Production technology of high-absorbability chrome tanned leather

A technology for chrome tanned leather and production process, which is applied in the field of production technology of high absorption chrome tanned leather, can solve the problems of heavy toxicity, waste of chrome resources, large amount of chrome tanning agent, etc., achieves excellent performance, promotes absorption and cross-linking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

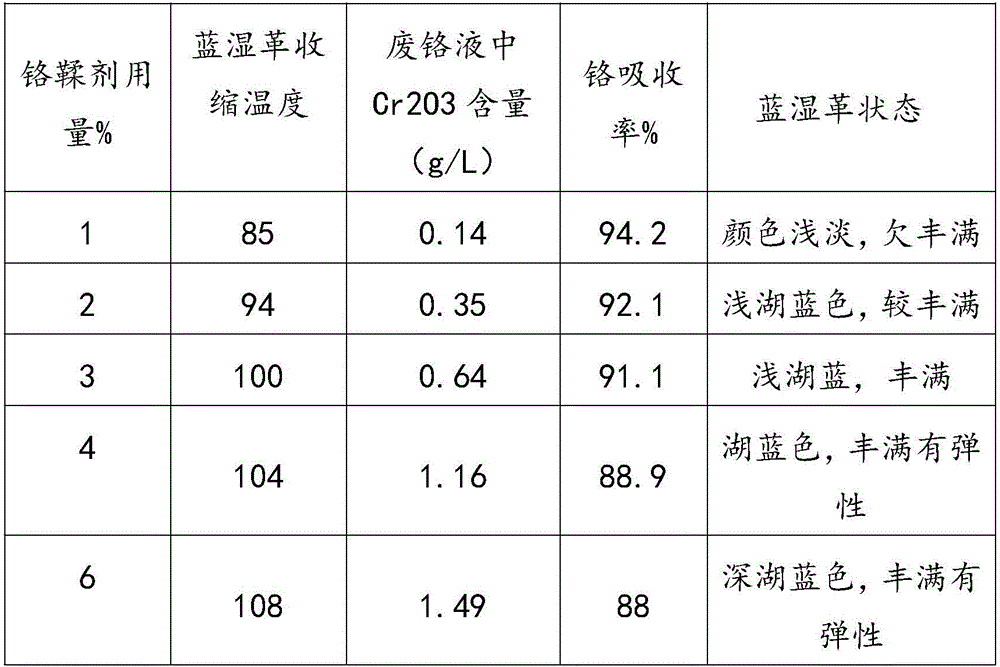

Examples

Embodiment Construction

[0036] In order to make the objectives, technical solutions, and advantages of the embodiments of the present invention clearer, the following describes the technical solutions in the embodiments of the present invention clearly and completely. Obviously, the described embodiments are part of the embodiments of the present invention, but not all of them. Examples.

[0037] The production process of high absorption chrome tanned leather of the present invention includes the following steps:

[0038] (1) Soften the raw materials to restore the fresh skin state, remove the unnecessary ingredients in the fur processing, after the full-thick gray leather is separated from the first layer and the second layer through the skinning process, the second layer of gray leather is put into the tanning drum for deliming , Softening, pickling;

[0039] (2) Add 80% of water and control the temperature to 22°C;

[0040] (3) Add 8% salt, rotate for 10 minutes, control the Baume degree between 7-8;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com