A kind of pretreatment method that improves walnut shell biodegradation effect

A technology of biodegradation and walnut shell, applied in the field of walnut shell pretreatment, can solve the problems of difficult biodegradation and high acid-insoluble lignin content in walnut shell, and achieve the advantages of increasing specific surface area, improving biodegradation effect, and increasing contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] Specific embodiment one: the pretreatment method that this embodiment improves walnut shell biodegradation effect, comprises the following steps:

[0027] 1. Physical pretreatment:

[0028] removing impurities in the walnut shell, physically grinding the walnut shell, and sieving to obtain walnut shell powder with a particle size of 60-80 mesh;

[0029] 2. Chemical pretreatment:

[0030] adding lye to the walnut shell powder treated in step 1, and treating it at 55-65° C. for 46-50 hours; the lye is Ca(OH) with a mass concentration of 6%-10%. 2 Solution; wherein the volume ratio of walnut shell powder and lye is 1:(0.9~1.1);

[0031] 3. Then filter out the lye, wash the residue with distilled water until the pH value does not change, adjust the pH value to 6-7 after suction filtration, and dry at 55-65°C to constant weight, which is complete.

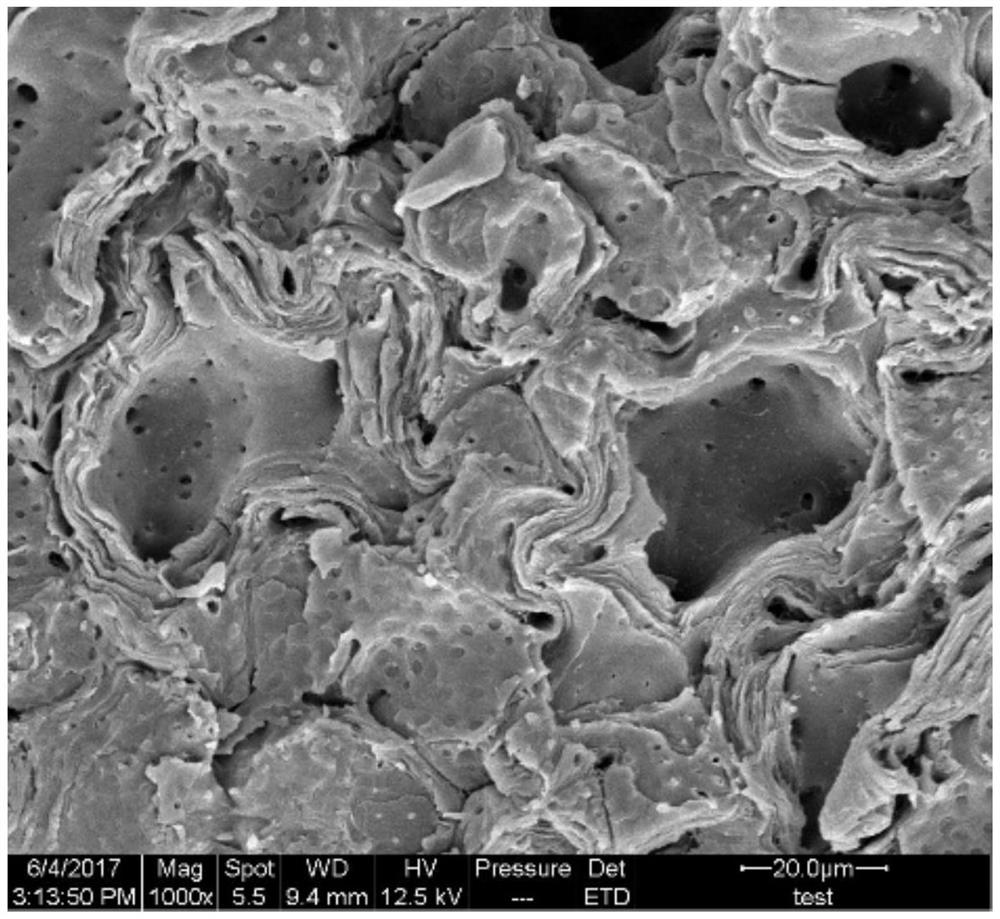

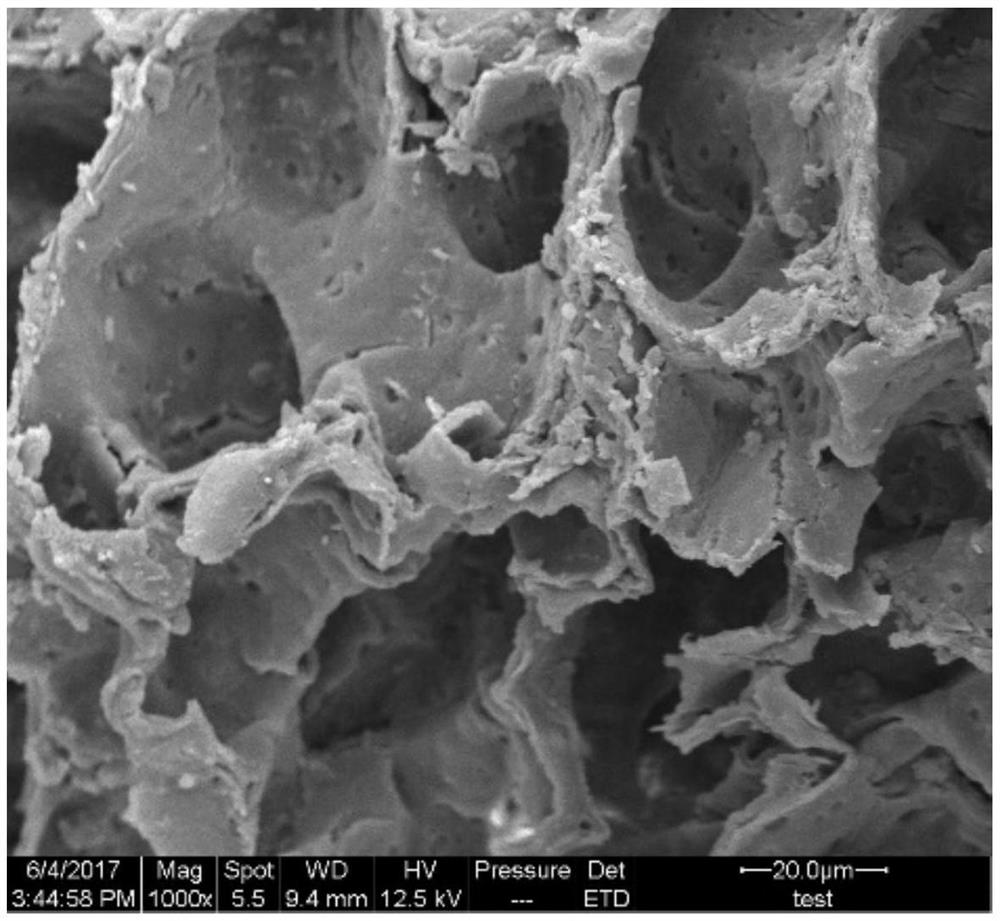

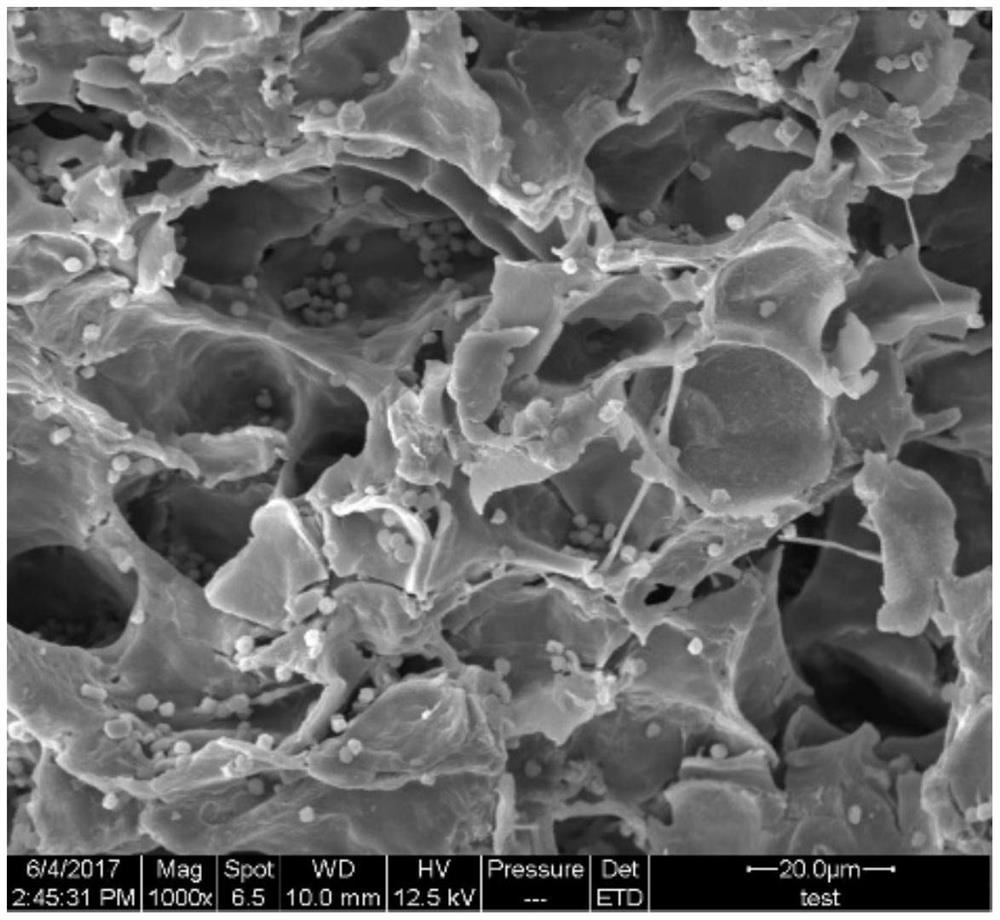

[0032] The combination of physical pretreatment and chemical pretreatment is used to comprehensively treat walnut shells. T...

specific Embodiment approach 2

[0033] Specific embodiment 2: This embodiment differs from specific embodiment 1 in that: in step 2, the process is carried out at 60° C. for 47 to 49 hours. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the lye described in the step two is the Ca(OH) of mass concentration 7%~9% 2 solution. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com