Adhesive for nano-silicon carbon anode material of lithium battery and preparation method of adhesive

A nano-silicon and lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of improved performance, superior mechanical and processability, high tensile strength and elastic recovery force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

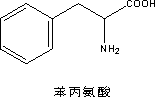

[0023] This embodiment provides a method for making a binder of a silicon-carbon negative electrode material and a negative electrode sheet, including the following steps:

[0024] (1) Add amino-rich phenylalanine dropwise to a solution of polyacrylic acid (PAA), and condense or polycondensate under the action of the initiator and occasional diisobutyronitrile (AIBN) to form a viscous polymer polymer binder;

[0025]

[0026] (2) Mix the silicon carbon negative electrode material with the binder and other auxiliary materials in the above step (1) and apply it on the negative electrode current collector, and dry it, wherein the auxiliary materials include conductive agents and solvents to obtain the negative electrode of the silicon battery piece.

[0027] (3) Use the negative electrode in step (2), use lithium sheet as counter electrode, polyolefin separator and electrolyte LiPF containing organic mixed solvent (EC (ethyl carbonate) + DMC (dimethyl carbonate)) 6 (The con...

Embodiment 2

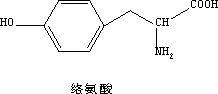

[0030]This embodiment provides a method for making a binder of a silicon negative electrode material and a negative electrode sheet, comprising the following steps:

[0031] (1) Add tyrosine rich in amino structure dropwise to the solution of polyacrylic acid (PAA), and condense or polycondensate under the action of the initiator occasionally diisobutyronitrile (AIBN) to form a viscous polymer material adhesive;

[0032]

[0033] (2) Mix the silicon carbon negative electrode material with the binder and other auxiliary materials in the above step (1) and apply it on the negative electrode current collector, and dry it, wherein the auxiliary materials include conductive agents and solvents to obtain the negative electrode of the silicon battery piece.

[0034] (3) Use the negative electrode in step (2), use lithium sheet as counter electrode, polyolefin separator and electrolyte LiPF containing organic mixed solvent (EC (ethyl carbonate) + DMC (dimethyl carbonate)) 6 (The...

Embodiment 3

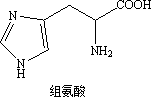

[0037] This embodiment provides a method for making a binder of a silicon-carbon negative electrode material and a negative electrode sheet, including the following steps:

[0038] (1) Add amino-rich histidine dropwise to a polyacrylic acid (PAA) solution, and condense or polycondense under the action of the initiator occasionally diisobutyronitrile (AIBN) to form a viscous polymer material adhesive;

[0039]

[0040] (2) Mix the silicon carbon negative electrode material with the binder and other auxiliary materials in the above step (1) and apply it on the negative electrode current collector, and dry it, wherein the auxiliary materials include conductive agents and solvents to obtain the negative electrode of the silicon battery piece.

[0041] (3) Use the negative electrode in step (2), use lithium sheet as counter electrode, polyolefin separator and electrolyte LiPF containing organic mixed solvent (EC (ethyl carbonate) + DMC (dimethyl carbonate)) 6 (The concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inverse capacity | aaaaa | aaaaa |

| Capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com