Vinyl acetate-acrylic emulsion and preparation method thereof

A technology of vinegar-acrylic emulsion and acrylate, which is applied in the coating field of coated paper, can solve the problems of poor surface strength of paper, achieve the effect of enhancing surface strength and improving the phenomenon of lint and powder falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

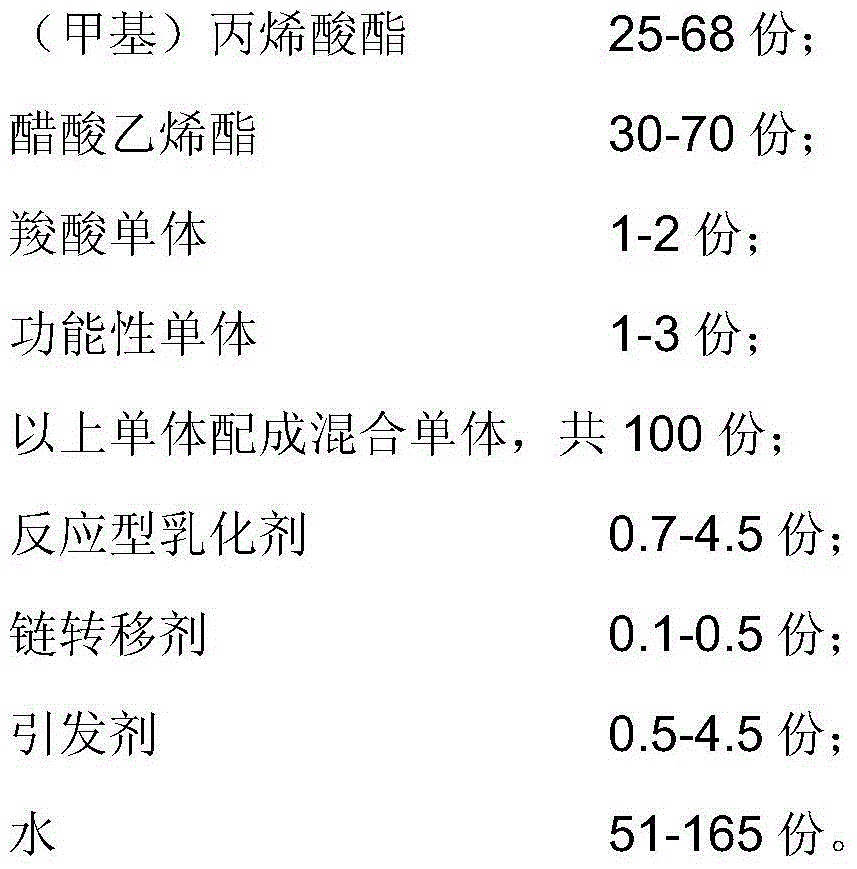

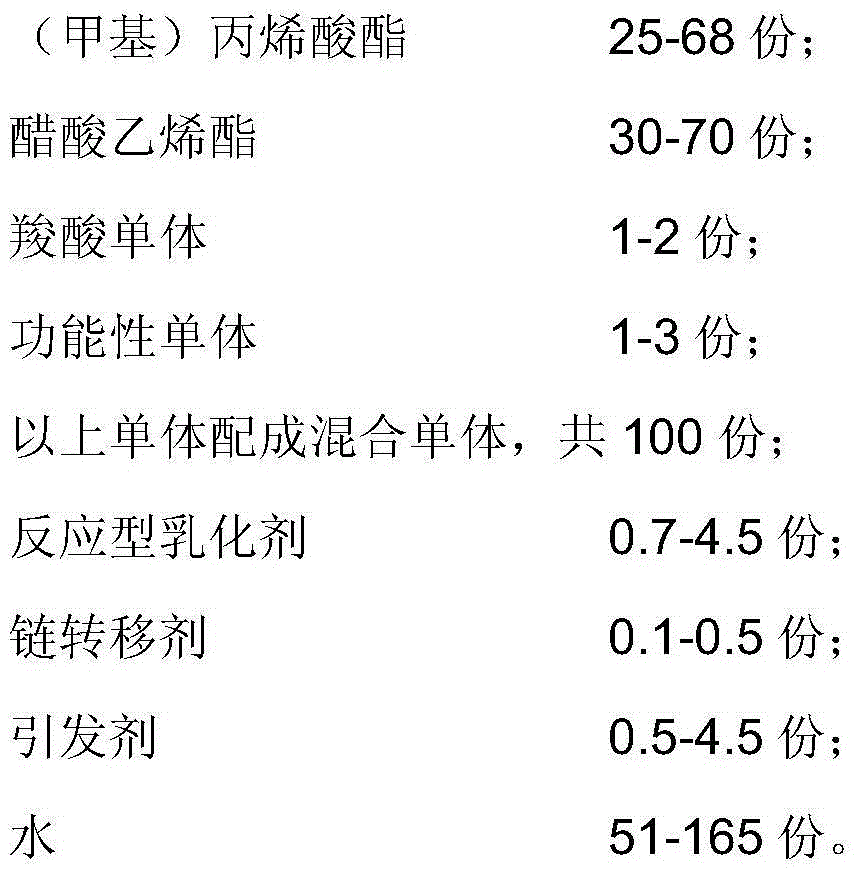

Method used

Image

Examples

Embodiment 1

[0026] Synthesis of vinegar-acrylic emulsion:

[0027] a) Mix 25g of n-butyl acrylate, 70g of vinyl acetate, 2g of acrylic acid and 0.1g of n-dodecanethiol to make a mixed monomer, and set aside.

[0028] b) Add 0.63g of allyl polyoxyethylene ether ammonium sulfate, 0.2g of potassium persulfate, 3g of 2-methyl-2 acrylate-2 hydroxyethyl phosphate and 35.7g of the mixed monomers in the 97.1ga) step Dissolve the ionic water into an aqueous solution, stir at high speed for 30 minutes, and set aside.

[0029] e) In an aqueous solution of 0.07g allyl polyoxyethylene ether ammonium sulfate, 0.3g potassium persulfate and 15.3g deionized water, react at 70°C for 40 minutes, and then add the mixed solution in step b) dropwise for 5 hours .

[0030] f) Incubate at 70°C for 2 hours. Cool down to 25° C., neutralize with 4 g of ammonium hydroxide aqueous solution with a solid content of 10% by weight, and continue stirring for 10 minutes. Filter through a 100-mesh sieve to obtain a styr...

Embodiment 2

[0032] Synthesis of vinegar-acrylic emulsion:

[0033] a) Mix 68g of ethyl acrylate, 30g of vinyl acetate, 1g of methacrylic acid and 0.5g of tert-dodecylmercaptan to prepare mixed monomers. spare.

[0034] b) Add 1.8g of allyl polyoxyethylene ether, 4.05g of sodium persulfate, 1g of N-acryloylthiourea and 65.7g of deionized water to dissolve the mixed monomers in step 79.6ga) into an aqueous solution, and stir at high speed for 30 minutes. spare.

[0035] c) Add the mixed monomers in step 19.9ga) into an aqueous solution of 2.7g allyl polyoxyethylene ether, 0.45g sodium persulfate and 98.55g deionized water, react at 95°C for 10 minutes, and then add b ) step of the mixed solution for 1 hour.

[0036] d) Incubate at 70°C for 1 hour. Cool down to 25°C, neutralize with 20 g of aqueous sodium hydroxide solution with a solid content of 40% by weight, and continue stirring for 10 minutes. Filter through a 100-mesh sieve to obtain a styrene-acrylic emulsion with a solid conten...

Embodiment 3

[0038] Synthesis of vinegar-acrylic emulsion:

[0039] a) Mix 20g of methyl methacrylate, 27g of 2-ethylhexyl acrylate, 50g of vinyl acetate, 1.5g of itaconic acid and 0.3g of n-butyl mercaptan to make a mixed monomer. spare.

[0040] b) Add 1.5g of vinyl polyoxyethylene ether, 1.5g of ammonium persulfate, 1.5g of N-methylolacrylamide and 50.15g of deionized water to dissolve the mixed monomers in step 88.92ga) into an aqueous solution, and stir at high speed for 30 minutes . spare.

[0041] e) Add the mixed monomers in step 9.88ga) to an aqueous solution of 1.5g vinyl polyoxyethylene ether, 1.5g ammonium persulfate and 50.15g deionized water, react at 80°C for 20 minutes, and then add b) dropwise Step mixture for 3 hours.

[0042] f) Incubate at 70°C for 2 hours. Cool down to 25°C, neutralize with 10 g of aqueous potassium hydroxide solution with a solid content of 20% by weight, and continue stirring for 10 minutes. Filter through a 100-mesh sieve to obtain a styrene-a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com