A kind of polymer composite binder and its application and lithium-ion battery negative electrode material prepared based on it and preparation method

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of limiting the practical application of silicon materials, poor electrode cycle stability, decreased cycle specific capacity, etc., and achieve cycle stability performance. Good, low equipment requirements, long battery life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

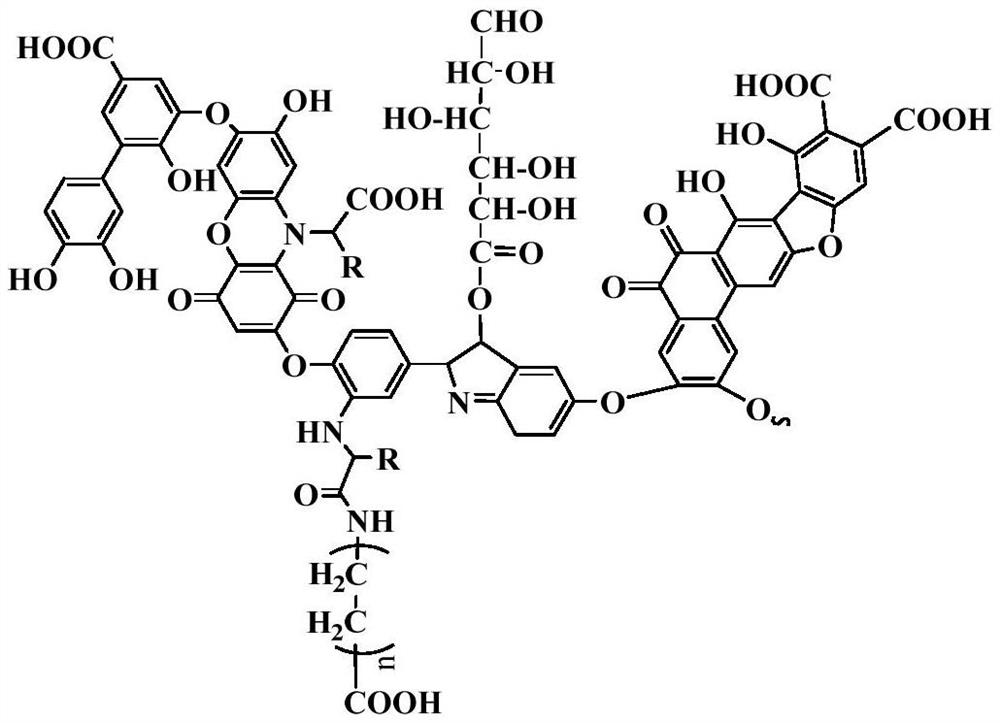

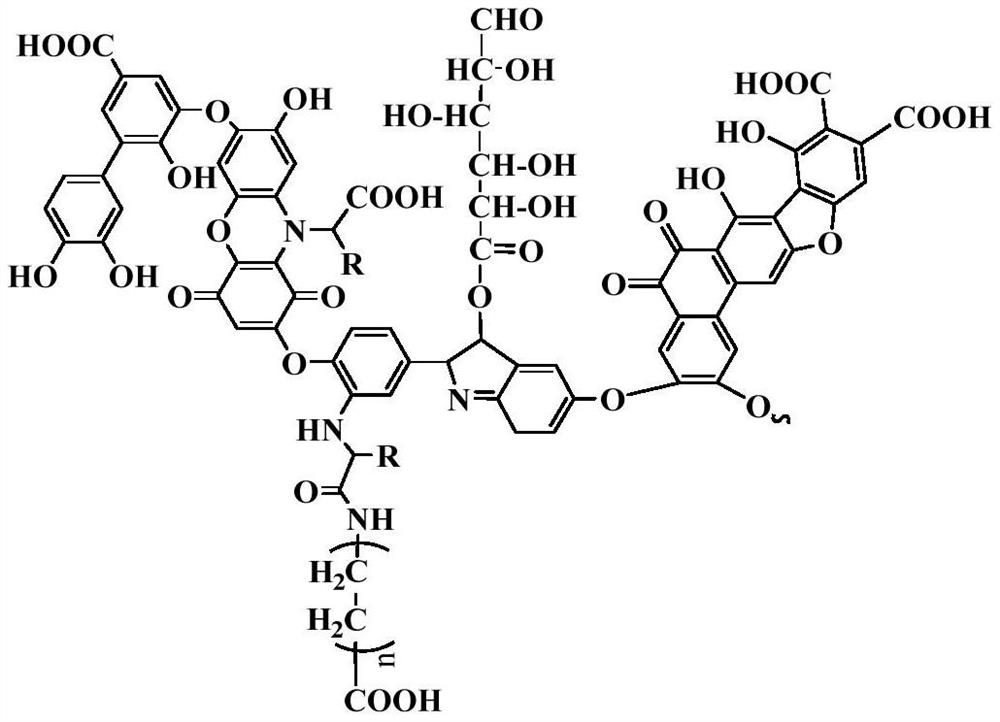

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of silicon negative pole material of lithium ion battery comprises the following steps:

[0038] Step 1: configuring the linear polymer and sheet polymer composite into a 0.5-2wt% aqueous solution;

[0039] Step 2: Put the active material and conductive agent in a mortar and grind for 5-10 minutes;

[0040] Step 3: Add the composite binder prepared in step 1 dropwise to the mixture in step 2, and grind until the binder is evenly mixed with the active material and the conductive agent;

[0041] Step 4: Add deionized water dropwise to the colloidal mixture with a certain viscosity obtained in step 3, and then fully grind for 20-30 minutes;

[0042] Step 5: Pour the mixture obtained in Step 4 onto the Cu sheet and spread evenly;

[0043] Step 6: The copper sheet obtained in step 5 is rapidly blown and dried to remove solvent water to obtain a pole piece, and the pole piece is vacuum-dried;

[0044] Step 7: After weighing the vacuum-dried electrode...

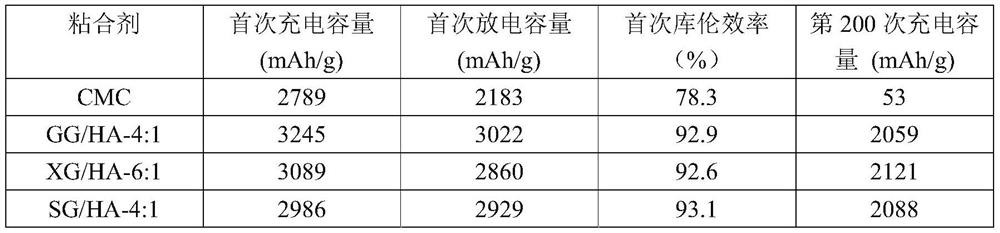

Embodiment 1

[0047] Firstly, guar gum (GG) and fulvic acid complex (GG / HA) were configured into a 0.5wt% aqueous solution, wherein the mass ratio of guar gum and fulvic acid was 4:1. Weigh 60.0 mg of nano-Si and 30.0 mg of acetylene black and place them in a mortar, grind for 10 minutes, and then dropwise add 2.0 g of 0.5 wt % guar gum and fulvic acid complex aqueous solution. Grind for 5 minutes until the binder is evenly mixed with silicon powder and carbon powder, then add 1mL of deionized water dropwise, and then grind thoroughly for 15-10 minutes. Place the pasty mixture on a Cu sheet, spread it evenly with a 100 μm spatula, quickly place it in a blast drying oven at 60° C., and take it out after five minutes. Then put the electrode piece into a vacuum drying oven, and vacuum dry at a constant temperature of 80° C. for 6 hours. After weighing the vacuum-dried electrode pieces, assemble them in the glove box in the 2032 battery case, use the lithium sheet as the positive electrode, us...

Embodiment 2

[0049] Firstly, the xanthan gum and fulvic acid complex (XG / HA) were formulated into a 2.0 wt% aqueous solution, wherein the mass ratio of xanthan gum and fulvic acid was 6:1. Weigh 70.0 mg of nano-Si and 10.0 mg of acetylene black in a mortar, grind for 10 minutes, and then add 1.0 g of 2.0 wt % xanthan gum and fulvic acid complex aqueous solution dropwise. Grind for 5 minutes until the binder is evenly mixed with Si powder and carbon powder, then add 1mL of deionized water dropwise, and then fully grind for 15-10 minutes. Place the pasty mixture on a Cu sheet, spread it evenly with a 100 μm spatula, quickly place it in a blast drying oven at 60° C., and take it out after five minutes. Then put the electrode piece into a vacuum drying oven, and vacuum dry at a constant temperature of 80° C. for 6 hours. After weighing the vacuum-dried electrode pieces, assemble them in the glove box in the 2032 battery case, use the lithium sheet as the positive electrode, use the polyethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com