Production process of high-flame-retardant and oil-resistant PVC particles

A production process, high flame retardant technology, applied in the field of production process of PVC particles, can solve the problems of not improving the oil resistance and low cold resistance of PVC, and achieve the effect of improving the performance, the compatibility coefficient is close, and the matching is reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

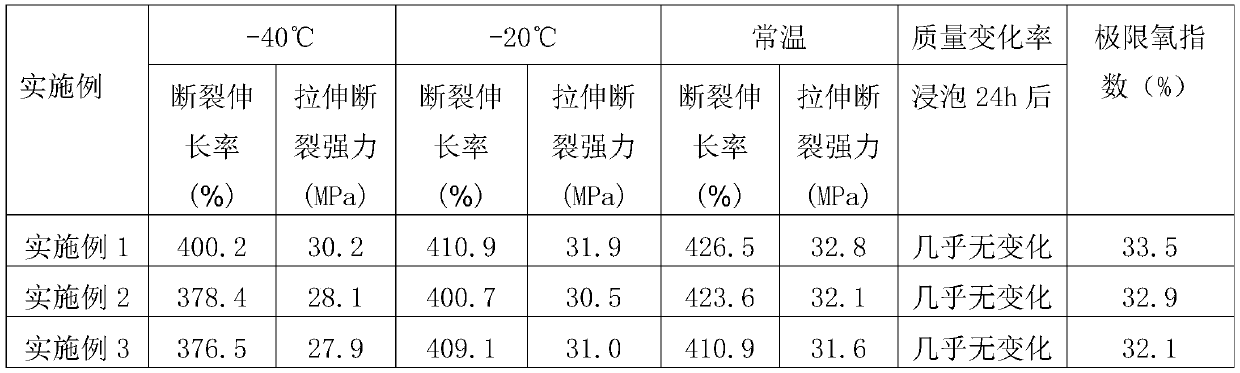

Embodiment 1

[0041] Preliminary preparation: conduct a comprehensive and detailed inspection of all equipment to confirm that there is no abnormality in the equipment;

[0042] Raw material preparation: The raw materials, in parts by mass, consist of the following components: 51 parts of polyvinyl chloride resin, 20 parts of plasticizer, 9 parts of filler, 5 parts of nano-rubber particles, 3 parts of stabilizer, flame retardant 3 parts, 1 part of lubricant Hst, 1 part of calcium oxide, 1 part of nano calcium carbonate, 1 part of viscosity reducer, 1 part of other additives P-830.

[0043] Preparation of filler: the filler is mesoporous silica, and the mesoporous silica is composed of the following components in parts by mass: 35 parts of ethyl orthosilicate, 12 parts of triethylamine, dodecane 11 parts of sodium lauryl sulfate, 8 parts of sodium lauryl sulfate, 8 parts of cetyltrimethylammonium bromide, appropriate amount of distilled water; the preparation of described mesoporous silica c...

Embodiment 2

[0051] Preliminary preparation: conduct a comprehensive and detailed inspection of all equipment to confirm that there is no abnormality in the equipment;

[0052] Raw material preparation: The raw materials, in parts by mass, consist of the following components: 50 parts of polyvinyl chloride resin, 20 parts of plasticizer, 10 parts of filler, 8 parts of nano-rubber particles, 3 parts of stabilizer, flame retardant 3 parts, 1 part of lubricant Hst, 1 part of calcium oxide, 1 part of nano calcium carbonate, 1 part of viscosity reducer, 1 part of other additives P-830.

[0053] Preparation of filler: the filler is mesoporous silica, and the mesoporous silica is composed of the following components in parts by mass: 34 parts of ethyl orthosilicate, 13 parts of triethylamine, dodecane 12 parts of sodium lauryl sulfate, 9 parts of sodium lauryl sulfate, 8 parts of cetyltrimethylammonium bromide, appropriate amount of distilled water; the preparation of described mesoporous silica ...

Embodiment 3

[0061] Preliminary preparation: conduct a comprehensive and detailed inspection of all equipment to confirm that there is no abnormality in the equipment;

[0062] Raw material preparation: The raw materials, in parts by mass, consist of the following components: 55 parts of polyvinyl chloride resin, 20 parts of plasticizer, 10 parts of filler, 8 parts of nano-rubber particles, 3 parts of stabilizer, flame retardant 3 parts, 1 part of lubricant Hst, 1 part of calcium oxide, 1 part of nano calcium carbonate, 1 part of viscosity reducer, 1 part of other additives P-830.

[0063] Preparation of filler: the filler is mesoporous silica, and the mesoporous silica is composed of the following components in parts by mass: 32 parts of ethyl orthosilicate, 12 parts of triethylamine, dodecane 10 parts of sodium lauryl sulfate, 10 parts of sodium lauryl sulfate, 10 parts of cetyltrimethylammonium bromide, appropriate amount of distilled water; the preparation of described mesoporous silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com