Patents

Literature

41results about How to "Strong moisture absorption and breathability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

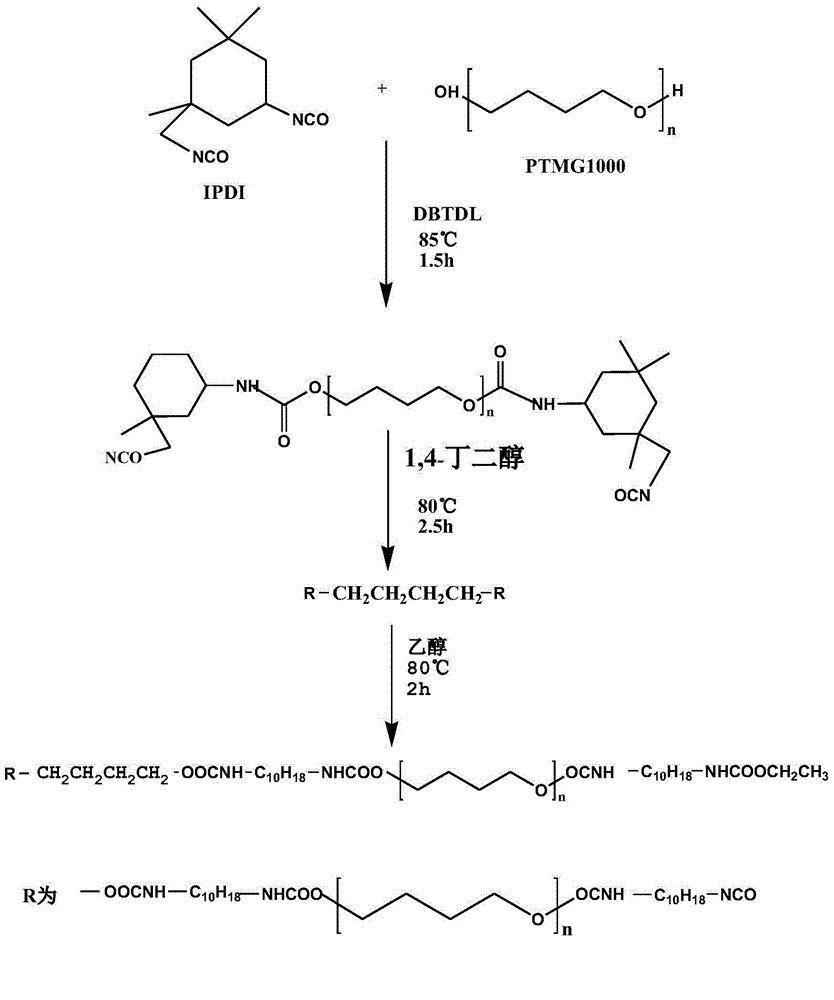

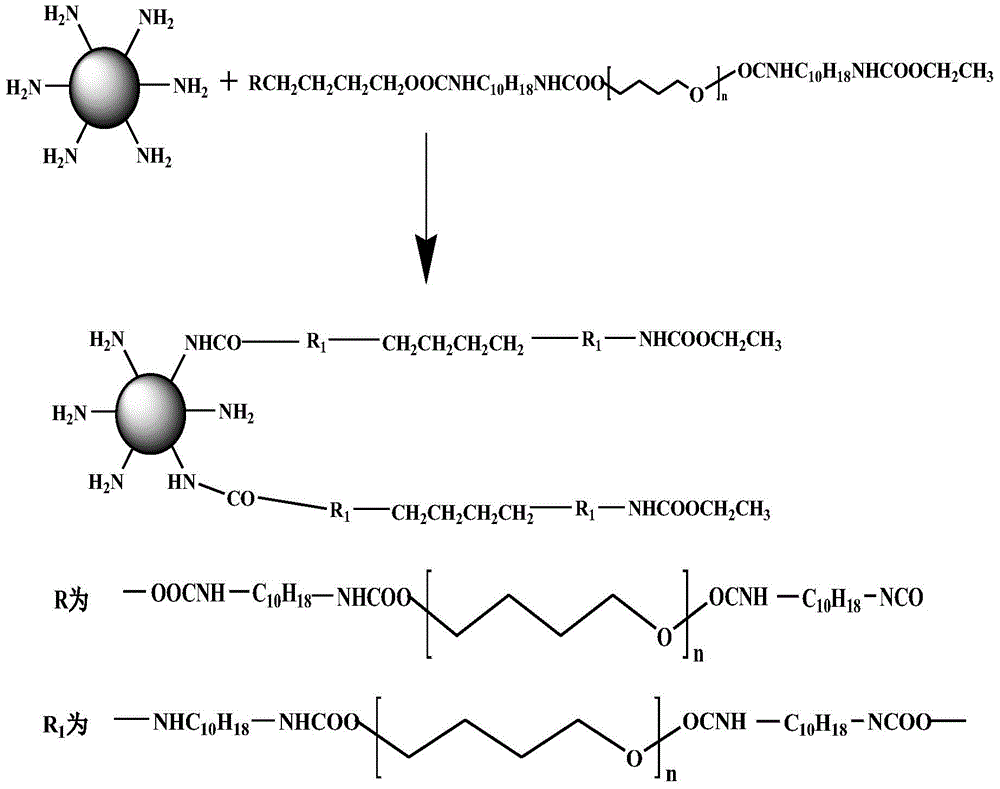

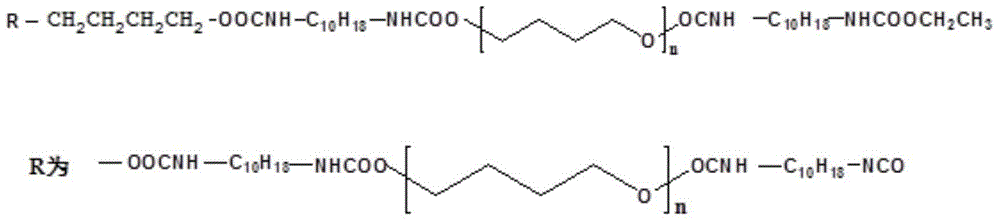

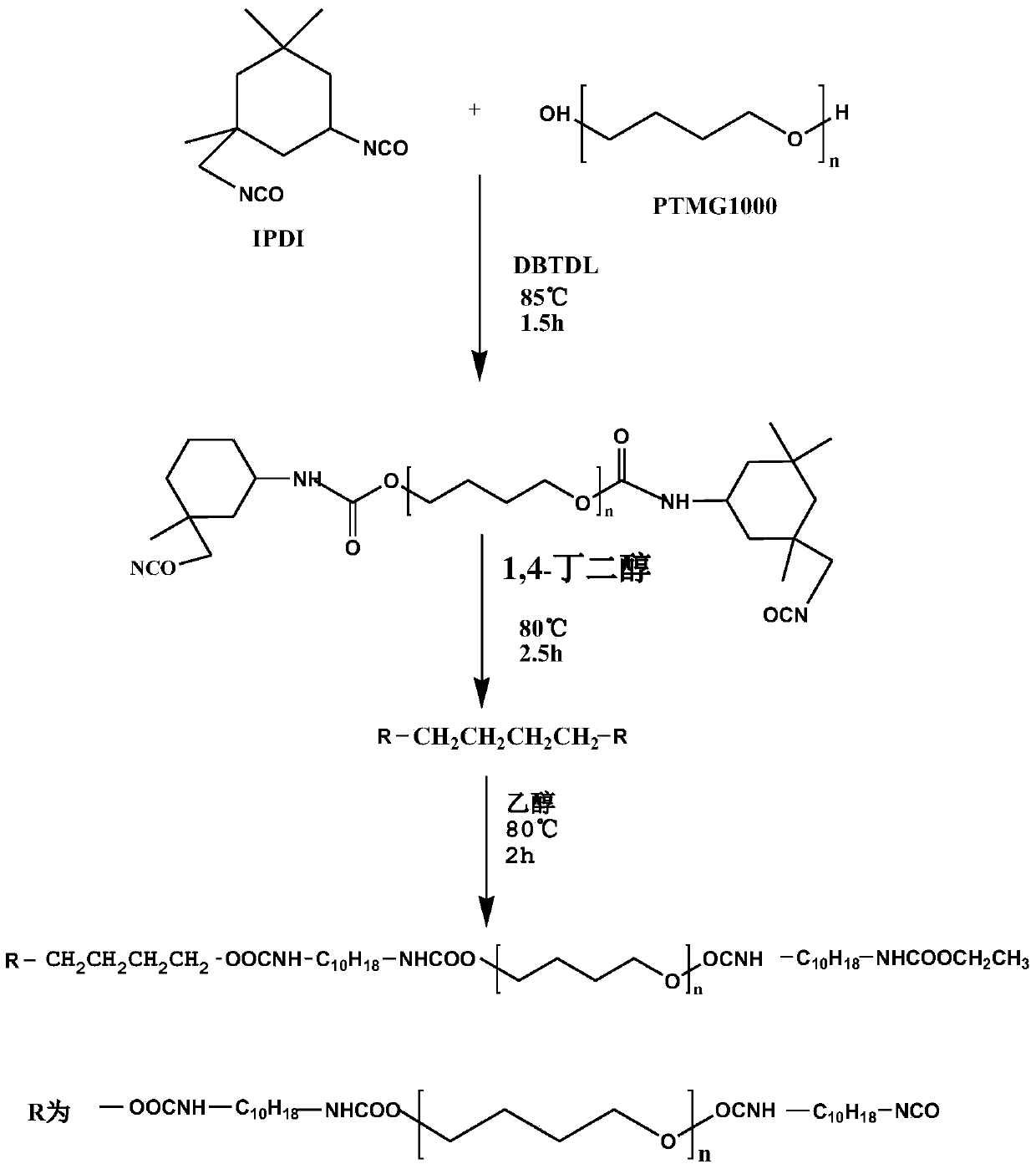

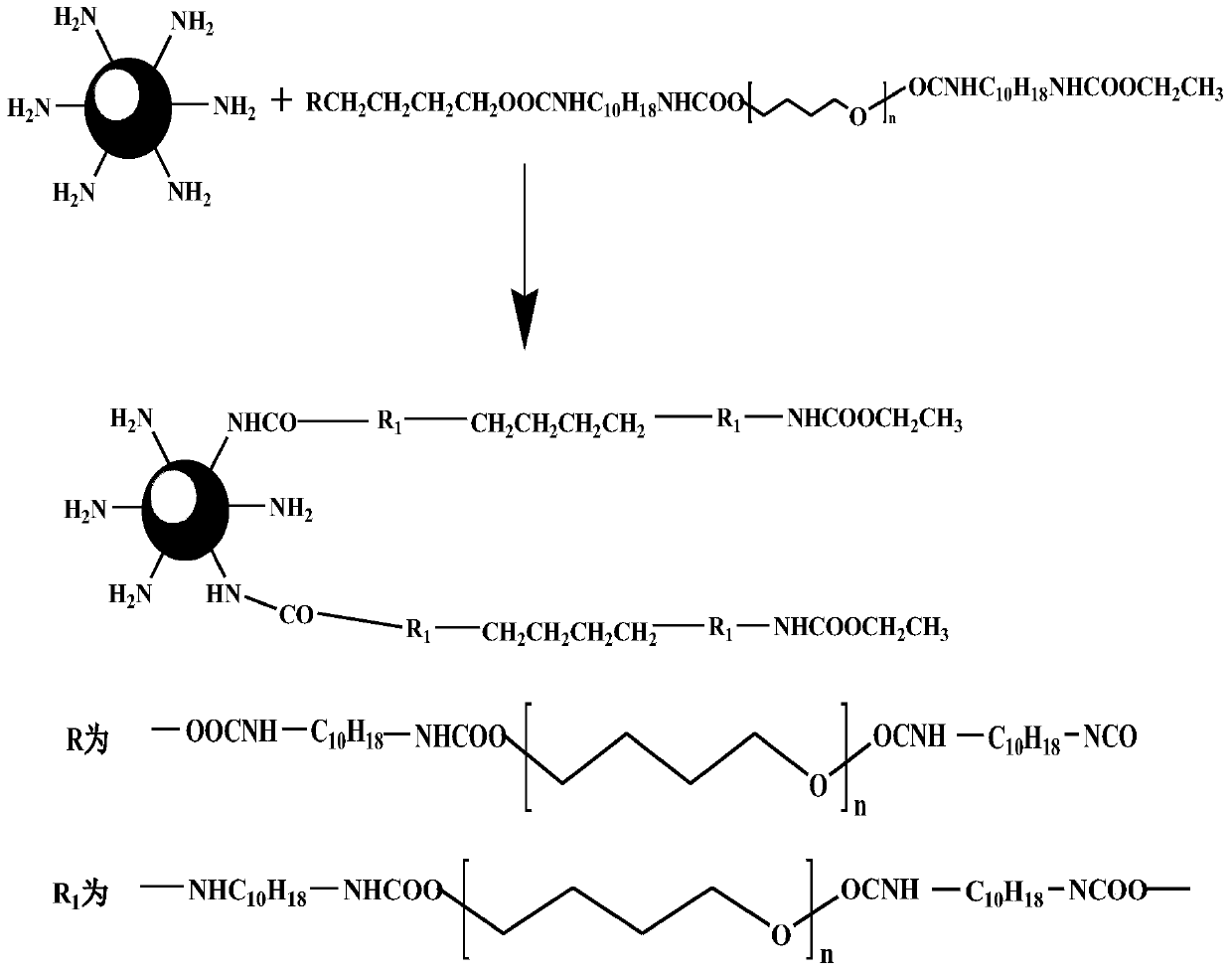

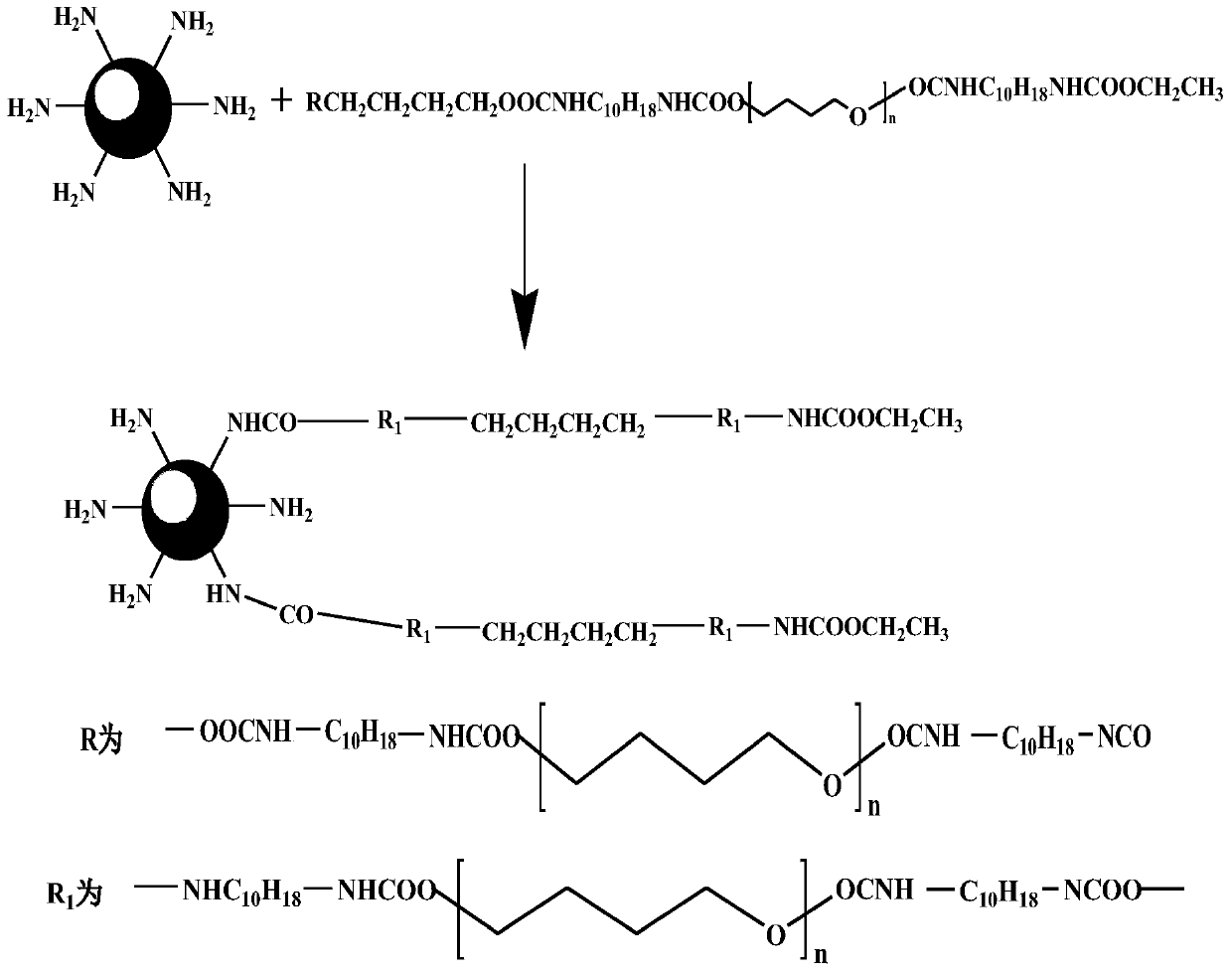

Hyperbranched polyurethane containing active amino groups and preparation method thereof

The invention discloses hyperbranched polyurethane containing active amino groups and a preparation method thereof. The preparation method comprises the steps that firstly, polyether polyol and diisocyanate are mixed and stirred to react; secondly, a catalyst is added, organic aprotic solvent serves as solvent, and a small-molecule chain extender is added for chain extension after the reaction is performed for a period of time; thirdly, an end-capping reagent is added for partial end capping, so that linear polyurethane pre-polymers are obtained; afterwards, amino-teminated hyperbranched polymers and the linear polyurethane pre-polymers are mixed and stirred to react, so that the hyperbranched polyurethane is obtained. Hyperbranched polyurethane resin obtained by synthesizing the hyperbranched polyurethane contains a lot of active amino groups and imino groups, so the sanitary property of a polyurethane film can be improved, and the dyeing property of the polyurethane film can also be improved.

Owner:SHAANXI UNIV OF SCI & TECH

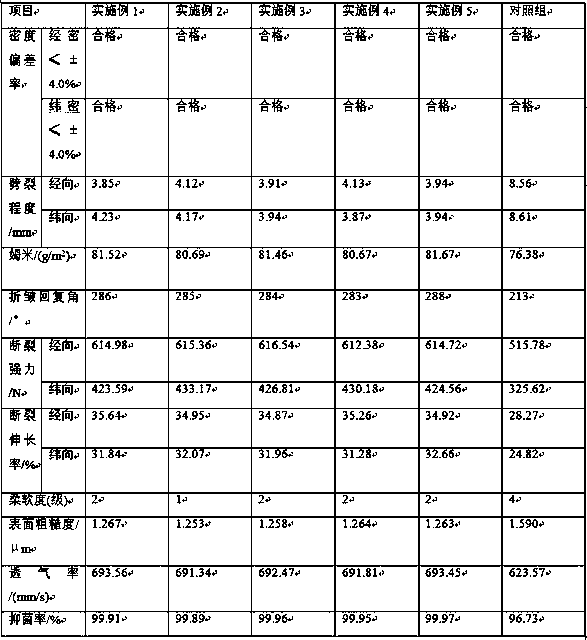

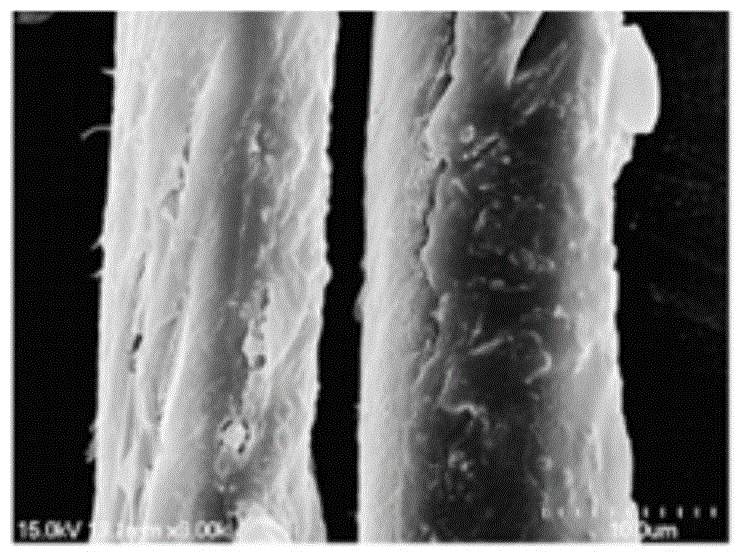

Preparation method of traditional Chinese medicine anti-microbial underwear fabric

InactiveCN109247627AGuaranteed antimicrobial propertiesGood skin affinityMonocomponent cellulose artificial filamentHandkerchiefsChemical industryFiber

The invention belongs to a separation and extraction technology for effective components of natural products of light industry and chemical industry biological technologies in biology and new medicine, and relates to the field of extraction and application of natural active components, in particular to a preparation method of a traditional Chinese medicine anti-microbial underwear fabric. The preparation method comprises the steps: the anti-microbial active components are extracted from traditional Chinese medicine through an ultrasound-assisted ethyl alcohol extraction technology firstly; then a mesoporous silica and chitosan composite is adopted to pack the natural anti-microbial components, and chitosan / mesoporous silica nano particles loaded with the medicine are prepared; and finally,after bamboo fibers, the chitosan / mesoporous silica nano particles loaded with the medicine, a natural antioxidant, water and a spinning assistant are mixed, then traditional Chinese medicine anti-microbial fibers are obtained through electrostatic spinning, then the traditional Chinese medicine anti-microbial fibers and hydrophobic modified cotton fibers are blended, and then the traditional Chinese medicine anti-microbial underwear fabric is obtained. The traditional Chinese medicine anti-microbial underwear fabric prepared by the preparation method has the anti-microbial and health-care effects, and has the wearing experience feeling of good skin-friendly property and high moisture-absorption and ventilating properties.

Owner:唐卫兵

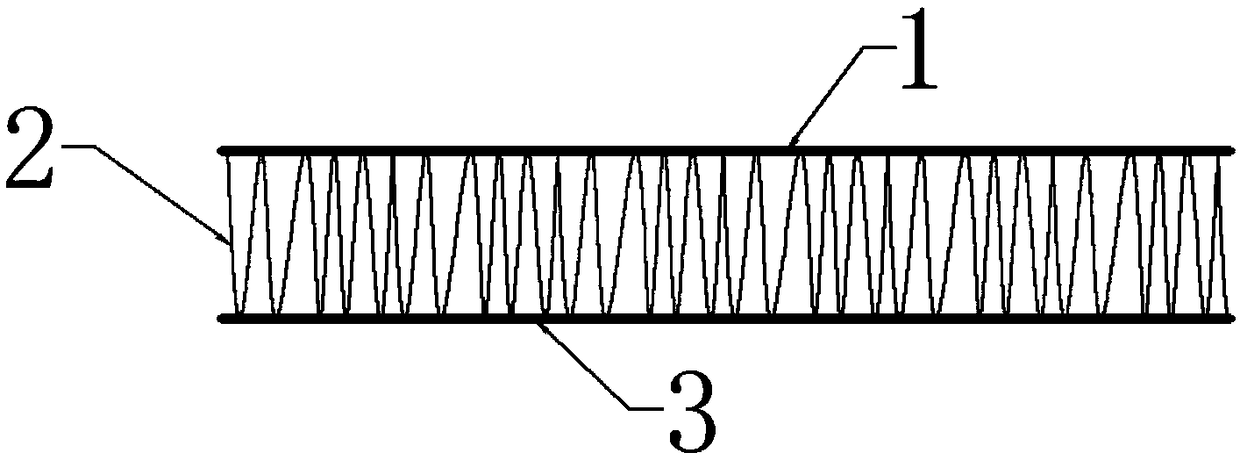

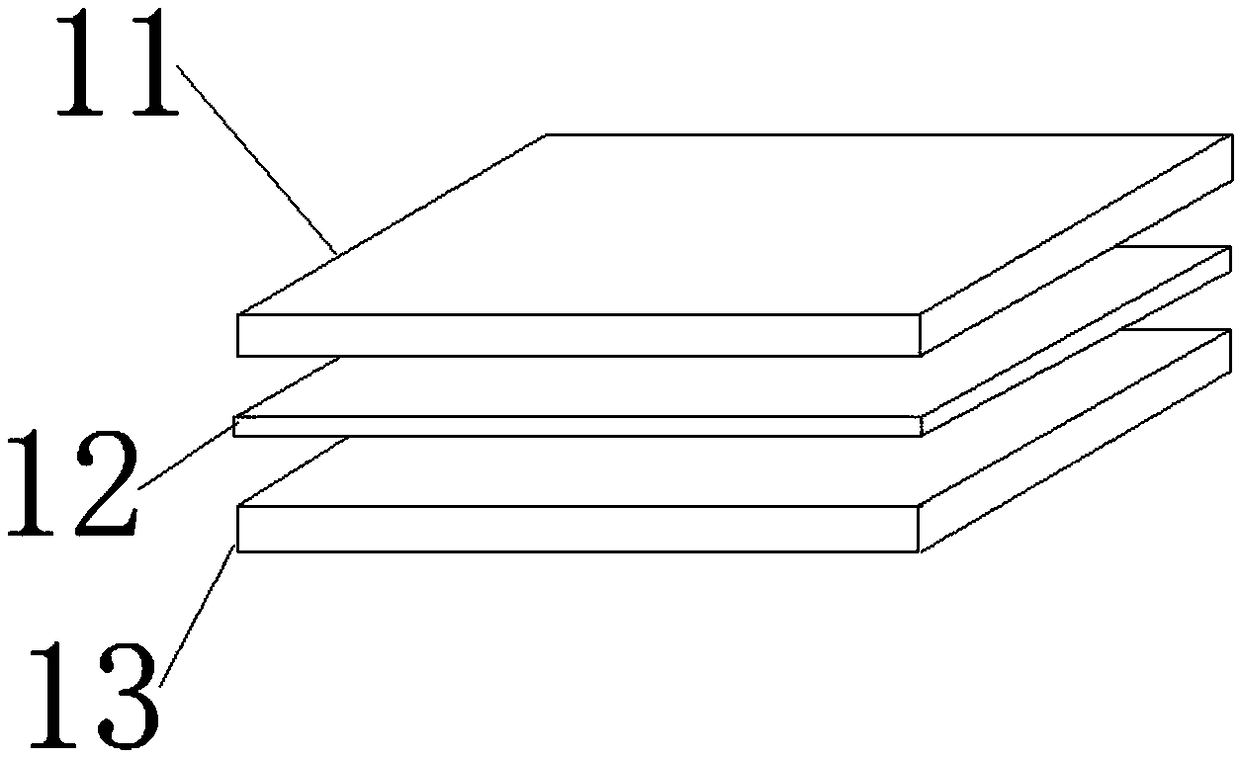

Alginate fiber electrostatic flocking fabric for medical treatment and manufacturing method thereof

ActiveCN103481549AWith far infrared raysWith insulationPattern makingLayered productsCelluloseAnti bacteria

The invention discloses an alginate fiber electrostatic flocking fabric for medical treatment, which comprises a nap layer, an adhesive layer and a base cloth layer, wherein the nap layer is made of alginate fiber, the base cloth is bamboo fiber plain woven cloth, and the middle adhesive layer is made of a hydroxymethyl cellulose adhesive. The invention also discloses a manufacturing method of the alginate fiber electrostatic flocking fabric, which is characterized by comprising the steps of cutting an alginate fiber strand into alginate fiber naps with length of 0.8-1.0mm, and performing electric conduction treatment and coloring treatment; pre-coating and primarily coating the flocking base cloth with an adhesive, wherein the total thickness of the adhesive is 0.15-0.2mm; generating an electric field by use of high-voltage alternating static electricity for flocking, and performing three-prevention treatment and baking on the cloth to obtain the alginate fiber flocking fabric. The fabric has anionic antibacterial and deodorant functions, is non-toxic and harmless, can be naturally degraded, realizes strong moisture absorbability and air permeability, prevents ultraviolet rays and can be applied to the medical treatment and healthcare industries.

Owner:山东领潮新材料有限公司

Preparation method of high strength antibacterial environmental protection fabric

InactiveCN108070941AImprove antibacterial propertiesNovel functional designBiochemical fibre treatmentDyeing processEnvironmental resistanceMoisture absorption

The invention discloses a preparation method of a high strength antibacterial environmental protection fabric. The fabric is prepare from that, by weight, 45% super fine denier polypropylene fiber, 35% cotton fiber, 10% chitosan fiber, 5% silver fiber and 5% soybean protein fiber are blended to obtain warp; by weight, 55% galamina fiber, 35% bamboo fiber and 10% milk protein fiber are blended to obtain weft. The high strength antibacterial environmental protection fabric not only makes a product have a good antibacterial property, protect the skin, but also has strong moisture absorption and permeability, an antibacterial finishing liquid is adopted, the antibacterial effect of the fabric is further increased, in dyeing process, all natural plant stains are adopted, after fixation, the dyeing is uniform, color cannot fade, the process is simple and the color is firm; the fabric adopts natural materials throughout the whole process, is environmental friendly and low in cost, the designof the fabric is novel and the grade of the fabric is high, and the product has good comfort degree and high added value.

Owner:TIANJIN SAIYUAN HEALTH PROD

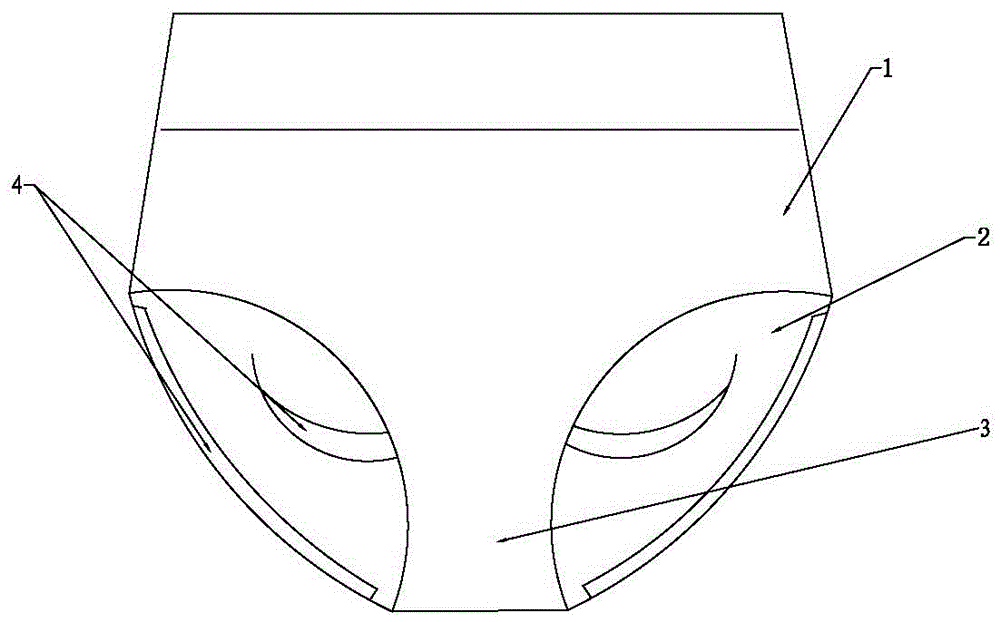

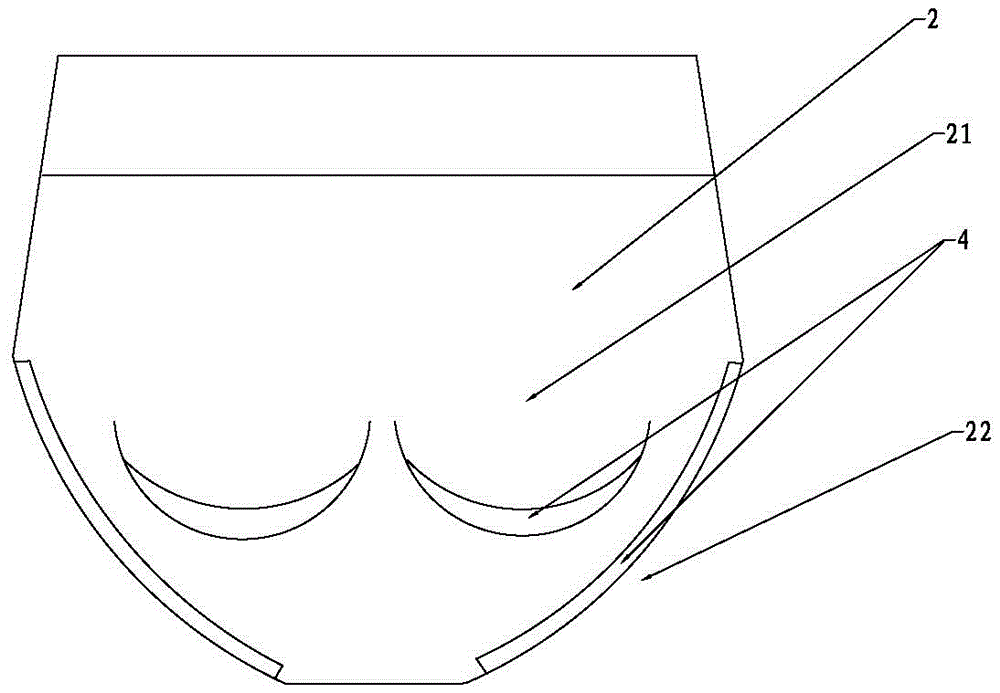

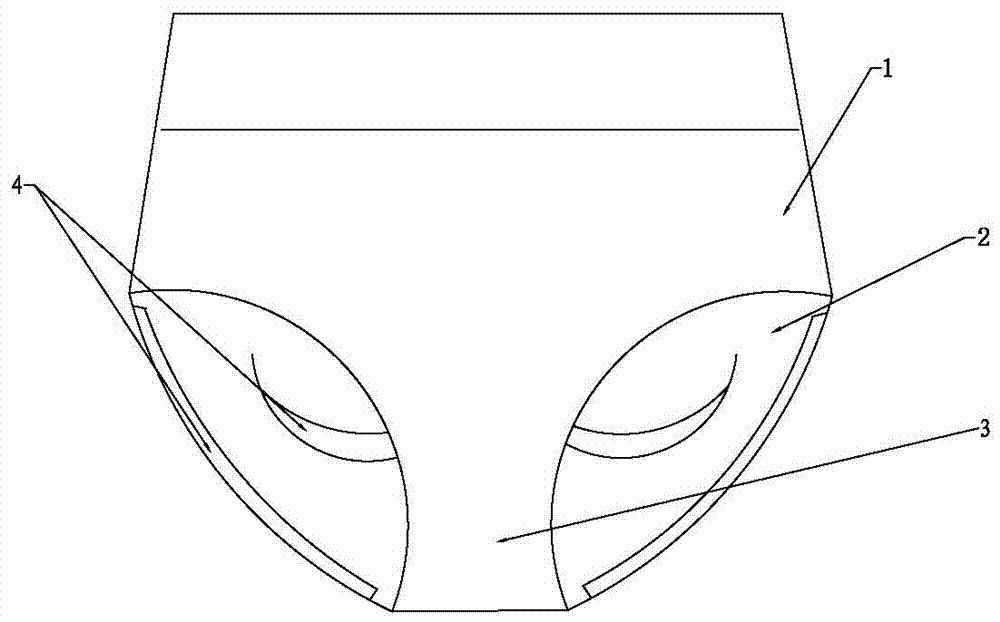

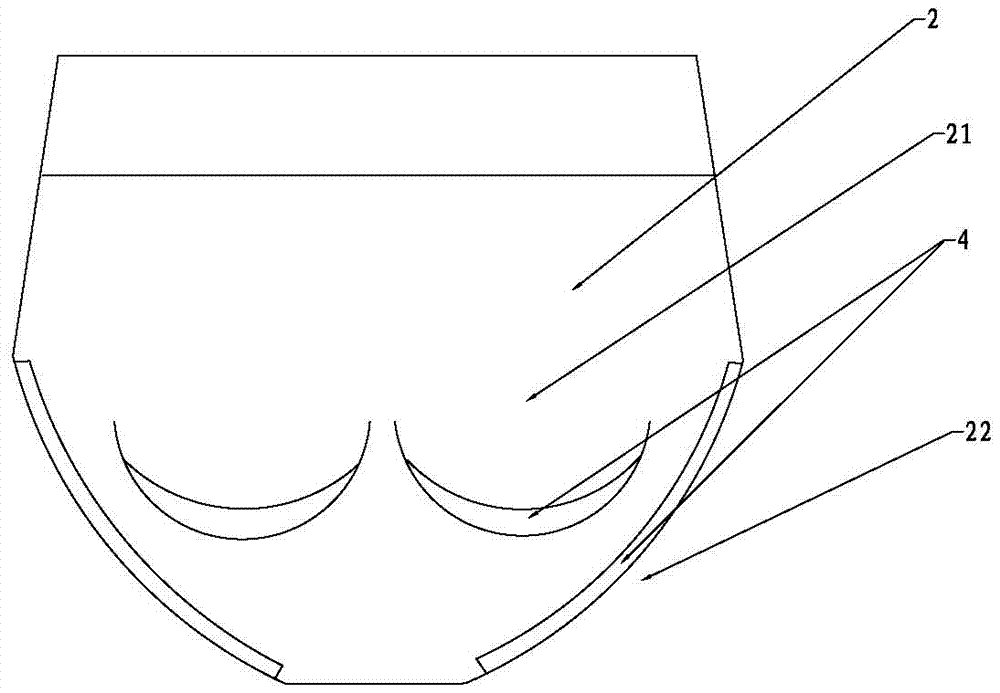

Comfortable hip lifting knickers

ActiveCN105614958AHigh-elastic buttock-lifting effect is goodImprove breathabilityHandkerchiefsBaby linensDiolCrotch

The invention relates to the technical field of underwear and knickers, in particular to comfortable hip lifting knickers. The comfortable hip lifting knickers comprise a front part and a rear part. A bottom crotch is arranged between the front part and the rear part. Hip lifting parts are symmetrically arranged on the rear part. Leg circumference parts are arranged at the lower end of the rear part. The surfaces of the leg circumference parts and the surfaces of the hip lifting parts are provided with hip lifting elastic glue layers. The hip lifting elastic glue layers are prepared from aliphatic diol, an aliphatic polyamine curing agent, a hydrophilic chain extender, aromatic isocyanate, a catalyst, rosin pentaerythrityl ester, a lactone compound, a silane coupling agent, antioxygen and a neutralizing agent. The comfortable hip lifting knickers have the advantages of being high in comfort, soft in hand feeling, good in hip lifting effect and good in breathability.

Owner:HONGJI UNDERWEAR CO LTD

High-grade elastic silk anti-wrinkle fabric and its preparation method

The invention belongs to the field of textile weaving, in particular to a high-grade elastic silk wrinkle-resistant fabric and a preparation method thereof. 40-50 part of mulberry silk, 5-8 parts of modify resin cotton, 2-3 parts of nano-Tencel, 1-4 parts of wool, 1-3 parts of bamboo pulp fib and 4-5 parts of milk protein fiber; 40-50 part of mulberry silk, 2-5 parts of spandex, 3-6 part of modified resin cotton, 3-5 parts of nano-Tencel, 2-4 parts of PTT fib and 1-4 parts of soybean protein fiber. A method for prepare that warp yarn and the weft yarn comprises respectively prepare the warp yarn and the weft yarn, weaving the warp yarn and the weft yarn on an air-jet loom, treating the finishing liquid, immersing the warp yarn and the weft yarn, rolling the warp yarn and the weft yarn, drying the warp yarn and the weft yarn, washing the warp yarn and the weft yarn, and airing to obtain the real silk wrinkle-resistant fabric.

Owner:广西南宁桂尔创环保科技有限公司

Antibacterial and anti-radiation pure silk fabric and preparation method thereof

ActiveCN108914327AGood effectTall and straightOrnamental textile articlesWoven fabricsPolytrimethylene terephthalateEngineering

The invention belongs to the field of weaving of textile products, in particular to an antibacterial and anti-radiation pure silk fabric and a preparation method thereof. The antibacterial and anti-radiation pure silk fabric consists of warp yarns and weft yarns, wherein each warp yarn is prepared from the following components in parts by weight: 40 to 50 parts of mulberry silk, 5 to 8 parts of modified resin cotton, 2 to 3 parts of nanometer tencel, 1 to 4 parts of wool fabric, 3 to 5 parts of bamboo pulp fiber, and 4 to 5 parts of milk protein fiber; each weft yarn is prepared from the following components in parts by weight: 40 to 50 parts of the mulberry silk, 2 to 5 parts of spandex, 2 to 3 parts of modified resin cotton, 4 to 8 parts of stainless steel fiber, 5 to 6 parts of chitosanfiber, 3 to 5 parts of nanometer tencel, 2 to 4 parts of PTT (polytrimethylene terephthalate) fiber, and 1 to 4 parts of soy protein fiber. The preparation method comprises the following steps of respectively weaving the warp yarns and the weft yarns; weaving the weft yarns and the warp yarns on a jet loom; arranging; finally, drying, washing by water, and airing, so as to obtain the antibacterial and anti-radiation pure silk fabric.

Owner:广西南宁桂尔创环保科技有限公司

A kind of hyperbranched polyurethane containing active amino group and preparation method thereof

The invention discloses hyperbranched polyurethane containing active amino groups and a preparation method thereof. The preparation method comprises the steps that firstly, polyether polyol and diisocyanate are mixed and stirred to react; secondly, a catalyst is added, organic aprotic solvent serves as solvent, and a small-molecule chain extender is added for chain extension after the reaction is performed for a period of time; thirdly, an end-capping reagent is added for partial end capping, so that linear polyurethane pre-polymers are obtained; afterwards, amino-teminated hyperbranched polymers and the linear polyurethane pre-polymers are mixed and stirred to react, so that the hyperbranched polyurethane is obtained. Hyperbranched polyurethane resin obtained by synthesizing the hyperbranched polyurethane contains a lot of active amino groups and imino groups, so the sanitary property of a polyurethane film can be improved, and the dyeing property of the polyurethane film can also be improved.

Owner:SHAANXI UNIV OF SCI & TECH

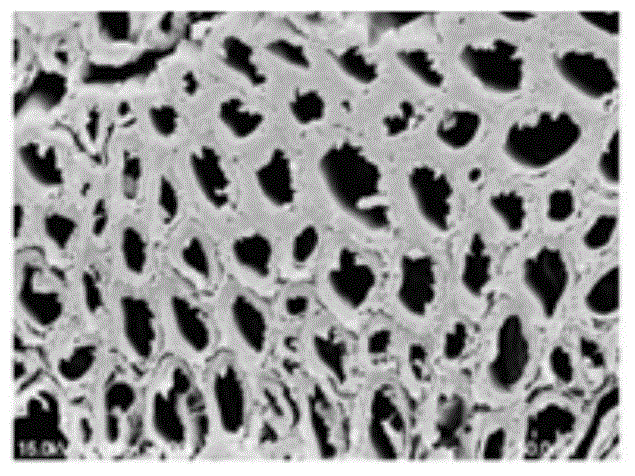

Preparation method of high elasticity chitosan underwear fabric

InactiveCN109468719AImprove spinnabilityImprove water resistanceYarnUndergarmentsFiberMaterials preparation

The invention belongs to a novel fiber and composite material preparation technology of a polymer material in a novel material, and relates to the field of fiber fabric production, in particular to apreparation method of a high elasticity chitosan underwear fabric. The method firstly prepares hydrophobic chitosan by hydrophobic modification on chitosan using dodecyl aldehyde; the hydrophobic chitosan, tetrahydrofuran, a natural antibacterial agent, a natural antioxidant and a spinning aid are uniformly mixed, and after the electrospinning treatment, an antibacterial chitosan fiber of the traditional Chinese medicine is obtained through drying; finally, the antibacterial chitosan fiber of the traditional Chinese medicine, the spandex, a pearl viscose fiber, a modal fiber and a cotton fiberare blended to obtain the high elastic chitosan underwear fabric. The chitosan underwear fabric not only has good elasticity, good skin-friendly property and strong moisture absorption and permeability, but also has antibacterial health care effect.

Owner:唐卫兵

Antibacterial radiation-proof pure silk fabric and preparation method thereof

InactiveCN109930283ATall and straightGood drapabilityBiochemical fibre treatmentLiquid/gas/vapor removalGlass fiberAir-jet loom

The invention belongs to the technical field of textile weaving, particularly relates to an antibacterial radiation-proof pure silk fabric and a preparation method thereof. The fabric consists of warps and wefts. The composition of raw materials and the ratio of parts by weight of the warps are: 30-45 parts of mulberry silk, 3-5 parts of nano-silver doped in mulberry silk, 7-10 parts of blended fiber with zinc-ion ceramic powder doped with polyacrylonitrile, 1-3 parts of nano-tencel, 3-6 parts of bamboo charcoal fiber; the composition of raw materials and the ratio of parts by weight of the wefts are: 30-40 parts of mulberry silk, 3-5 parts of nano silver doped in mulberry silk, 10-15 parts of bamboo pulp fiber, 3-5 parts of hollow glass fiber, 0.8-1 part of chitosan filled in hollow glassfiber, 3-5 parts of antibacterial stainless steel wire, 3-5 parts of nano-tencel, 2-3 parts of soybean protein fiber, the preparation method comprises the following steps of: preparing warps and wefts respectively, and then weaving the warps and the wefts on an air jet loom, finishing processing, drying, washing and drying to obtain the antibacterial radiation-proof pure silk fabric.

Owner:杭州丝绸之路文化艺术有限公司

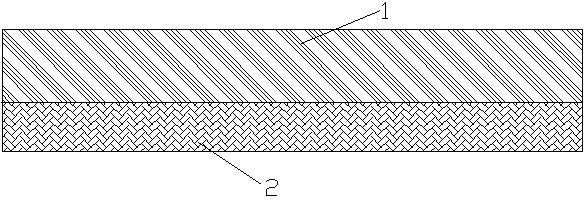

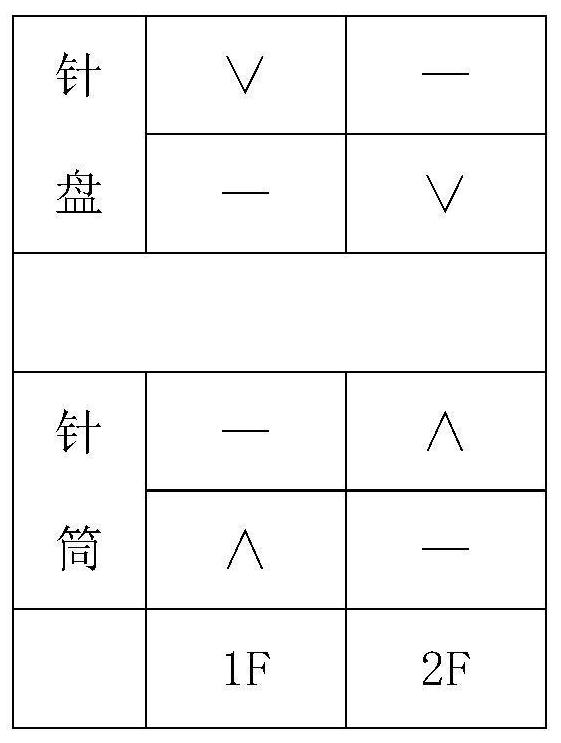

Sandwich seat fabric and preparation method thereof

InactiveCN108998965AEasy to dyeImprove breathabilityStain/soil resistant fibresBiochemical fibre treatmentPolyesterFiber

The invention discloses sandwich seat fabric and a preparation method thereof. The sandwich seat fabric comprises a mesh surface, connecting monofilaments and a plain cloth bottom surface, wherein themesh surface and the plain cloth bottom surface are connected through the connecting monofilaments, and a two-needle-bar Raschel machine is adopted for weaving; the mesh surface is woven by yarn containing flame-retardant polyester fibers with mass fraction being 80%-86% and cotton fibers with mass fraction being 14%-20%; the plain cloth bottom surface is woven by yarn containing the cotton fibers with mass fraction being 80%-86% and the flame-retardant polyester fibers with mass fraction being 14%-20%; the connecting monofilaments are woven by the flame-retardant polyester fibers with mass fraction being 28%-42% and nylon filaments with mass fraction being 58%-72%; phosphorus content of the flame-retardant polyester fibers is 0.4%-0.6%. The fabric prepared from the components with the process has flame retardance, higher moisture absorption and air permeability and antibacterial property and is not prone to producing static electricity.

Owner:ZHEJIANG SUNON FURNITURE MFG

Process for manufacturing novel yarns

InactiveCN103451825AEasy to produceIncrease elasticityWoven fabricsYarnMoisture absorptionFilament yarn

The invention discloses a process for manufacturing novel yarns, and relates to the field of textile manufacture and processing. The process includes steps of mixing yarns; manufacturing carded silver; manufacturing rolls; drawing the silver; manufacturing rough yarns; mixing filaments; manufacturing finished products; packaging and storing the finished products. The process has the advantages that cotton and hemp blended yarns and the filaments are mixed with one another to manufacture the novel yarns, a production mode is simple and convenient, the novel yarns have all characteristics of cotton, hemp and the filaments, shortcomings of an elastic textile made of spandex core-spun yarns are overcome, a textile made of the novel yarns is good in elasticity and high in dimensional stability, a garment made of the novel yarns is good in comfortableness, and the novel yarns are easy to manage, high in moisture absorption and breathability, easy to dye and good in draping performance, stretching restoration performance and easy-care performance, have a sterilization function and are odor-resistant.

Owner:六安市凯旋大麻纺织有限责任公司

Making method of polyester-yarn plain-weave fabric

InactiveCN107217370AStrong moisture absorption and breathabilityNot easy to wrinkleBiochemical fibre treatmentGrip property fibresHigh densitySizing

The invention discloses a making method of a polyester-yarn plain-weave fabric. Polyester warp yarns undergo warping, sizing and denting and are interwoven with polyester weft yarns together according to 1 / 1 plain weave to produce the high-density plain-weave fabric. Sizing is performed by adopting titanium sol, the effect of making a fabric surface smooth can be played, and the defects of curve and tonal variation are not produced, so that the fabric has the soft and moist hand feeling of a wool fabric and a woven pile fabric. Dotted protrusions and recesses distributed between two warp-wise lines make the filament-yarn plain-weave wool-like fabric have the style of a jacquard fabric, and the quality of the fabric is improved.

Owner:福建金源纺织有限公司

Manufacturing method of healthcare underwear

ActiveCN108968172AImprove joint functionGood skin affinityMonocomponent cellulose artificial filamentHandkerchiefsFiberElectrospinning

The invention relates to a manufacturing method of healthcare underwear. The manufacturing method comprises the steps that firstly, the micro-encapsulation technology is used for encapsulating hyaluronic acid, vitamins and collagen into chitosan microcapsules to prepare chitosan micro-capsule powder; then, nano-crystalline cellulose, chitosan micro-capsule powder, natural anti-oxidant, water and spinning auxiliaries are mixed to be uniform, then, a fiber spinning solution is obtained, and drying is performed after static electricity spinning processing is performed to obtain healthcare fiber;finally, after the healthcare fiber and hydrophobic modified cotton fiber are blended, the healthcare fiber fabric is obtained, and the healthcare underwear is obtained after tailoring sewing. The manufactured healthcare underwear has the antibacterial healthcare function, and has the wearing experience with good skin-friendliness and high moisture absorption breathability.

Owner:广东欣薇尔服装有限公司

Comfortable fabric with parasite expelling and mothproof functions

InactiveCN103419425ASoft touchStrong moisture absorption and breathabilityLayered productsCotton fibreEngineering

The invention discloses a comfortable fabric with parasite expelling and mothproof functions. The comfortable fabric comprises a surface parasite expelling and mothproof fabric layer and an inner moisture pickup and ventilation fabric layer, wherein the parasite expelling and mothproof fabric layer is made by blend weaving superfine fiber, bamboo fiber and cotton fiber; pest repellent made of natural parasite expelling plant is stuck on the surface of the superfine fiber; the inner moisture pickup and ventilation fabric layer is made by mutually weaving warp and weft; the warp is made by weaving kendyr fiber; the weft is made by weaving modal fiber; superfine fiber stuck with the pest repellent made of natural parasite expelling plant, as well as bamboo fiber and cotton fiber are used for mutual weaving to manufacture the fabric which is parasite expelling, mothproof, soft, natural and pollution-free, and has special scent of a natural plant; the inner layer is made by weaving warp and weft of kendyr fiber and modal fiber, so that the formed fabric is strong in moisture pickup and ventilation properties, is soft and comfortable, and is warm in winter and cool in summer.

Owner:胡明喜

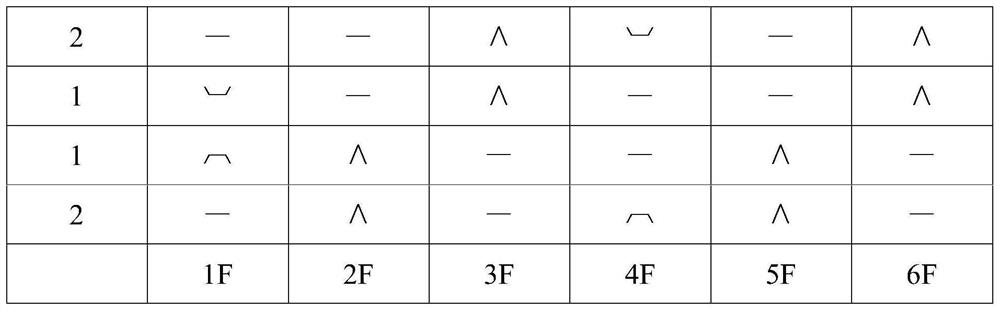

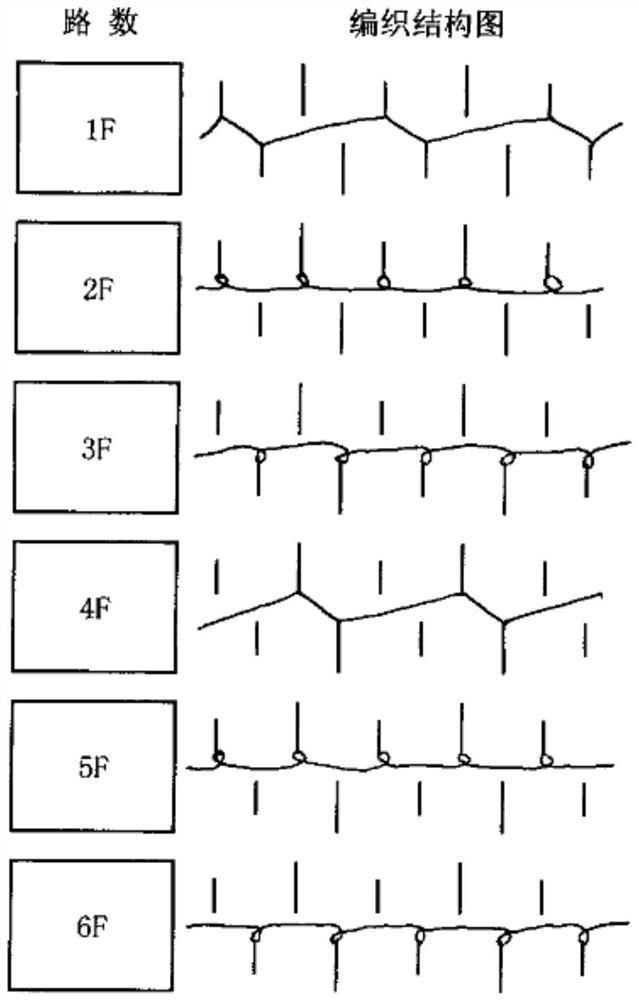

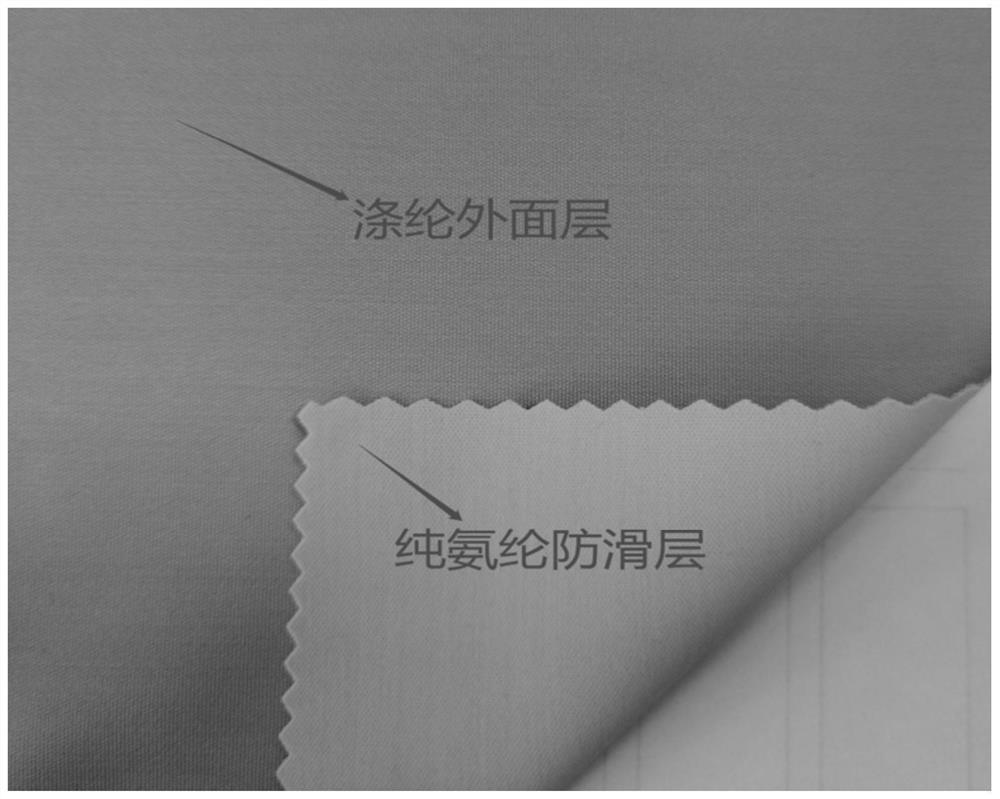

Freely-cut knitted fabric with polyester on one side and pure spandex on other side and production method of knitted fabric

PendingCN113699658AHigh modulusIncrease elasticityWeft knittingOrnamental textile articlesPolyesterYarn

The invention discloses a freely-cut knitted fabric with polyester on one side and pure spandex on other side. The knitted fabric comprises a fabric body; the fabric body comprises a polyester outer surface layer, a pure spandex anti-skid layer and a connecting layer; the polyester outer surface layer and the pure spandex anti-skid layer are arranged in a two-way two-needle full-out mode; the connecting layer is arranged in a two-way one-containing one-flat mode; the polyester outer surface layer and the pure spandex anti-skid layer are positioned on two sides of the connecting layer and are connected through the connecting layer; the polyester outer surface layer is made of surface yarns of 50D / 36F low-elasticity semi-gloss moisture absorption and sweat releasing polyester DTY and laid-in yarns of 70D spandex; the pure spandex anti-skid layer is made of anti-skid yarns of 70D spandex; and the connecting layer is made of connecting yarns of 70D spandex. According to the fabric obtained through the production method of the fabric, through the corresponding weaving arrangement mode, the fabric body has the advantages of being high in four-side modulus, high in elasticity, capable of absorbing moisture, breathable, stiff, smooth, comfortable, good in skid resistance and capable of being cut freely.

Owner:GUANGDONG DERUN TEXTILE CO LTD

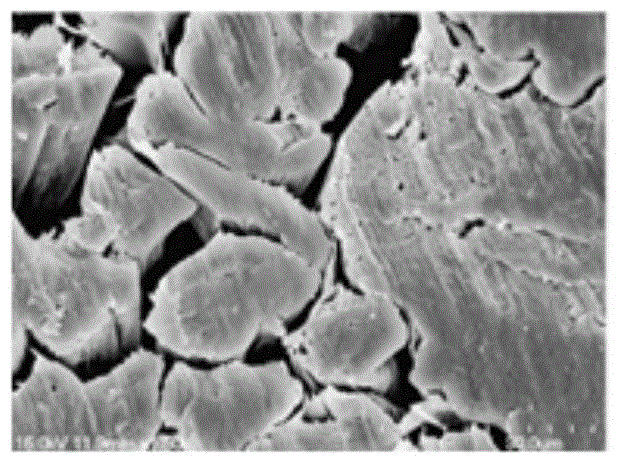

Method for preparing cotton-linter fiber

ActiveCN103147146AEfficient use ofSoft and smoothArtificial filaments from viscoseBleaching apparatusState of artFiber

The invention aims to disclose a method for preparing a cotton-linter fiber. The method comprises the following steps of: (1) pulping: preparing materials, steaming, bleaching and washing; and (2) spinning: thickening a pulp, impregnating, pressing and dispersing an alkali cellulose, ageing, yellowing, mixing solutions, filtering, defoaming and spinning for forming. Compared with the prior art, the cotton-linter fiber is utilized effectively, spun and woven, has soft and smooth handfeel and strong moisture absorptivity and air permeability, is friendly to skin and environment-friendly and can be degraded naturally. Therefore, the purposes of the invention are achieved.

Owner:SHANGHAI SHUIXING HOME TEXTILE

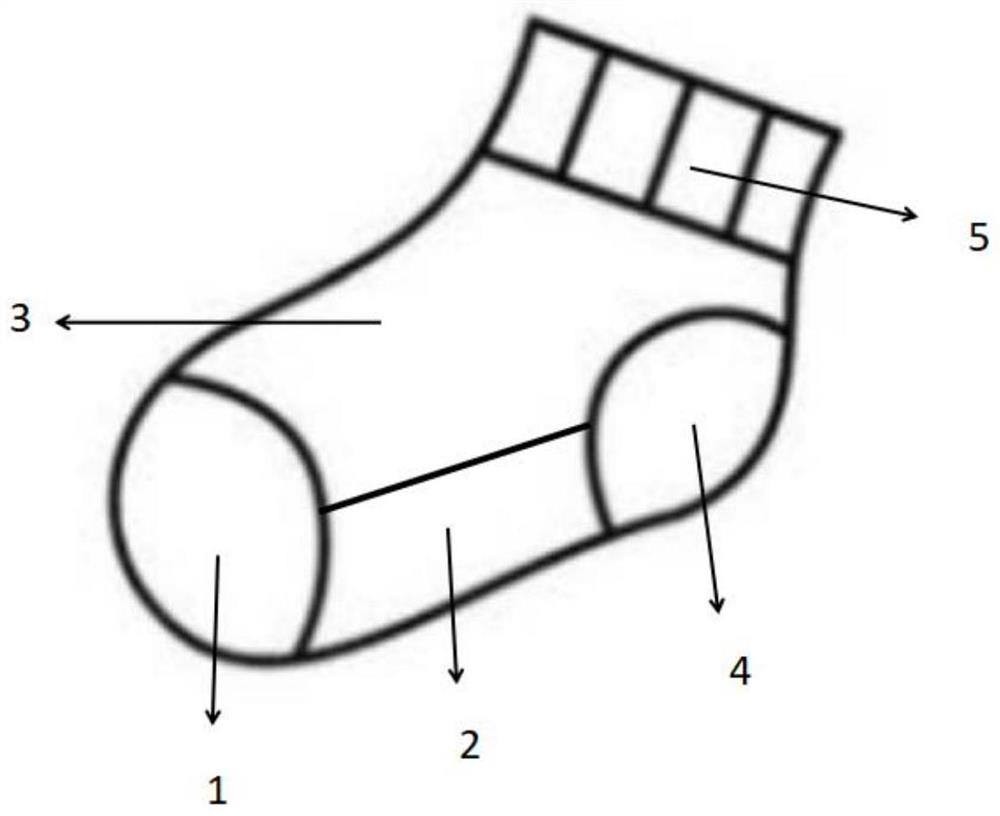

Antibacterial bamboo fiber and recycle polyester blended sock

PendingCN113558308AImprove antibacterial propertiesAvoid breedingBiochemical fibre treatmentPanty-hosePolyesterYarn

The invention discloses an antibacterial bamboo fiber and recycle polyester blended sock. The antibacterial bamboo fiber and recycle polyester blended sock comprises a sock toe, a sock heel, a sock welt and a sock surface. The sock is simple in structure, the sock is divided into four parts, fibers are selected according to different human body functions of all the parts, the foot feeling is more comfortable when the sock is used, the sock bottom is made of nano-silver loaded bamboo fibers and regenerated polyester blended yarn, the surface layer and the sock welt are made of cotton fibers, and the sock head and the sock heel are made of recycle polyester and cotton fiber blended yarn. The sock sole can effectively prevent bacteria from breeding, can kill mites, and is odor-resistant and high in wear resistance.

Owner:JIANGSU QIANLIMA STOCKINGS

Novel anti-radiation fabric

InactiveCN108754757AAdd radiation protection functionStrong moisture absorption and breathabilityWeft knittingWarp knittingPolyesterMoisture permeability

The invention relates to a fabric, in particular to a novel anti-radiation fabric. The fabric is prepared from, by weight, 30-40 parts of nano elastic complex, 35-45 parts of polyester fiber, 15-20 parts of bamboo carbon fiber and 10-15 parts of metal fiber. Through the above method, the anti-radiation fabric has the advantages that by adopting improved proportion, the anti-radiation function of the fabric is greatly improved, the moisture permeability of the fabric is high, the hand feeling is comfortable, the fabric has elasticity, and the problems are solved that an existing clothes fabricdoes not have the anti-radiation function and endangers the health of the human body.

Owner:NANTONG LONGAO CLOTHING CO LTD

Flock pulping process

InactiveCN107254718AStrong moisture absorption and breathabilitySoft and smoothArtificial filaments from viscoseSpinning solutions preparationCelluloseFiber

The invention discloses a flock pulping process. The flock pulping process is characterized by comprising the following steps that (1) cotton flocks work as raw material; at ordinary pressure and the temperature of under 85 DEG C, 2.5 to 3.5% alkali is added to the cotton flocks, and then stewed for 25 to 35 minutes to achieve cotton pulp, or, the cotton flocks are directly bleached rather than being immersed into the alkali and steamed, and then processed for 30 to 50 minutes in 3.5% to 5.2% of chlorine with the pH value of being 3.2 to 4.4 to achieve cotton pulp; (2) filaments are spinned; pulp is glued, then immersed, pressed and dispersed and alkali cellulose is aged, yellowed, mixed with solution, filtered, defoamed and spinned and formed. Cotton pulp strength and utilization rate can be improved; consumption and cost can be reduced and pollution can be reduced or eliminated; the cotton flock fibers can be effectively utilized, spinned and weaved; the cotton flock fibers are soft and smooth, have great moisture absorbing and ventilating properties, and friendly to skin; the cotton flocks are environment-friendly and can be naturally degraded; and aims of the invention can be achieved.

Owner:东至县鸿棉工贸有限责任公司

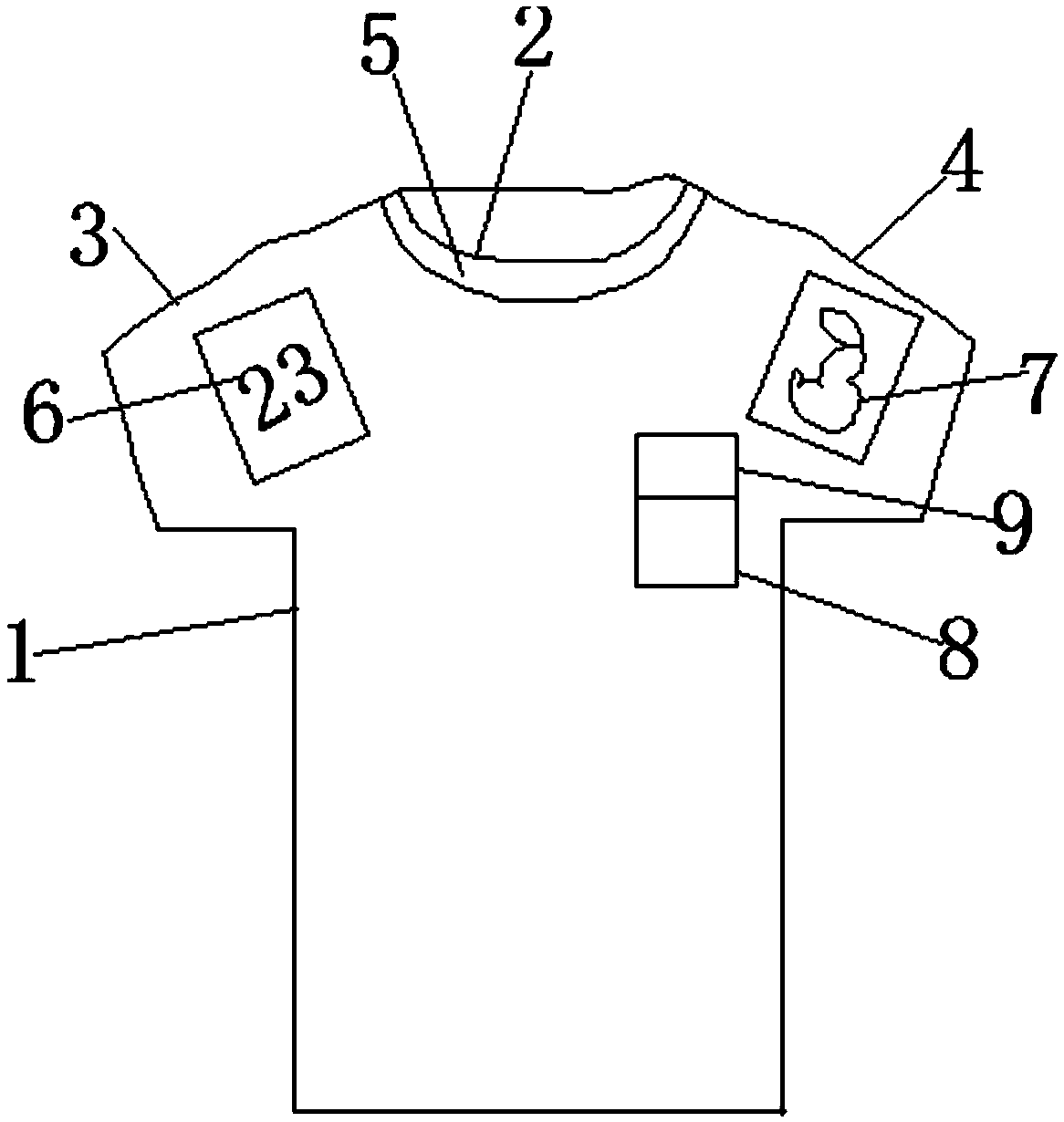

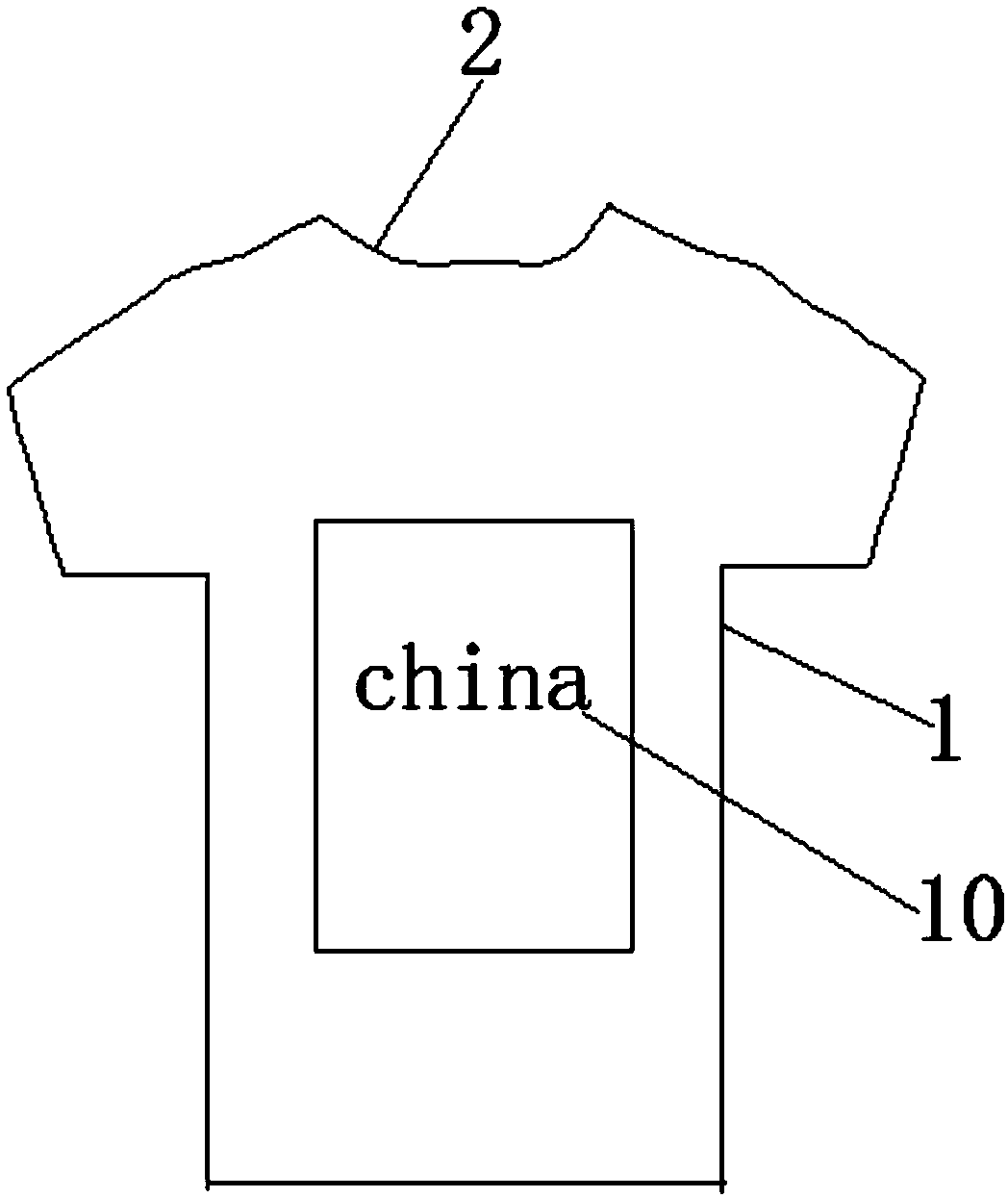

Moisture-absorbing breathable silk protein fiber garment

InactiveCN108968174AEffective protectionQuality improvementProtective garmentSpecial outerwear garmentsYarnEngineering

The invention relates to the technical field of fiber garments, in particular to a moisture-absorbing breathable silk protein fiber garment, which comprises a garment body, wherein the garment body isprovided with a round collar; the garment body is provided with a first shortsleeveand a second shortsleeve; the round collar is provided with a protective layer; and the first shortsleeve is provided with a decorative font, the second shortsleeve is provided with a personal decoration pattern, the garment body is provided with a personal pocket, and the personal pocket is provided with a pocketcover. According to the invention, the circular collar is provided with a pure cotton protective layer, the neck of a person can be effectively protected. The first short sleeve and second short sleeve are provided with the font and pattern so that the garment is not monotonous, and English letters are arranged on the back, so that elements are added but not redundant.By arranging a wear-resistantlayer, the quality of the garment can be improved, by arranging a composite material layer and an antibacterial layer, the comfortable feeling is stronger, and by arranging the silk protein fiber yarn,the moisture absorption property and air permeability are provided.

Owner:ANHUI XIANGFEI TEA CO LTD

Mask paper containing texture pulp and preparation method for mask thereof

ActiveCN108316046BGood flexibilityStrong moisture absorption and breathabilityCosmetic preparationsSpecial paperFiberNatural product

The invention relates to facial mask paper containing a paper mulberry bark pulp and a preparation method of a facial mask, and belongs to facial beauty care products. The facial mask paper containingthe paper mulberry bark pulp is prepared by the steps of firstly performing pulping on paper mulberry bark, adding hemicellulose, performing beating, performing sizing, performing pressing and performing papermaking to prepare the facial mask paper; and the facial mask containing the paper mulberry bark pulp comprises the facial mask paper containing the paper mulberry bark pulp and a natural extraction liquid, the facial mask is prepared by immersing the facial mask paper containing the paper mulberry bark pulp into the natural extraction liquid, and the content of the natural extraction liquid in the facial mask is 60-70%. According to the facial mask paper containing the paper mulberry bark pulp and the preparation method of the facial mask provided by the invention, a natural plant primary pulp is adopted for preparation, no chemical substances are added in the preparation process, the facial mask has no toxic or side effects, is used comfortably and conveniently and has strong air permeability; the facial mask paper has high wet strength, high bursting resistance, water absorption and moisturizing, and is easy to carry; and natural products have no influences on the environment, and the preparation method of the facial mask is a novel way of comprehensive utilization of paper mulberry bark fibers.

Owner:广州白云山维一实业股份有限公司

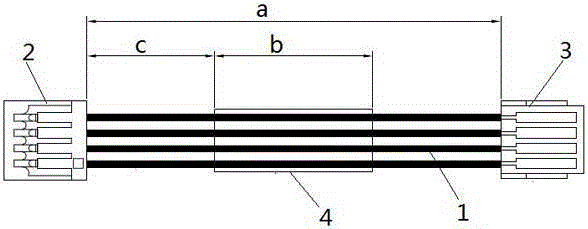

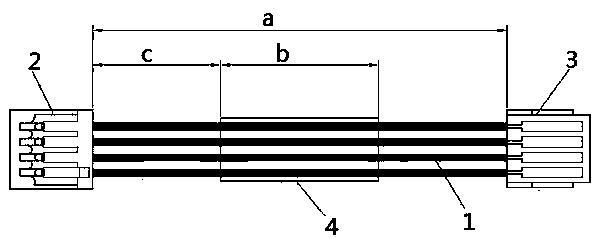

Fine and small puncture camera power supply cable

ActiveCN103700955BImprove performanceExtended service lifeCoupling device connectionsPower cablesPower cableAging resistance

The invention discloses a miniature puncture-type camera power supply connecting line. The connecting line comprises a plurality of copper alloy wires which are equidistantly arranged side by side, wherein the two ends of each copper alloy wire respectively penetrate into a first miniature puncture-type connector and a second miniature puncture-type connector in a puncture manner, the number and position of connecting joints of the first and second miniature puncture-type connectors correspond to the number and position of the copper alloy wires, and the copper alloy wires are fixedly arranged through wrapping by an acetate tape. The camera power supply connecting line disclosed by the invention has the beneficial effects that the structure of the line is improved, the connection between the connectors and the copper alloy wires is subjected to puncture treatment, the miniature puncture-type connectors with the spacing of 0.8mm are adopted, the copper alloy wires are halogen-free copper alloy wires made from TPE (Thermoplastic Elastomer), and meanwhile, the acetate tape which has the advantages that the moisture absorption and air permeation capability is strong, the resilience is good, the washing and drying are easy, static electricity and hair bulbs are not caused, the ageing resistance is excellent and the service life is more than 15 years is adopted.

Owner:昆山爱光电子有限公司

Preparation process of environment-friendly sugarcane peel fibers

InactiveCN105803537AStrong moisture absorption and breathabilityGood rigidity and flexibilityVegetable materialSingle fiberMoisture absorption

The invention discloses a preparation process of environment-friendly sugarcane peel fibers. The preparation process comprises the following steps of: (1), firstly, removing sugarcane peels and transversely cutting the sugarcane peels into small sections with the length of 50mm-75mm; putting the sugarcane peels into clean water and washing; then putting the sugarcane peels into a water batch at the bath ratio of 1 to 30, and boiling for 1-2 hours; replacing the clean water and repeatedly boiling for 1-3 times, and drying; (2) putting the dried sugarcane peels into a mixed solution of hydrochloric acid and formic acid under a stirring condition that the temperature is 80-90 DEG C at the bath ratio of 1 to (20-35), and extracting the sugarcane peel fibers; (3) washing the obtained sugarcane peel fibers with water, and putting the sugarcane peel fibers into an alkaline solution under a stirring condition that the temperature is 75-80 DEG C at the bath ratio of 1 to (20-35) and carrying out alkali boiling treatment; and (4) putting the sugarcane peel fibers subjected to the alkali boiling treatment into a weak acid solution and carrying out neutralizing treatment, and washing with the water and drying to obtain 50%-70% of sugarcane peel single fibers, with the residue of bundle fibers. The sugarcane fibers prepared by the invention have strong moisture absorption and air permeability, good rigidness and softness and strength elongation property, and are environmentally friendly and biodegradable.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Miniature puncture-type camera power supply connecting line

ActiveCN103700955AImprove performanceExtended service lifeCoupling device connectionsPower cablesEngineeringAging resistance

The invention discloses a miniature puncture-type camera power supply connecting line. The connecting line comprises a plurality of copper alloy wires which are equidistantly arranged side by side, wherein the two ends of each copper alloy wire respectively penetrate into a first miniature puncture-type connector and a second miniature puncture-type connector in a puncture manner, the number and position of connecting joints of the first and second miniature puncture-type connectors correspond to the number and position of the copper alloy wires, and the copper alloy wires are fixedly arranged through wrapping by an acetate tape. The camera power supply connecting line disclosed by the invention has the beneficial effects that the structure of the line is improved, the connection between the connectors and the copper alloy wires is subjected to puncture treatment, the miniature puncture-type connectors with the spacing of 0.8mm are adopted, the copper alloy wires are halogen-free copper alloy wires made from TPE (Thermoplastic Elastomer), and meanwhile, the acetate tape which has the advantages that the moisture absorption and air permeation capability is strong, the resilience is good, the washing and drying are easy, static electricity and hair bulbs are not caused, the ageing resistance is excellent and the service life is more than 15 years is adopted.

Owner:昆山爱光电子有限公司

Ultrathin moisture-absorbing and breathable high-stitch-length weft-knitted double-sided fabric and production process

The invention discloses an ultrathin moisture-absorbing and breathable high-stitch-length weft-knitted double-sided fabric. The fabric comprises a fabric body; the fabric body is knitted by adopting a50-stitch 34-inch 84-path weft-knitted double-sided circular knitting machine; the fabric body adopts a complete circulating double-rib structure formed by two knitting needles and two paths of yarns; a yarn arrangement mode of the fabric body is that two paths form one cycle; and 15D / 12F low-elasticity semi-gloss polyester DTYs are used as surface yarns and 20D polyurethane is used as laid-in yarns in the two paths. The production process of the fabric comprises the steps that after the fabric body is knitted, the obtained fabric body is dyed and finished, wherein the dyeing and finishing process comprises the steps of open-width water washing, pre-shaping, dyeing, dewatering and post-shaping. Therefore, the fabric produced by the production process has the characteristics of being ultrathin, comfortable, good in elasticity, strong in moisture absorption and air permeability, capable of being cut at will, fine and smooth in cloth marks and good in touch sense by changing the tissue structure, the yarn arrangement mode and the yarn feeding amount of the fabric.

Owner:GUANGDONG DERUN TEXTILE CO LTD

Multi-component yarn and preparation method thereof

The invention discloses a multi-component yarn. The multi-component yarn comprises the following components in percentage by weight: 15 to 45 percent of polyterephthalate-1,3-propylene glycol ester fiber, 15 to 45 percent of polylactic acid fiber and 15 to 45 percent of viscose. The multi-component yarn has high moisture absorption, air permeability, elasticity, fluffy and soft handfeel, high comfortability when contacting with skin, bright color and rich luster in cloth and excellent heat resistance and ultraviolet resistance, is easy to dye, and can be widely applied to textiles, in particular to the textiles for clothes. The invention also discloses a method for preparing the multi-component yarn. By the method, the conventional spinning equipment is fully utilized and a spinning machine does not need to be researched singly, so the spinning difficulty is reduced, the product quality is improved and the method is suitable for industrialized production.

Owner:ZHEJIANG MODERN TEXTILE IND RES INST

A preparation method of health underwear

ActiveCN108968172BImprove joint functionGood skin affinityMonocomponent cellulose artificial filamentHandkerchiefsElectrospinningCotton fibre

The invention relates to a manufacturing method of healthcare underwear. The manufacturing method comprises the steps that firstly, the micro-encapsulation technology is used for encapsulating hyaluronic acid, vitamins and collagen into chitosan microcapsules to prepare chitosan micro-capsule powder; then, nano-crystalline cellulose, chitosan micro-capsule powder, natural anti-oxidant, water and spinning auxiliaries are mixed to be uniform, then, a fiber spinning solution is obtained, and drying is performed after static electricity spinning processing is performed to obtain healthcare fiber;finally, after the healthcare fiber and hydrophobic modified cotton fiber are blended, the healthcare fiber fabric is obtained, and the healthcare underwear is obtained after tailoring sewing. The manufactured healthcare underwear has the antibacterial healthcare function, and has the wearing experience with good skin-friendliness and high moisture absorption breathability.

Owner:广东欣薇尔服装有限公司

Moisture-absorbing breathable novel textile fabric and production process thereof

ActiveCN112626677ADensity thinStrong moisture absorption and breathabilityHeating/cooling textile fabricsDry-cleaning apparatus for textilesYarnPolymer science

The invention relates to the field of garment fabrics, and particularly discloses a moisture-absorbing and breathable novel textile fabric and a production process thereof. The fabric comprises segment color yarns and sirofil yarns; the segment color yarns comprise a first rough yarn and a second rough yarn; the first rough yarn comprises first colored antibacterial polyamide fiber and PVA fiber; the second rough yarn comprises second colored antibacterial polyamide fiber and tencel fiber; the sirofil yarn comprises a third rough yarn and a colored chinlon ATY filament; the preparation method of the fabric comprises the following steps of taking the segment color yarns and the sirofil yarns as warp yarns, and performing sectional warping, sizing and drafting; weaving the segment color yarns and the sirofil yarns in an air jet weaving mode; and shaping, desizing, softening and tentering the fabric, adjusting the pH value of the fabric, and finally pre-shrinking. The fabric is high in moisture absorption and air permeability, high in antibacterial property, high in softness and high in comfort.

Owner:常州丁丁纺织科技有限公司

Comfortable hip-lifting underwear

The invention relates to the technical field of underwear and knickers, in particular to comfortable hip lifting knickers. The comfortable hip lifting knickers comprise a front part and a rear part. A bottom crotch is arranged between the front part and the rear part. Hip lifting parts are symmetrically arranged on the rear part. Leg circumference parts are arranged at the lower end of the rear part. The surfaces of the leg circumference parts and the surfaces of the hip lifting parts are provided with hip lifting elastic glue layers. The hip lifting elastic glue layers are prepared from aliphatic diol, an aliphatic polyamine curing agent, a hydrophilic chain extender, aromatic isocyanate, a catalyst, rosin pentaerythrityl ester, a lactone compound, a silane coupling agent, antioxygen and a neutralizing agent. The comfortable hip lifting knickers have the advantages of being high in comfort, soft in hand feeling, good in hip lifting effect and good in breathability.

Owner:HONGJI UNDERWEAR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com