Preparation process of environment-friendly sugarcane peel fibers

A preparation process, sugarcane peel technology, applied in the chemical post-treatment of fibers, fiber treatment, textiles and papermaking, etc., can solve the problem of not being used well, and achieve the effects of strong moisture absorption, air permeability, and good strength and elongation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

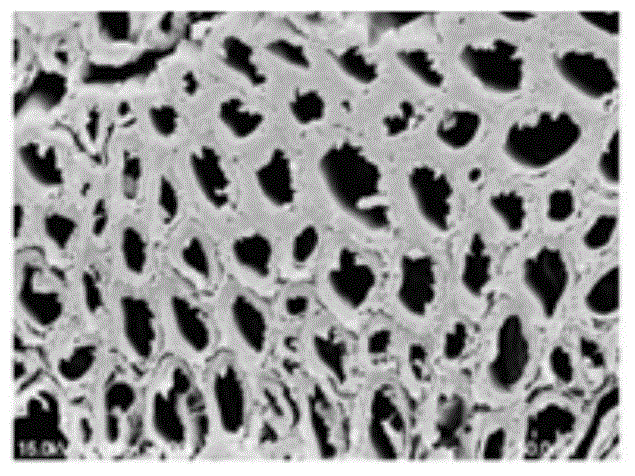

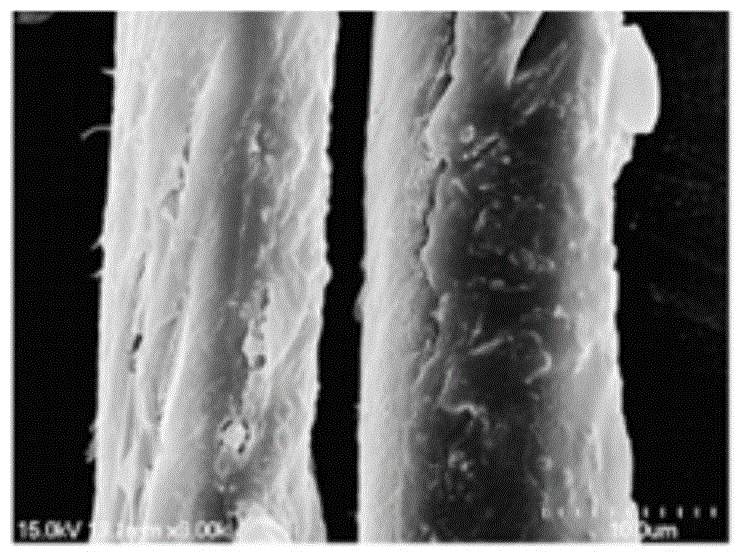

[0028] The invention discloses a preparation process of environment-friendly sugarcane husk fiber; the preparation process comprises the following steps:

[0029] (1) First remove the sugarcane skin and cut the transverse section into 50-75mm long pieces, wash them in clean water, then boil them in a water bath for 1-2 hours according to the bath ratio of 1:30, and repeat after replacing the clean water Boiling treatment 1-3 times, drying;

[0030] (2) According to the bath ratio of 1:20, under the condition of stirring at a temperature of 80°C, place the dried sugarcane skin in a mixed solution of hydrochloric acid and formic acid for treatment to extract sugarcane skin fibers; in the mixed solution , by mass percentage, the concentration of hydrochloric acid is 0.8%, the concentration of formic acid is 8%, and the treatment time is 20min;

[0031] (3) Wash the obtained sugarcane husk fiber with water, then place it in an alkaline solution for alkali boiling treatment at a t...

Embodiment 2

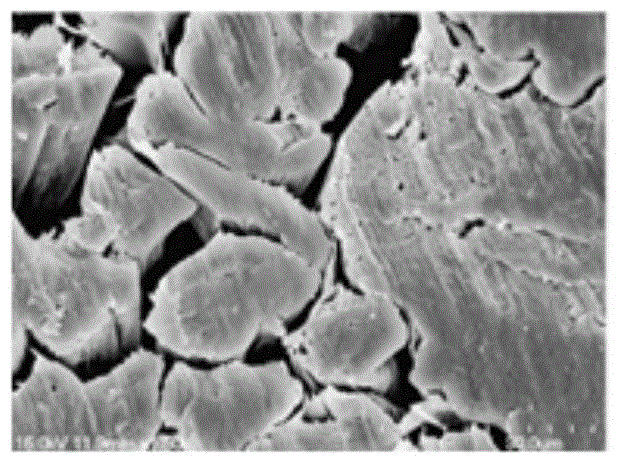

[0034] The invention discloses a preparation process of environment-friendly sugarcane fiber; the preparation process comprises the following steps:

[0035] (1) First remove the sugarcane skin and cut the transverse section into 50-75mm long pieces, wash them in clean water, then boil them in a water bath for 1-2 hours according to the bath ratio of 1:30, and repeat after replacing the clean water Boiling treatment 1-3 times, drying;

[0036] (2) According to the bath ratio of 1:35, under the condition of stirring at a temperature of 90°C, place the dried sugarcane skin in a mixed solution of hydrochloric acid and formic acid for treatment to extract sugarcane skin fibers; in the mixed solution , by mass percentage, the concentration of hydrochloric acid is 1.5%, the concentration of formic acid is 18%, and the treatment time is 80min;

[0037] (3) Wash the obtained sugarcane husk fiber with water, then place it in an alkaline solution for alkali boiling treatment at a tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com