, an end-capping reagent is added for partial end capping, so that linear polyurethane pre-polymers are obtained; afterwards, amino-teminated hyperbranched polymers and the linear polyurethane pre-polymers are mixed and stirred to react, so that the hyperbranched polyurethane is obtained. Hyperbranched polyurethane resin obtained by synthesizing the hyperbranched polyurethane contains a lot of active amino groups and imino groups, so the sanitary property of a polyurethane film can be improved, and the dyeing property of the polyurethane film can also be improved.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing washable semi-vegetable-tanning sheepskin garment leather

ActiveCN106282438AHigh color fastnessImprove bindingTanning treatmentPre-tanning chemical treatmentChromium freeSoftening

A method for preparing washable semi-vegetable-tanning sheepskin garment leather comprises the following steps that (1) tanning is conducted, unhaired pickled skin is subjected to rotation tanning in a drum, then primary fixing treatment is conducted to obtain wet-white leather, and a tanning agent adopted in the tanning process is a TWS chromium-free tanning agent; (2) the tanned wet-white leather is sequentially subjected to horsing and wringing shaving treatment; (3) retanning and dyeing are conducted to obtain colored leather; (4) the retanned and dyed colored leather is sequentially subjected to secondary horsing, stretching and wringing; hang-drying; water spraying, standing, vibration softening, shaving, dust removal, trimming, milling, toggling and polishing to obtain a finished product. The semi-vegetable-tanning sheepskin garment leather obtained through the method has water resistance and is washable.

Owner:隆丰革乐美时尚有限公司

A method for improving the dyeing performance of superfine fiber synthetic leather base cloth

ActiveCN103603197BImprove dyeing effectAdd active groupsFibre treatmentDyeing processLeather industryAlkaline protease

The invention relates to a method for improving the dyeing property of superfine fiber synthetic leather base cloth. The method comprises the following steps: adding water into gelatin, stirring to enable the gelatin to expand to obtain a gelatin solution, and adding alkaline protease into the gelatin solution for hydrolysis; adding the superfine fiber synthetic leather base cloth into a rotating drum, and treating the superfine fiber synthetic leather base cloth by acid to obtain surface modified superfine fiber synthetic leather base cloth; adding collagen into the rotating drum, performing graft modification on the collagen with the surface modified superfine fiber synthetic leather base cloth, and reacting to obtain collagen modified superfine fiber synthetic leather base cloth; and adding a dye into the rotating drum to dye the collagen modified superfine fiber synthetic leather base cloth. According to the invention, the superfine fiber synthetic leather base cloth is modified by the collagen, so that the superfine fiber synthetic leather base cloth is covalently modified by the collagen, furthermore, the dyeing performance of the superfine fiber synthetic leather is effectively improved, the dye uptake is up to about 94.21%, and the superfine fiber synthetic leather industry can be favorably developed.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of paper handle agent

ActiveCN106317323AHigh viscosityComplete copolymerizationNon-fibrous pulp additionPaper/cardboardGlycidyl methacrylateNitrogen

A preparation method of a paper handle agent comprises: (1) taking, by molar percentage, 70-80% of acrylamide, 20-30% of N-methylolacrylamide, 8-15% of glycidyl methacrylate, 0.01-5% of a crosslinking agent and 0.05-5% of a chain transfer agent, and adding them in water while stirring to obtain mixed aqueous solution; introducing nitrogen, adding an initiator and a catalyst, heating to 60-90 DEG C, and polymerizing for 30-90 min to obtain polyacrylamide copolymer; (2) adding suitable organic amine in the product of step (1), carrying out aminomethylation condensation at 60-90 DEG C; cooling the reaction product to 50 DEG C and below, and adding an acid to adjust pH of polymer solution to 6-9; the paper handle agent has the advantages that by adding the handle agent into pulp, finished paper is better in toughness and stiffness and has improved bulkiness and texture.

Owner:GUANGDONG PAPER IND RES INST

Preparation method for composite dry strength agent with high bonding strength

InactiveCN108060609AHigh bonding strengthPlay a reinforcing roleReinforcing agents additionPaper/cardboardFiberSilicon oxygen

The invention relates to the technical field of preparation of auxiliary agents in a papermaking process, specifically to a preparation method for a composite dry strength agent with high bonding strength. According to the invention, cationic starch and cationic polyacrylamide are self-prepared; with the cationic starch as a carrier, the cationic polyacrylamide as a retention aid and polypropyleneand orthosiliconic acid as reinforcements, a reaction is performed, and hydrogen bonding is easily formed among cationic starch molecules and paper fiber molecules, so a reinforcement effect is exerted; meanwhile, charges are mutually attracted, and the cationic polyacrylamide plays retention ability, so the bonding strength between the dry strength agent and the paper fiber molecules is improved, and a polypropylene copolymer can play a certain reinforcement action; and the silicon hydroxyl group of the orthosiliconic acid generates dehydration condensation with the hydroxyl group of the paper fiber, and a stable silicon-oxygen bond is formed to be adsorbed on the surface of the paper fiber, so the bonding strength between the dry strength agent and the paper fiber molecules is further improved, and extensive application prospect is obtained.

Owner:常州帝君金属构件厂

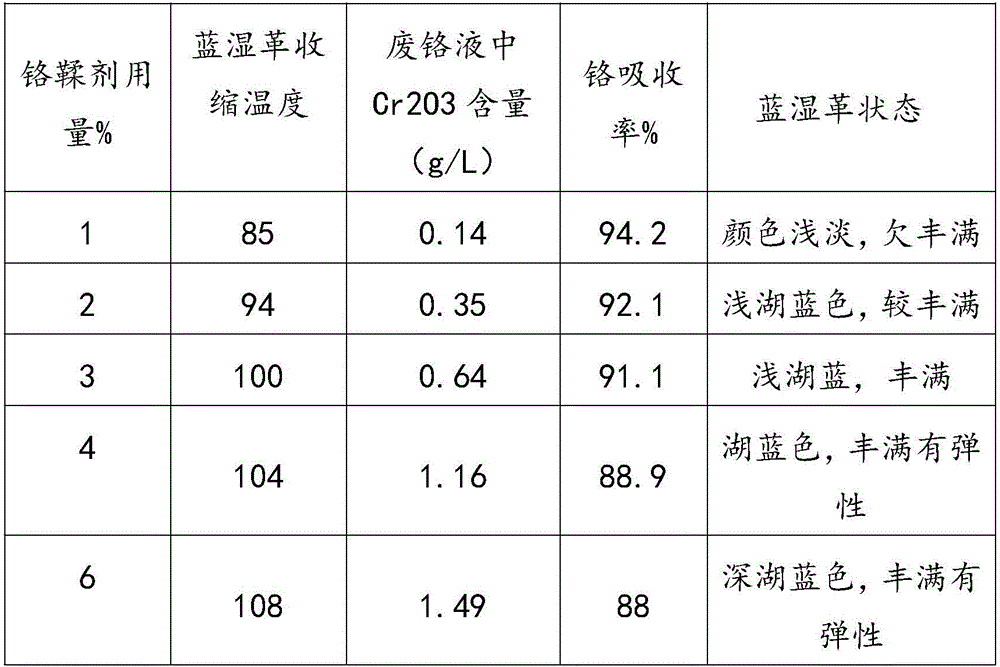

Production technology of high-absorbability chrome tanned leather

ActiveCN106319104AIncrease the binding pointPromote absorptionTanning treatmentPre-tanning chemical treatmentGlyoxylic acidEmulsion

The invention discloses a production technology of high-absorbability chrome tanned leather. The production technology comprises following steps: raw materials are softened, and are restored to be in the fresh skin state, not-required components in fur machining are removed, according to a full-depth limed skin, a first layer and a second layer are separated through the splitting working procedure, and the second limed skin is put into a tanning drum to be subject to deliming, softening and pickling; 80% of water is added, and the temperature is controlled to 22 DEG C; 8% of salt is added, and rotating is carried out for 10min; 150% of water is continuously added, and the temperature is controlled to 45 DEG C; 0.6% of formic acid is added, and rotating is carried out for 30 min; 2% of glyoxylic acid is added, and rotating is carried out for 30 min; 0.4% of sulfuric acid is added, rotating is carried out for 120 min, and the PH value is controlled to range from 3.0 to 3.2 until core penetrating is achieved; 4% of a chrome tanning agent is added; 0.15% of a mildew preventive is added, and rotating is carried out for 180 min; 0.45% of a leather basifying agent is added, rotating is carried out for 360 min, and the PH value is controlled to range from 4.0 to 4.2; the composite mixing technology is achieved; household leather is dyed; emulsion is oiled.

Owner:ZHEJIANG MINGXIN XUTENG LEATHER IND CO LTD

Preparation method of hydrophobic lignosulfonate

The invention relates to a preparation method of hydrophobic lignosulfonate, and belongs to the field of surface treatment technologies of lignosulfonate. The preparation method comprises the steps of dissolving and grafting, wherein the grafting comprises the steps of uniformly mixing a lignosulfonate aqueous solution and a titanate coupling agent, reacting for 4-6h at 160-170 DEG C, standing, filtering, drying, dispersing in an organic solvent, standing, filtering, washing and drying. The preparation method has the benefits that hydrophobic lignosulfonate is prepared by adopting a chemical grafting method; reaction is stable and reliable; the lipophilicity of grafted lignosulfonate is improved significantly; and the method provides the possibility for further improving the compatibility between lignosulfonate and a high polymer material, and for preparing a high-performance wood-plastic composite.

Owner:DALIAN POLYTECHNIC UNIVERSITY

High wear resistant automobile foot pad material

The invention relates to a high wear resistant automobile foot pad material prepared from the following raw materials by weight: 35-40 parts of ethylene-propylene-diene monomer, 30-35 parts of polyurethane, 15-22 parts of a nano-filler, 8-10 parts of carbon black, 3-4 parts of glass fibers, 3-4 parts of dioctyl phthalate, and 2-3 parts of paraffin oil. An automobile foot pad provided by the invention adopts the ethylene-propylene-diene monomer and polyurethane as base rubber; by addition of the nano-filler and the glass fibers for compositing, a traditional reinforcing method using a large amount of carbon black is changed; the novel nano-filler is used for increasing the crosslinking points of rubber; meanwhile, the bonding points of carbon black, the nano-filler and rubber are significantly increased due to good dispersity of the filler, a space network structure is formed, and the strength, wear resistance and aging resistance of the rubber are effectively enhanced.

Owner:合肥凯大新型材料科技有限公司

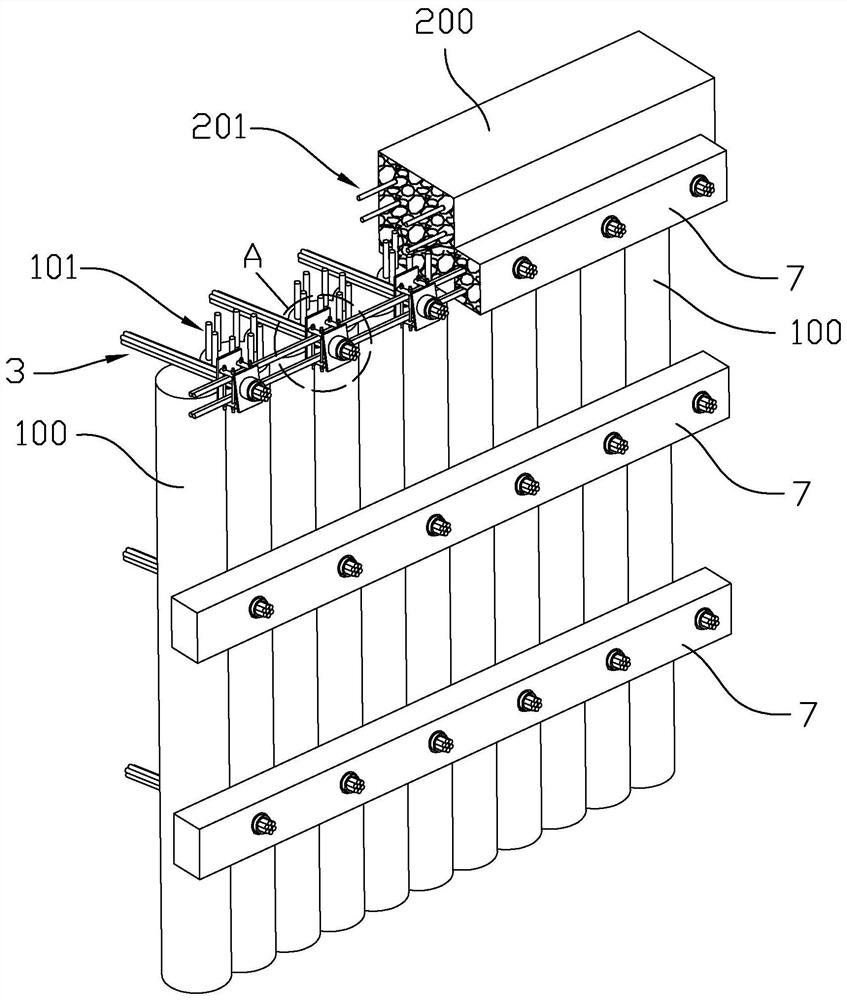

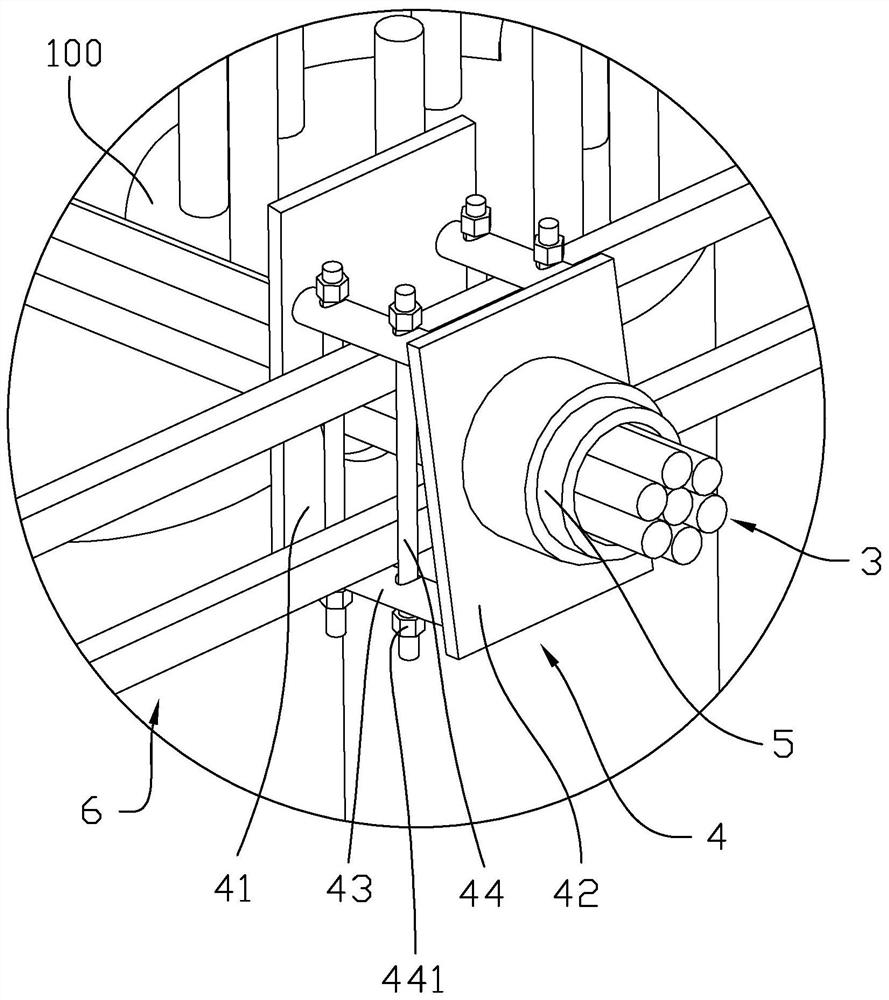

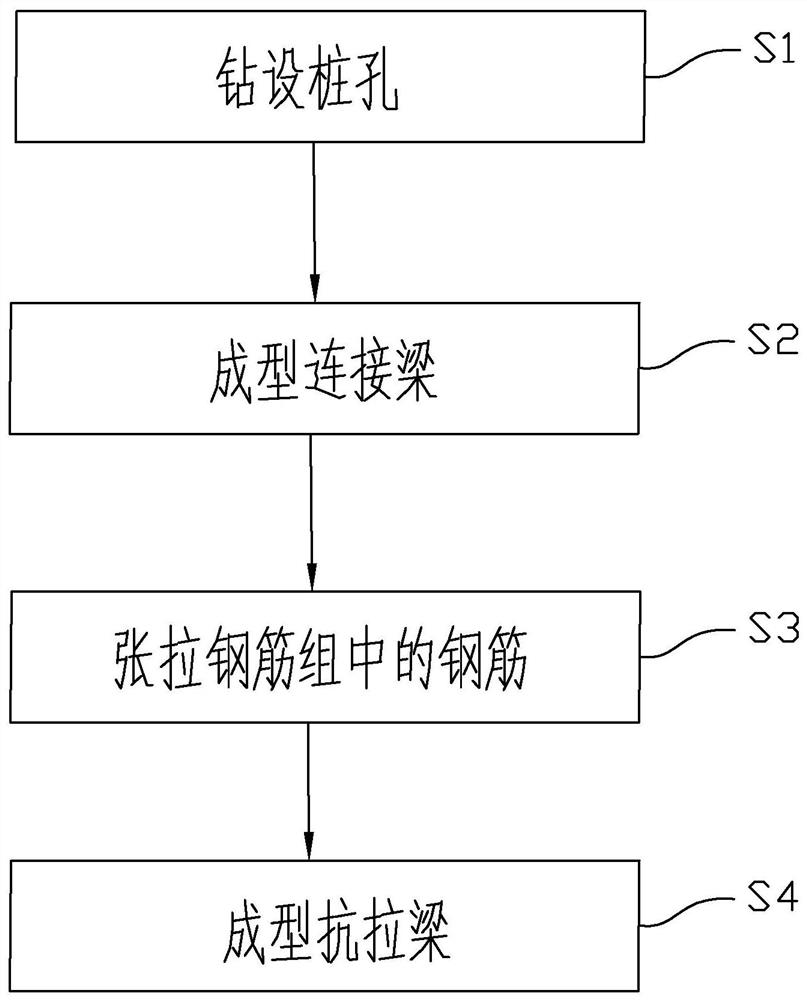

Foundation pit waterproof curtain and construction method thereof

InactiveCN113136886APlay a connecting rolePlay a tensile roleBulkheads/pilesWater stopArchitectural engineering

The invention relates to the field of constructional engineering, and discloses a foundation pit waterproof curtain and a construction method thereof. The foundation pit waterproof curtain comprises a plurality of water stop columns, wherein the plurality of water stop columns are engaged with one another, reinforcement cages I are pre-buried in the water stop columns, one end of the reinforcement cages I extend to the positions above the top surfaces of the water stop columns, connecting beams are poured among the tops of the plurality of water stop columns, reinforcement cages II are pre-buried in the connecting beams, a plurality of bundles of steel bar groups are inserted into the reinforcement cages II, one end of each steel bar group penetrates through the connecting beams and are located on the side, away from a foundation pit, of the waterproof curtain, and the other end of each steel bar group is located in the foundation pit. The foundation pit waterproof curtain has the effect of reducing deformation of the waterproof curtain caused by side pressure so as to increase the stability of the waterproof curtain.

Owner:广东铭濠润建工有限公司

A kind of polymer composite binder and its application and lithium-ion battery negative electrode material prepared based on it and preparation method

ActiveCN108428869BIntegrity guaranteedFirmly connectedCell electrodesSecondary cellsElectrical batteryAdhesive

The invention discloses a polymer composite adhesive, an application thereof, a lithium ion battery anode material prepared based on the polymer composite adhesive and a preparation method, and belongs to the technical field of electrochemistry and new energy materials. The adhesive is dissolved in a dispersion medium to form a solution with concentration of 0.5%-2.0%, wherein the dispersion medium is deionized water, and the mass ratio of a linear polymer to a lamellar polymer is (6-16): (1-4). The lithium ion battery anode slurry using the composite adhesive is prepared from an active material, a conductive agent and the adhesive in a mass ratio of (50-80): (10-30): (10-20). The adhesive is composited from the linear polymer and the lamellar polymer, the polymer composite adhesive can construct a cross-linked three-dimensional network structure around silicon particles, the silicon particles are effectively prevented from irreversible slippage, volume change is buffered, and electrical connection and integrity of electrodes are maintained. The composite adhesive adopts widely sourced raw materials and is green and environmentally friendly.

Owner:SHAANXI UNIV OF SCI & TECH

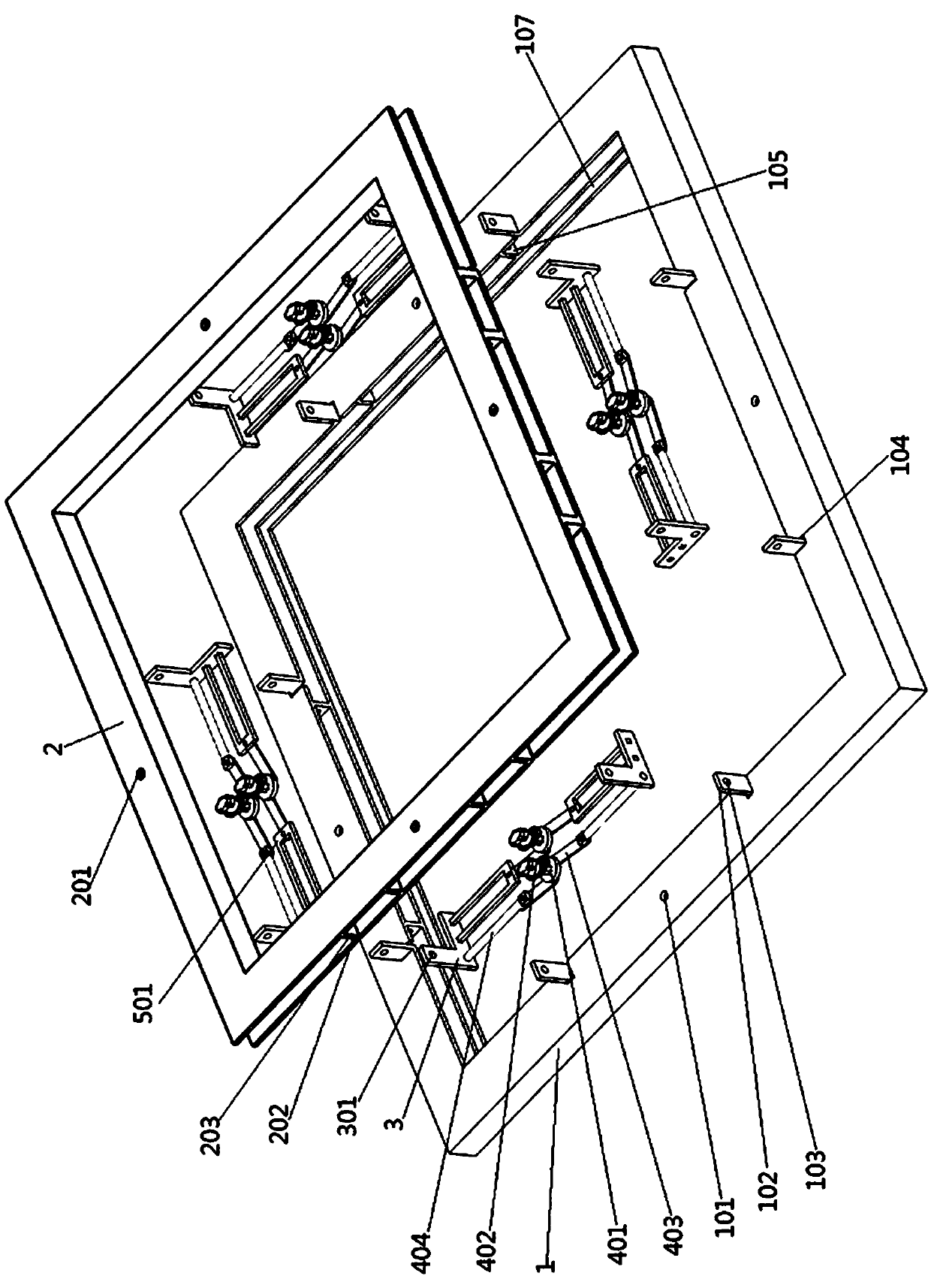

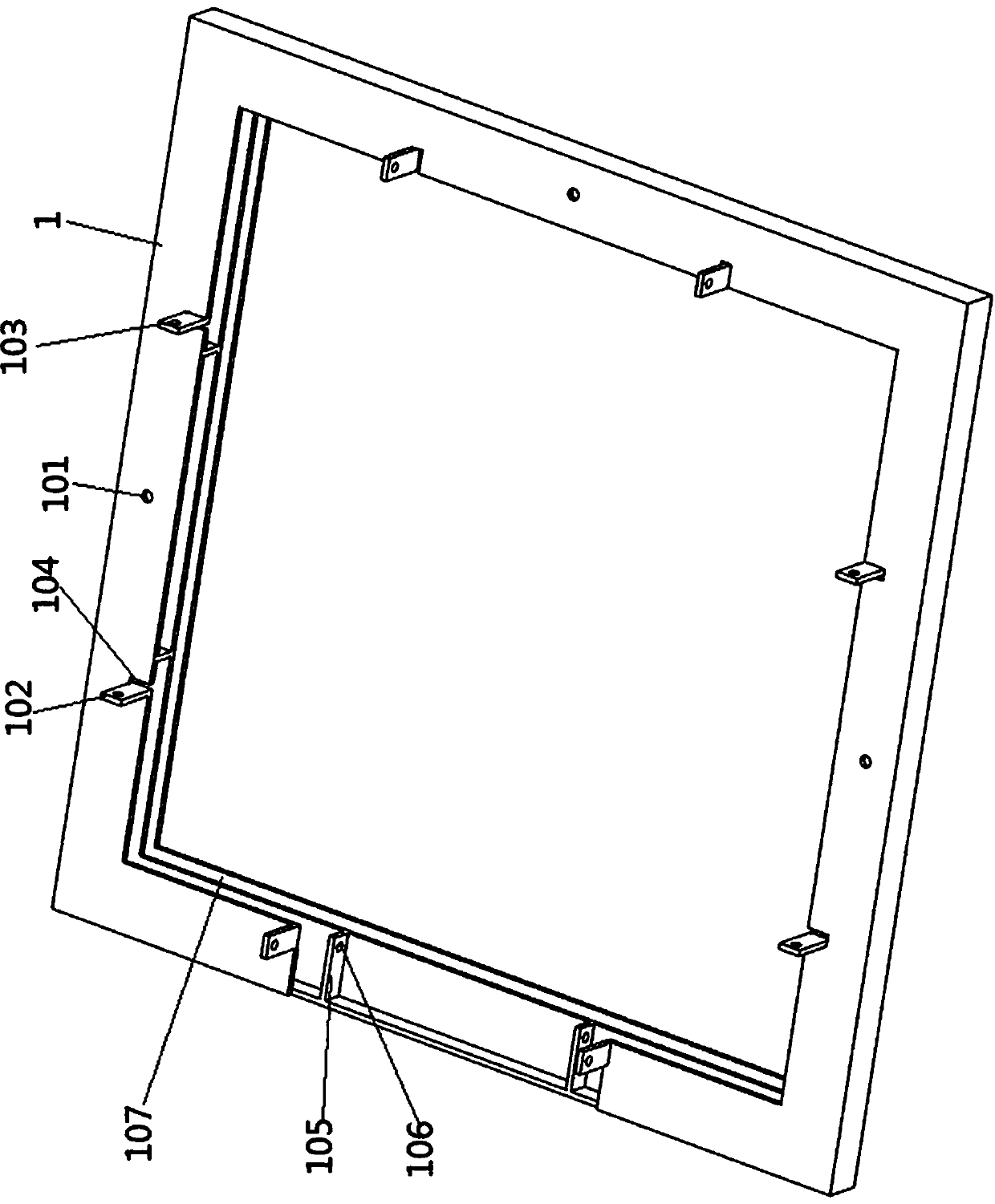

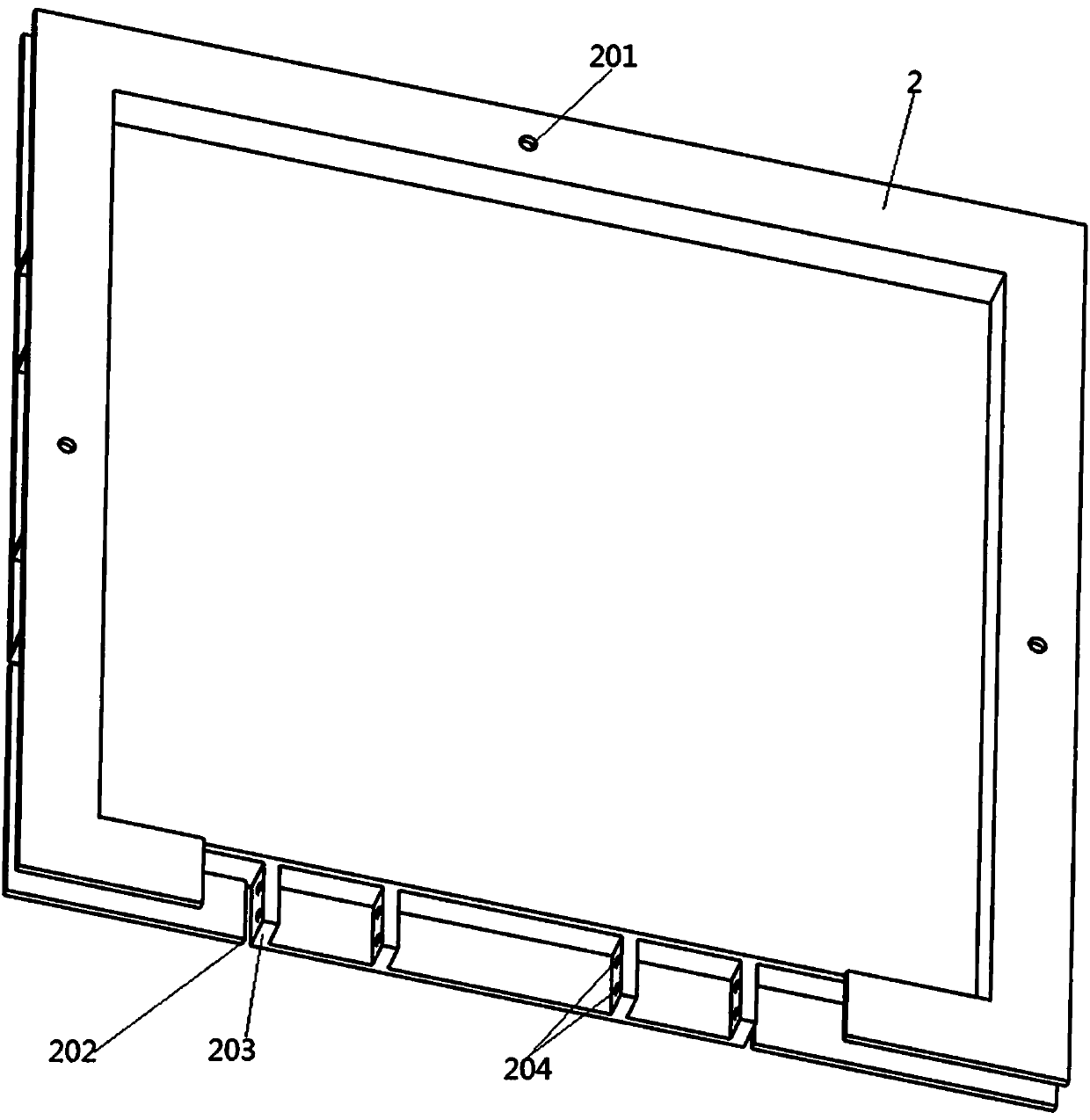

Connection structure of architectural window

ActiveCN110469237ARealize free-hand disassemblyIncrease the binding pointBuilding locksWing fastenersEngineeringUltimate tensile strength

Owner:HEILONGJIANG COLLEGE OF CONSTR

Production process of high-flame-retardant and oil-resistant PVC particles

A production process of high-flame-retardant and oil-resistant PVC particles include the following steps of preliminary preparation, raw material preparation, filler preparation, mixing, extrusion, granulation and qualification test. Raw materials are composed of, by mass, 45-55 parts of polyvinyl chloride resin, 20-30 parts of a plasticizer, 8-10 parts of a filler, 5-8 parts of nano rubber particles, 3-5 parts of a stabilizer, 3-5 parts of a fire retardant, 3-5 parts of a lubricant Hst1, 1-2 parts of calcium oxide, 1-2 parts of nano calcium carbonate, 1-2 parts of a viscosity reducer, and 1-2parts of other additives P-830. The production process of the high-flame-retardant and oil-resistant PVC particles is simple, the compatibility of the substances is significantly improved through thefiller, the oil resistance and cold resistance of PVC are improved through the nano rubber particles, the flame resistance of PVC is improved through the fire retardant, the formula of the raw materials is reasonable, all components are good in compatibility, play their own roles and have synergistic effects, and the prepared PVC particles have good flame resistance, oil resistance, cold resistance, mechanical properties and wide application prospects.

Owner:苏州华盟塑化有限公司

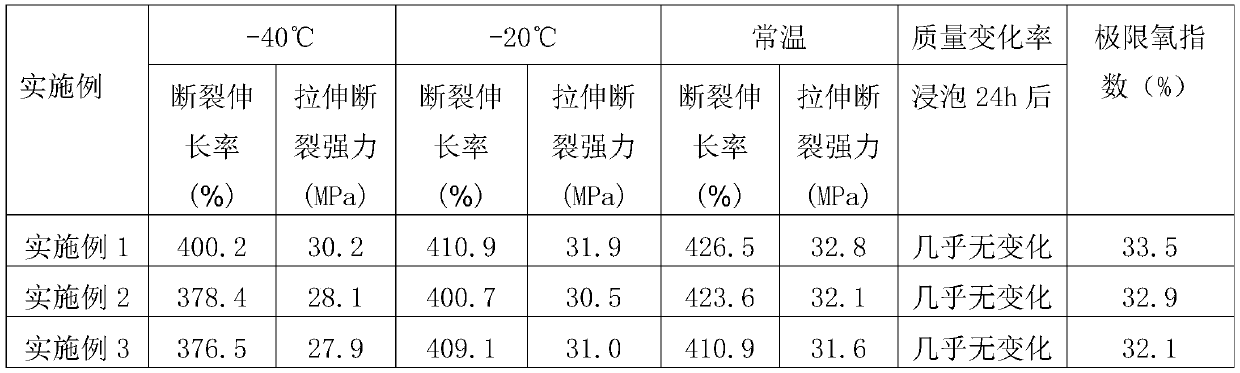

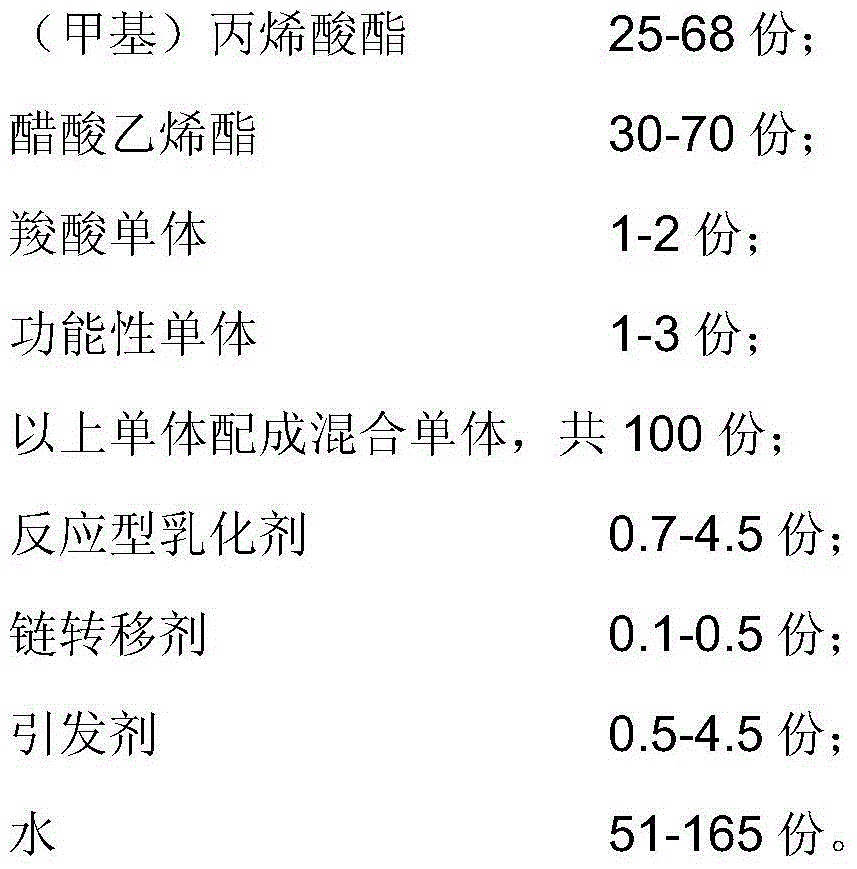

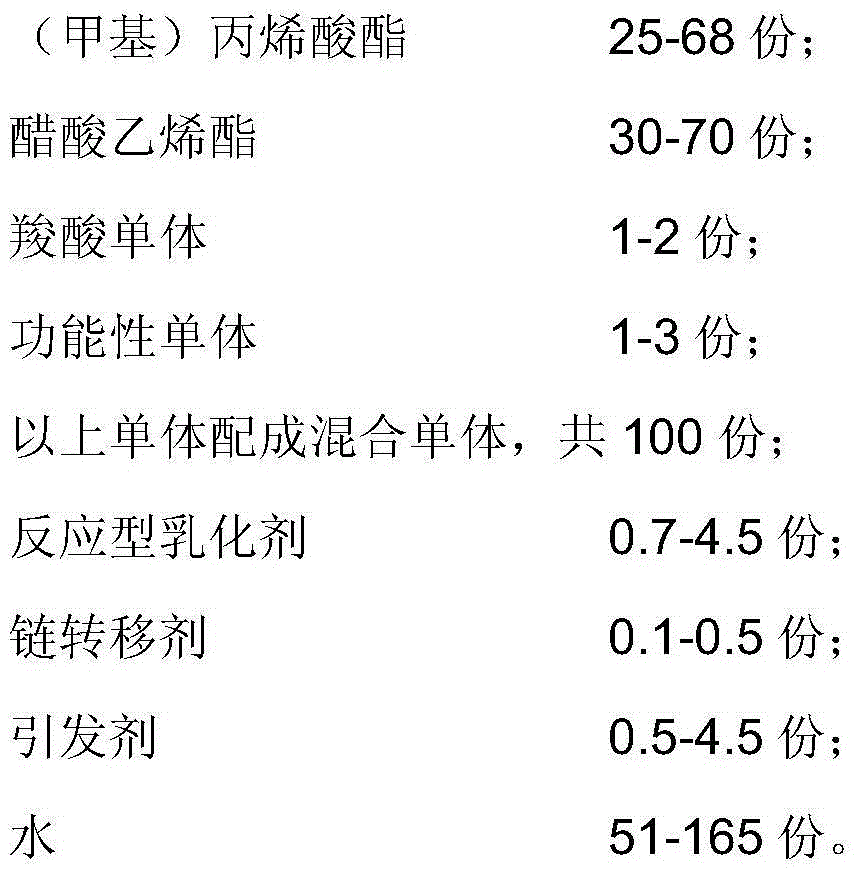

Vinyl acetate-acrylic emulsion and preparation method thereof

InactiveCN105713149AImprove surface strengthImprove the phenomenon of hair loss and powder lossFunctional monomerCarboxylic acid

A kind of vinegar acrylic emulsion and preparation method thereof, the specific steps include: mixing (meth)acrylic acid ester, vinyl acetate, carboxylic acid monomer and chain transfer agent to make monomer; % of the mixed monomer is uniformly mixed with 40-90% reactive emulsifier, 40-90% by weight initiator, and functional monomer in the weight percentage; body with 10-60% by weight of emulsifier and 10-60% by weight of initiator, react at 70°C-95°C for 10-40 minutes, and then drop the mixed solution for 1-5 Hours; keep warm at 70-95°C for 1-2 hours, then cool down to 25°C, adjust the pH to 5-8 to obtain vinegar-acrylic emulsion. This product is used in the coating of coated paper, which can significantly enhance the surface strength of coated paper and improve the phenomenon of lint and powder falling.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Fabric with lasting flower fragrance and preparation method thereof

The invention discloses fabric with lasting flower fragrance and a preparation method thereof. The fabric with lasting flower fragrance comprises modified plant fibers and perfume. The compact structure of plant fiber bundles is destroyed by flash explosion treatment, so that lignin and hemicellulose are lost along with treatment, the hardness of the plant fibers is reduced, the specific surface area of the plant fibers is increased, the accessibility and hydrophobicity of the plant fibers are improved, thus polylactic acid molecular chains are tightly attached to the surface of the fabric, the density of the fabric is increased, the perfume is sealed in the fabric, and the loss of the perfume during washing is reduced; bond energy of polylactic acid molecules is improved by acetylation of the plant fibers, so that bonding points between polylactic acid molecular chains are increased, intermolecular hydrogen bonds are generated with adjacent hydroxyl groups while intramolecular hydrogen bonds are formed, thus complex interface bonding grids are formed on the surfaces of the plant fibers, and the wear resistance of the plant fibers is further improved while the tensile strength of the fabric is guaranteed.

Owner:冯飞

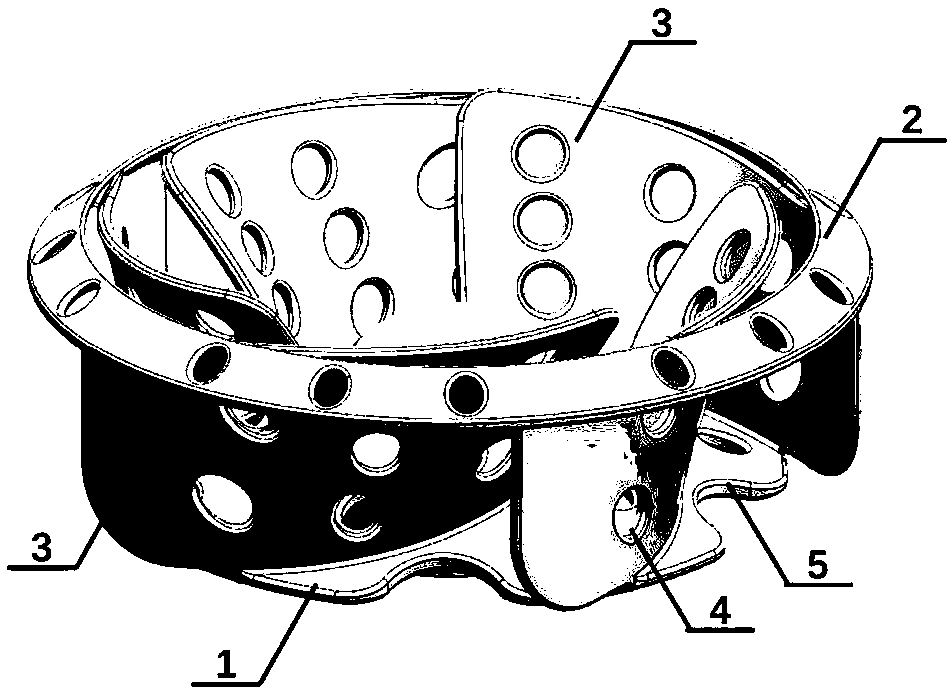

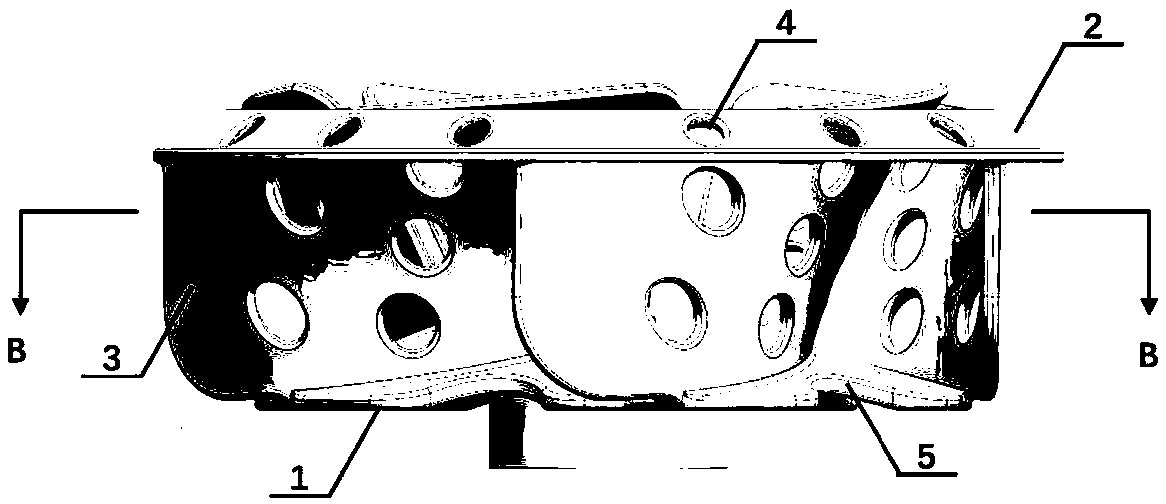

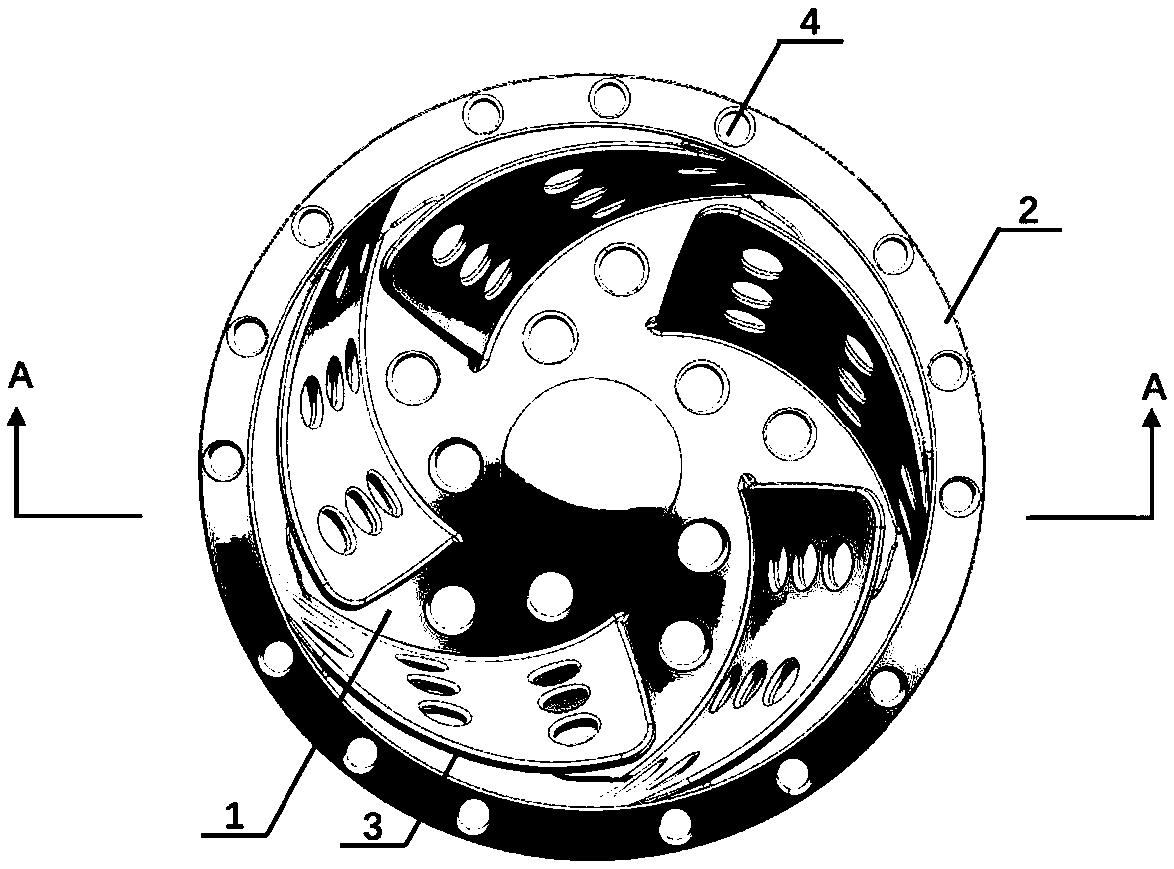

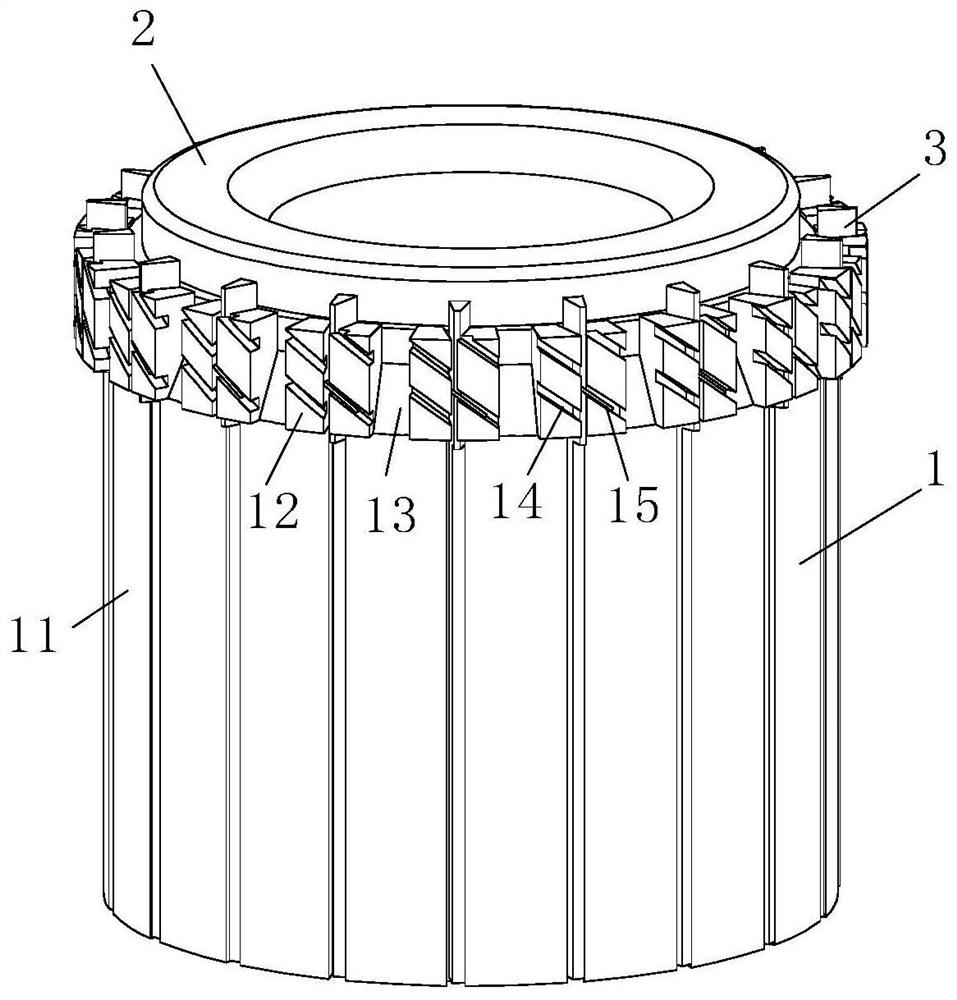

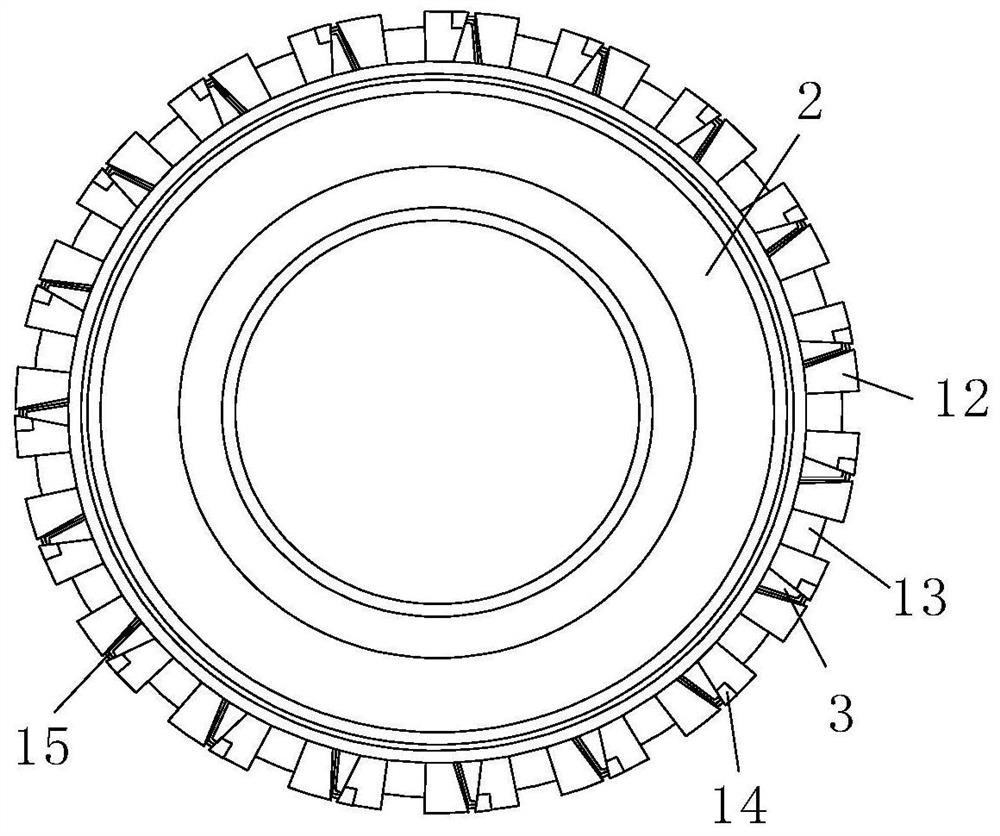

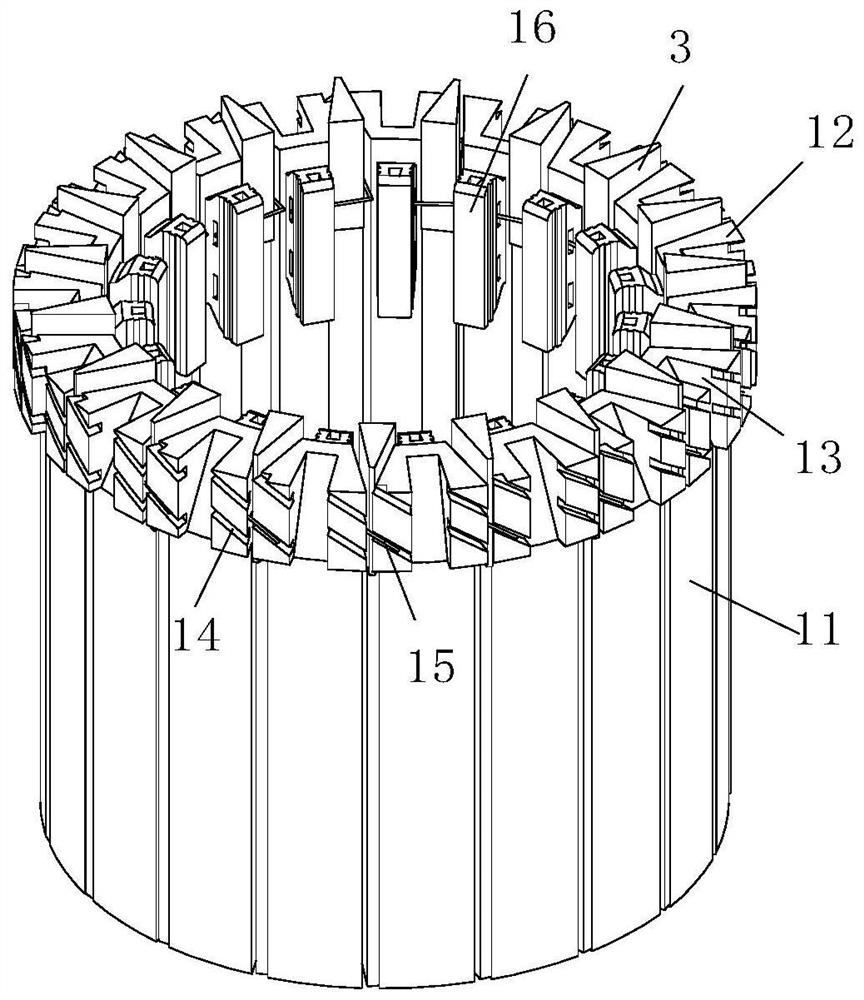

Metal framework for casting metal and non-metal composite impeller and preparation method thereof

PendingCN109236730AIncrease the binding pointHigh bonding strengthPump componentsPumpsImpellerMaterials preparation

The invention relates to the field of casting mold design, in particular to a metal framework for casting a metal and non-metal composite impeller and a preparation method thereof. The metal frameworkcomprises a bottom plate and an upper cover, wherein the bottom plate and the upper cover are connected through blades, and the blades extend from the inner side of the bottom plate to the outer sidein a vortex shape. The bottom plate is provided with a through hole which is positioned at 1 / 2 of the joint position of the adjacent blade and the bottom plate, the through hole arranged on the uppercover is positioned between the joint position of the adjacent blade and the upper cover, and the surface of the blade is also provided with the through hole. After the non-metal layer is poured, a net structure can be formed by means of the through holes to wrap the metal framework, so that the bonding effect is enhanced. The preparation method of the metal framework comprises the steps of designing the metal framework, manufacturing a wood former, pouring and heat treatment, surface polishing and machining, size detection, pouring impeller and impeller detection, and design correction. Saidmethod for casting the composite impeller by using the metal framework comprises the steps of metal framework surface treatment, nonmetal material preparation, vacuum hot casting, impeller heat treatment and machining, and impeller detection.

Owner:SUZHOU AONITE SILICON CARBIDE CERAMIC TECH CO LTD

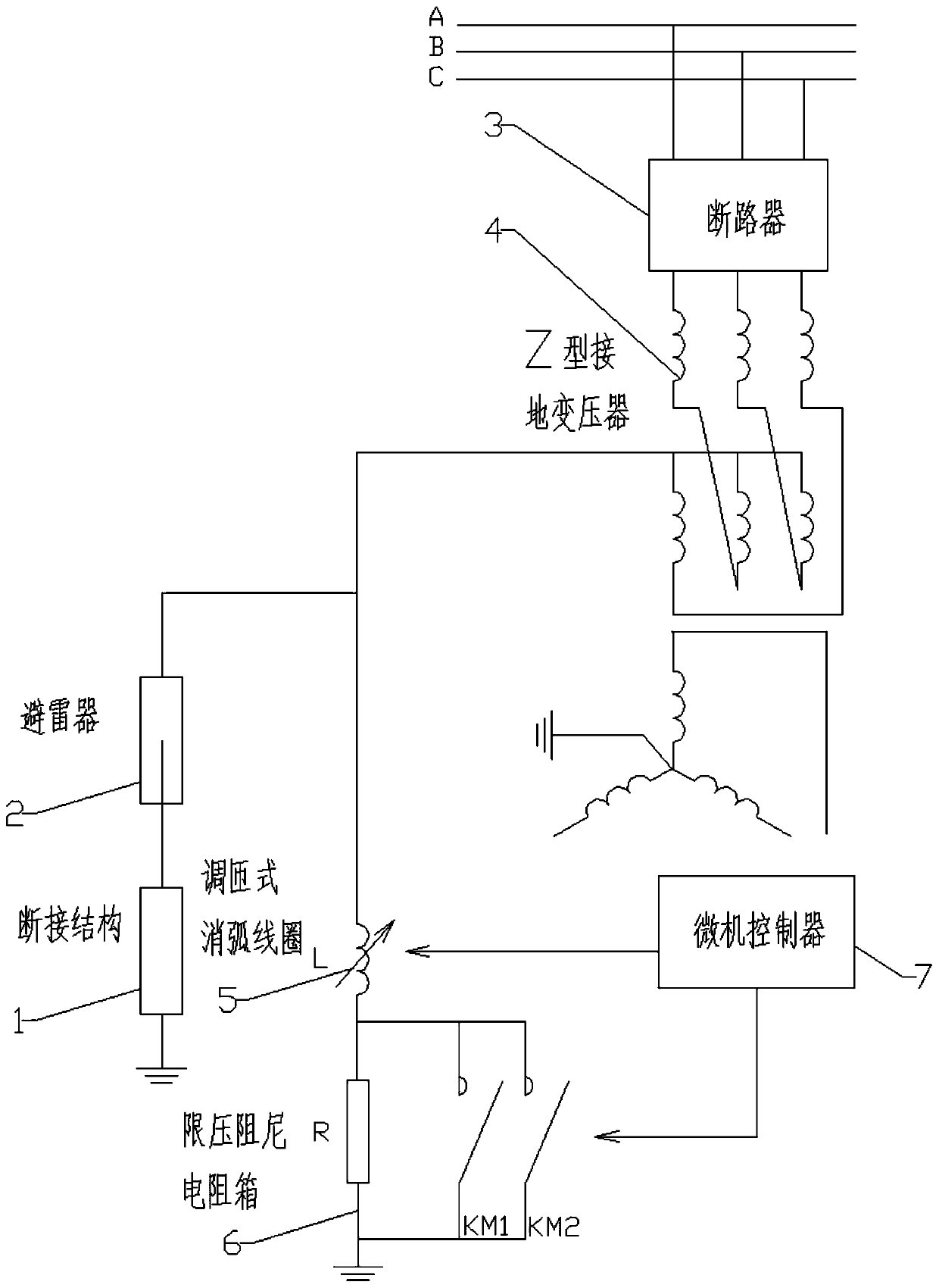

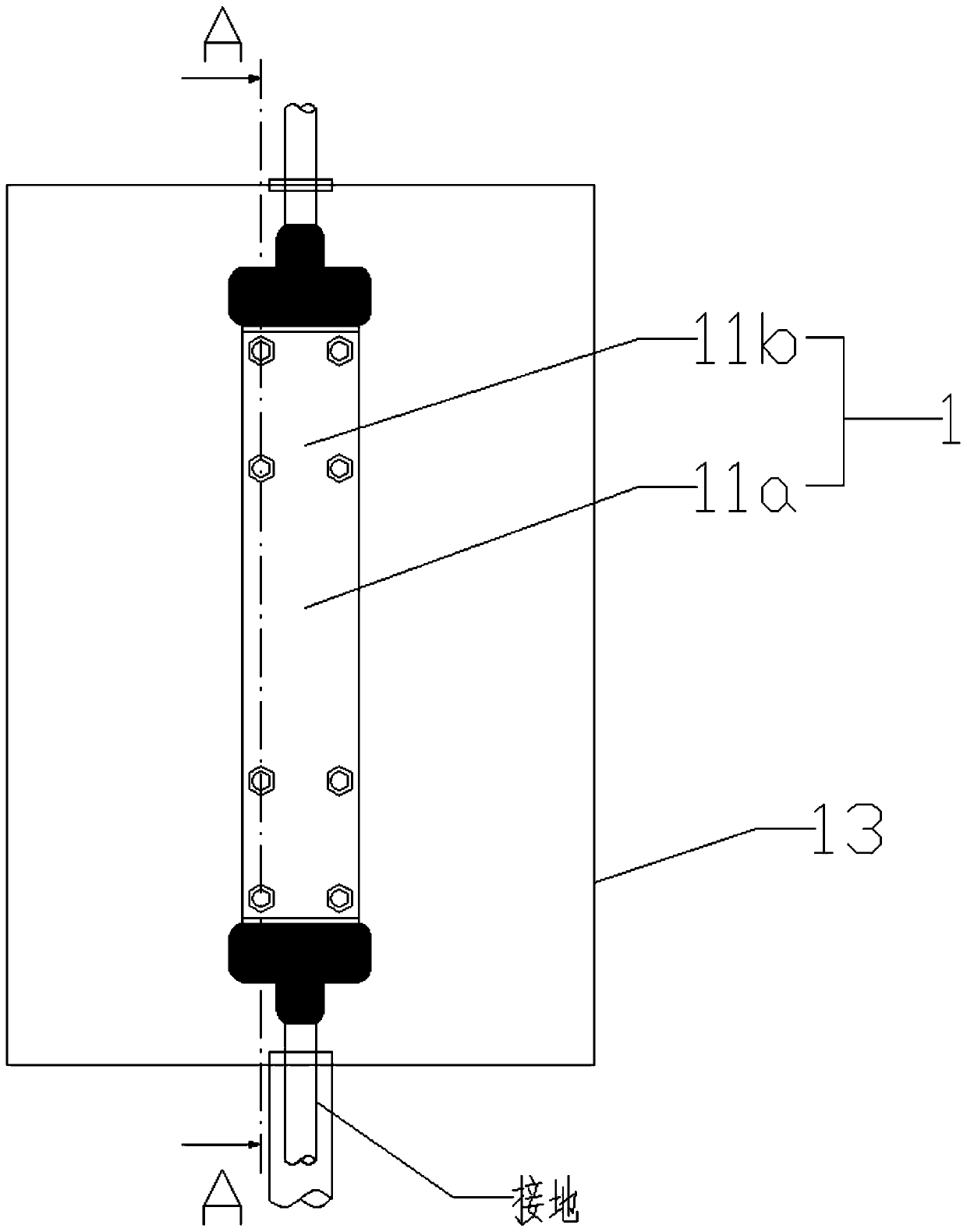

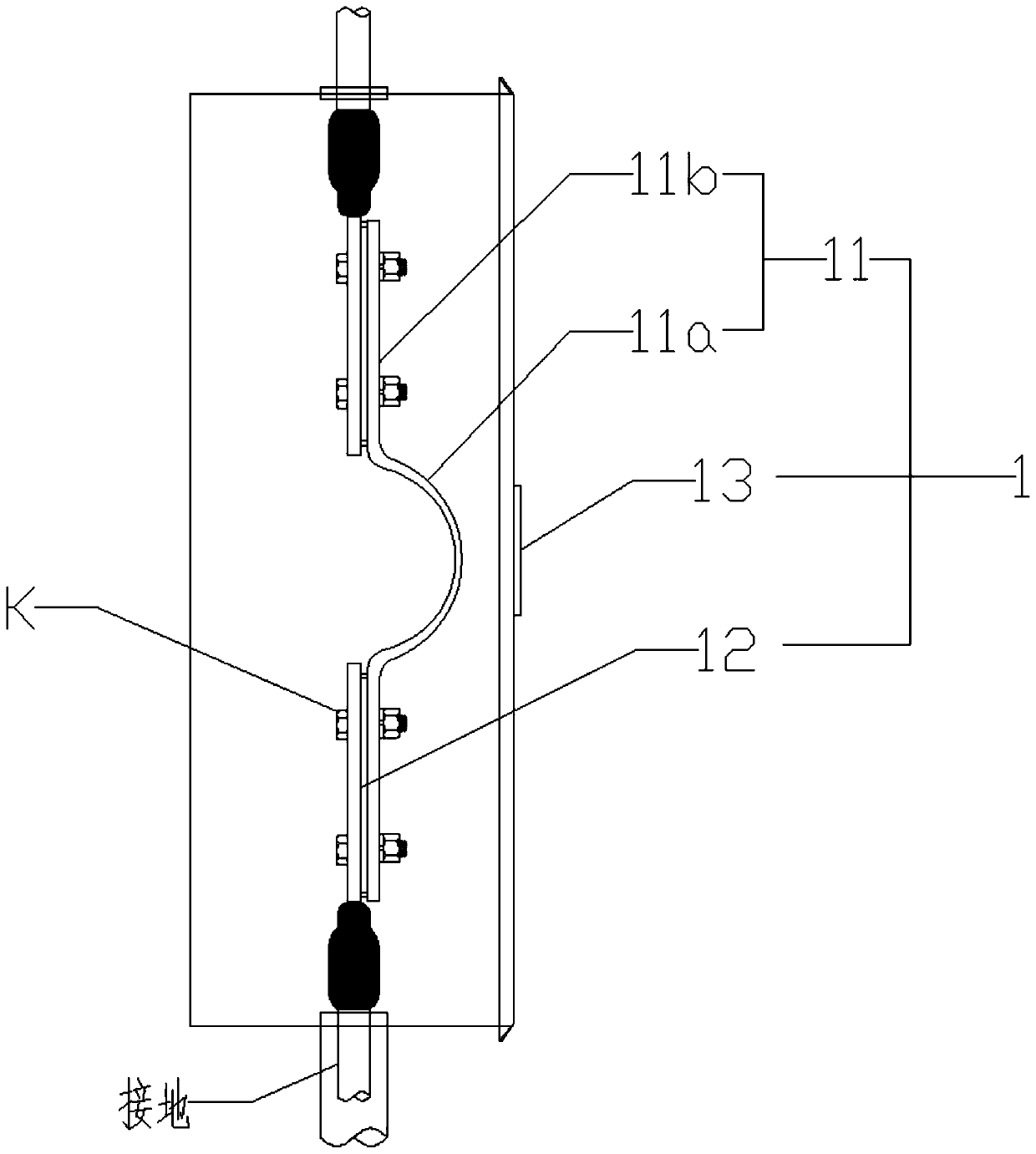

Arc suppression coil device with disconnection structure

PendingCN109936125AImprove stressImprove anti-looseningEmergency protective arrangements for limiting excess voltage/currentWater vaporTransformer

The invention relates to the technical field of power distribution grounding devices, and especially relates to an arc suppression coil device with a disconnection structure. The device comprises thedisconnection structure, a lightning arrester, a circuit breaker, a Z-shaped grounding transformer, a turn-adjusting arc suppression coil, a voltage-limiting damping resistance box, a microcomputer controller, a disconnection clamp, a wiring board, a protection box and the like. The disconnection clamp and the wiring board are connected and fixed through a threaded fastener, and an anti-looseningspring washer is arranged at a nut. Trapezoidal teeth are arranged on the connecting surface of the disconnection clamp and the wiring board. A connecting bridge of the disconnection clamp is of an arc structure, and the arc structure has certain elasticity and can be used for compensating for deformation caused by thermal expansion and cold contraction and reducing shear force on the threaded fastener. Waterproof foam is arranged around the trapezoidal teeth, and protection wires are arranged outside the disconnection clamp and the wiring board and used for reducing external water vapor and other corrosive substances entering the disconnection mechanism. According to the invention, the grounding current is small, the arc can be automatically extinguished when an instantaneous fault occurs, the working efficiency of maintenance and inspection is high, and the labor cost can be reduced.

Owner:广州市雷斯盾电气科技发展有限公司

A kind of preparation method of dyeable polyurethane film

The invention discloses a preparation method for a dyeable polyurethane film. The preparation method comprises the following steps: firstly, adding N, N-methylene bisacrylamide and diethylenetriamine into N, N-dimethylformamide to prepare an amino-terminated hyperbranched polymer; terminating the obtained product by using ethanol terminated isophorone diisocyanate; then, adding the terminated product into an N, N-dimethylformamide solution of polyurethane to prepare a casting film solution; pouring the casting film solution on a substrate; dipping in a coagulating bath to form a film by a wet process; and drying to obtain the dyeable polyurethane film. According to the film prepared by the method, as an active group -NH2 is introduced into a component of the film, bonding points of the dye are increased. Moreover, in an acidic solution, the film has positive charges, so that an anionic dye is gradually bonded with amino (P-NH3+) with positive charges in the film by virtue of ionic bonds to play a dyeing effect, thereby improving the dyeing rate and the color fastness. Meanwhile, the method is simple, convenient and feasible to operate, low in requirements on equipment and easy for industrial popularization.

Owner:汕头市亮彩新材料科技有限公司

Polymer composite adhesive, application thereof, lithium ion battery anode material prepared based on polymer composite adhesive and preparation method

ActiveCN108428869AEasy to operateLow equipment requirementsCell electrodesSecondary cellsCross-linkPolymer science

The invention discloses a polymer composite adhesive, an application thereof, a lithium ion battery anode material prepared based on the polymer composite adhesive and a preparation method, and belongs to the technical field of electrochemistry and new energy materials. The adhesive is dissolved in a dispersion medium to form a solution with concentration of 0.5%-2.0%, wherein the dispersion medium is deionized water, and the mass ratio of a linear polymer to a lamellar polymer is (6-16): (1-4). The lithium ion battery anode slurry using the composite adhesive is prepared from an active material, a conductive agent and the adhesive in a mass ratio of (50-80): (10-30): (10-20). The adhesive is composited from the linear polymer and the lamellar polymer, the polymer composite adhesive can construct a cross-linked three-dimensional network structure around silicon particles, the silicon particles are effectively prevented from irreversible slippage, volume change is buffered, and electrical connection and integrity of electrodes are maintained. The composite adhesive adopts widely sourced raw materials and is green and environmentally friendly.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of preparation method of paper feel agent

ActiveCN106317323BHigh viscosityComplete copolymerizationNon-fibrous pulp additionPaper/cardboardGlycidyl methacrylateNitrogen

A preparation method of a paper handle agent comprises: (1) taking, by molar percentage, 70-80% of acrylamide, 20-30% of N-methylolacrylamide, 8-15% of glycidyl methacrylate, 0.01-5% of a crosslinking agent and 0.05-5% of a chain transfer agent, and adding them in water while stirring to obtain mixed aqueous solution; introducing nitrogen, adding an initiator and a catalyst, heating to 60-90 DEG C, and polymerizing for 30-90 min to obtain polyacrylamide copolymer; (2) adding suitable organic amine in the product of step (1), carrying out aminomethylation condensation at 60-90 DEG C; cooling the reaction product to 50 DEG C and below, and adding an acid to adjust pH of polymer solution to 6-9; the paper handle agent has the advantages that by adding the handle agent into pulp, finished paper is better in toughness and stiffness and has improved bulkiness and texture.

Owner:GUANGDONG PAPER IND RES INST

High-strength groove type commutator

The invention belongs to the technical field of commutators, and particularly relates to a high-strength groove type commutator, which comprises commutation copper sheets, a plastic mold core and mica sheets, wherein the commutation copper sheets are uniformly distributed around the periphery of the plastic mold core, a gap exists between the adjacent commutation copper sheets to form an insulation gap, the mica sheets for separating the adjacent commutation copper sheets are arranged in the insulation gap, the upper end face of the mica sheet is higher than the upper end face of the commutation copper sheet and lower than the upper end face of the plastic mold core, and a semi-enclosed space higher than the commutation copper sheet is formed between the upper end of the mica sheet and the upper end of the plastic mold core; through the arrangement of the mica sheets, the mica sheets and the plastic mold core can form a semi-enclosed space higher than the commutation copper sheets, so that the contact between the adjacent side surfaces of the adjacent commutation copper sheets can be prevented, and the condition that the adjacent commutation copper sheets are in contact due to the existence of welding slag caused by the fact that the welding slag generated after wire welding of the wire welding grooves enters the upper ends of the commutation copper sheets can be reduced; therefore, the safety performance is ensured.

Owner:浙江利丰电器有限公司

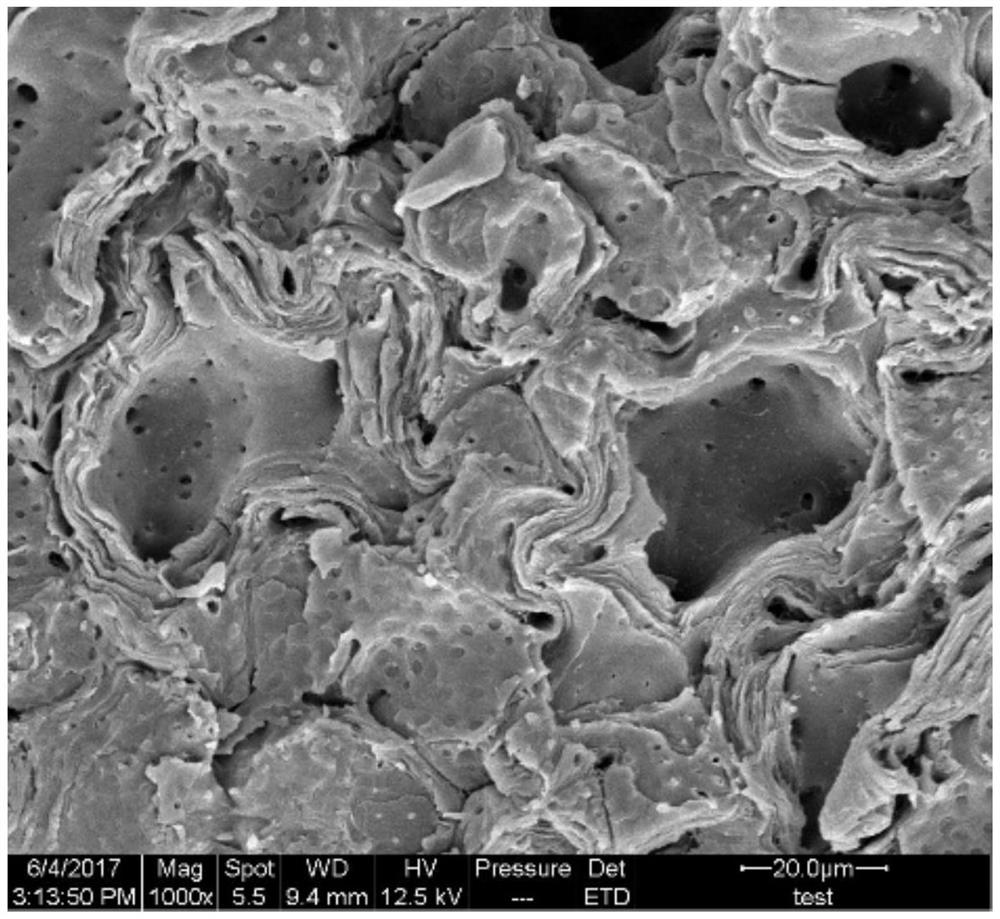

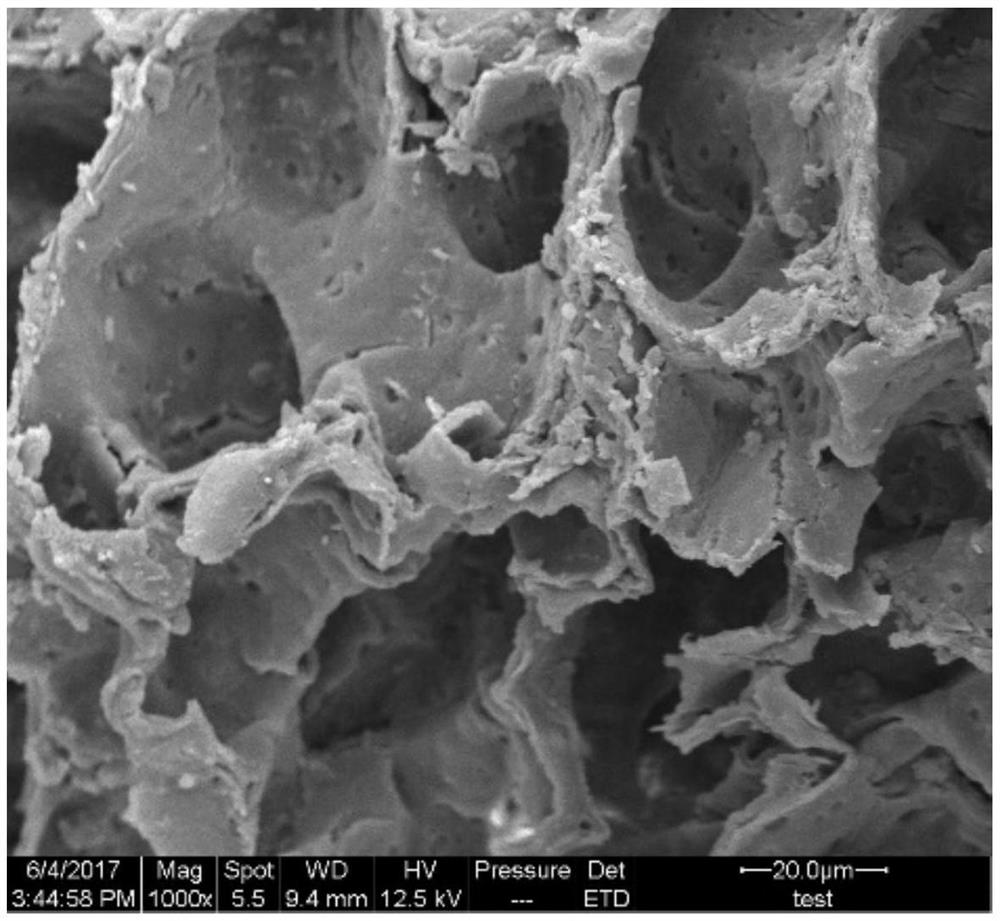

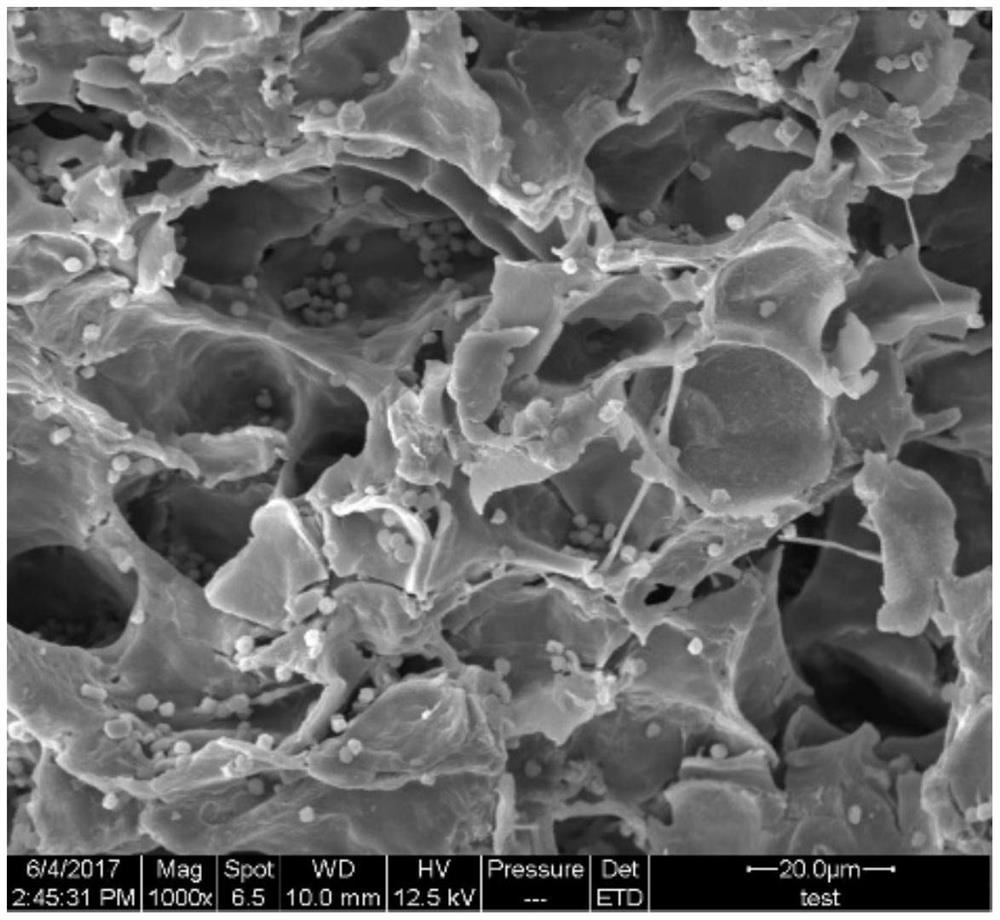

A kind of pretreatment method that improves walnut shell biodegradation effect

ActiveCN109293942BIncrease contact areaReduce the degree of polymerizationChemical treatmentFiltration

Owner:HARBIN UNIV OF SCI & TECH

A kind of preparation method of high temperature aging resistant natural fiber paper

ActiveCN107254795BIncrease the binding pointJunction GuaranteeNatural cellulose pulp/paperPulp properties modificationPulp and paper industryNatural fiber

The invention belongs to the field of technologies for processing packaging paper, and particularly relates to a method for preparing high-temperature-aging-resistant natural fiber paper. The method includes preparing mixed pulp from natural color needle leaf wood pulp and broadleaf wood pulp, concentrating the pulp, adding nucleotide solution into the mixed pulp and carrying out soaking and grinding to obtain pulp; concentrating the ground pulp, placing the pulp into a sealing bag and balancing moisture under the low-temperature conditions; sequentially carrying out papermaking, rolling and drying, impregnating adhesive liquid with six-member heterocyclic compounds on the surfaces of paper, drying the paper and carrying out hot-press to obtain the finished high-temperature-aging-resistant natural fiber paper. Compared with the prior art, the method has the advantages that the mechanical strength of the paper can be improved, then the adhesive liquid with the six-member heterocyclic compounds is impregnated on the surfaces of the paper by means of impregnation, the paper is dried and is subjected to hot-press, accordingly, chemical bonds between fibers are connected with one another to form fiber network structures, physical entanglement points between the fibers are increased, the fibers are promoted to be chemically bonded with the adhesive liquid, the strength of the high-temperature-aging-resistant natural fiber paper can be guaranteed, the high-temperature-resistant grade of the high-temperature-aging-resistant natural fiber paper can be upgraded, and the service range of the high-temperature-aging-resistant natural fiber paper can be expanded.

Owner:HEFEI LONGFA PACKING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com