Hyperbranched polyurethane containing active amino groups and preparation method thereof

A technology of hyperbranched polyurethane and linear polyurethane, which is applied in the field of hyperbranched polyurethane and its preparation, can solve the problems of poor moisture absorption and air permeability of polyurethane film, achieve good water affinity, excellent mechanical properties, and increase the effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

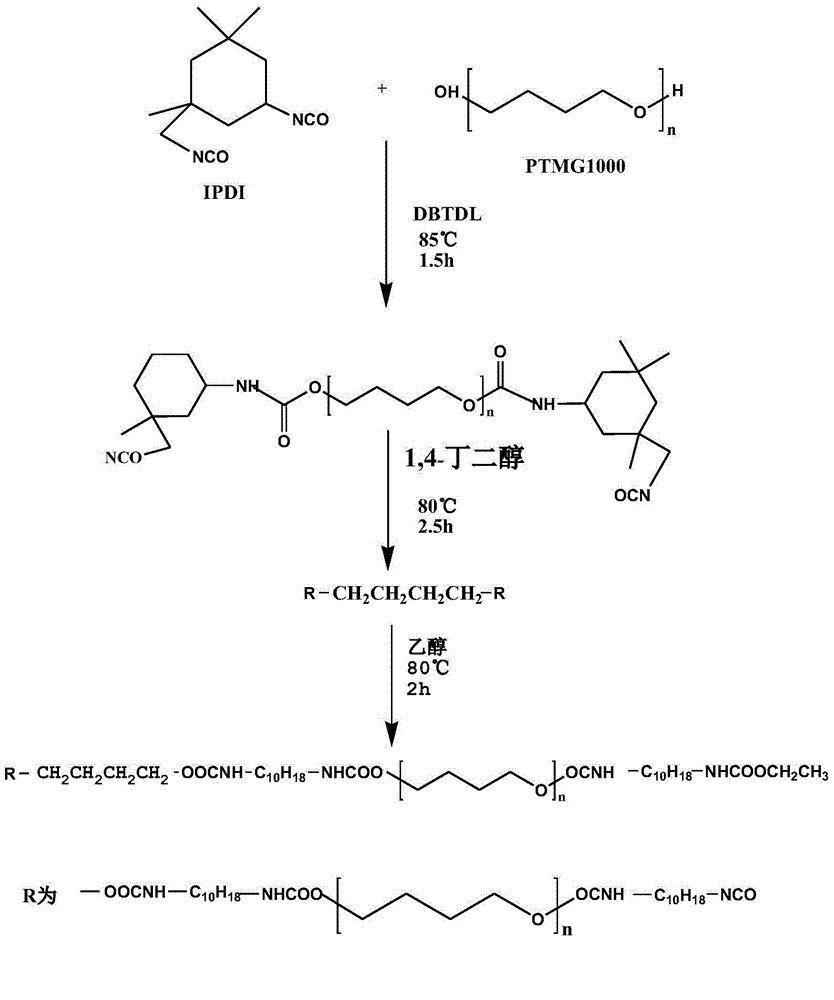

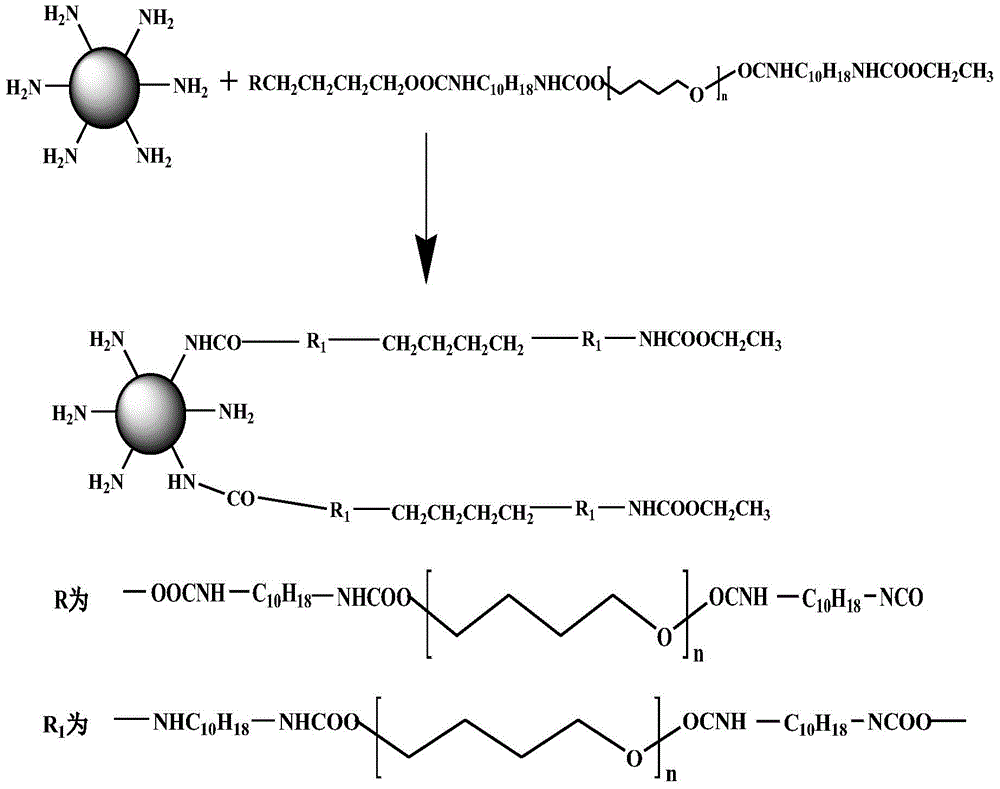

[0030] Such as figure 1 with figure 2 Shown, a kind of preparation method that contains the hyperbranched polyurethane of amino group, comprises the steps:

[0031] 1) Weigh 10.00g of polytetrahydrofuran ether glycol 1000 (abbreviated as PTMG1000) and dissolve it in 15ml of dried N,N-dimethylformamide (abbreviated as DMF);

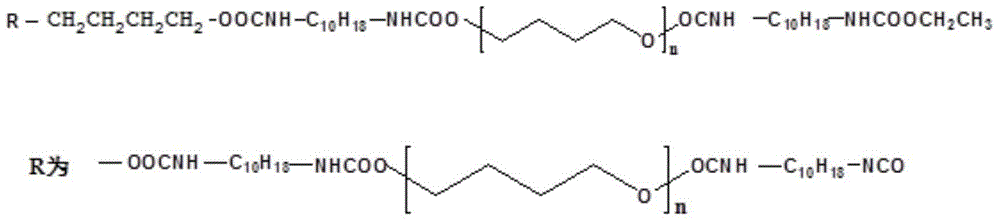

[0032] 2) Under the condition of nitrogen protection, according to the material ratio of -NCO and -OH of 2.5:1, with 0.007% dibutyltin dilaurate (abbreviated as DBTDL) as the catalyst, 5.55g of isophorone di Isocyanate (abbreviated as IPDI) was stirred and reacted with polyether polyol at 85°C for 1.5h, then 0.81g of 1,4-butanediol was added, and stirred at 85°C for 2.5h for chain extension; finally, 0.37g was added Anhydrous ethanol, stirred and reacted at 80°C for 2 hours, and partially blocked to obtain a linear polyurethane prepolymer;

[0033] 3) The molar ratio of the amino-terminated hyperbranched polymer to the linear polyurethane prepolymer is...

Embodiment 2

[0036] A kind of preparation method of the hyperbranched polyurethane containing amino group, preparation flow is referred to as figure 1 with figure 2 , including the following steps:

[0037] 1) Weigh 10.00g of polyethylene glycol 1000 (abbreviated as PEG1000) and dissolve it in 15ml of dried N,N-dimethylacetamide (abbreviated as DMAC);

[0038] 2) Under the condition of nitrogen protection, according to the molar ratio of -NCO and -OH as 2.5:1, with 0.007% dibutyltin dilaurate (abbreviated as DBTDL) as catalyst, add 4.35g of toluene diisocyanate (abbreviated as DBTDL) dropwise TDI) to react with polyether polyol at 85°C for 1.5h, then add 0.81g of 1,4-butanediol, stir at 85°C for 2.5h for chain extension; finally add 0.37g of absolute ethanol , stirred and reacted at 80°C for 2 hours, and partially blocked to obtain a linear polyurethane prepolymer;

[0039] 3) The molar ratio of the amino-terminated hyperbranched polymer to the linear polyurethane prepolymer is 1:1.15,...

Embodiment 3

[0042] A kind of preparation method of the hyperbranched polyurethane containing amino group, preparation flow is referred to as figure 1 with figure 2 , including the following steps:

[0043] 1) Weigh 10.00g of polypropylene glycol 1000 (abbreviated as PPG1000) and dissolve it in 15ml of dried N,N-dimethylformamide (abbreviated as DMF);

[0044] 2) Under the condition of nitrogen protection, according to the material ratio of -NCO and -OH is 3:1, with 0.007% dibutyltin dilaurate (abbreviated as DBTDL) as catalyst, add 6.66g of isophorone di Isocyanate (abbreviated as IPDI) was stirred and reacted with polyether polyol at 85°C for 1.5h, then 1.08g of 1,4-butanediol was added, stirred and reacted at 85°C for 2.5h for chain extension; finally, 0.46g was added Anhydrous ethanol, stirred and reacted at 80°C for 2 hours, and partially blocked to obtain a linear polyurethane prepolymer;

[0045] 3) The molar ratio of the amino-terminated hyperbranched polymer to the linear poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com