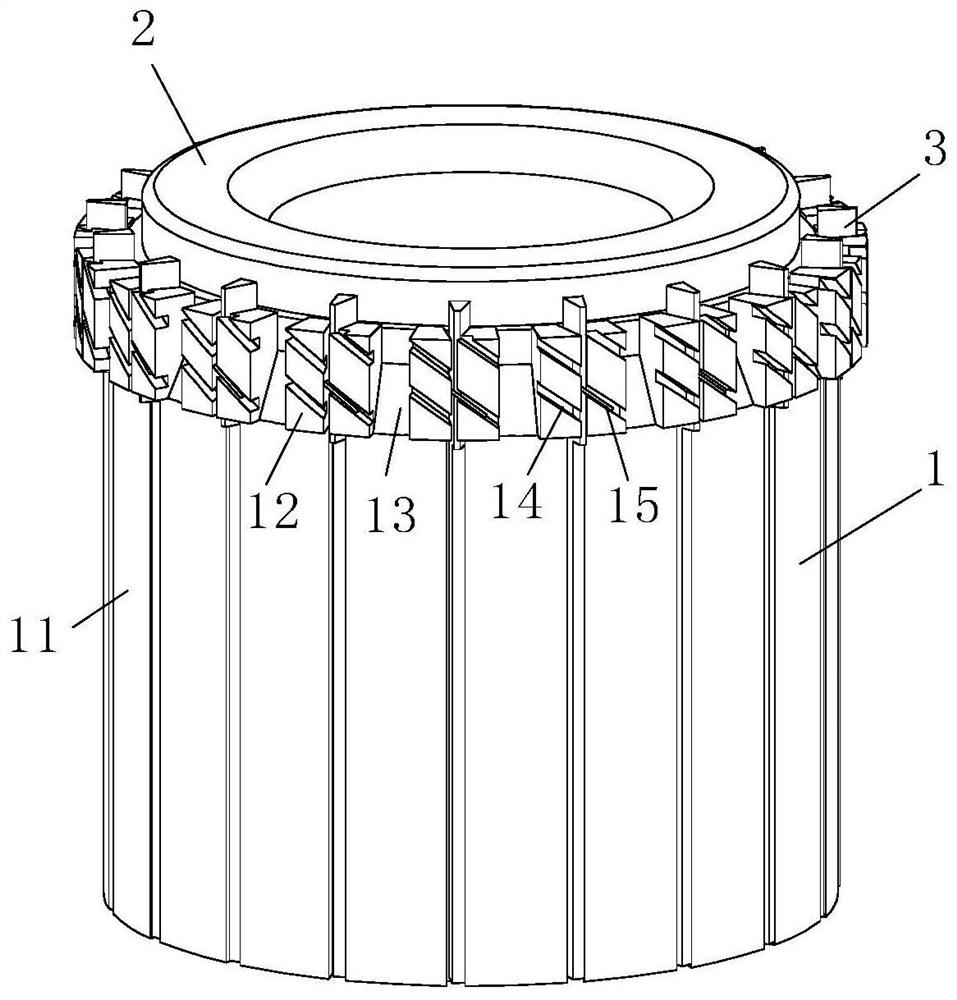

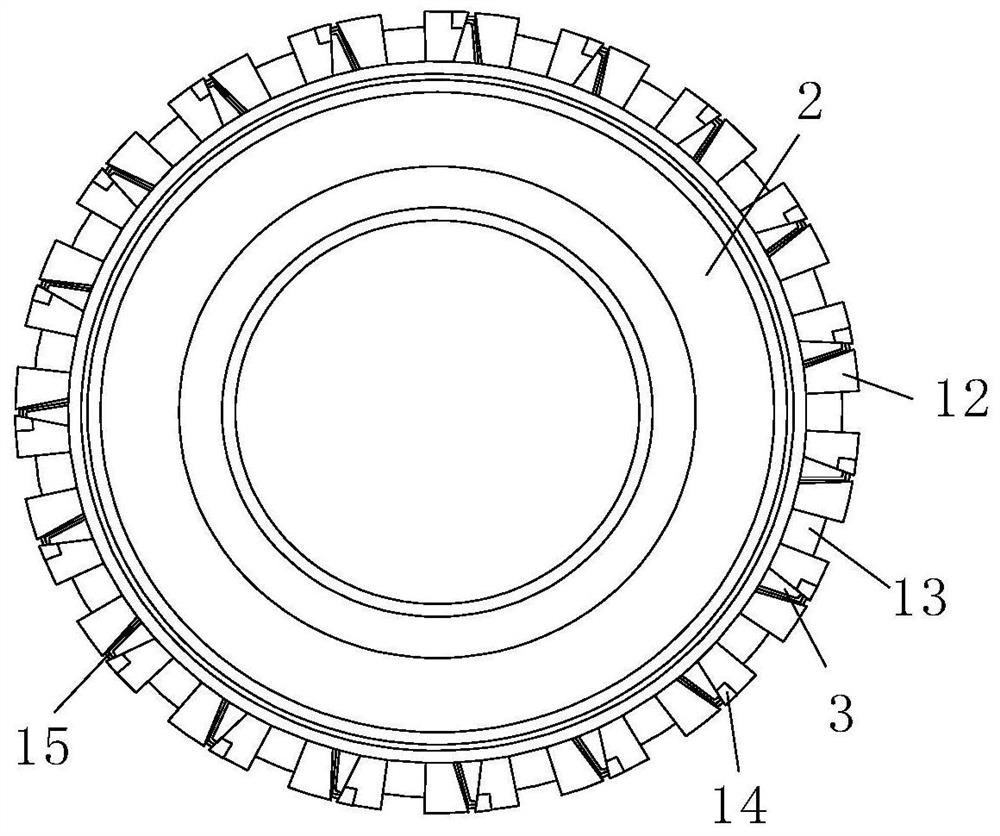

High-strength groove type commutator

A commutator, high-strength technology, applied in the direction of current collectors, rotating current collectors, electrical components, etc., can solve the problems of commutator work influence, welding slag falling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

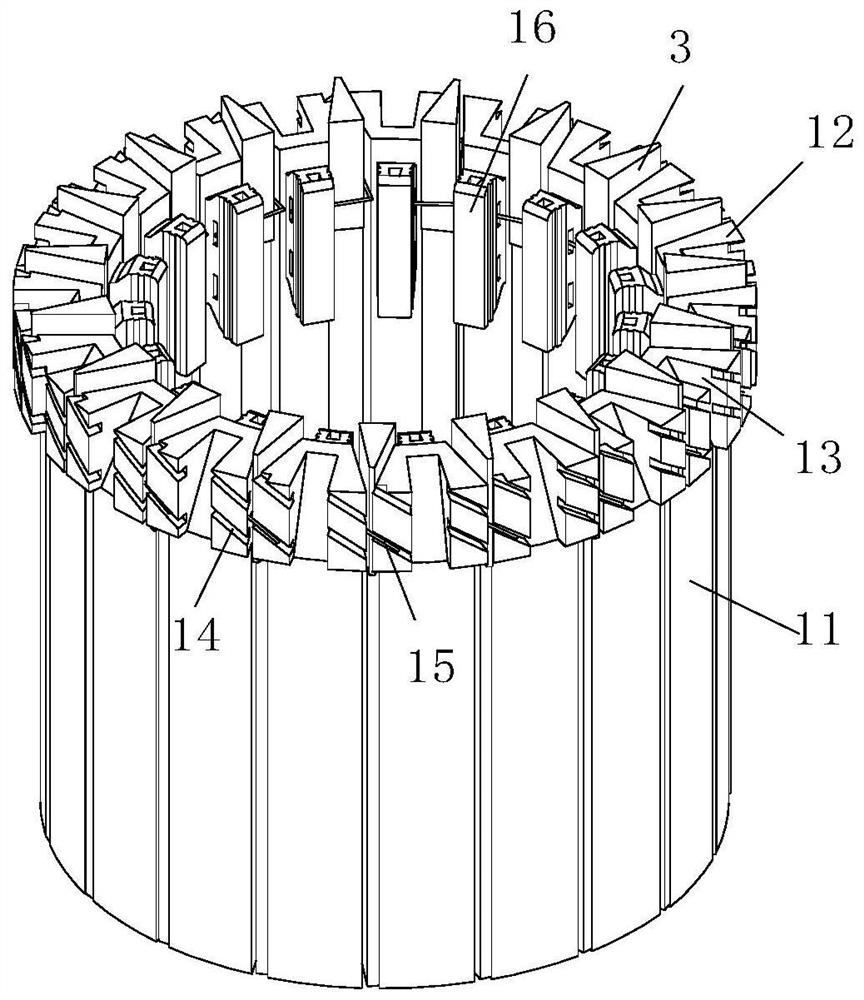

[0031]As an embodiment of the present invention, the upper and lower fixing feet 16 and 17 are provided with first through holes 161 that penetrate up and down, and the first through holes 161 in the upper fixing feet 16 and the lower fixing feet 17 in the same vertical plane. Through the setting of the first through hole 161, on the one hand, the material used for the upper fixing leg 16 and the lower fixing leg 17 can be reduced, and the cost can be reduced; Filling, after being formed, the upper end of the upper fixing foot 16 and the lower end of the lower fixing foot 17 can be connected to the material in the dovetail groove 18 from the inside of the upper fixing foot 16 and the lower fixing foot 17. direction movement, thereby improving the mechanical strength and overspeed performance of the slot commutator.

[0032] As an embodiment of the present invention, the upper fixing leg 16 and the lower fixing leg 17 are both provided with a plurality of second through holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com